Classification and bin separation type garbage automatic collection system

A technology of automatic collection and garbage collection, applied in garbage collection, trash can, garbage cleaning, etc., can solve the problems of unpleasant odor, imperfect design, high cost, reduce explosion risk, avoid secondary pollution, improve The effect of suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

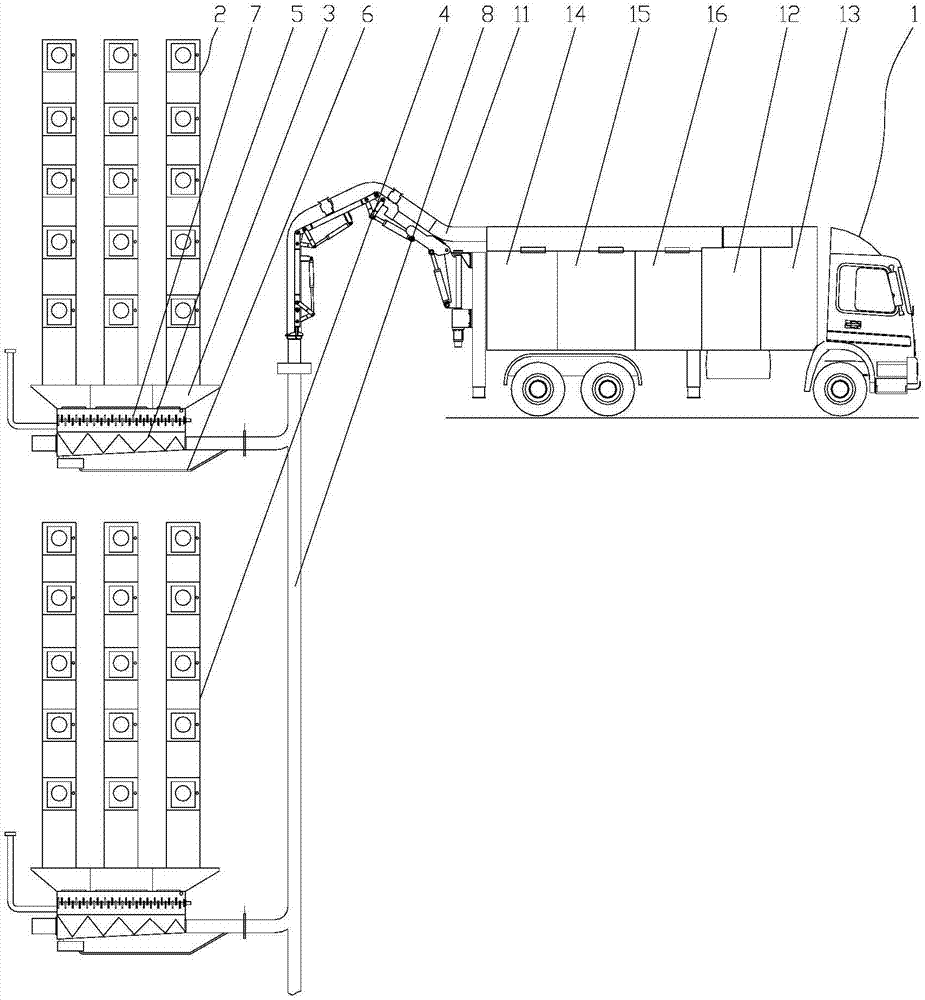

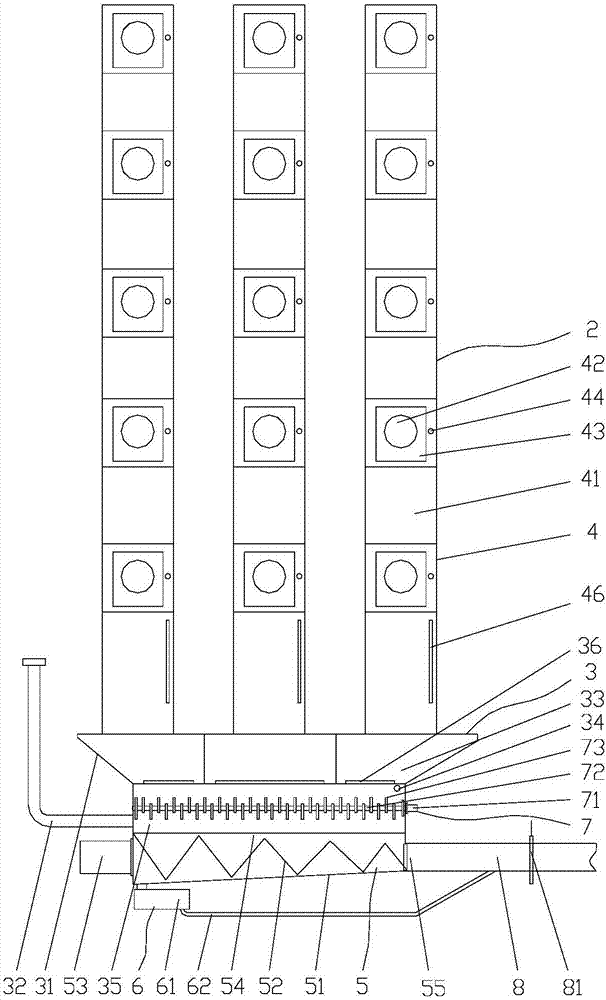

[0029] Such as figure 1 or figure 2 As shown, the automatic collection system for classified and binned garbage of the present invention includes a control center (not shown in the figure), an aerodynamic suction vehicle 1 and more than two garbage collection devices 2, and between the two or more garbage collection devices The control center communicates with the aerodynamic suction vehicle 1 and the garbage collection device 2 respectively through the suction pipeline, and is used to control the aerodynamic suction vehicle 1 and the garbage collection device 2 to perform operations. The garbage collection device 2 includes A garbage storage mechanism 3, three garbage delivery mechanisms 4 and a laid suction pipe network 8, the three garbage delivery mechanisms 4 are all located above the garbage storage mechanism 3, and the three garbage delivery mechanisms 4 are respectively used for putting in and transporting For recyclable garbage, non-recyclable garbage and other garb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com