Workbench device for adhering adhesive tape to bottom of lithium battery cell

A workbench and lithium battery technology, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low degree of automation and unfavorable intelligent production, so as to improve the level of automation and intelligent production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

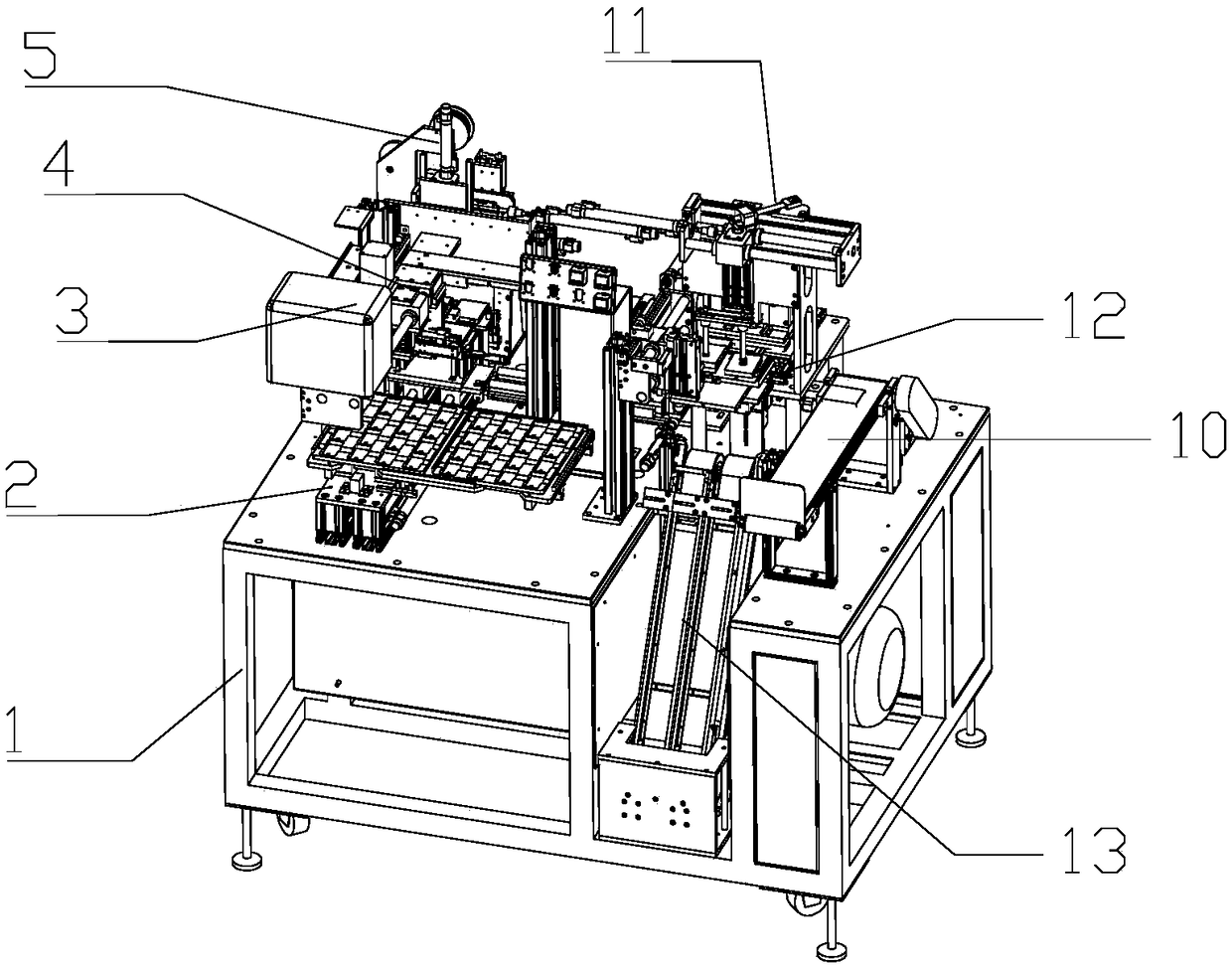

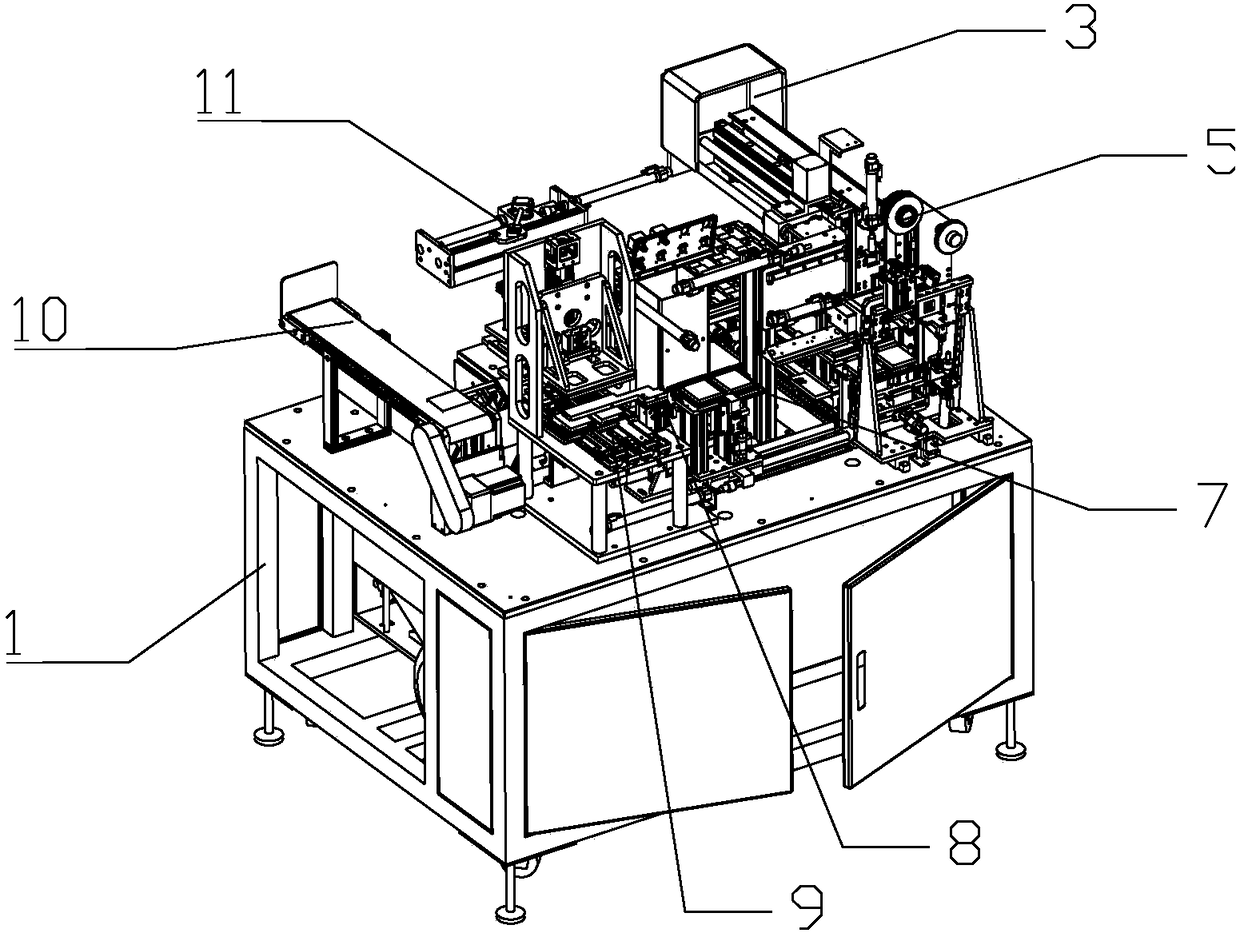

