Tank bottom head automatic welding device and control method thereof

An automatic welding and head sealing technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of short welding strength processing cycle, insufficient welding torch pressure, uneven welding speed, etc., to achieve a good working environment and avoid The effect of repeated welding and maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

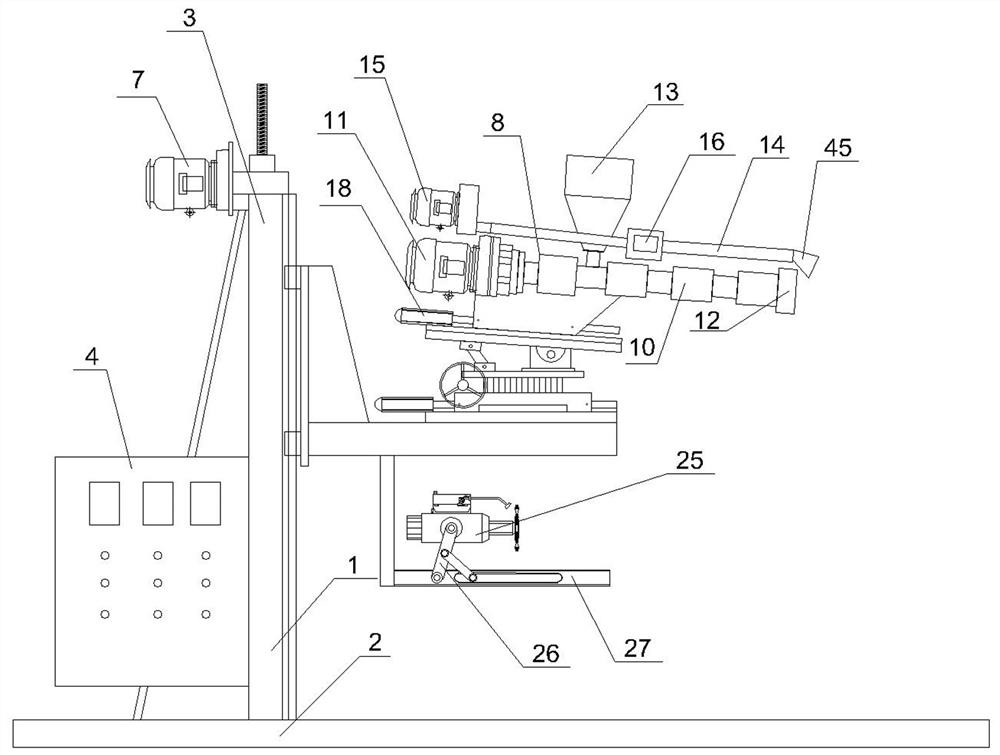

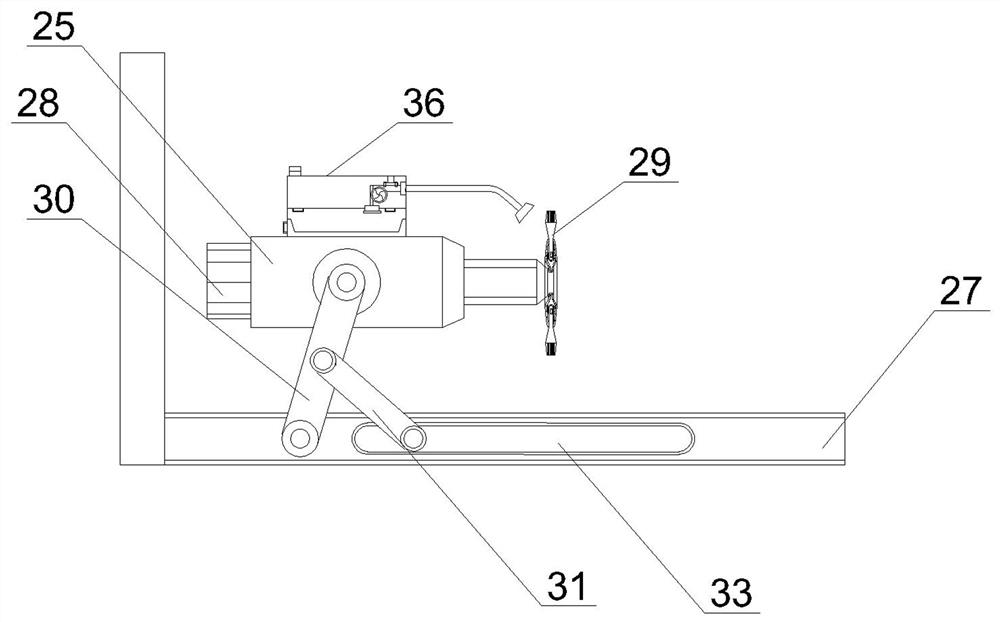

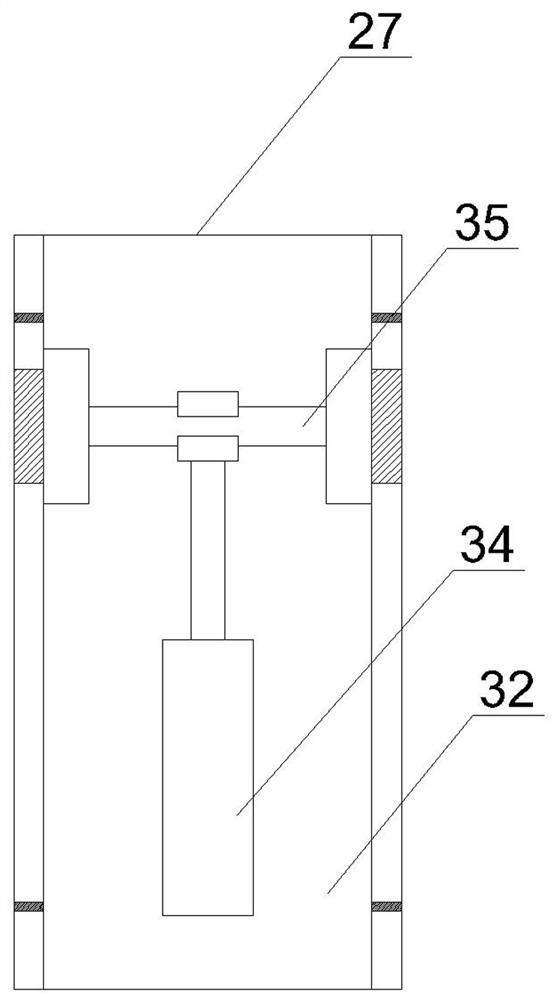

[0047] Embodiment: According to the attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 For further explanation, a kind of tank bottom head automatic welding equipment in this example includes a supporting main support 1, the main support 1 includes a base 2, and the base 2 is provided with a slide perpendicular to the base 2 Rod 3, control cabinet 4 is provided on the left side of described slide bar 3, and described slide bar 3 is slidably connected with welding bracket 5, and described welding bracket 5 is provided with welding device, and described welding bracket A welding slag cleaner is provided below the frame 5, a plastic tank 6 is provided on the right side of the welding device, and a driving motor 7 for adjusting up and down is provided on the top of the slide bar 3. The control end of the welding device, the welding slag cleaning device The control end of the controller and the control end of the up and down adjustment drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com