Preparation method of high-toughness metal-based nanometer composite material

A technology of nanocomposite materials and composite materials, which is applied in the field of preparation of high-strength and tough metal matrix nanocomposites, can solve the problems of small stirring area in friction stir processing, difficulty in preparing uniform nanomaterials, difficult fine-grain strengthening mechanism, etc., to achieve control of crystallization grain size, inhibition of grain growth, and the effect of easy grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of high strength and toughness AlN / Al nanocomposites.

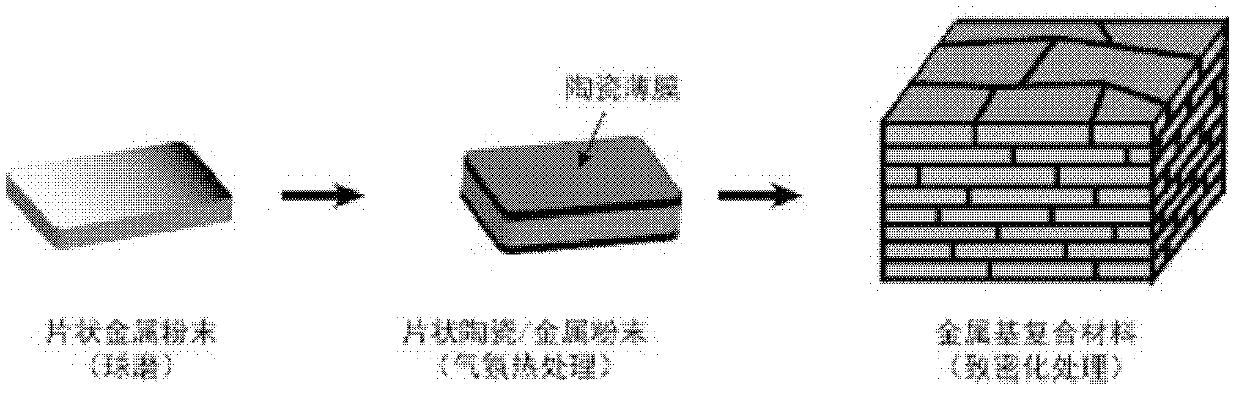

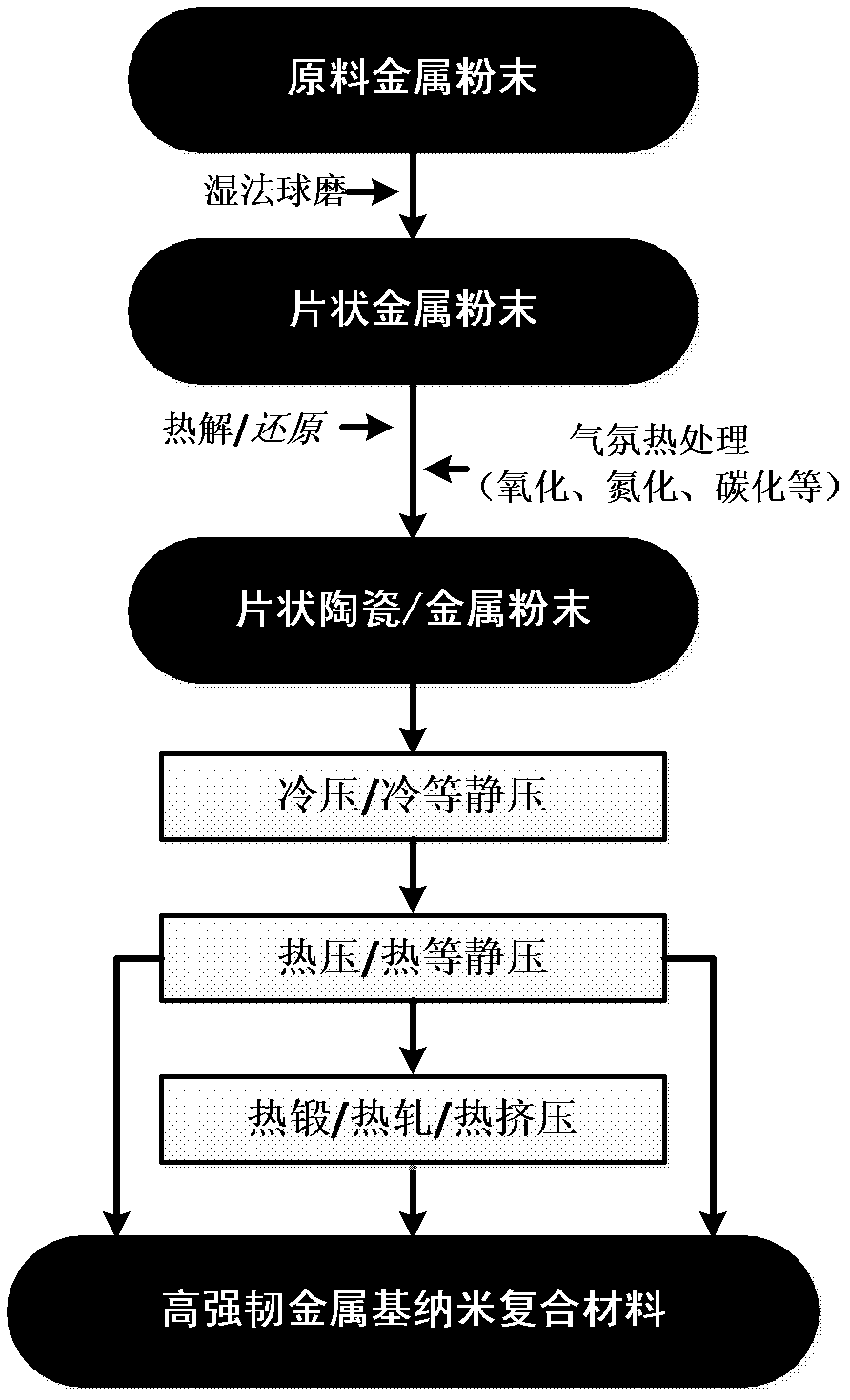

[0031] like figure 2 Shown is the flow chart of the composite material preparation process.

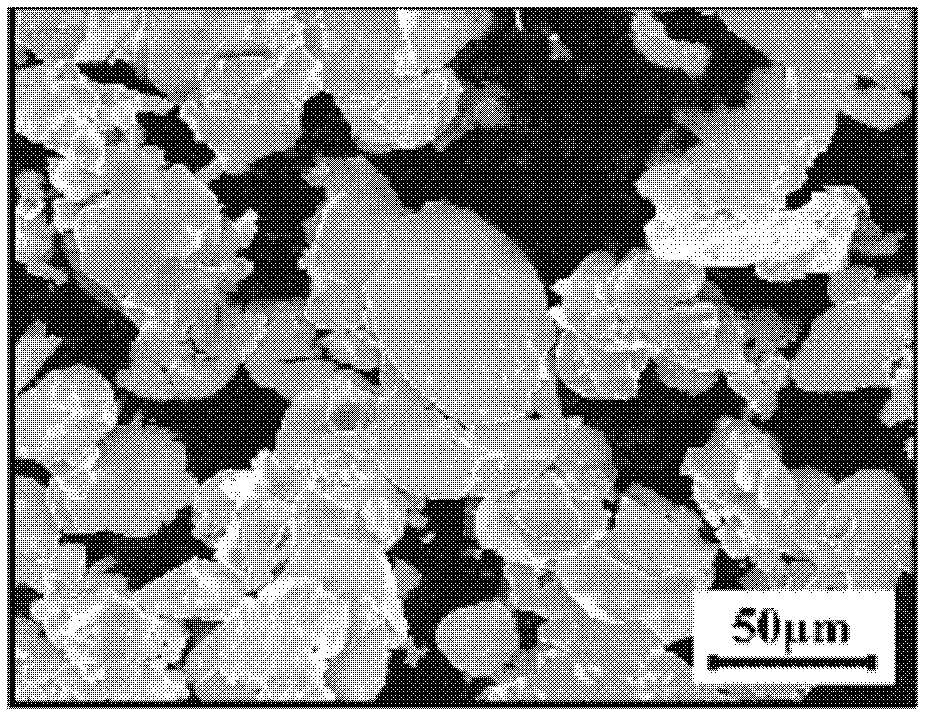

[0032] Put the spherical pure aluminum powder with a median particle size of 10 μm into a 01-HD experimental grinder and grind it to prepare flake aluminum powder. The ball milling medium is stainless steel balls (diameter 6mm, ball-to-material ratio 20:1), and the solvent is absolute ethanol , the grinding aid is titanate (consumption is 3% of the aluminum powder mass), the mill speed is 352r / min, and the ball milling time is 4h, and the finally prepared flake aluminum powder with a sheet thickness of about 500nm, such as image 3 The SEM photo of the flake powder prepared as shown, the X-ray analysis shows that the grain size is about 50-60nm.

[0033] After the prepared flake powder is suction filtered and dried, it is put into an atmosphere furnace with argon gas to pyrolyze the organic matter (solvent a...

Embodiment 2

[0036] A high-strength and toughness AlN / Al nanocomposite was prepared in the same manner as in Example 1.

[0037] The ball milling time of the original aluminum powder was shortened to 2h, and flake aluminum powder with a thickness of about 1000nm was obtained. The heat treatment temperature was 600°C, and the treatment time was 8h, and a flake AlN / Al powder with a surface AlN film thickness of about 100nm was obtained; Process is identical with embodiment 1. The final composite material has a tensile strength of 220MPa and an elongation of 22.4%.

Embodiment 3

[0039] A high-strength and toughness AlN / Al nanocomposite was prepared in the same manner as in Example 1.

[0040] The ball milling time of the original aluminum powder was shortened to 3h, and flake aluminum powder with a thickness of about 750nm was obtained. The heat treatment temperature was 550°C, and the treatment time was 6h, and a flake AlN / Al powder with a surface AlN film thickness of about 50nm was obtained; Process is identical with embodiment 1. The finally obtained composite material has a tensile strength of 250 MPa and an elongation of 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com