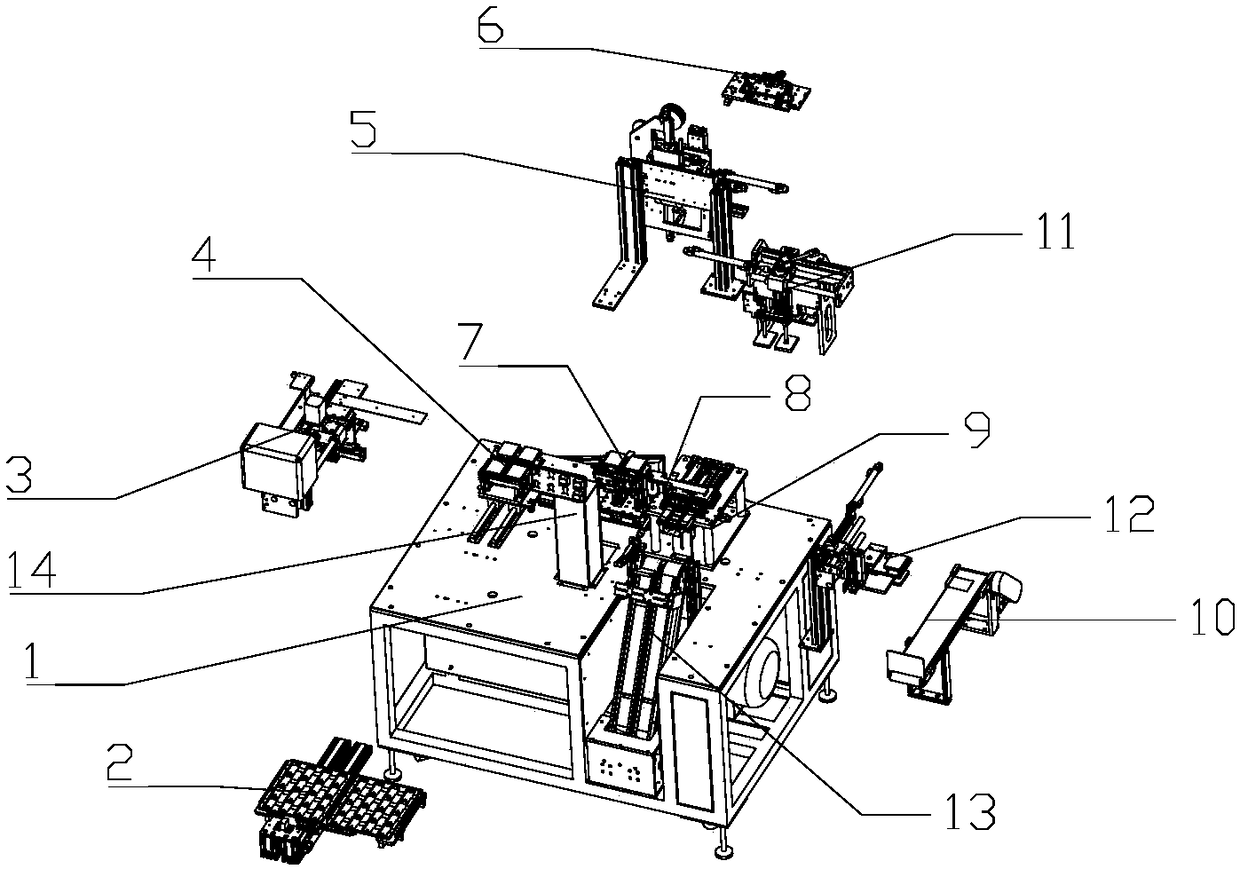

[0055] Such as figure 1 , figure 2 , image 3 Shown is an automatic new energy lithium battery cell adhesive packaging equipment, which includes a frame assembly 1, a cell material tray device 2, a cell handling device 3, a first workbench 4, and a tape fixed-length cutting device 5. Tape sticking device 6, translational conveying device 7, flipping conveying device 8, second workbench 9, aluminum shell feeding device 10, aluminum shell conveying device 11, battery unloading device 12, finished product blanking device 13 and control Component 14. The frame assembly 1 is used to install other devices, the cell material tray device 2 is fixedly arranged on the frame assembly 1, and is used to accept the cells to be processed, and the cell handling device 3 is fixedly arranged on the frame assembly 1 , installed above the cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com