Industrial waste gas treatment device with monitoring function

A technology for industrial waste gas and treatment devices, which is applied in gas treatment, mixers with rotating stirring devices, combined devices, etc., can solve the problems of lack of waste gas treatment effect adjustment function, lack of gas composition monitoring function, and reduce system volume, etc., to achieve Improve the effect of waste gas treatment, increase the area and probability, and ensure the effect of treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0050] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

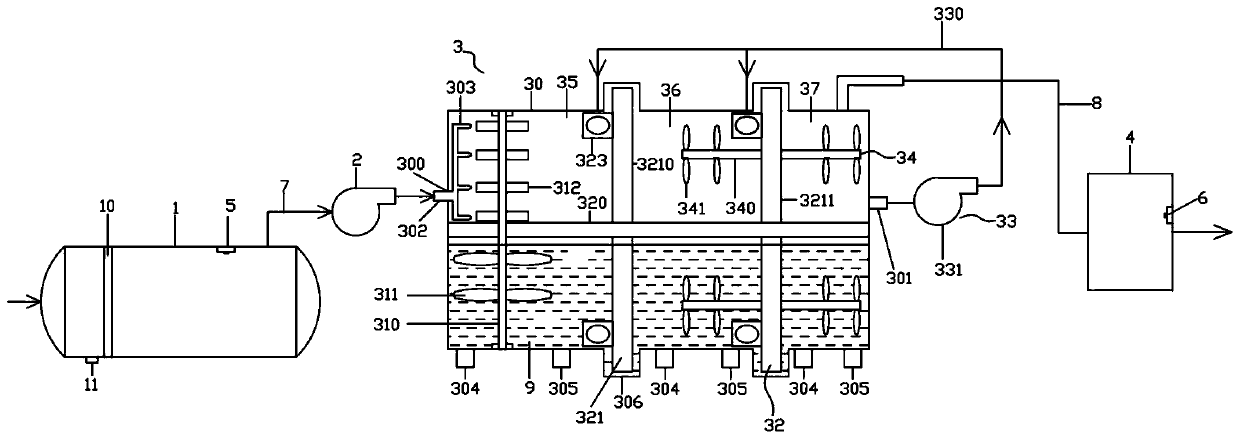

[0051] Such as figure 1 As shown, an industrial waste gas treatment device with a monitoring function in this embodiment includes a buffer tank 1, an air intake fan 2, a waste gas treatment tank 3, a filter device 4, and a first gas set arranged in sequence along the airflow direction. The monitoring device 5 and the second gas monitoring device 6 arranged at the gas outlet end of the filter device 4 .

