Circulating pretreatment system for carbon dioxide capture of coal-fired power plant

A carbon dioxide, coal-fired power plant technology, applied in chemical instruments and methods, combined devices, dispersed particle separation, etc., can solve problems such as poor washing effect, and achieve high washing efficiency, automatic control, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

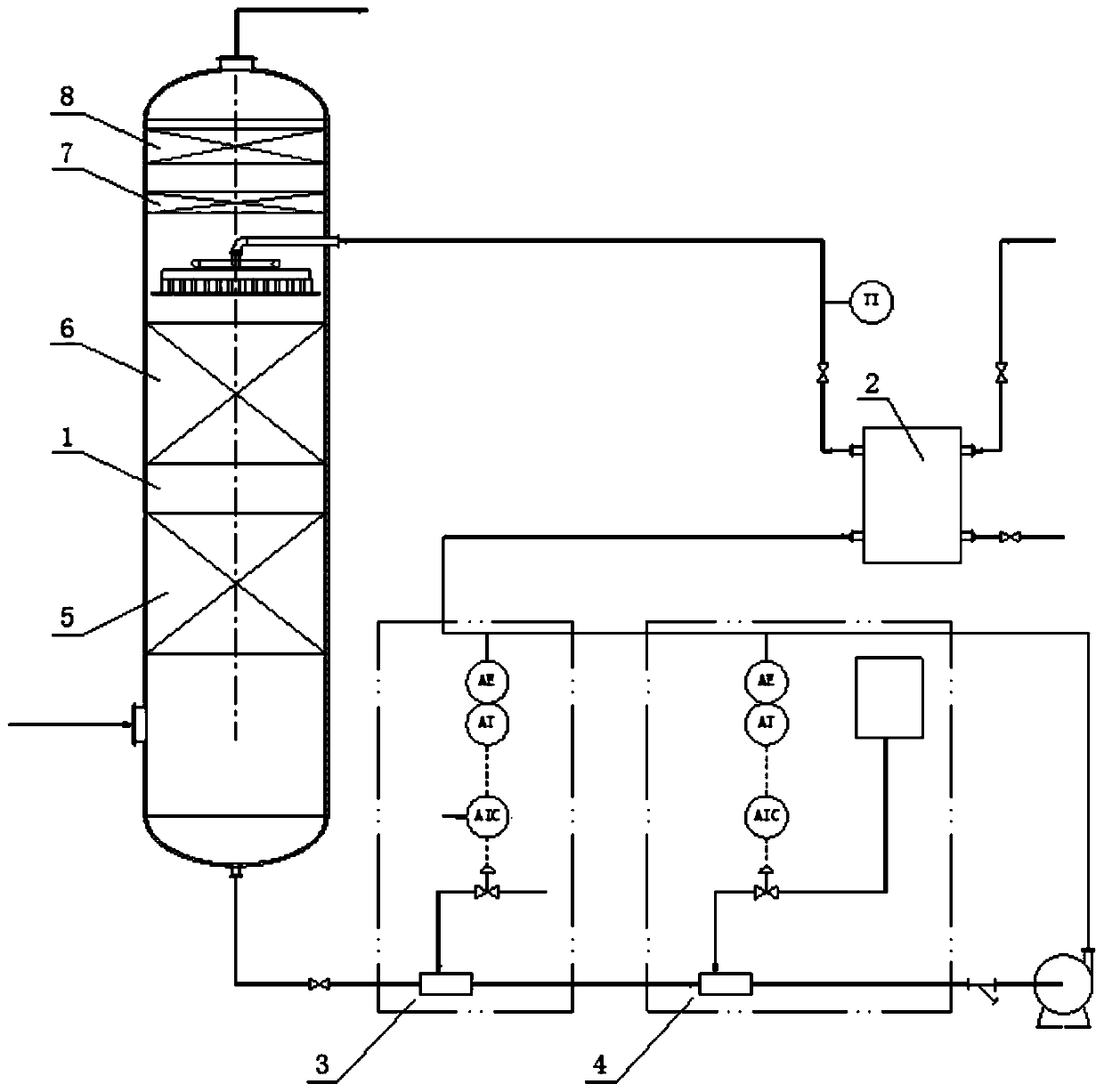

[0026] The core of the present invention is to provide a circulating pretreatment system for carbon dioxide capture in coal-fired power plants, which has high water washing efficiency and good effect, and can realize automatic control of pH value and salinity in circulating water.

[0027] It should be noted that the directions of the orientation words "up and down" appearing in this article refer to figure 1 The upper and lower directions in the middle; "inner" refers to the figure 1 The direction of the inside of the water washing tower, "outside" refers to figure 1 The direction of the exterior of the washing tower with medium water. The orientation words appearing in this article are established based on the customary usage of those skilled in the art and the drawings in the specification, and their appearance should not affect the protection scope of the present invention.

[0028] In order to enable those skilled in the art to better understand the solution of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com