One-step large-deformation rolling method of beta solidification TiAl alloy plate

A technology of alloy sheet and large deformation, which is applied in metal rolling, metal rolling, tool manufacturing, etc., can solve the problems of poor uniformity of sheet structure and performance, difficulty in sheet forming, and many times of reheating, and achieve simplified rolling process, Overcoming the poor thermal processing performance and avoiding the effect of alloy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

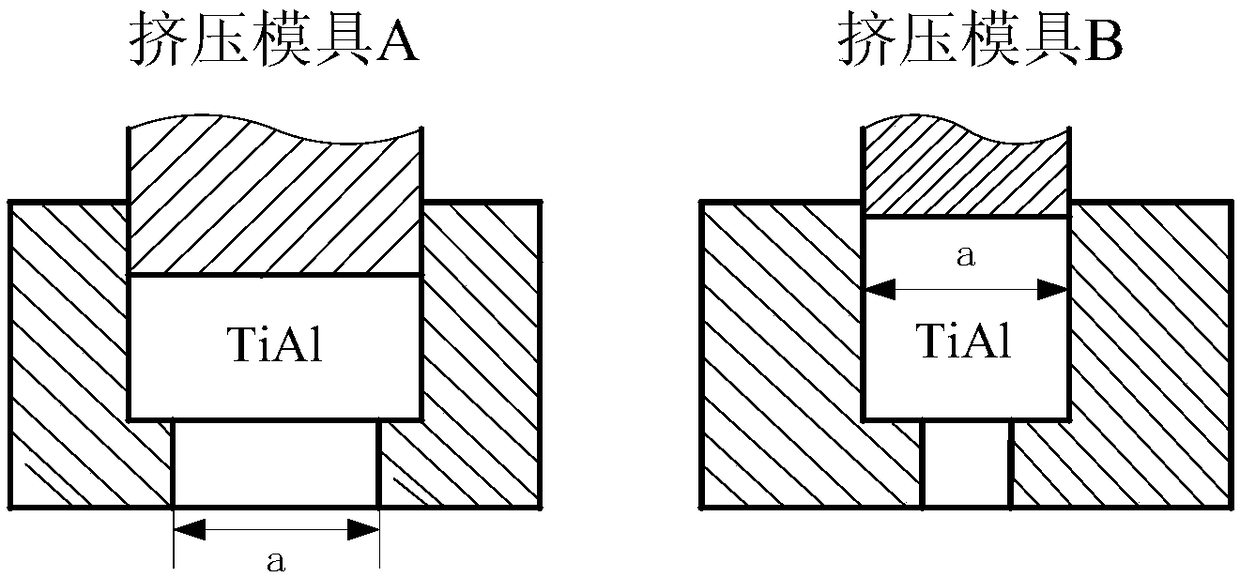

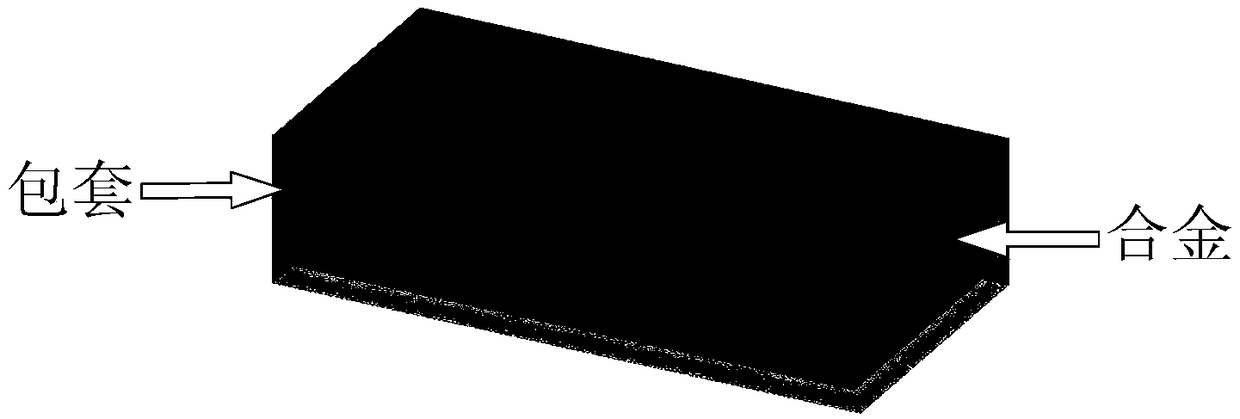

Method used

Image

Examples

Embodiment 1

[0042] Example 1. Preparation of β-solidified TiAl alloy plate of Ti-43Al-2Cr-1Mn-0.5Mo-0.1B

[0043] (1) Raw material preparation: According to the nominal composition of the alloy, select sponge titanium, high-purity aluminum, high-purity chromium, aluminum-manganese alloy, aluminum-molybdenum alloy and boron powder as raw materials and weigh them. The atomic percentage content of each element is: 43 %Al, 2%Cr, 1%Mn, 0.5%Mo, 0.1%B, and the balance is Ti and unavoidable impurities. The principle of raw material ratio is to ensure that the alloy contains about 20% β phase.

[0044] (2) Ingot preparation: put the raw materials prepared in step (1) into a vacuum degree of 2.0×10 -3 Melting in a vacuum induction shell melting furnace of MPa, and then pouring into a cylindrical mold to obtain a TiAl alloy ingot.

[0045] (3) Heat treatment and preprocessing of ingots:

[0046] a. In order to reduce the internal stress caused by the chilling of the ingot, put the TiAl alloy ingo...

Embodiment 2

[0056] Example 2. Preparation of β-solidified TiAl alloy plate of Ti-44Al-2Cr-2Mn-0.5Mo-0.2B

