Composite cathode material for lithium ion cell and preparing method thereof

A lithium-ion battery and negative electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of the first coulombic efficiency and cycle performance, and achieve the effects of improving charge and discharge efficiency, avoiding cold welding, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the composite negative electrode material of lithium ion battery, comprises the following steps:

[0024] 1) Preparation of disordered carbon-coated composite silicon-based materials, Si / G / DC:

[0025] Add 1.2g of nano-silica powder with an average particle size of 50nm and 2.8g of natural graphite into trichlorethylene dissolved with 4g of pitch, the ball-to-material ratio is 15:1, and ball mill at a speed of 250 rpm for 18 hours under the protection of argon. , after ball milling, stir at 70°C until dry;

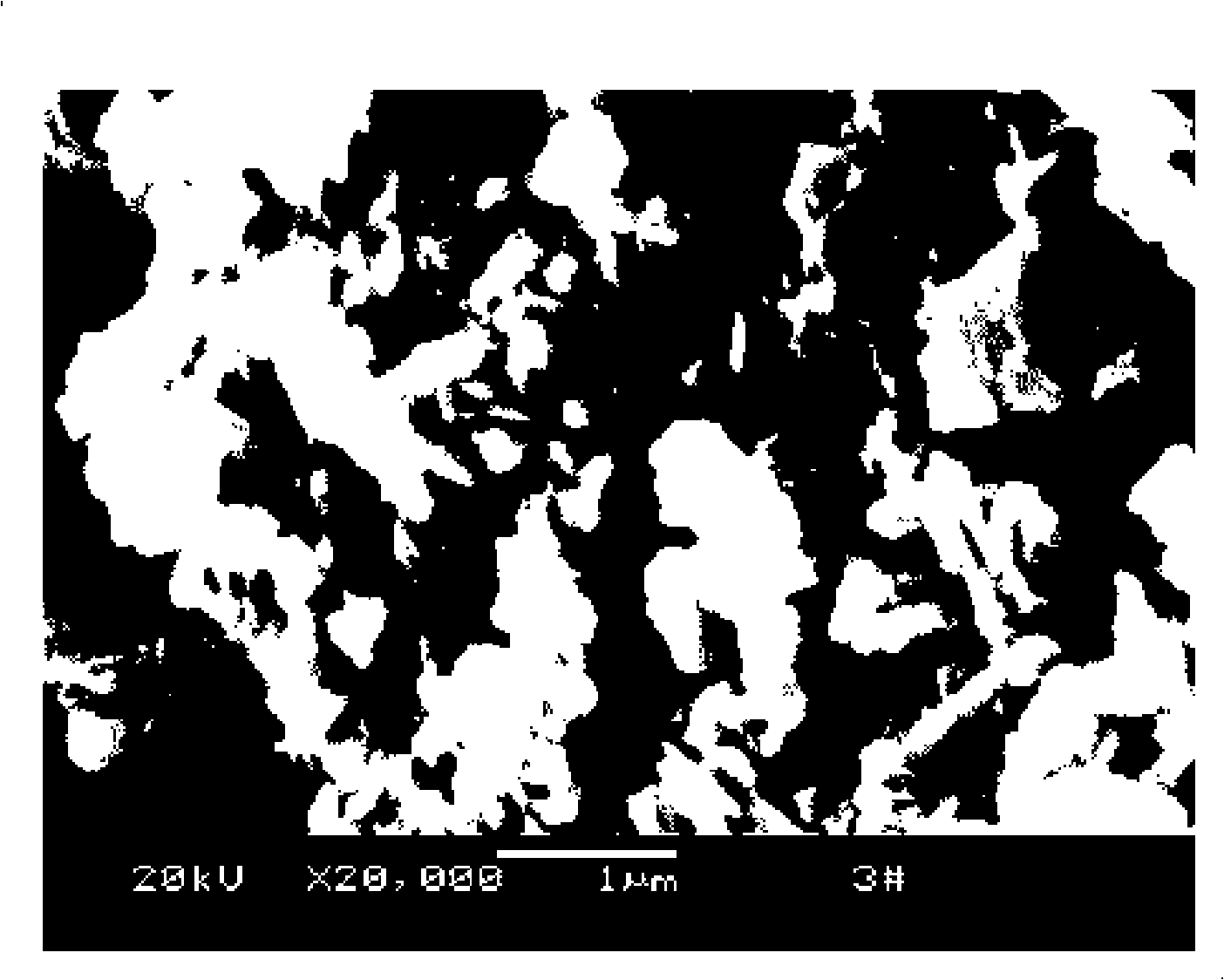

[0026] Under the protection of argon, it was treated at 1000 °C for 2 h, and then naturally cooled to room temperature. Among them, the flow rate of Ar gas is 100ml / min, and the heating rate is 5°C / min, and the disordered carbon-coated Si / G / DC material is made. The Si / G / DC material is ground and sieved with a 300-mesh standard sieve for later use.

