Novel paint stirring device

A technology of stirring device and coating, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of biological chain and production efficiency, insufficient human processing, and low efficiency of production methods, etc. To achieve the effect of high work efficiency, avoid manual operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

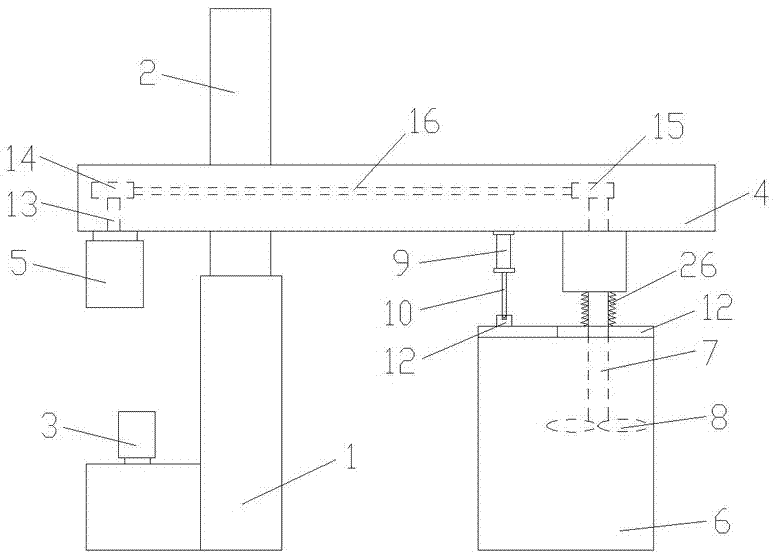

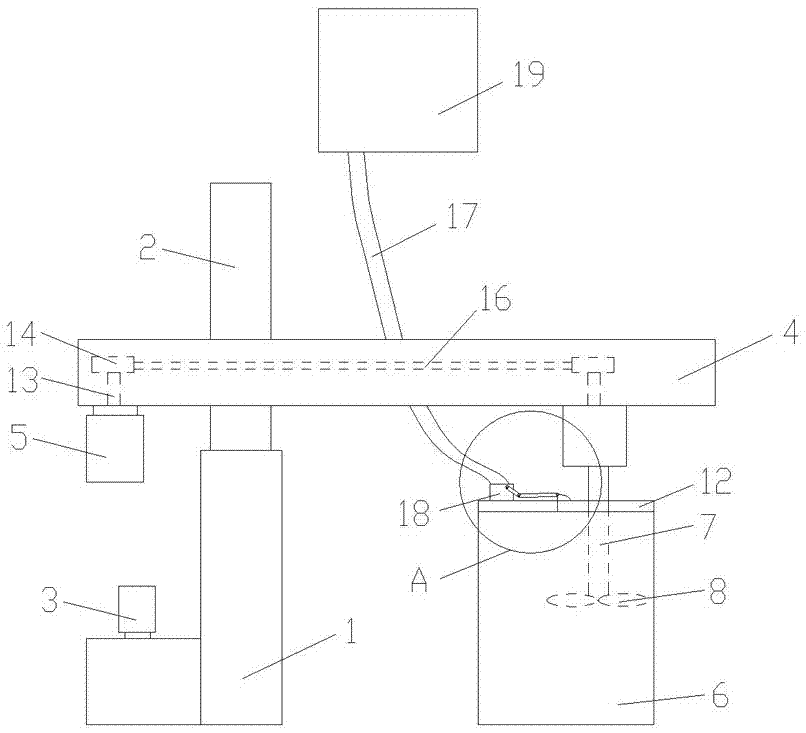

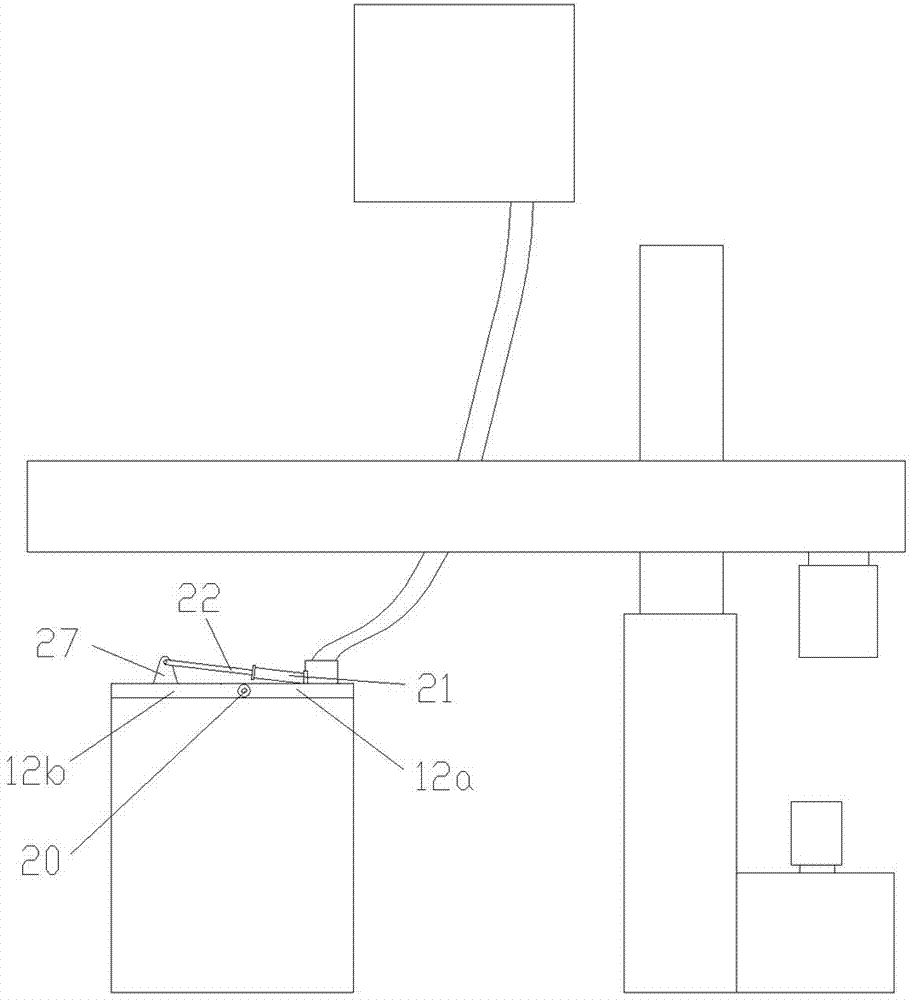

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0025] Such as Figure 1 to Figure 4 As shown: a new type of paint stirring device, which is characterized in that it includes a lifting base 1, a lifting rod 2 is extended to the height of the lifting base 1, a lifting motor 3 is arranged on one side of the lifting base 1, and the lifting motor 3 is passed on the lifting rod 2. 3 The driving slide is provided with a stirring arm 4, one end of the stirring arm 4 is provided with a stirring motor 5, the other end of the stirring arm 4 is provided with a stirring bucket 6, and the other end of the stirring arm 4 is provided with a rotating shaft 7, and the rotating shaft 7 One end is driven and connected with a stirring blade 8 through a stirring motor 5 , and the stirring blade 8 extends into the mixing barrel 6 through a rotating shaft 7 .

[0026] Specifically, the stirring arm 4 is arranged on the lifting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com