Outburst coal seam 'five-fixation' gas treatment method based on directional drilling machine

A technology for directional drilling rigs and outburst coal seams, which is applied in directional drilling, gas discharge, earth-moving drilling, etc., can solve problems such as inaccurate determination of coal seam gas content, inaccurate coal seam gas content testing, and inability to truly reflect gas conditions, and reduce The effect of preparation time, reliable judgment, and effective governance measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

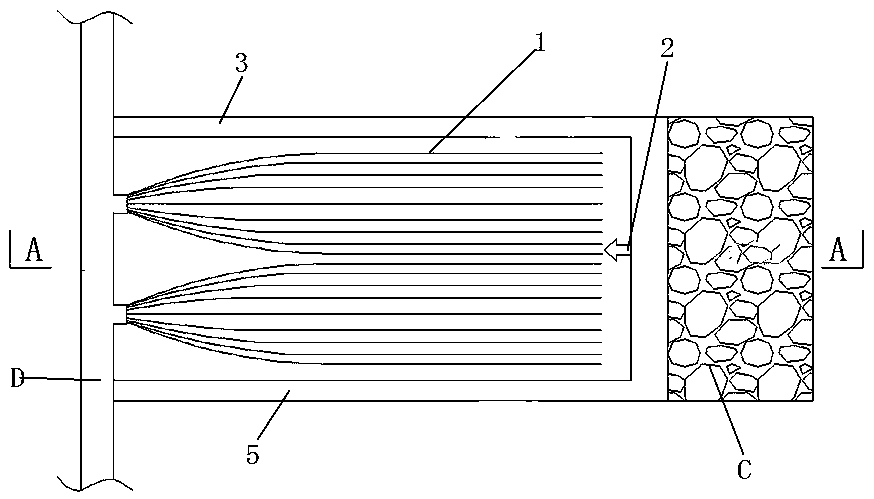

[0040] as attached Figures 1 to 7 As shown, a specific embodiment 1 of a "five fixed" gas control method for outburst coal seams based on directional drilling rigs includes the following steps:

[0041] The first step is to collect and sort out geological exploration drilling data in the target area, divide different drainage geological units and evaluate the feasibility of adopting the "five determinations" gas control method for each drainage geological unit;

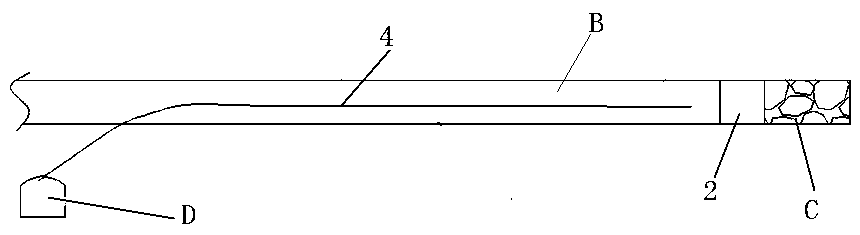

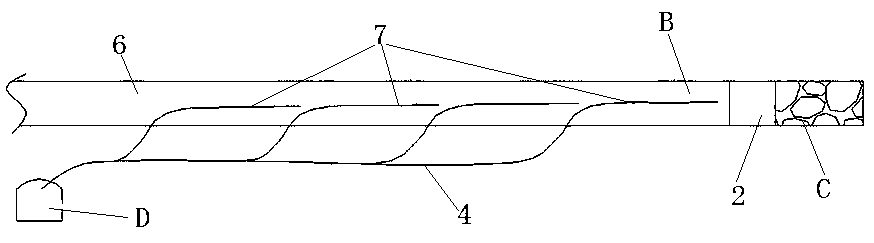

[0042] In the second step, directional drilling is carried out on the drainage geological units that have the feasibility of the "five fixed" gas control methods in the first step. For soft coal seams with a coal seam firmness coefficient f<0.5, select the main hole 4 for directional drilling Arranged in the rock formation on the top or floor of the coal seam, construct the branch hole 6 from the main hole 4 to the coal seam B; for the hard coal seam with a coal seam firmness coefficient f≥0.5, directly arrange the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com