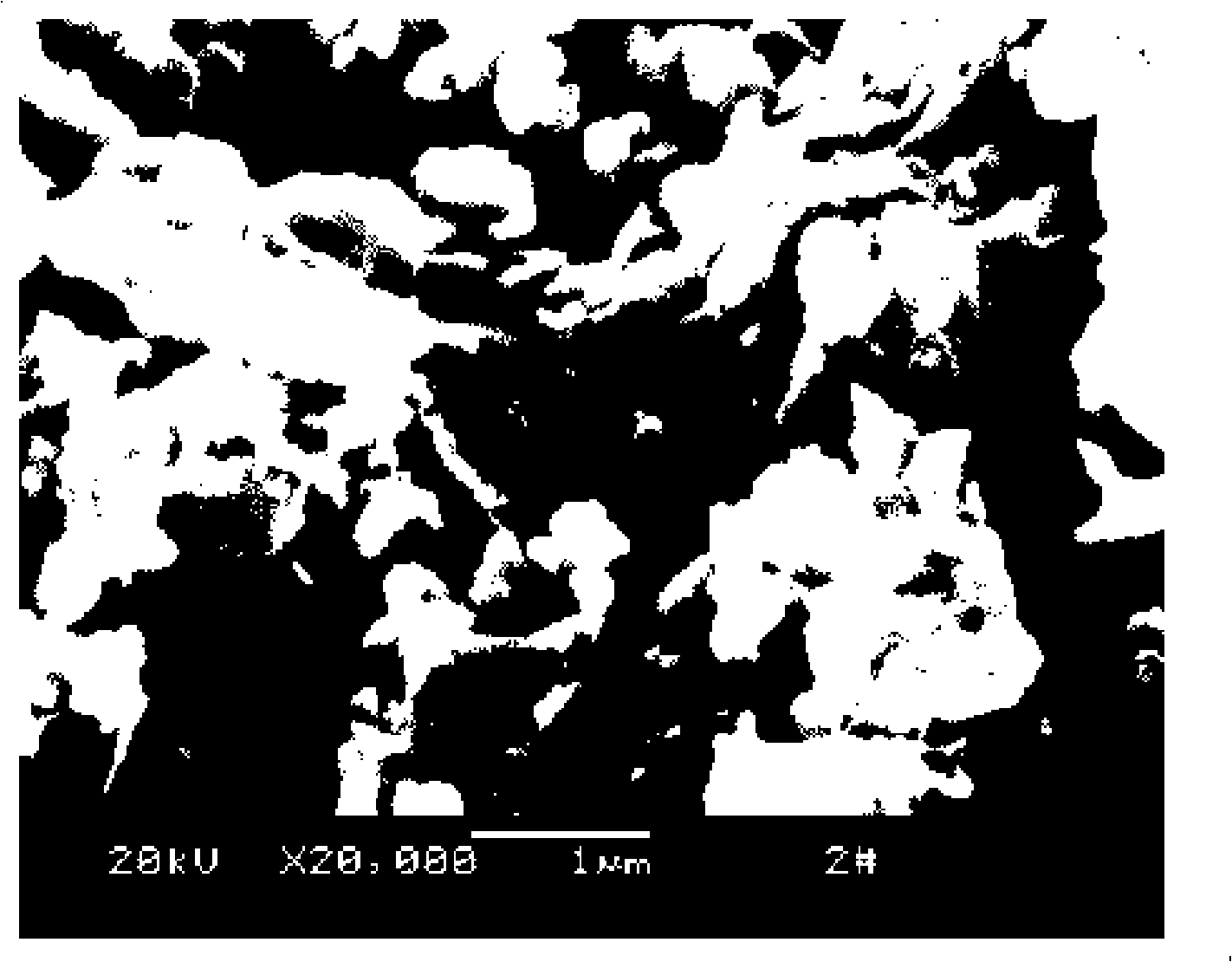

[0027] 2) Li 2 ZrO 3 Preparation of coated Si / G / DC materials: Li 2 ZrO 3 The precurso...

