A method for grain refinement and size distribution homogenization of ultrafine-grained cemented carbide

A technology of grain size and hard alloy, which is applied in the field of industrial preparation of ultra-fine grain WC-Co hard alloy, can solve the problem of high surface energy and deformation storage energy of ultra-fine or nano WC-Co powder, and grain growth , poor uniformity of grain structure of cemented carbide bulk materials, etc., to achieve the effect of inhibiting the rapid growth of grains and eliminating deformation storage energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

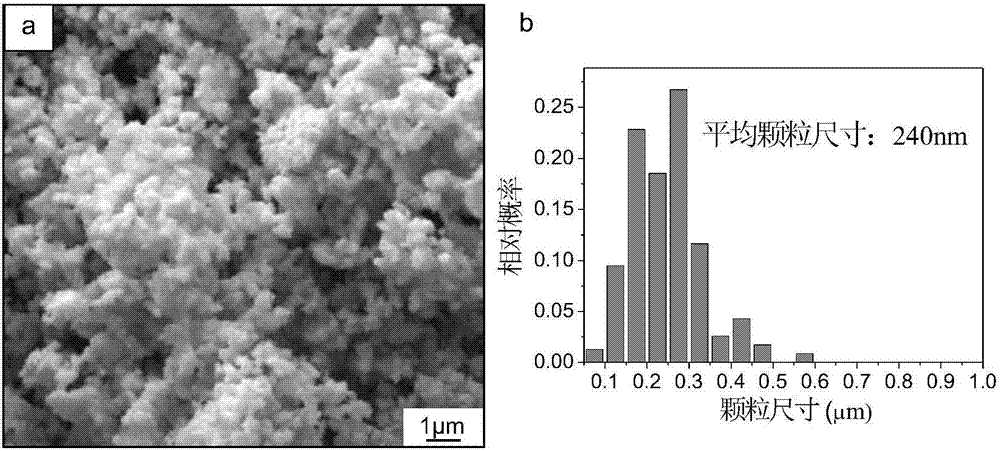

[0020] WC-8Co composite powder was prepared with the existing authorized patent technology (Patent No. ZL 200610165554.2), and the grain growth inhibitor Cr 3 C 2 The powder is added to the composite powder for ball milling, where Cr 3 C 2 The amount of powder added is 0.6wt.%, with absolute ethanol as the grinding medium, 0.2wt.% Tween-80 is added as the dispersant, the mass ratio of the grinding ball to the powder is 5:1, and the volume ratio of the grinding medium to the material is 1:1, the speed of the ball mill is 300r / min, and the ball milling time is 30 hours. The wet powder obtained after ball milling is passed through a 325 mesh sieve, and the suspension is separated after settling for 2 minutes, and WC, Co and Cr are obtained after drying. 3 C 2 mixed powder;

[0021] The obtained powder was annealed at 600°C in a tube furnace, and annealed with argon and 5% hydrogen as protective gas for 7 hours. The annealing process was: heating at 10°C / min, holding at 200°C...

