Cutting device and cutting method of rubber stopper vulcanized rubber sheet

A technology of vulcanized rubber sheet and cutting device, which is applied in the direction of metal processing, etc. It can solve the problems of low efficiency, high rubber content and thin thickness of rubber vulcanized rubber sheet, and achieve the effects of reducing labor intensity, improving production efficiency, and increasing cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

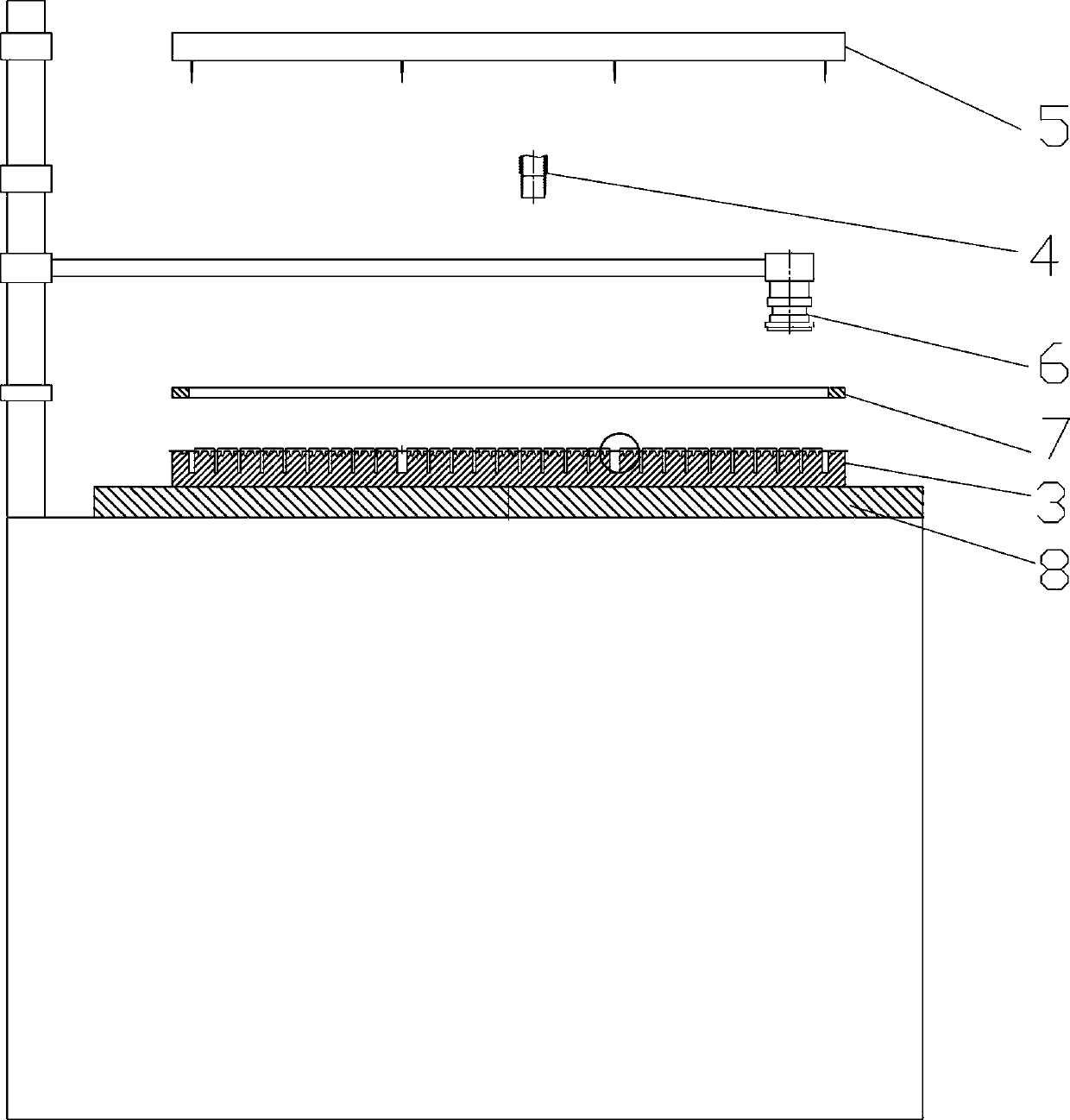

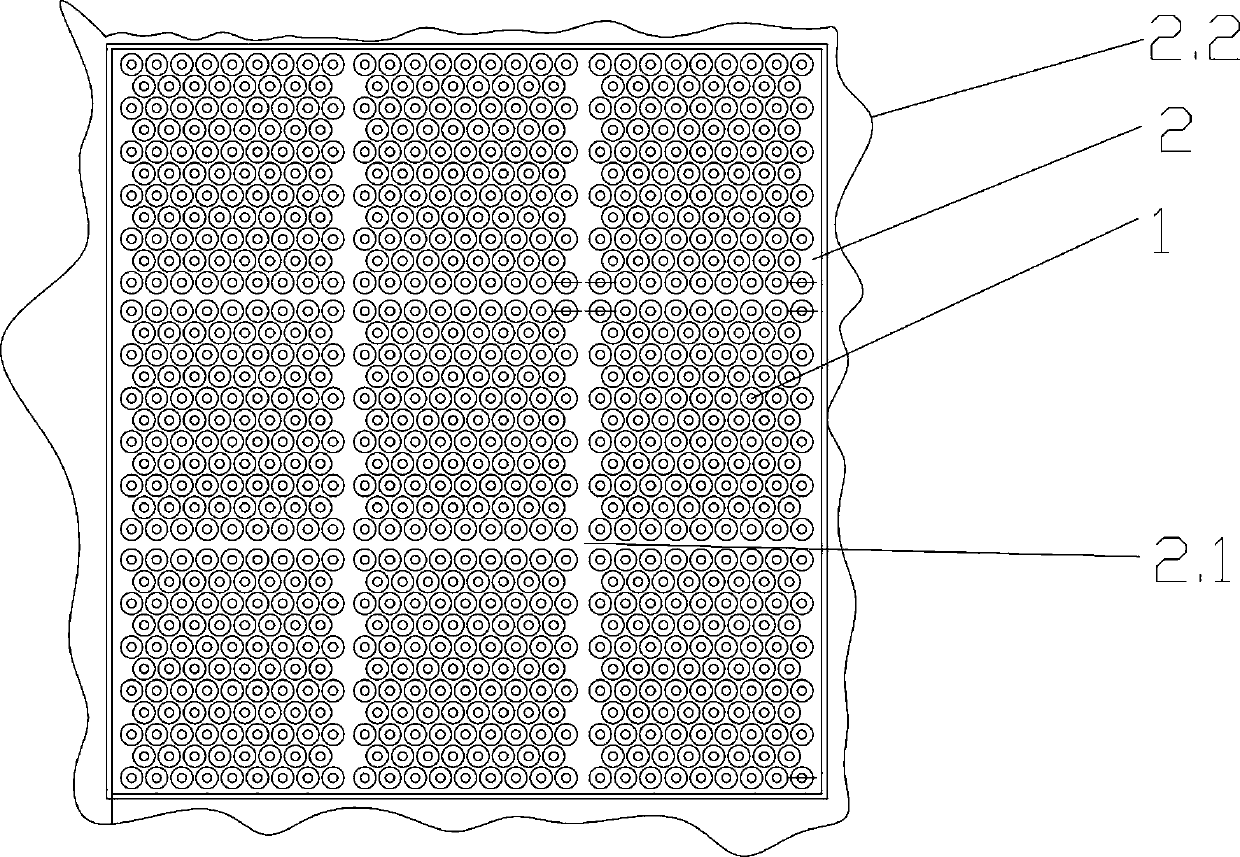

[0036] Such as Figures 1 to 7 As shown, a cutting device for rubber stopper vulcanized film, it includes a positioning plate 3 for positioning the rubber stopper 1 and the vulcanized film 2, above the positioning plate 3 is provided with a trap for removing defective products of the rubber stopper 1 Cylindrical perforated cutter 4 and square perforated cutter 5 for cutting vulcanized rubber sheet 2.