[0057] (1) Raw material preparation: According to the nominal composition of the alloy, select sponge titanium, high-purity aluminum, high-purity chromium, aluminum-manganese alloy, aluminum-molybdenum alloy and boron powder as raw materials and weigh them. The atomic percentage content of each element is: 44 %Al, 2%Cr, 2%Mn, 0.5%Mo, 0.2%B, and the balance is Ti and unavoidable impurities. The principle of raw material ratio is to ensure that the alloy contains about 25% β phase.

[0058] (2) Ingot preparation: put the raw materials prepared in step (1) into a vacuum degree of 2.5×10 -3 Melting in a vacuum induction shell melting furnace of MPa, and then pouring into a cylindrical mold to obtain a TiAl alloy ingot.

[0059] (3) Heat treatment and preprocessing of ingots:

[0060] a. In order to reduce the internal stress caused by the chilling of the ingot, put the TiAl alloy ingo...

Embodiment 3

[0069] Example 3. Preparation of β-solidified TiAl alloy plate of Ti-42Al-1Cr-0.5Mn-1Mo-0.5B

[0070] (1) Raw material preparation: According to the nominal composition of the alloy, select sponge titanium, high-purity aluminum, high-purity chromium, aluminum-manganese alloy, aluminum-molybdenum alloy and boron powder as raw materials and weigh them. The atomic percentage content of each element is: 42 %Al, 1%Cr, 0.5%Mn, 1%Mo, 0.5%B, and the balance is Ti and unavoidable impurities. The principle of raw material ratio is to ensure that the alloy contains about 15% β phase.

[0071] (2) Ingot preparation: put the raw materials prepared in step (1) into a vacuum degree of 3×10 -3 Melting in a vacuum induction shell melting furnace of MPa, and then pouring into a cylindrical mold to obtain a TiAl alloy ingot.

[0072] (3) Heat treatment and preprocessing of ingots:

[0073] a. In order to reduce the internal stress caused by the chilling of the ingot, put the TiAl alloy ingot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com