Powder metallurgy refractory multi-principal-element high-entropy alloy and preparation method thereof

A high-entropy alloy and powder metallurgy technology, which is applied in the field of powder metallurgy refractory multi-principal high-entropy alloy and its preparation, can solve the problem of restricting the application and promotion of refractory multi-principal high-entropy alloy materials, and refractory multi-principal high-entropy alloys. Difficulty in large-scale mass production of alloys, high cost and other issues, to achieve the effect of easy safety risk control, fine microstructure, and conducive to diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A method for preparing a powder metallurgy refractory multi-principal element high-entropy alloy, specifically comprising the following steps:

[0054] Step S1: pass the refractory metal element through a 300-mesh sieve; the powder is mixed in a multi-component powder mixing method to obtain a mixture;

[0055] The compound is at least four elements of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W;

[0056] The atomic percentage of each element in the mixture is 5%-35%; the total percentage is 100%;

[0057] Step S2: pressing and forming to obtain a compact;

[0058] Step S3: Vacuum high-temperature solid phase sintering to obtain a sintered block.

[0059] The present invention adopts multi-element powder mixing mode to process raw material powder.

[0060] This method uses high-purity elemental powders for mixing. The difference from high-energy ball milling mechanical alloying is that this method only mixes multi-element powders without grinding. It has the following advantage...

