Method for preparing titanium dioxide for delustering chemical fibers

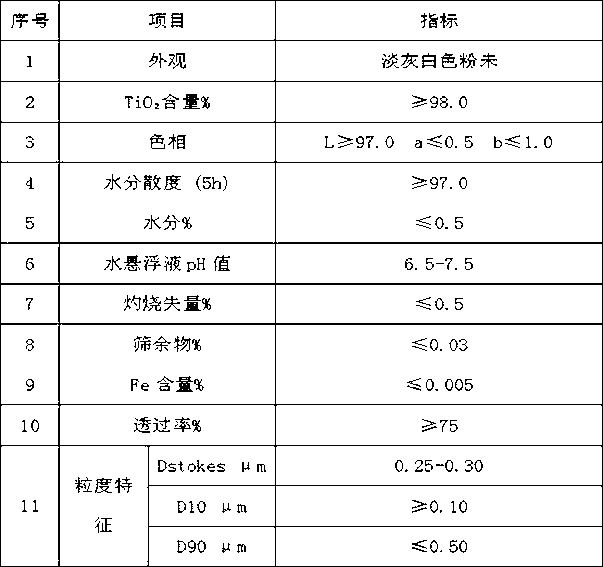

A titanium dioxide and chemical fiber technology, which is applied in the field of preparation of titanium dioxide for chemical fiber extinction, can solve the problems of poor color phase, reduction of surface potential of titanium dioxide particles, and unfavorable dispersion of titanium dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of titanium dioxide for chemical fiber matting, comprising the steps of:

[0051] 1) Add polycarboxylate with a raw material solid content of 0.2% in deionized water, put in raw material titanium dioxide, stir and disperse, and prepare a slurry with a raw material solid content of 40-50%;

[0052] 2) Use the iron removal filter to perform preliminary filtration and iron removal on the slurry;

[0053] 3) Use one or two consecutive sand mills to further disperse titanium dioxide;

[0054] 4) Dilute the above-mentioned wet-milled slurry into a diluted slurry with a solid content of 20%;

[0055] 5) Use iron removal filter to filter and remove iron from the diluted slurry;

[0056] 6) Classify and surface treat the diluted slurry after filtration and iron removal;

[0057] 7) Wash and settle the diluted slurry obtained in the previous step to obtain concentrated slurry;

[0058] 8) Spray-dry the concentrated slurry obtained in the previous step to ob...

Embodiment 2

[0072] A preparation method of titanium dioxide for chemical fiber matting, comprising the steps of:

[0073] 1) Add polycarboxylate with a raw material solid content of 0.2% in deionized water, put in raw material titanium dioxide, stir and disperse, and prepare a slurry with a raw material solid content of 40-50%;

[0074] 2) Use the iron removal filter to perform preliminary filtration and iron removal on the slurry;

[0075] 3) Use one or two consecutive sand mills to further disperse titanium dioxide;

[0076] 4) Dilute the above-mentioned wet-milled slurry into a diluted slurry with a solid content of 20%;

[0077] 5) Use iron removal filter to filter and remove iron from the diluted slurry;

[0078] 6) Classify and surface treat the diluted slurry after filtration and iron removal;

[0079] 7) Wash and settle the diluted slurry obtained in the previous step to obtain concentrated slurry;

[0080] 8) Spray-dry the concentrated slurry obtained in the previous step to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com