High-abrasion-resisting glass fiber fabric and preparation method thereof

A technology of glass fiber cloth and glass fiber, which is applied in the field of high wear-resistant glass fiber cloth and its preparation, and glass fiber cloth. It can solve problems such as wear, non-waterproof, and easy to break, and achieve the effect of increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

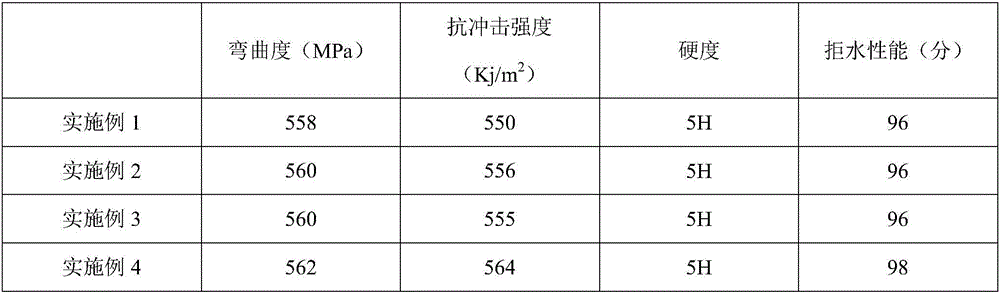

Examples

Embodiment 1

[0030] A preparation method of high wear-resistant glass fiber cloth, the steps are as follows:

[0031] (1) glass fiber monofilament plain weaving (density is 50 orders / cm), obtains basic glass fiber cloth;

[0032] (2) Arrange the basic glass fiber in the slurry and soak for 2 hours. The slurry is made of the following components: 5 kg of polytetrafluoroethylene emulsion, 0.1 kg of ultrafine mica powder, and 0.3 kg of dibutyl phthalate , PEG2000 2kg, guar gum 0.6kg, sodium carboxymethyl starch 0.01kg, hollow glass microspheres 4kg, water 100kg; the particle diameter of the hollow glass microspheres is within the range of 15-50 microns;

[0033] The preparation method of the slurry is: while stirring, add the sodium carboxymethyl starch of the formula amount into the water, stir for 12 hours, continue to add the guar gum, PEG2000 and superfine mica powder of the formula amount, stir evenly and then add the formula amount of Polytetrafluoroethylene emulsion, hollow glass micr...

Embodiment 2

[0040] A preparation method of high wear-resistant glass fiber cloth, the steps are as follows:

[0041] (1) glass fiber monofilament plain weaving (density is 80 orders / cm), obtains basic glass fiber cloth;

[0042] (2) Arrange the basic glass fiber in the slurry and soak for 3 hours. The slurry is made of the following components: 5kg of polyvinyl chloride emulsion, 0.1-0.2kg of ultra-fine mica powder, and 0.3kg of dibutyl phthalate ~0.5kg, PEG4000 3kg, guar gum 0.8kg, carboxymethyl starch sodium 0.02kg, hollow glass microspheres 6kg, water 100kg; the particle size of the hollow glass microspheres is within the range of 15-50 microns;

[0043] The preparation method of the slurry is: add the formula amount of sodium starch glycolate into water while stirring, stir for 24 hours, continue to add the formula amount of guar gum, PEG4000 and superfine mica powder, stir evenly and then add the formula amount of Polyvinyl chloride emulsion, hollow glass microspheres and dibutyl ph...

Embodiment 3

[0050] A preparation method of high wear-resistant glass fiber cloth, the steps are as follows:

[0051] (1) glass fiber monofilament plain weaving (density is 50 orders / cm), obtains basic glass fiber cloth;

[0052] (2) Arrange the basic glass fiber in the slurry and soak for 3 hours. The slurry is made of the following components: 5kg of silicone rubber emulsion, 0.1kg of ultrafine mica powder, 0.5kg of dibutyl phthalate, PEG2000 2kg, guar gum 0.8kg, sodium carboxymethyl starch 0.01kg, hollow glass microspheres 5kg, water 100kg; the particle size of the hollow glass microspheres is within the range of 15-50 microns;

[0053] The preparation method of the slurry is: add the formula amount of sodium starch glycolate into water while stirring, stir for 24 hours, continue to add the formula amount of guar gum, PEG2000 and superfine mica powder, and then add the formula amount of Silicone rubber emulsion, hollow glass microspheres and dibutyl phthalate, stirred evenly;

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com