PE drain pipe and production process thereof

A production process and drainage pipe technology, which is applied in the field of plastic products, can solve the problems of polymers with low molecular weight, prone to failure of joints, and high control requirements, so as to improve mechanical strength, avoid micropores, and widen the temperature range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

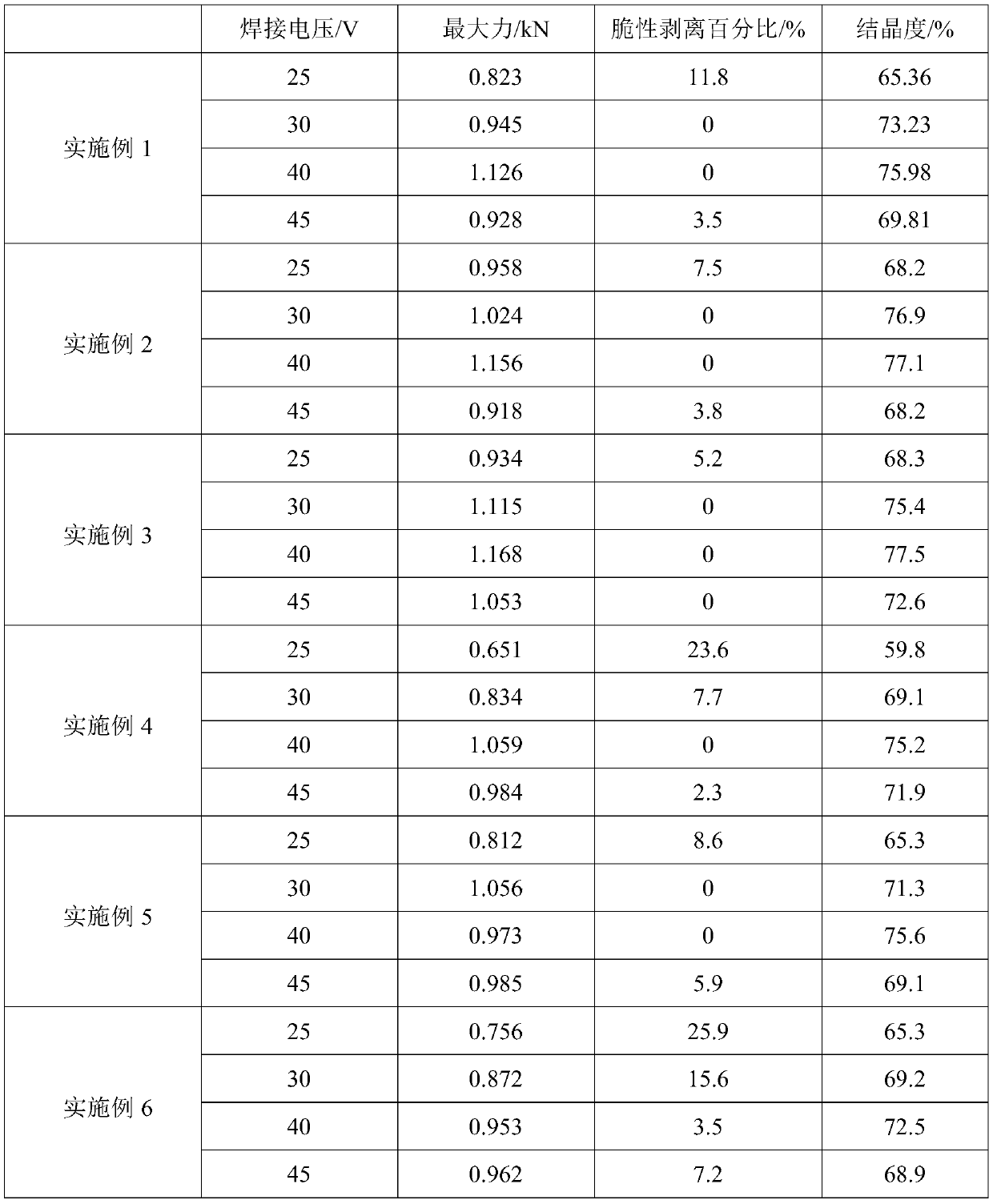

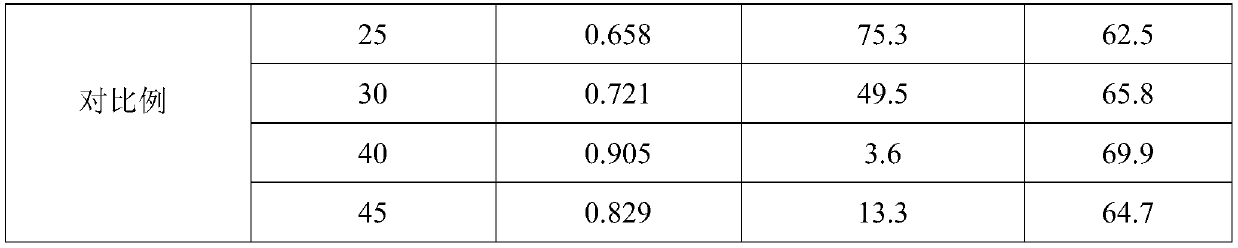

Examples

Embodiment 1

[0025] A kind of PE drainage pipe production process is characterized in that, comprises the following steps:

[0026] S1. After drying 3 parts of nano-MgO, 5 parts of nano-MnS, and 5 parts of heavy calcium carbonate, stir them with 5 parts of phosphate ester coupling agent in a high-speed mixer for 15 minutes, and obtain 5 parts of phosphate ester coupling agent after activation treatment Treated nano-MgO, nano-MnS, heavy calcium carbonate mixture;

[0027] S2. Stir the mixture obtained in step S1 evenly and heat it to 100° C., add 100 parts of PE, heat and stir for 3 minutes, and cool to normal temperature to obtain a premix;

[0028] S3, the premix obtained in step S2 is mixed with 3 parts of EVA, 3 parts of flame retardant, 10 parts of toughening agent, 1 part of organotin stabilizer, and 2 parts of acrylate processing aids and mixed into the kneader, Knead at 70°C, cool the discharged material to normal temperature, and add it to the twin-screw extruder for extrusion. Th...

Embodiment 2

[0032] A kind of PE drainage pipe production process is characterized in that, comprises the following steps:

