Preparation method of titanium, aluminum, niobium, zirconium and molybdenum alloy

A technology of molybdenum alloy and titanium-aluminum-niobium alloy, which is applied in the field of preparation of titanium-aluminum-niobium-zirconium-molybdenum alloy, can solve the problems of the influence of the mechanical properties of the prepared alloy, the limitation of the use of titanium alloy, and the high price of titanium alloy, so as to avoid coarse grains and sintering. The effect of short time and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

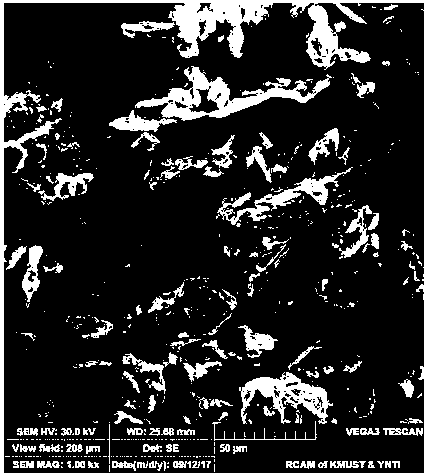

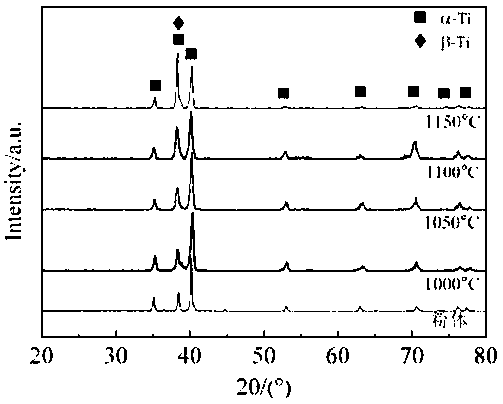

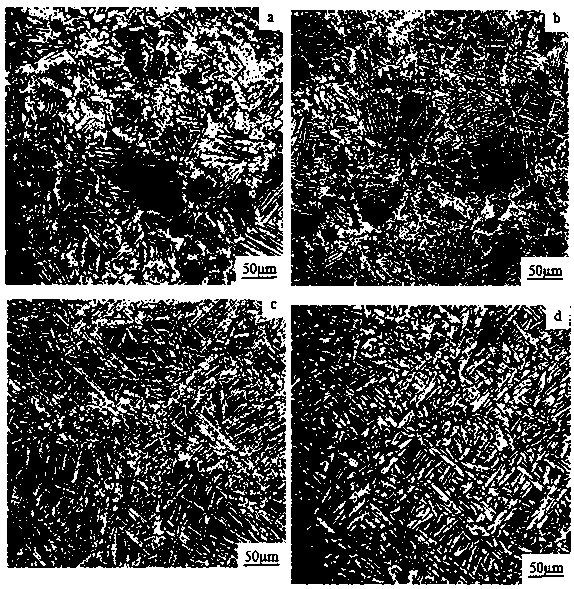

[0021] (1) Weigh metal powder Ti, Al, Nb, Zr, Mo alloy according to mass percentage Al: 6%, Nb: 3%, Zr: 2%, Mo: 1%, Ti: 88%, Ti, Zr , The particle size of the Mo powder is 23 μm, the particle size of the Al powder is 48 μm, the particle size of the Zr powder is 10.5 μm, and the purity is 99.5%.

[0022] (2) Put the metal powder with a good ratio and stearic acid with a mass of 3% of the metal powder mass into the vacuum ball mill tank of the planetary ball mill, add stainless steel balls with a diameter of 3mm according to the ball-to-material ratio of 3:1, and pump it Vacuum to 10Pa and fill with argon, ball mill the mixed powder intermittently for 20 hours at a speed of 200r / min with a pause of 60 minutes every 90 minutes, and then degrease the obtained mixed powder for 2 hours under argon atmosphere at a temperature of 200°C deal with. Put 20g of uniformly mixed powder into a high-strength graphite mold with an inner diameter of 20.5mm, and after adding the upper and lower...

Embodiment 2

[0030] (1) According to the mass percentage of metal powder Ti, Al, Nb, Zr, and Mo alloy, Nb: 4%, Zr: 2%, Mo: 2%, stearic acid: 1%, and the mass percentage of Al is 5%, 6%, 7%, and balance Ti to weigh three parts of mixed powder, the particle size of Ti, Nb, Mo, Zr powder is 70μm, the particle size of Al powder is 100μm, and the purity is 99.5%.

[0031] (2) Put the powder into the vacuum ball mill tank of the planetary ball mill, add stainless steel balls with a diameter of 6 mm according to the ball-to-material ratio of 5:1, vacuumize it to 5 Pa, and fill it with argon gas. Ball milling for 60 minutes and pausing for 60 minutes to intermittently ball mill and mix the powder for 5 hours, and then degrease the obtained mixed powder for 1 hour at a temperature of 400° C. under argon atmosphere.

[0032] (3) Put 10g of mixed powder into a high-strength graphite mold with an inner diameter of 10mm, and add the upper and lower indenters. The powder, the mold and the indenters are ...

Embodiment 3

[0036] (1) Metal powder Ti, Al, Nb, Zr, and Mo alloys with a particle size of 23, 50, and 75 μm were respectively prepared according to the mass percentage of Al: 4.5%, Nb: 2%, Zr: 1%, Mo: 1.2%, stearic acid : 5%, the remainder Ti weighs three parts of mixed powder, the purity is 99.5%.

[0037] (2) Put the powder into the vacuum ball mill tank of the planetary ball mill, add stainless steel balls with a diameter of 5mm according to the ball-to-material ratio of 2:1, vacuumize it to 5Pa, fill it with argon, and mill at a speed of 500r / min per ball Intermittent ball milling and mixing for 20 hours by pausing for 120 minutes for 60 minutes, and then degreasing the obtained mixed powder for 3 hours in an argon atmosphere at a temperature of 300°C.

[0038] (3) Put 30g of mixed powder into a high-strength graphite mold with an inner diameter of 25mm, pre-press at 60MPa, and put it into a spark plasma sintering equipment for sintering. Before sintering, the vacuum degree in the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com