Closed automated garbage collection system

A technology of automatic collection and garbage collection, applied in the direction of garbage collection, trash can, garbage transfer, etc., can solve the problems of blockage of storage section, system stuck, discharge valve failure, etc., to improve suction efficiency, reduce frictional resistance, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

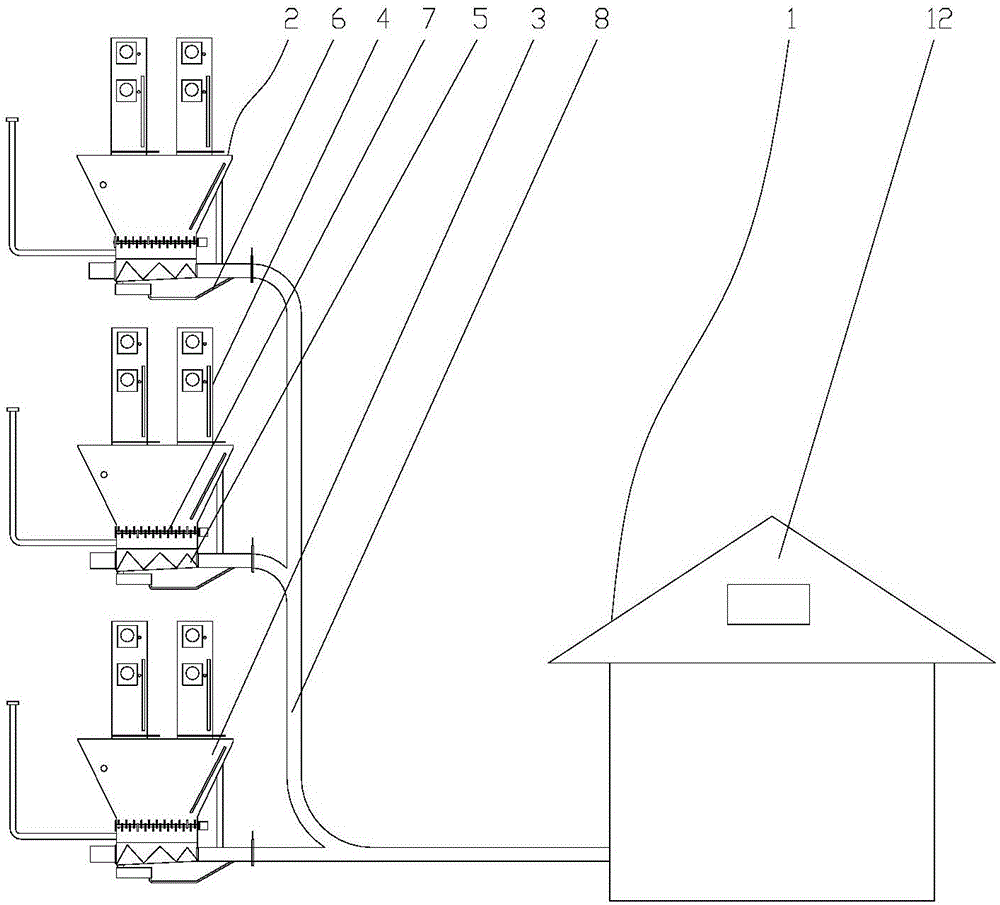

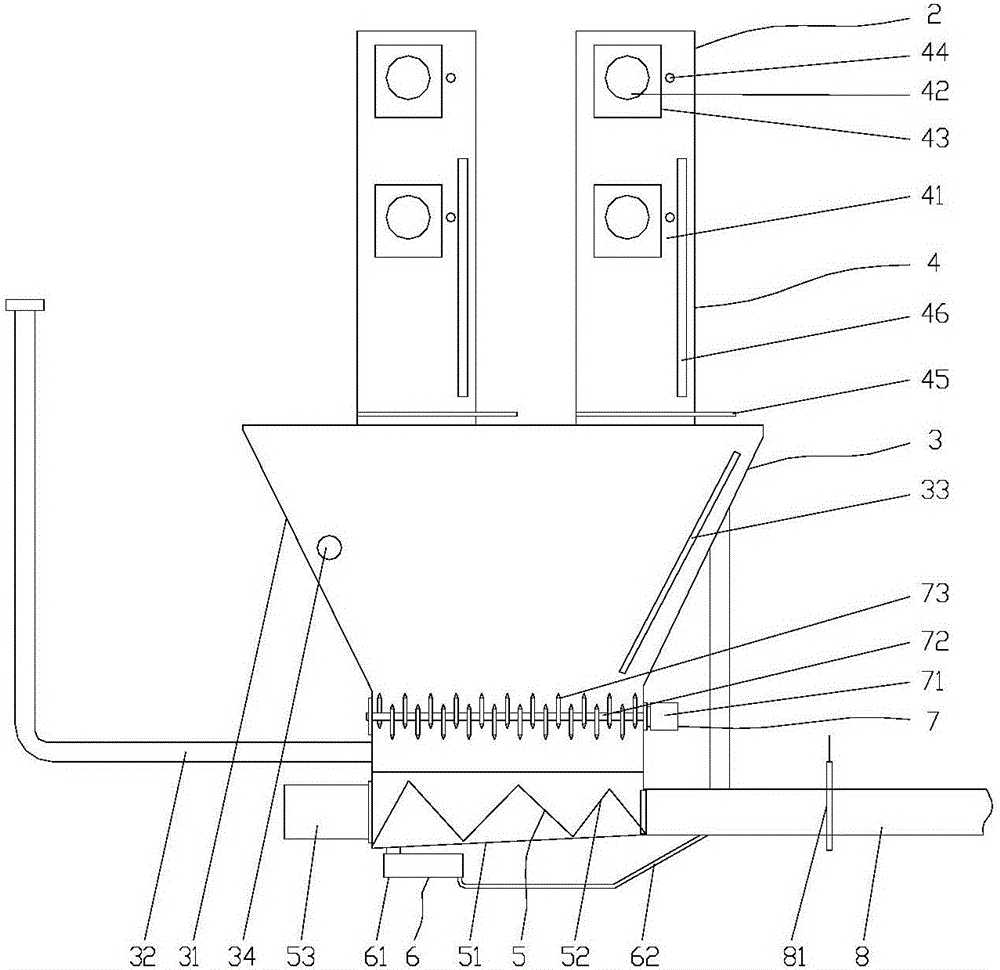

[0047] like figure 1 or figure 2 As shown, the closed automatic garbage collection system of the present invention includes three garbage collection devices 2, the suction transfer device 1 is a central garbage collection device 12, and the central garbage collection device 12 has negative pressure power equipment; as the garbage collection device 2 A kind of structure, above the garbage storage mechanism 3 described in each garbage collection device, there are two garbage throwing mechanisms 4, and the throwing channels 41 of each of the garbage throwing mechanisms 4 are all set in the building, and each of the throwing Each floor of the corresponding building on the channel 41 is provided with a garbage delivery port 42, and the number of the bag breaking mechanism 7 is one, and the bag breaking mechanism 7 is arranged in the garbage storage mechanism 3 above the feed opening of the screw propulsion mechanism 5.

Embodiment 2

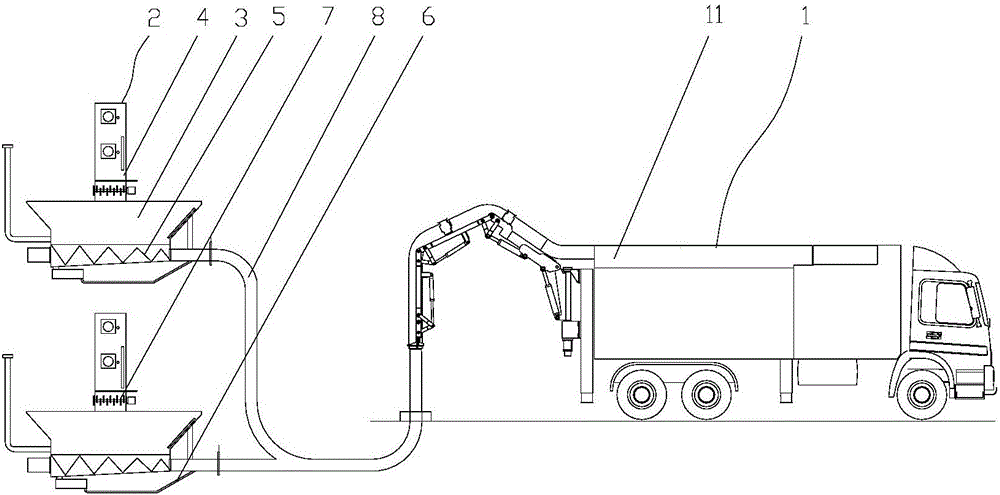