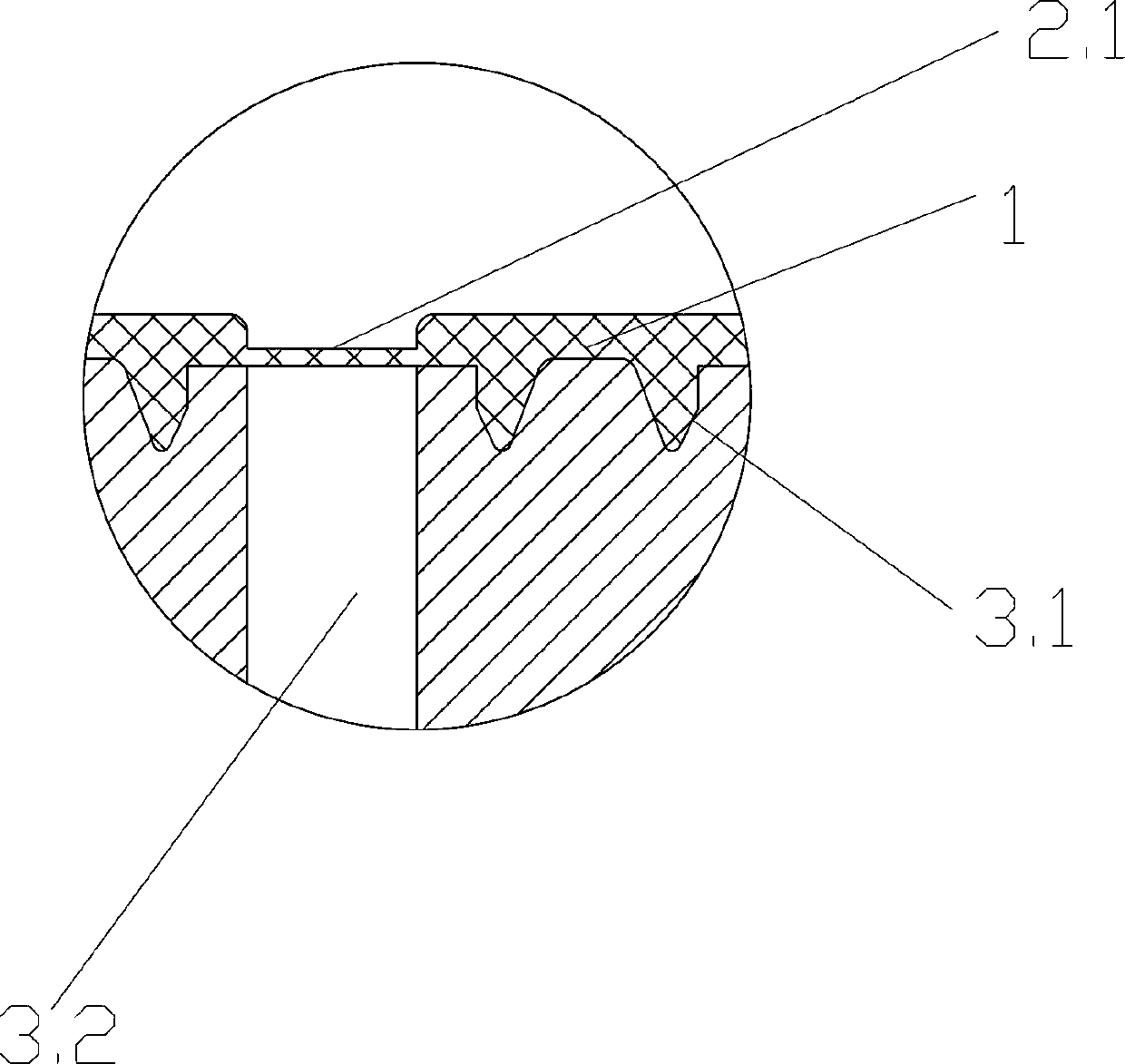

[0037] Preferably, the upper surface of the positioning plate 3 is provided with a positioning groove 3.1 that cooperates with the rubber stopper 1, and the side of the positioning groove 3.1 is also provided with a slice groove 3.2 that cooperates with the cylindrical perforated knife 4 and the square perforated knife 5. The shape of the positioning groove 3.1 matches the rubber stopper 1, for example, it matches the neck or the crown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com