Embodiment 2

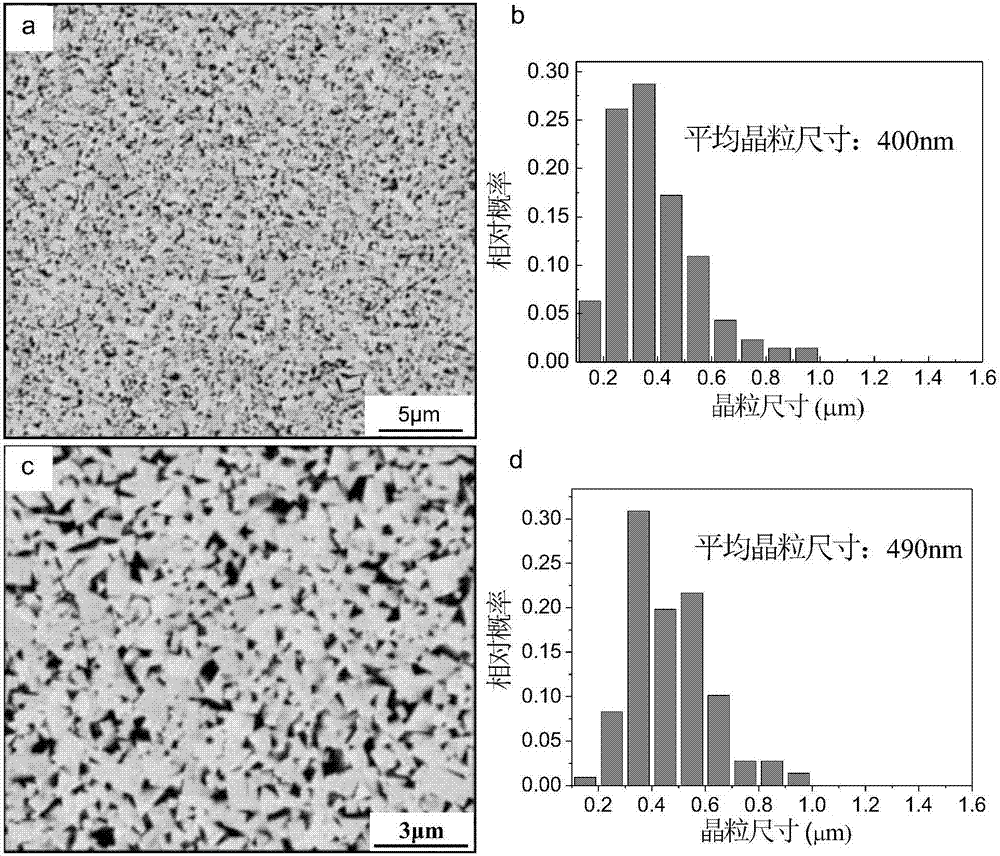

[0024] WC-10Co composite powder was prepared with the existing authorized patent technology (Patent No. ZL 200610165554.2), and the grain growth inhibitor VC and Cr 3 C 2 The powder is added to the composite powder for ball milling, wherein the VC powder is added in an amount of 0.2wt.%, Cr 3 C 2 The amount of powder added is 0.3wt.%, with absolute ethanol as the grinding medium, 0.6wt.% Tween-80 is added as the dispersant, the mass ratio of the grinding ball to the powder is 7:1, and the volume ratio of the grinding medium to the material is 1:1, the ball mill speed is 300r / min, the ball milling time is 30 hours, the wet powder obtained after ball milling is passed through a 325 mesh sieve, and the suspension is separated after settling for 2 minutes, and WC, Co, VC and Cr are obtained after drying 3 C 2 mixed powder;

[0025] The obtained powder was annealed at 700°C in a tube furnace, and annealed with argon and 5% hydrogen as protective gas for 6 hours. The annealing p...

Embodiment 3

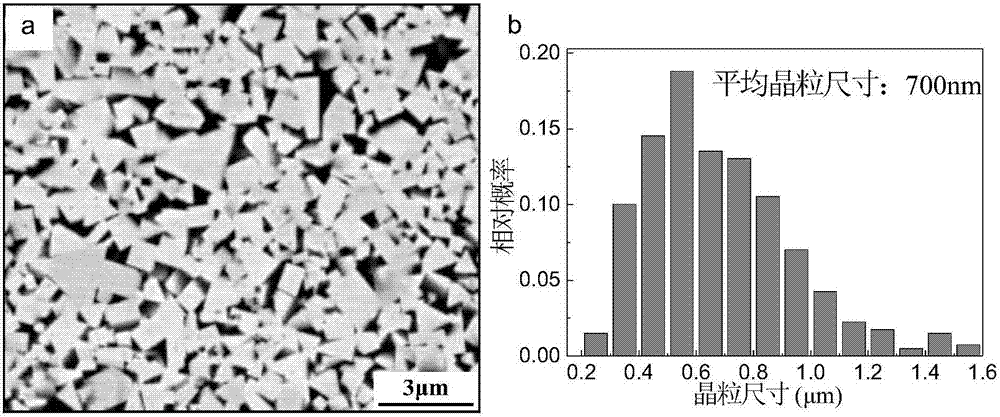

[0028] WC-12Co composite powder was prepared with the existing authorized patent technology (Patent No. ZL 200610165554.2), and the grain growth inhibitor Cr 3 C 2 The powder is added to the composite powder for ball milling, where Cr 3 C 2 The amount of powder added is 0.8wt.%, with absolute ethanol as the grinding medium, 0.3wt.% Tween-80 is added as the dispersant, the mass ratio of the grinding ball to the powder is 5:1, and the volume ratio of the grinding medium to the material is 1:1, the speed of the ball mill is 300r / min, the ball milling time is 30 hours, the wet powder obtained after ball milling is passed through a 325 mesh sieve, and the suspension is separated after settling for 3 minutes, and WC, Co and Cr are obtained after drying 3 C 2 mixed powder;

[0029] The obtained powder was annealed at 600°C in a tube furnace, and annealed with argon and 5% hydrogen as protective gas for 5 hours. The annealing process was: heating at 10°C / min, holding at 200°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com