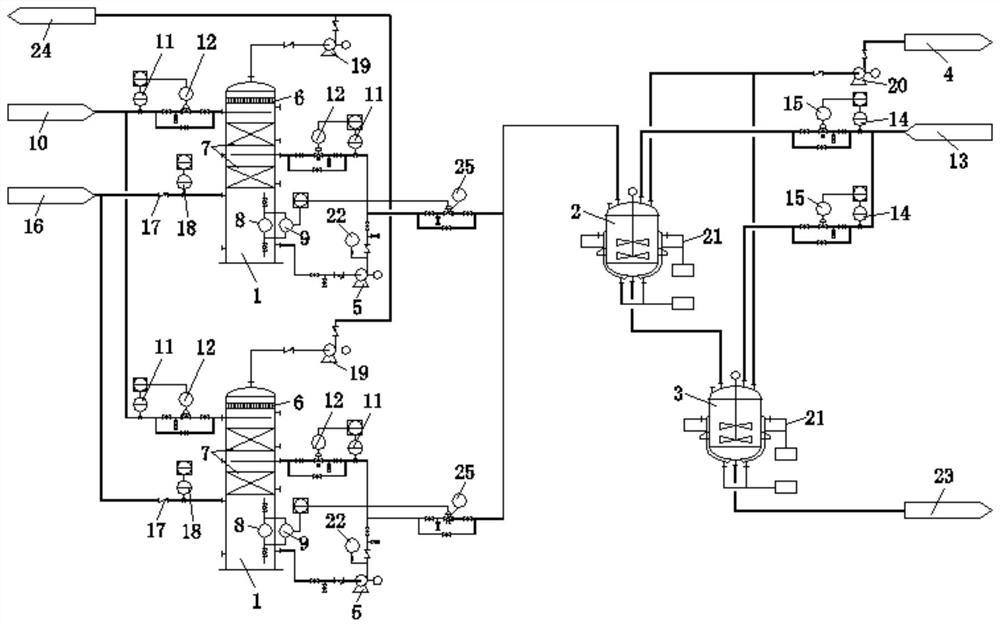

Low-concentration waste gas degassing conversion and high-concentration waste gas incineration recovery system and process

A recovery system and high-concentration technology, applied in incinerators, combustion methods, gas treatment, etc., can solve the problems of lye waste, increase the difficulty of sewage treatment, and failure to recycle, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] On the basis of the above-mentioned structure, in this embodiment, the interior of the spray tower 1 is fixedly installed with spray devices 6 and a plurality of packing layers 7 at intervals from top to bottom, the lye inlet communicates with the spray devices 6, and a plurality of The packing layer 7 is located above the exhaust gas inlet, and the bottom of the spray tower 1 is connected to the top of the first section of the reactor 2 through a pipeline; the circulating pump 5 is connected to the part above any packing layer 7 on the spray tower 1 through a return pipe . During the alkali cleaning process, the waste gas containing hydrogen sulfide enters the spray tower 1 from the waste gas inlet at the lower part of the spray tower 1, and continues to rise; at the same time, the waste lye enters the spray device from the lye inlet at the top of the spray tower 1, Spray through the spraying device 6; the waste gas containing hydrogen sulfide contacts and reacts with ...

Embodiment 2

[0043] On the basis of Embodiment 1, in this embodiment, the lower part of the spray tower 1 is fixed with an on-site liquid level gauge 8 by bolts, and the on-site liquid level gauge 8 is located below a plurality of packing layers 7; A remote liquid level gauge 9 is also fixedly installed by bolts, and the remote liquid level gauge 9 is connected with the on-site liquid level gauge 8 . Monitor the liquid level inside the spray tower 1 in real time through the on-site liquid level gauge 8 to avoid excessive liquid level; at the same time, the remote liquid level gauge 9 and the on-site liquid level gauge 8 maintain the same liquid level, that is, the remote liquid level gauge 9 The liquid level is the liquid level in the spray tower 1, and the corresponding liquid level signal is sent to the controller, so that the on-site workers can know the liquid level inside the spray tower 1 in time.

Embodiment 3

[0045] On the basis of the above-mentioned structure, in the present embodiment, the lye inlet is communicated with the lye equipment 10 through the lye pipeline, and the lye equipment can be a box housing the lye, and a delivery pump is installed in the box, and the delivery pump Send the spent lye to the spray tower 1; the lye pipeline, the return pipe, and the pipeline between each circulation pump 5 and the first section of the reactor 2 are respectively connected with maintenance pipes at the parts close to the corresponding spray tower 1 Road one, the inlet and outlet of each=maintenance pipe one are respectively connected on the corresponding pipeline; on each maintenance pipeline one and on the lye pipeline, on the return pipe and the pipe between the circulating pump 5 and one section of the reactor 2 Valves 1 are respectively installed on the positions between the inlet and the outlet of corresponding maintenance pipeline 1 on the road. The maintenance pipeline is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com