Spinning process for superfine chenille yarn

A chenille yarn and fine-count technology, which is applied in the field of superfine-count chenille yarn spinning technology, can solve the problems of stiff hand feeling of textiles and thick chenille yarn fibers, etc., so as to prolong the service life, improve the quality, Effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

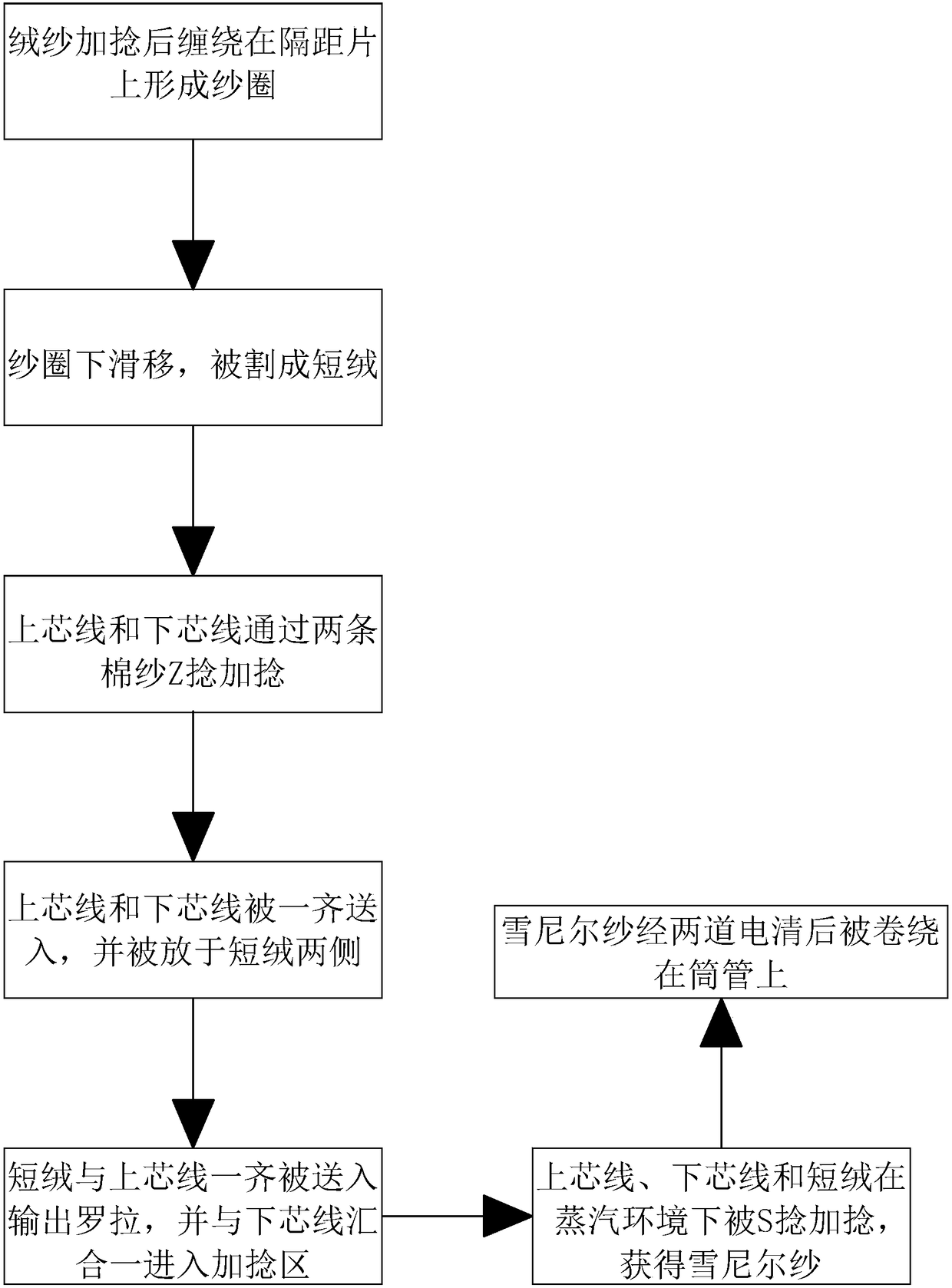

[0035] The following is attached figure 1 The present invention is described in further detail.

[0036] A kind of spinning technique of superfine chenille yarn, comprises the following steps:

[0037] Step 1: Two to three velvet yarns are twisted at 8000rpm with the rotation of the rotary head, and then wound on the spacer to form yarn loops, and the thickness of the spacer is 0.3mm and the width is 0.8mm;

[0038] Step 2: The yarn loop slides down with the pressure of the nylon roller, and is cut into short piles when it encounters the blade;

[0039] Step 3: Both the upper core thread and the lower core thread are obtained by twisting 1000 r / m of two cotton yarns in a Z-twisting manner;

[0040] Step 4: The upper core wire and the lower core wire are unwound from the bobbin under the action of the traction roller, and are fed together at a line speed of 16m / min, and under the action of the nylon roller and the spacer, the upper core wire The thread and the lower core thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com