Light calcium carbonate chaff burning furnace heat-supplying and flue gas treatment device

A technology for light calcium carbonate and flue gas treatment, applied in calcium carbonate/strontium/barium, dry gas layout, lighting and heating equipment, etc., can solve the problems of large environmental pollution, high energy consumption, high labor intensity, etc., and achieve Reduce energy consumption, produce energy saving, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

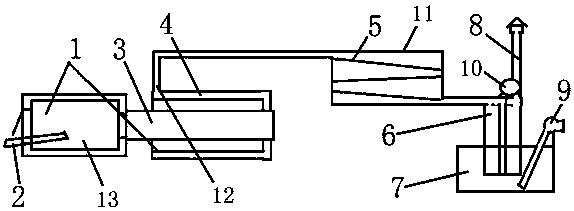

[0026] A heat supply and flue gas treatment device for a light calcium carbonate chaff burning furnace, comprising a light calcium carbonate filter cake drying box 11, characterized in that the light calcium carbonate filter cake drying box 11 is equipped with a drying box The hot air pipe 5, the hot air pipe 5 of the drying box is connected with the hot air supply pipe 12 of the chaff burning furnace, and the drying hot air of the hot air pipe 5 of the drying box is made by the chaff burning furnace 1 and passes through the hot air supply. The air pipe 12 is sent to the hot air pipe 5 of the drying box; the outlet of the hot air pipe 5 of the drying box is connected to the flue gas dust removal treatment device 6, and after the hot air work is completed, it will enter the flue gas dust removal treatment device 6 for treatment, and pass through the flue after reaching the standard discharge.

[0027] Further, the chaff burning furnace 1 includes a hearth 13, the chaff is sent ...

Embodiment 2

[0032] The principle of embodiment two is the same as that of embodiment one, but the system device adopted is different, which is a light calcium carbonate chaff combustion furnace heat supply and flue gas treatment device, including light calcium carbonate filter cake airflow drying device , which is characterized in that the light calcium carbonate filter cake airflow drying device is equipped with an airflow drying device hot air pipe, the airflow drying device hot air pipe is connected with the hot air supply pipe of the chaff burning furnace, and the drying hot air of the airflow drying device The hot air produced by the chaff burning furnace is sent to the hot air pipe of the airflow drying device through the hot air supply pipe; the outlet of the hot air pipe of the airflow drying device is connected to the flue gas dust removal treatment device, and the hot air will enter the flue gas dust removal treatment device after the work is completed. After reaching the standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com