Preparation method and application of MAX-phase enhanced nickel-based high-temperature lubricating composite material

A composite material and high-temperature technology, which is applied in the direction of mechanical equipment, jet propulsion devices, engine components, etc., can solve the problems of poor bonding between the reinforcement phase and the matrix interface, and achieve excellent high-temperature mechanical properties, good bonding, excellent corrosion resistance and resistance The effect of wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

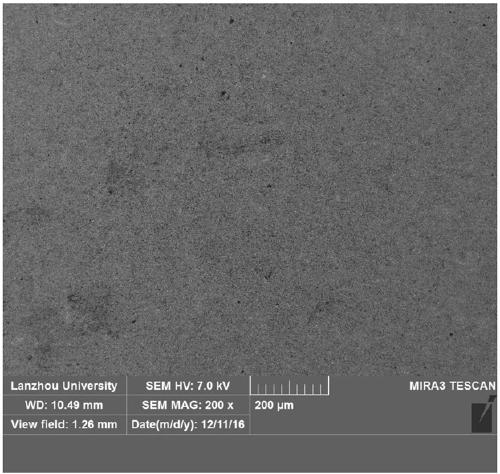

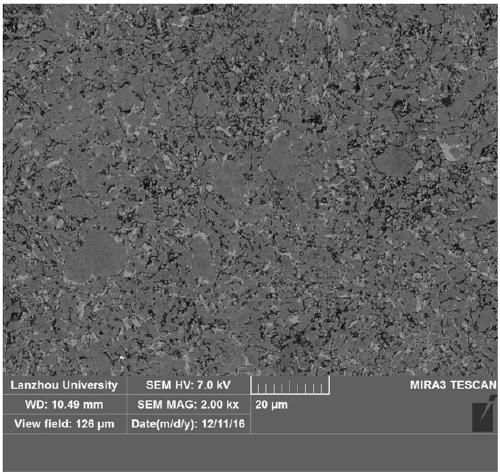

Image

Examples

preparation example Construction

[0031] The invention discloses a method for preparing a novel MAX phase reinforced nickel-based high-temperature lubricating composite material. The nickel-based composite material is synthesized by powder metallurgy, and the MAX phase ceramic particles are used as a reinforcing phase to effectively improve the mechanical properties and high-temperature tribological properties of the matrix material. Performance, so that the composite material exhibits excellent comprehensive performance, the specific steps are as follows:

[0032] S1. According to the molar ratio Ti:Si:TiC=1:1:(1.8~2.5), weigh Ti powder, Si powder and TiC powder, ball-to-material ratio (5~10):1, put it in a ball mill jar, seal it, and Mill on a planetary ball mill at a speed of 20-100r / min for 3-6 hours;

[0033] NiAl and Ti in nickel-based high-temperature lubricating composite materials 3 SiC 2 The phase contents are 60-90% and 10-40%, respectively.

[0034] S2. Form the uniformly mixed powder compact, pla...

Embodiment 1

[0041] According to the molar ratio of different elements Ti: Si: TiC = 1:1:1.8, weigh Ti powder, Si powder and TiC powder, the ball material ratio is 5:1, put it in the ball mill pot, seal it, and put it on the planetary ball mill at 20r Ball mill at a speed of 1 / min for 3 hours; the uniform raw material powder is screened with a 100-mesh sieve; placed in a 6mm graphite mold coated with boron nitride, a unidirectional load of 5MPa is applied perpendicular to the direction of the sample, pressed into shape, and dried in a drying oven for 1h , put the green body in a vacuum sintering furnace, heat it up to 1300°C at a heating rate of 10°C / min, hold it for 30min, sinter without pressure in a protective atmosphere, and cool to room temperature with the furnace to obtain a loose block Ti 3 SiC 2 ceramics; the Ti 3 SiC 2 The ceramics are put into the jaw crusher and crushed into small particles of 5mm, and then the small particles continue to be crushed to obtain particles smalle...

Embodiment 2

[0044] According to the molar ratio of different elements Ti: Si: TiC = 1:1:2, weigh Ti powder, Si powder and TiC powder, the ball-to-material ratio is 7:1. Ball milling at a speed of 1 / min for 4 hours; the uniform raw material powder was screened with a 120-mesh sieve; placed in a 60mm graphite mold coated with boron nitride, a unidirectional load of 10MPa was applied perpendicular to the direction of the sample, pressed into shape, and dried in a drying oven for 2 hours. Put the green body in a vacuum sintering furnace, heat it up to 1350°C at a heating rate of 12°C / min, hold it for 15 minutes, sinter it without pressure in a protective atmosphere, and cool it to room temperature with the furnace to obtain a loose block Ti 3 SiC 2 ceramics; the Ti 3 SiC 2 The ceramics are put into the jaw crusher and crushed into small particles of 10mm, and then the small particles are continued to be crushed to obtain particles smaller than 2mm; Ti 3 SiC 2 NiAl and NiAl accounted for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com