Bean product raw material impurity removing method and device for realizing same

A technology for raw materials and soy products, applied in the field of pre-processing of soy products raw materials, can solve the problems of unsanitary and low efficiency of manual cleaning, and achieve the effects of saving costs, saving labor costs and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

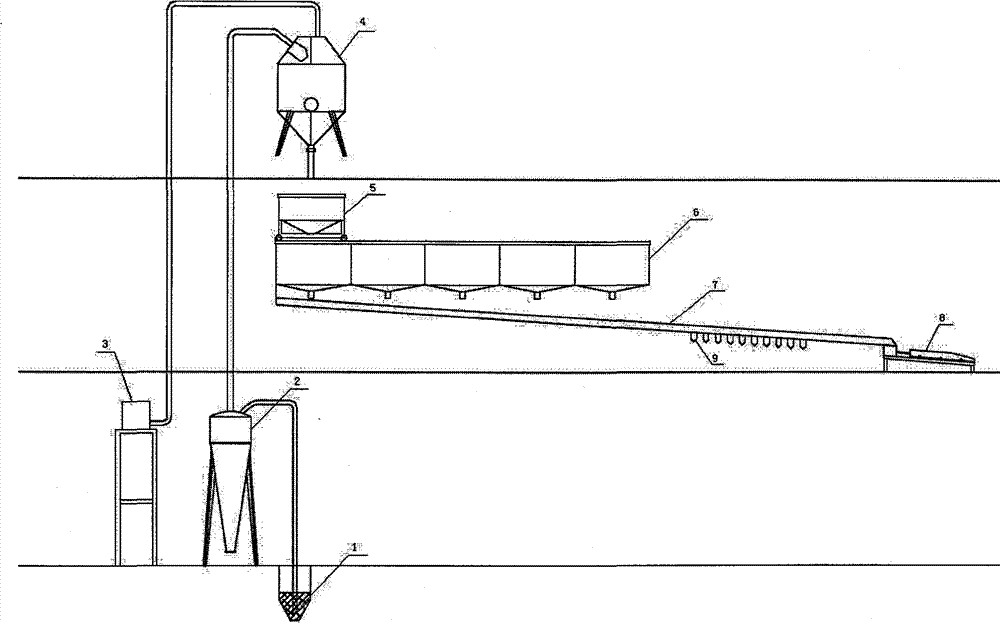

[0030] Such as figure 1 As shown, the method for removing impurities from soybeans includes the following steps: after the soybeans are checked and accepted, they are stored at a constant temperature and humidity, and poured into the bean storage tank 1 for standby when in use; Suction principle: Soybeans enter the cyclone dust collector 2 through vacuum lifting, and use the principle of poor quality to separate impurities and dust to the bottom of the cyclone dust collector 2, and regularly open the valve to remove impurities and dust; soybeans that have been preliminarily removed are sucked to the storage bean bucket 4, and then flow into the rail conveyor 5 through the valve at the bottom, the rail conveyor 5 is controlled by a computer, and the soybean products are distributed to the three soaking buckets 5, and the purpose of further impurity removal is achieved after soaking; After the soaking time, the valve at the bottom of the soaking tank is opened, and the soybeans ...

Embodiment 2

[0034] Such as figure 1 As shown, the method for removing impurities from soybeans includes the following steps: After the soybeans are checked and accepted, they are stored at a constant temperature and humidity, and poured into the bean storage tank 1 for standby when in use; Suction principle: Soybeans enter the cyclone dust collector 2 through vacuum lifting, and use the principle of poor quality to separate impurities and dust to the bottom of the cyclone dust collector 2, and regularly open the valve to remove impurities and dust; soybeans that have been preliminarily removed are sucked to the storage bean bucket 4, and then flow into the rail conveyor 5 through the valve at the bottom, and the rail conveyor 5 is controlled by a computer to distribute the soybean products to 5 soaking buckets 5, and achieve the purpose of further removing impurities after soaking; After the soaking time, the valve at the bottom of the soaking tank is opened, and the soybeans automaticall...

Embodiment 3

[0038] Such as figure 1As shown, the method for removing impurities from soybeans includes the following steps: After the soybeans are checked and accepted, they are stored at a constant temperature and humidity, and poured into the bean storage tank 1 for standby when in use; Suction principle: Soybeans enter the cyclone dust collector 2 through vacuum lifting, and use the principle of poor quality to separate impurities and dust to the bottom of the cyclone dust collector 2, and regularly open the valve to remove impurities and dust; soybeans that have been preliminarily removed are sucked to the storage bean bucket 4, and then flow into the rail conveyor 5 through the valve at the bottom, the rail conveyor 5 is controlled by a computer, and the soybean products are distributed to 10 soaking buckets 5, and the purpose of further impurity removal is achieved after soaking; After the soaking time, the valve at the bottom of the soaking tank is opened, and the soybeans automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com