[0033] S1. After drying 5 parts of nano-MgO and 15 parts of heavy calcium carbonate, stir them with 2 parts of phosphate ester coupling agent in a high-speed mixer for 20 minutes, and after activation treatment, obtain 2 parts of phosphate ester coupling agent. MgO, nano MnS, heavy calcium carbonate mixture;

[0034] S2. Stir the mixture obtained in step S1 evenly and heat it to 110° C., add 80 parts of PE, keep stirring for 5 minutes, and cool to normal temperature to obtain a premix;

[0035]S3. Mix 5 parts of the premix flame retardant, 3 parts of the toughening agent and 5 parts of the lead salt stabilizer obtained in step S2 and send them into the kneader, knead at 70 ° C, and cool the discharge to normal temperature, and add to Extrude with a twin-screw extruder. The process parameters of the twin-screw extruder are: barrel extrusion temperature is 200°C, mold...

Embodiment 3

[0039] A kind of PE drainage pipe production process is characterized in that, comprises the following steps:

[0040] S1. After drying 4 parts of nano-MgO, 3 parts of nano-MnS, and 10 parts of heavy calcium carbonate, stir them with 4 parts of phosphate coupling agent in a high-speed mixer for 17 minutes, and obtain phosphate coupling agent 4 after activation treatment Nano-MgO, nano-MnS, heavy calcium carbonate mixture after treatment;

[0041] S2. Stir the mixture obtained in step S1 evenly, heat it to 115° C., add 90 parts of PE, keep stirring for 4 minutes, and cool to normal temperature to obtain a premix;

[0042] S3, the premix obtained in step S2 is mixed with 1.5 parts of EVA, 4 parts of flame retardant, 6 parts of toughening agent, 3 parts of organotin stabilizer, and 1 part of acrylic ester processing aid and mixed into the kneader, Knead at 75°C, cool the discharged material to room temperature, and extrude it into a twin-screw extruder. The process parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com