[0049] like image 3 As shown, the closed automatic garbage collection system of the present invention includes two garbage collection devices 2, the suction transfer equipment 1 is an aerodynamic suction vehicle 11, and the aerodynamic suction vehicle 11 has negative pressure power equipment; Another structure of the device 2, a garbage delivery mechanism 4 is arranged above the garbage storage mechanism 3 of each garbage collection device, and the delivery channel of each garbage delivery mechanism 4 is set in the building, and each of the garbage delivery mechanisms 4 Each floor of the corresponding building on the delivery channel is provided with a garbage delivery port, and the number of the bag breaking mechanism 7 is the same as that of the garbage delivery mechanism 4, and the bag breaking mechanism 7 is arranged in the garbage delivery mechanism 4 lower ends.

Embodiment 3

[0051] like Figure 4 As shown, the closed automatic garbage collection system of the present invention includes a garbage collection device 2, and the suction transfer equipment 1 is an aerodynamic suction vehicle 11, and the aerodynamic suction vehicle 11 has negative pressure power equipment; as a garbage collection device 2, three garbage dispensing mechanisms 4 are arranged above the garbage storage mechanism 3 of each garbage collection device, and the dispensing channel 41 of each of the garbage dispensing mechanisms 4 is set outside the building, and the broken bag The quantity of mechanism 7 is identical with the quantity of garbage throwing mechanism 4, and three breaking bag mechanisms 7 are respectively arranged in corresponding garbage throwing mechanism 4 lower ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com