Cylindrical pre-cleaning screen

A technology of initial cleaning and cylinder, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of poor cleaning effect, easy material blockage, insufficient material entry, etc., to avoid poor material blockage, full clearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

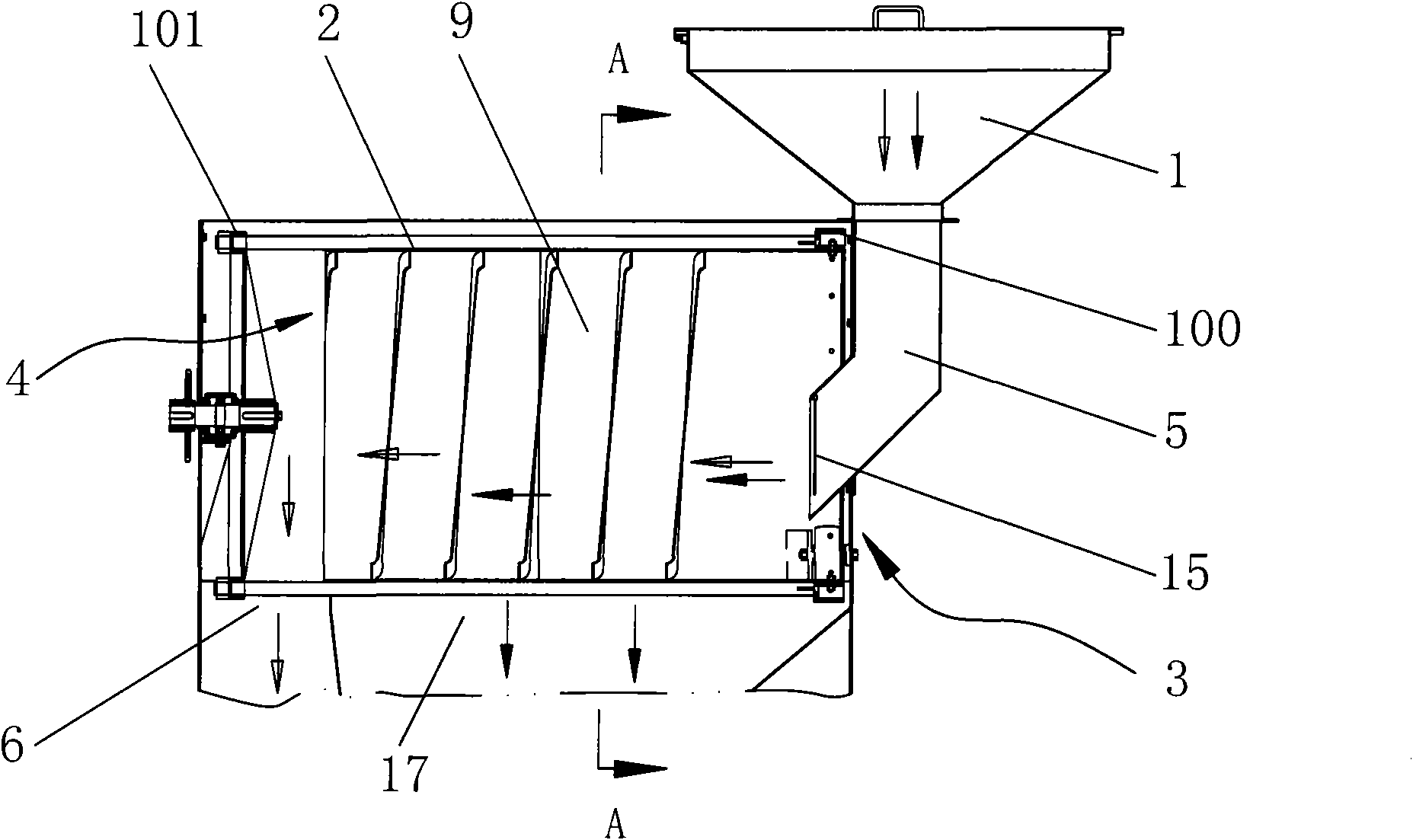

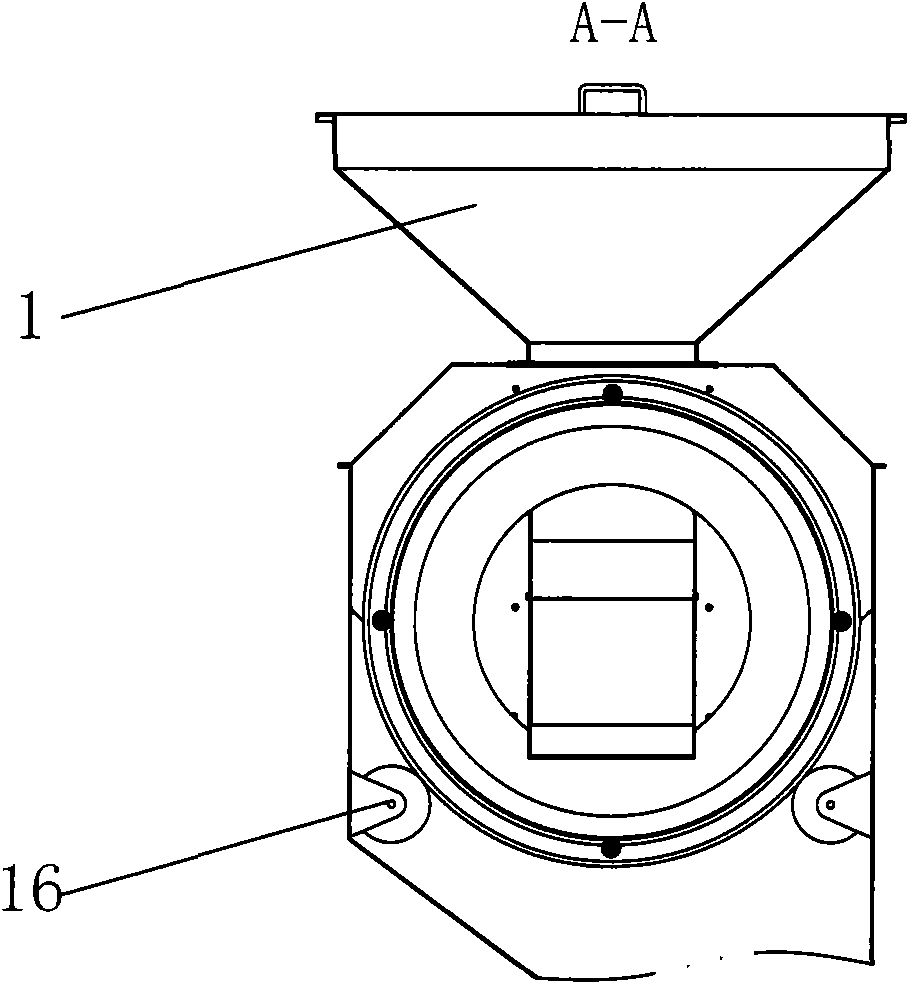

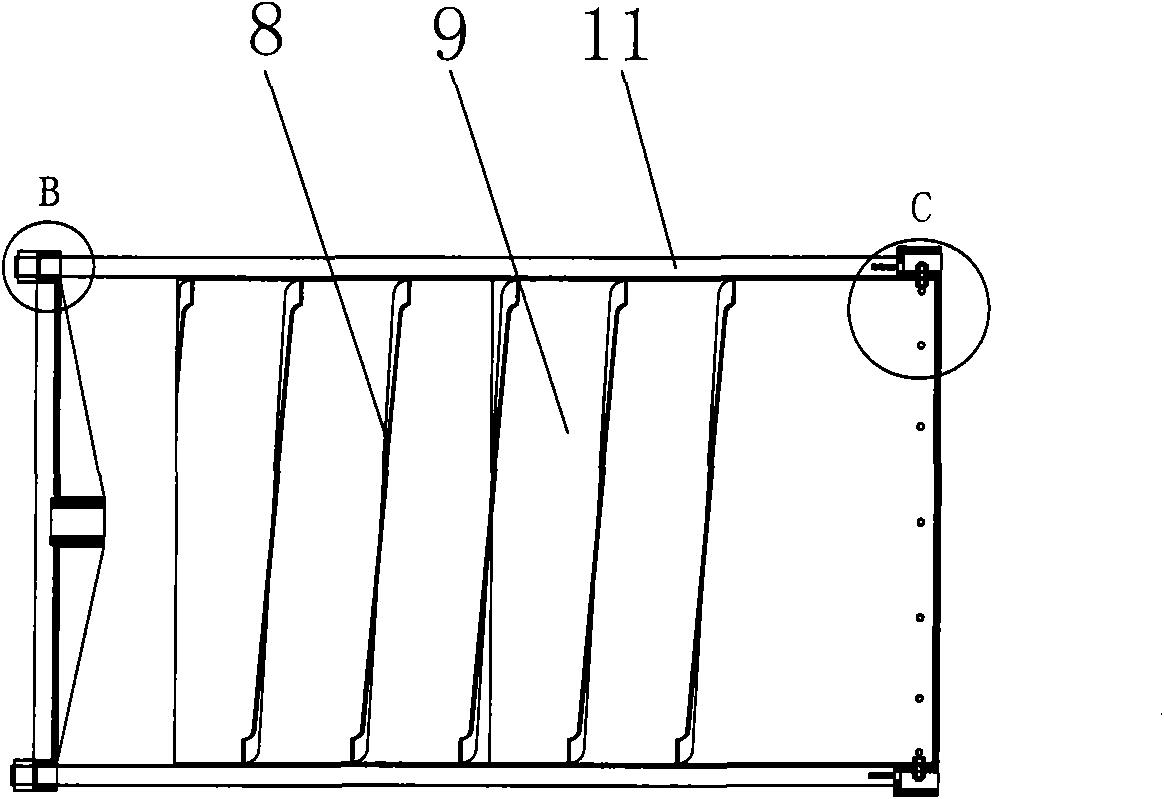

[0022] Such as figure 1 , 2 , a kind of cylinder preliminary cleaning screen shown in 3, it comprises the sieve cylinder 2 that can rotate, and the rotational axis line of sieve cylinder 2 is arranged along horizontal direction, and sieve cylinder 2 has left end 4 and right end 3, and sieve cylinder is in The right end 3 is provided with an inlet for conveying the material to be screened, and the left end 4 of the screen drum is provided with an outlet for removing impurities, and the outlet is connected with an impurity discharge channel 6 . The inner wall of the screen cylinder 2 is provided with a spiral material guide groove 8 extending along the direction of the rotation axis of the screen cylinder 2, and a screening channel 9 is formed inside the screen cylinder 2, and the inner wall of the screen cylinder 2 is provided with a channel that only allows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com