Environment-friendly classification and different-cabin type automatic garbage collection system

An automatic collection and garbage collection technology, which is applied in garbage collection, garbage cans, garbage containers, etc., can solve the problems of unsorted garbage, unpleasant odor, and system jamming, so as to reduce the quantity and number of transfers, reduce the Effect of noise pollution and elimination of working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

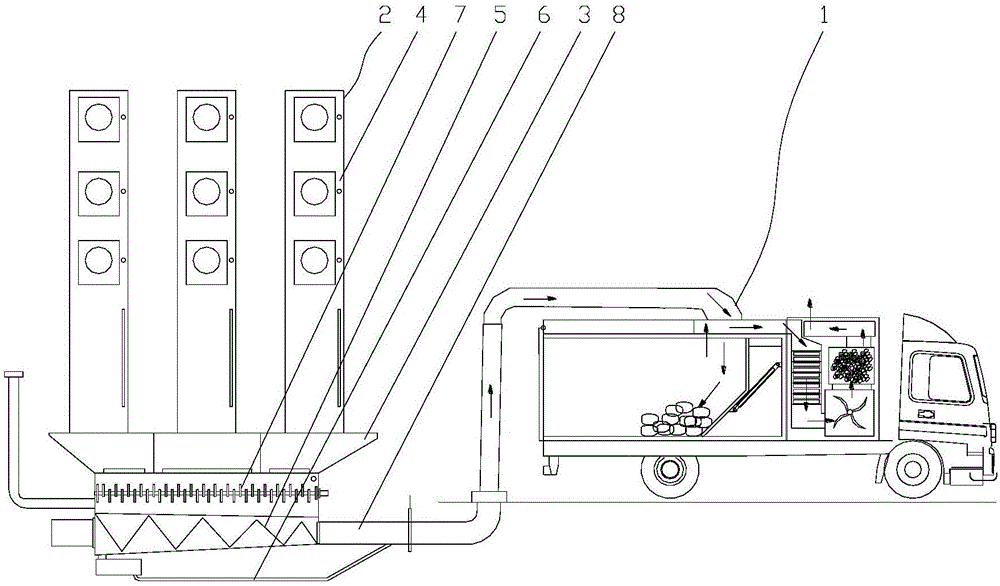

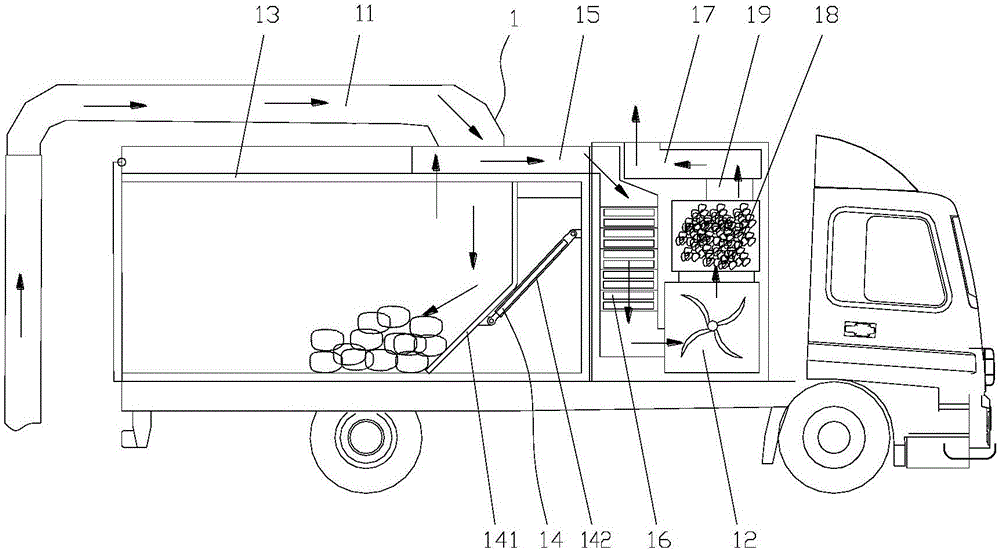

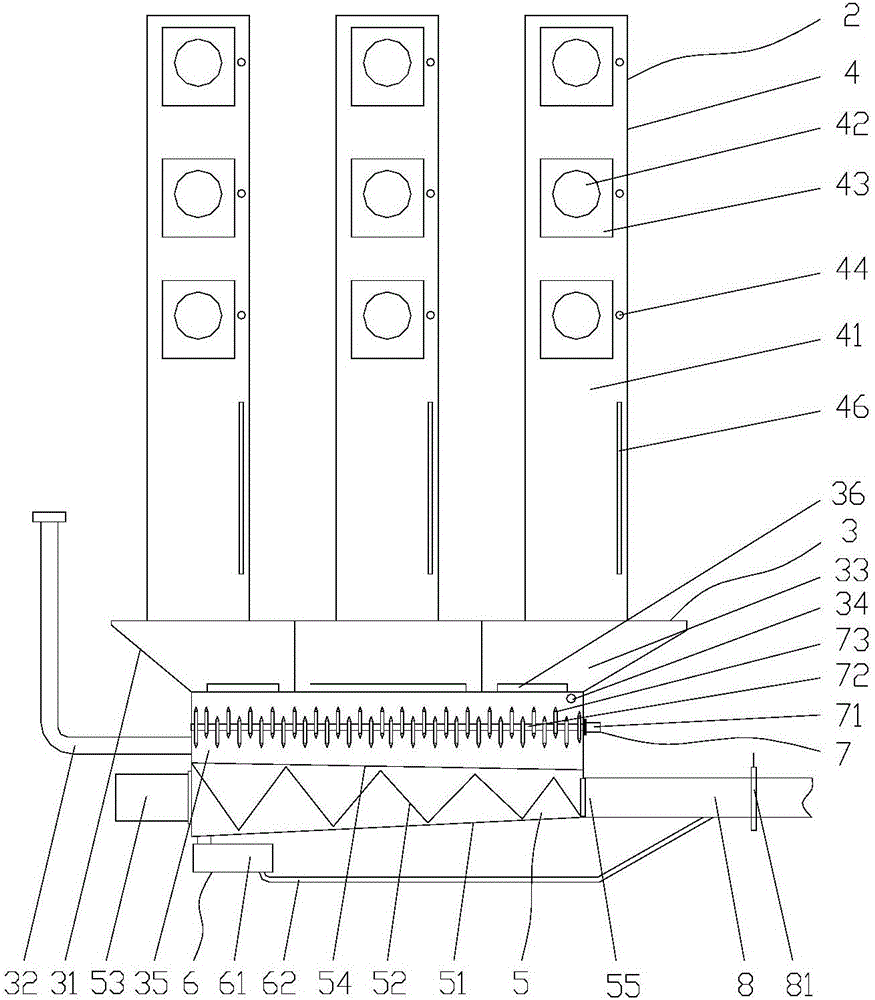

[0039] like Figure 1-3 As shown in one of the present invention, the environment-friendly classification and bin-type garbage automatic collection system of the present invention includes a control center (not shown in the figure), a suction type garbage collection vehicle 1 and a garbage collection device 2, and the control center is connected with the garbage collection device 2 respectively. The suction type garbage collection vehicle 1 and the garbage collection device 2 are connected in communication, and are used to control the suction type garbage collection vehicle 1 and the garbage collection device 2 to perform operations; the garbage collection device 2 includes a garbage storage mechanism 3 and three garbage delivery devices Mechanism 4, the three garbage dispensing mechanisms 4 are located above the garbage storage mechanism 3, and the three garbage dispensing mechanisms 4 are respectively used to put and transport recyclable garbage, non-recyclable garbage and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com