Embodiment

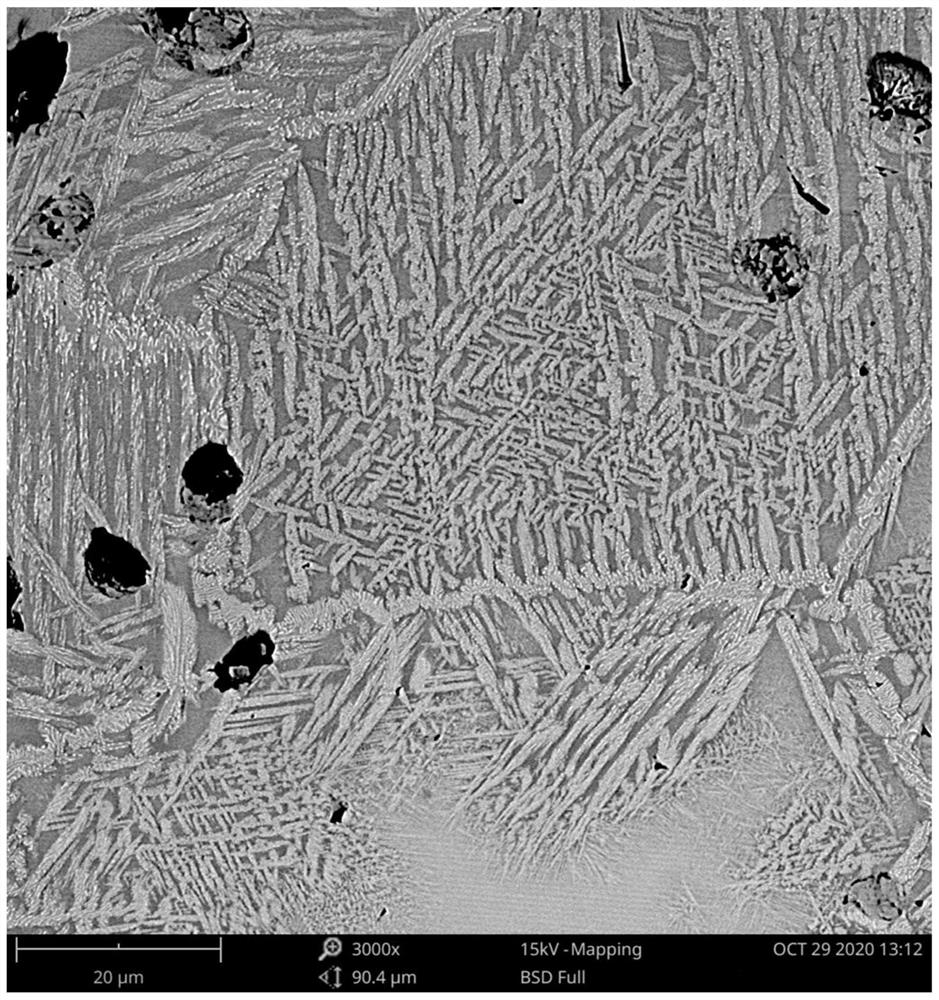

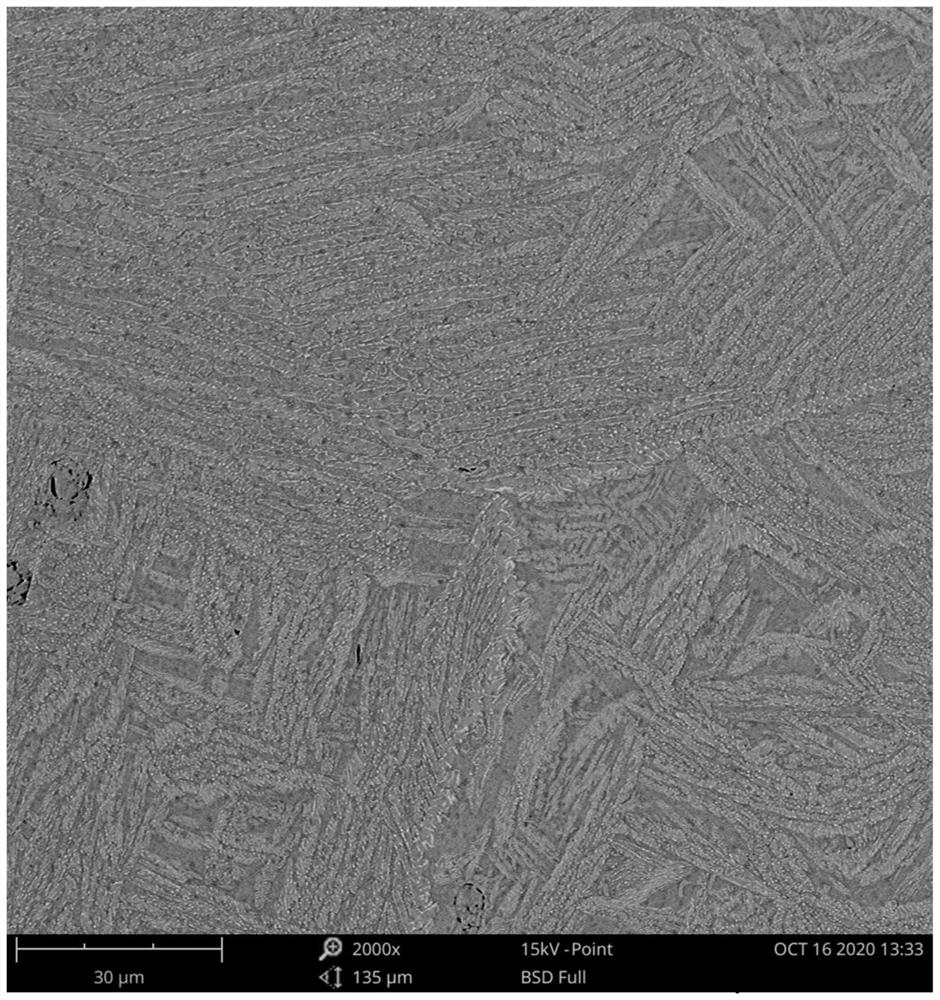

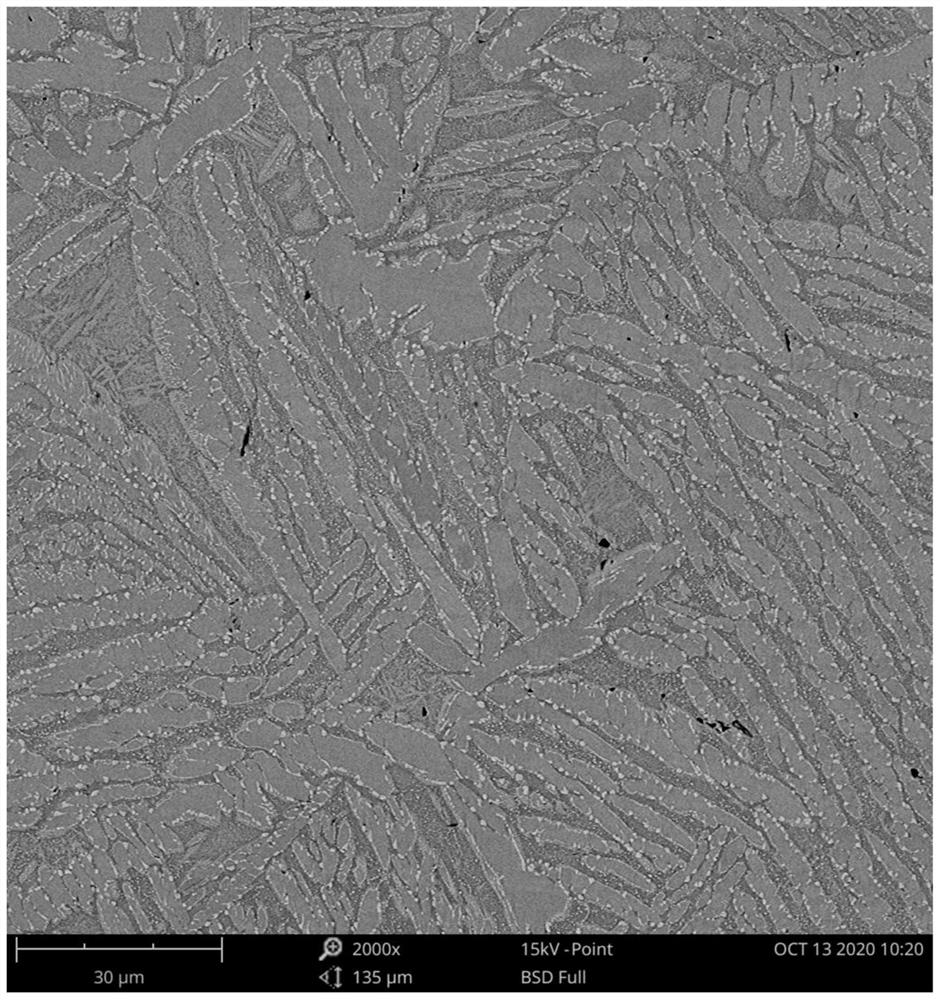

[0093]A refractory multi-principal high-entropy alloy containing Ti, Zr, Hf and Ta is taken as an example, wherein the atomic percentages of Ti, Zr, Hf and Ta are 28.33%, 28.33%, 28.33% and 15.01% respectively. According to the data, the melting point T of the alloy m About 1850°C, from the sintering temperature T s = α·T m Calculated, its sintering temperature T s The range is 1387.5°C-1585.7°C. In order to facilitate the setting of sintering process parameters, 1400°C and 1500°C within this range are taken as the sintering temperature for the test. The test set the sintering process parameters composed of different sintering temperature and holding time, respectively 1500°C×60 minutes, 1500°C×180 minutes, 1500°C×300 minutes, 1500°C×420 minutes, 1400°C×300 minutes, 1300°C × 300 minutes, 1800°C × 300 minutes.

[0094] 1. Preparation

[0095] Step S1: multi-element powder mixing;

[0096] Commercially available Ti powder, Zr powder, Hf powder and Ta powder with purity ≥ 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com