Dredging machine under wharf and dredging method thereof

A machine tool and wharf technology, applied in port wharf dredging equipment and its construction field, can solve the problems of difficult control of underwater flatness, difficult control and high construction cost, achieve superior productivity ratio, simple and convenient operation, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

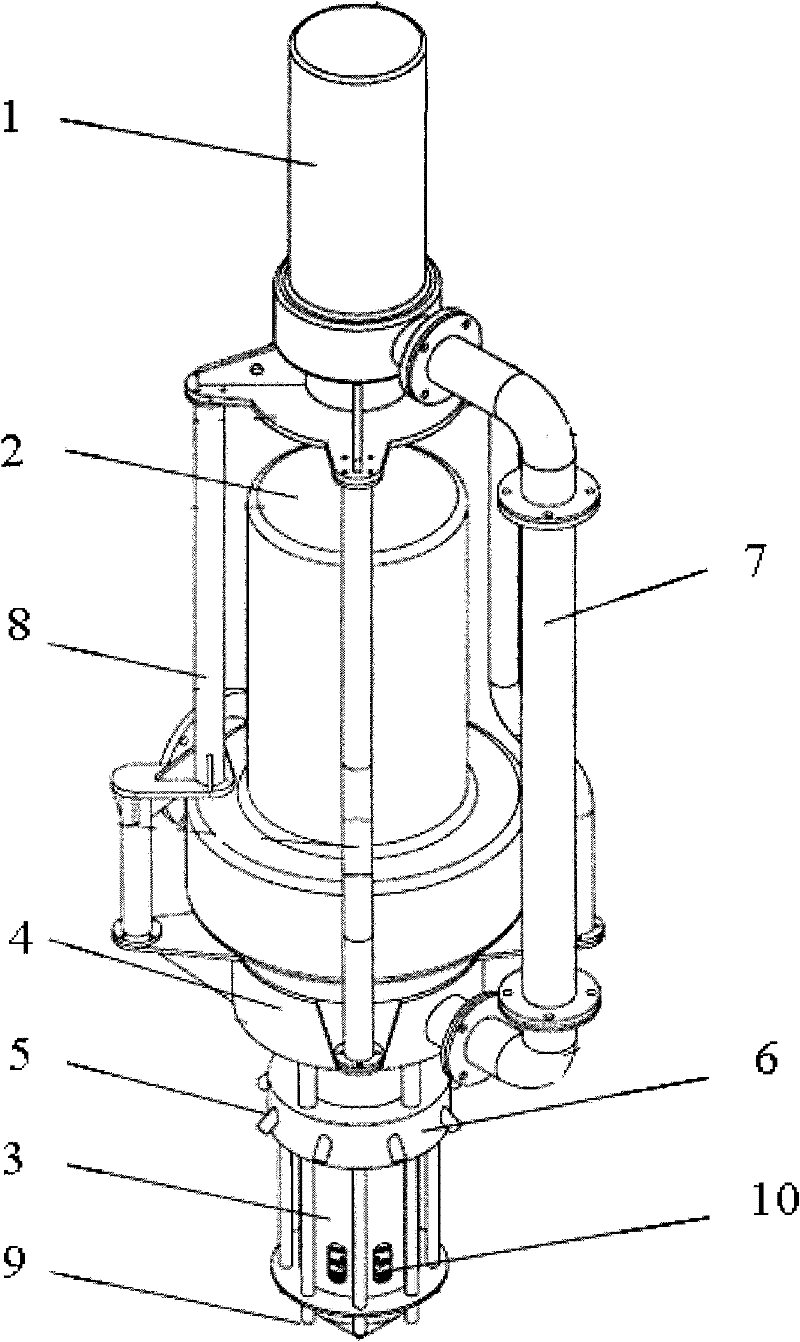

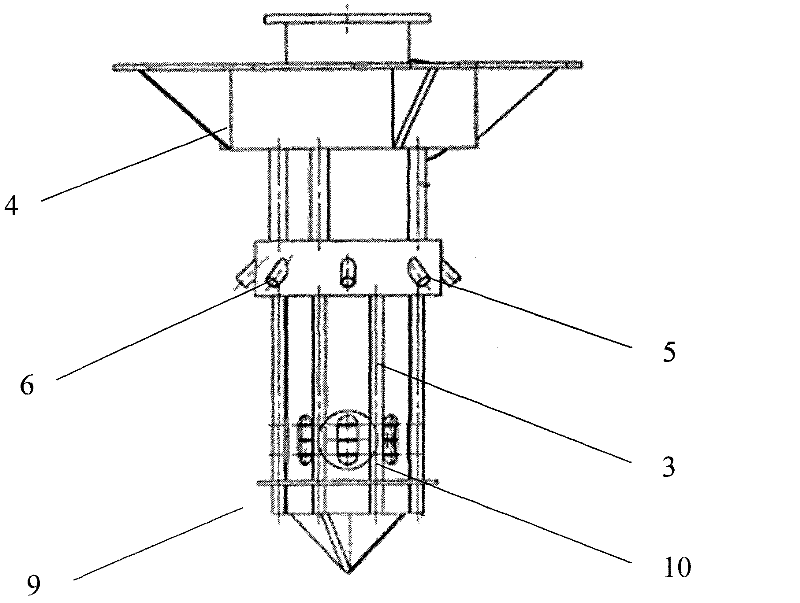

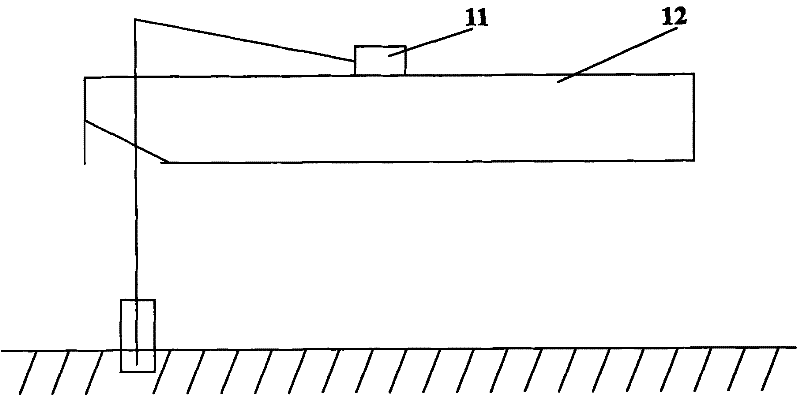

[0009] The present invention (see accompanying drawing) adopts high-pressure flushing pump 1, submersible mud pump 2, dredging head 3, nozzle, mud delivery pipe, and high-pressure flushing pump 1 is connected on the top of submersible mud pump 2 by a set of pipe fittings 8 and flange, submersible The bottom of the mud pump 2 is connected to the dredging head 3 through a flange. The high-pressure flushing pump 1 leads the high-pressure water to the transition water tank 4 through the water pipe 7, and then connects to the high-pressure flushing water tank 6 located in the middle of the dredging head 3 through the water pipe. The high-pressure flushing water tank 6 is connected to the bottom of the dredging head with 8 water pipes , 8 vertical nozzles 9 are installed in 8 water pipes, and 8 high-pressure flushing nozzles 5 that are 45° with the horizontal plane are evenly distributed around the high-pressure flushing water tank. The bottom of the dredging head 3 is tapered and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com