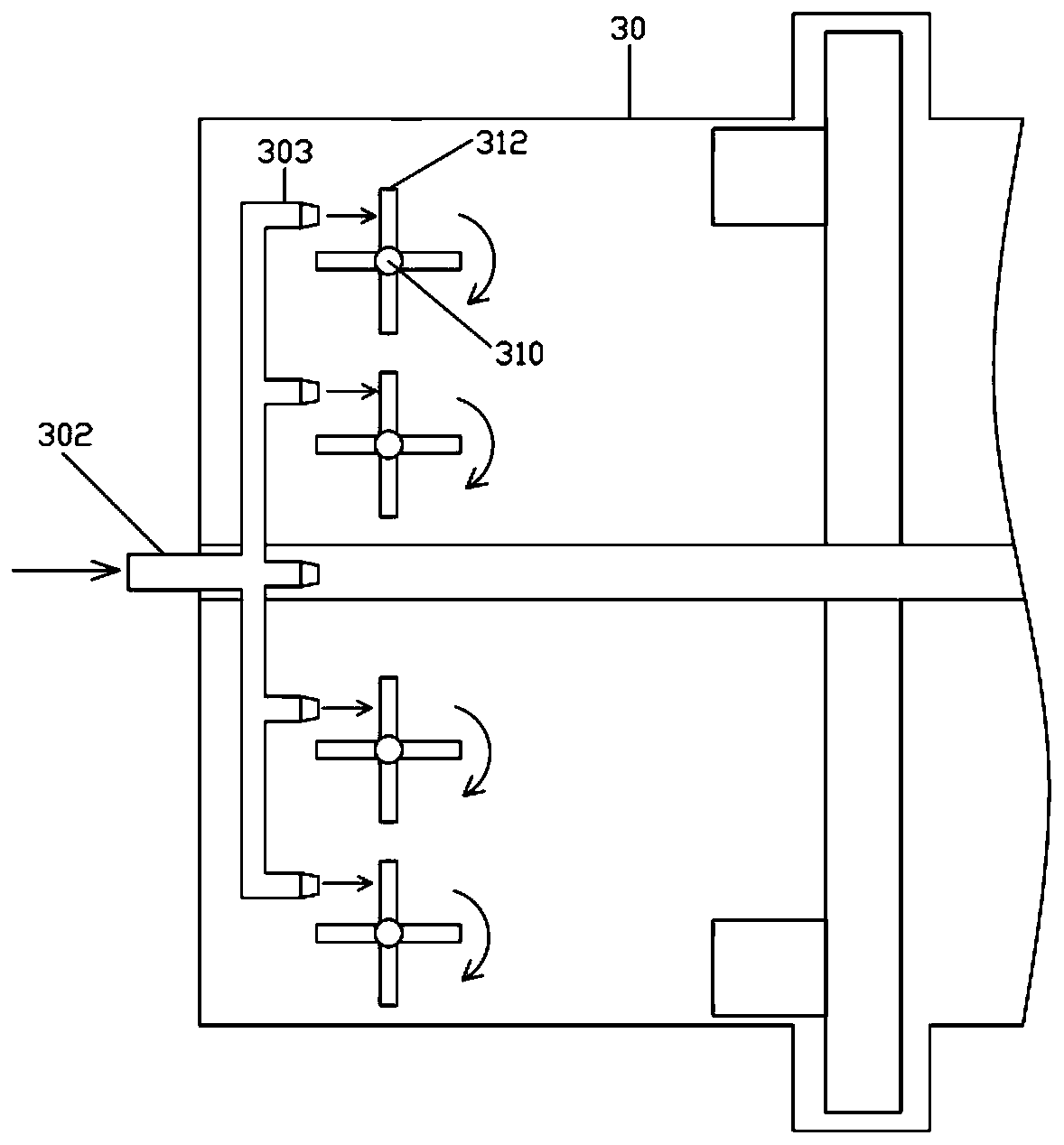

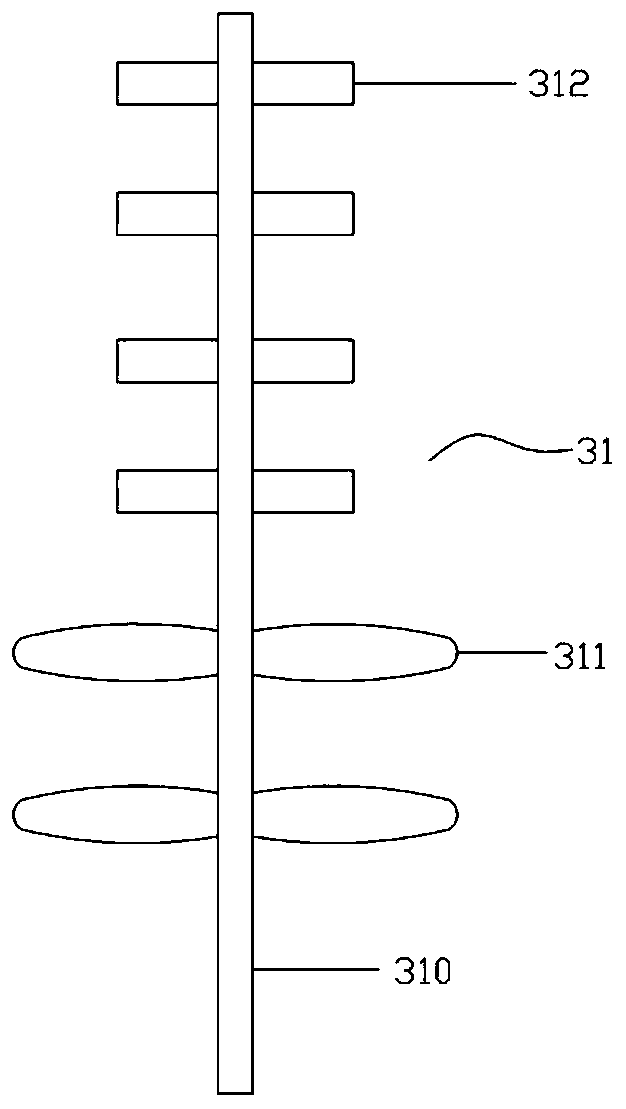

[0052] The exhaust gas treatment tank 3 includes a cylindrical treatment tank body 30, a main stirring device 31 disposed inside the treatment tank body 30 along the vertical direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com