Embodiment 2

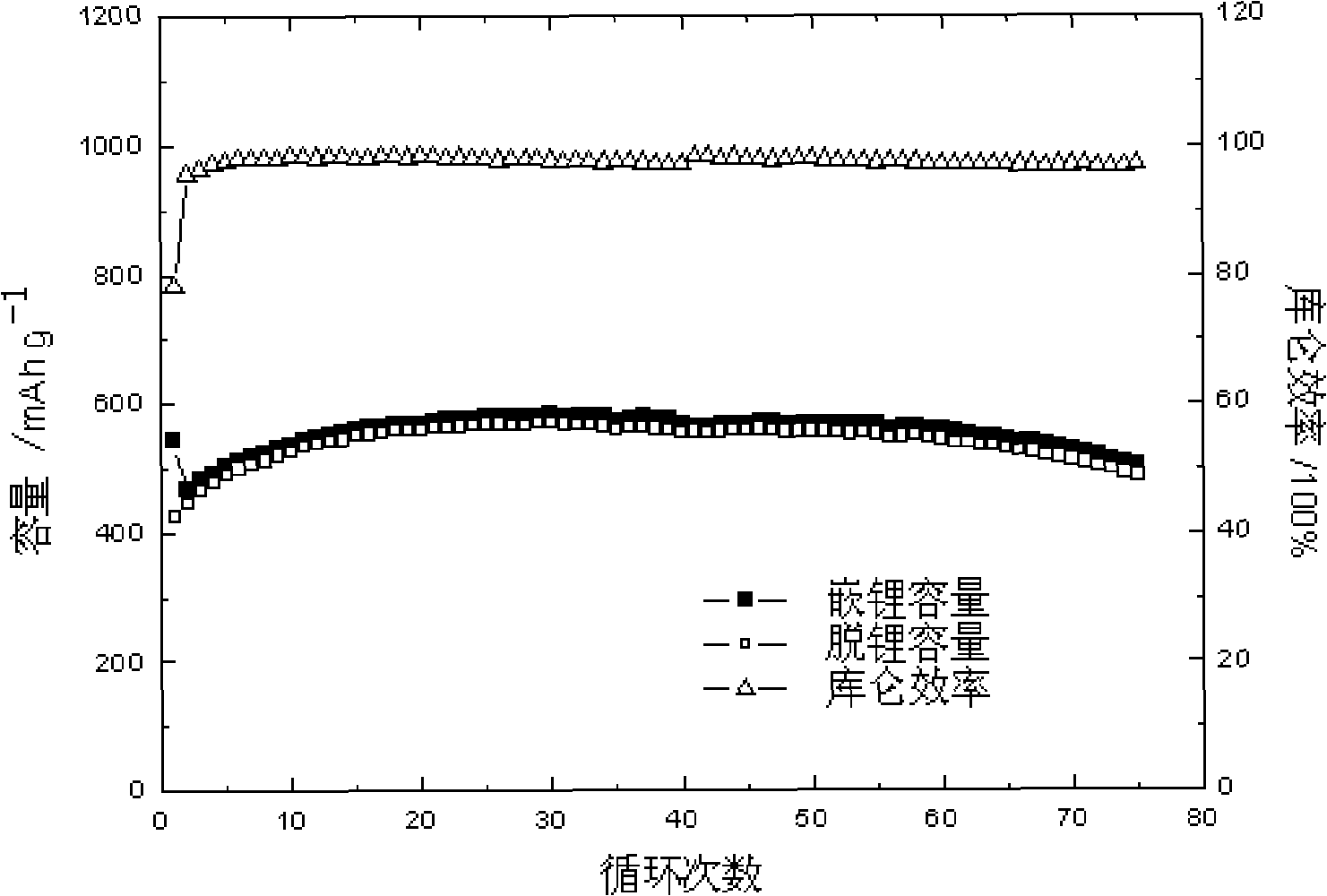

[0036] Its preparation process is with embodiment 1, difference is that Li 2 ZrO 3 The coating amount is 1%. The electrode preparation method, electrode composition and testing method are the same as in Example 1. Figure 4 It is the cycle performance curve of the composite negative electrode material in this example. The initial discharge capacity is 552mAh / g. The capacity increases in the first 20 cycles, but the capacity decays rapidly after 30 cycles. After 75 cycles, lithium intercalation The capacity is 311mAh / g.

Embodiment 3

[0038] Its preparation process is with embodiment 1, difference is that Li 2 ZrO 3 The coating amount is 3%. The electrode preparation method, electrode composition and testing method are the same as in Example 1. 3% Li 2 ZrO 3 The first reversible capacity of the coating material is 331mAh / g. The lithium intercalation depth of the material is too shallow, which greatly affects the specific capacity, and can no longer show the characteristics of high specific capacity of silicon-containing materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com