Erosion-resistant pressure experimental device for inner blowout prevention tool

An experimental device and erosion-resistant technology, used in measuring devices, testing wear resistance, instruments, etc., can solve the problem of not meeting the erosion test conditions of internal blowout tools, and achieve a high degree of automation, easy control, and test performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

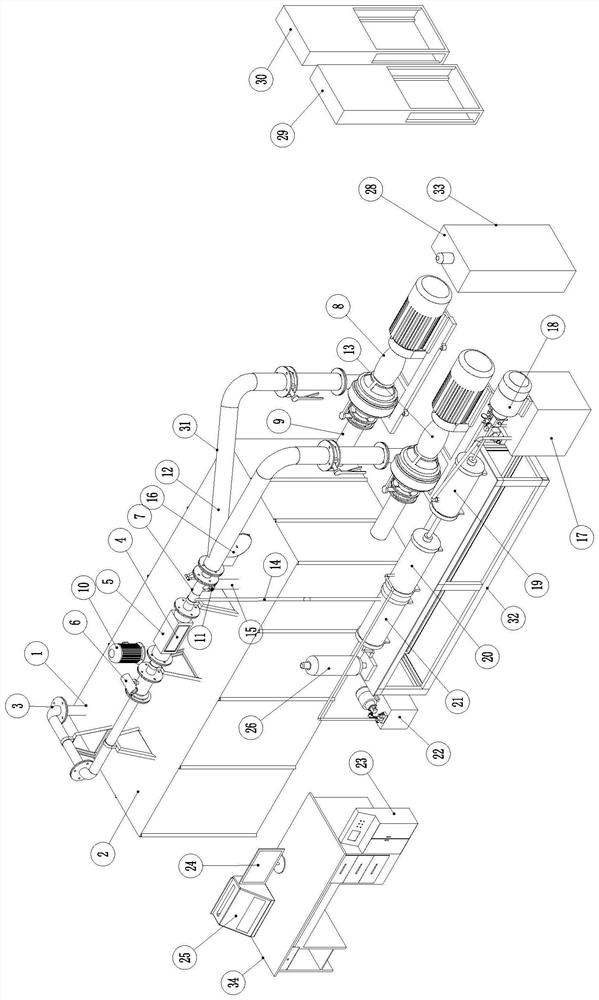

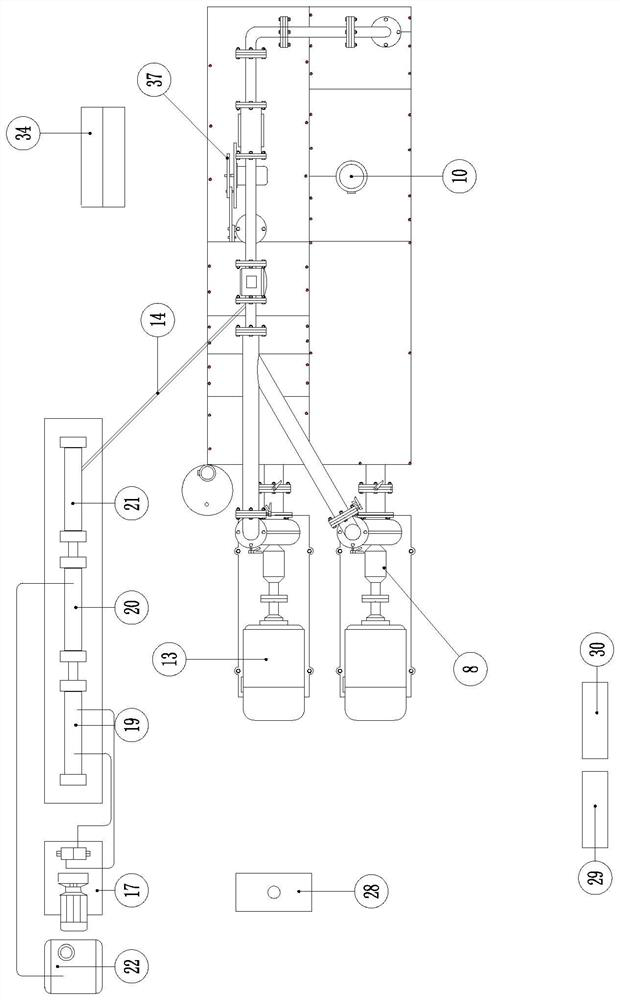

[0015] Specific implementation mode 1: The present invention is designed with an original composite erosion test device, which is composed of a simulated pipe flow erosion test system and a pressure jet test erosion system, and integrates the two into a system to simulate erosion. The simulation effect of the working conditions of the erosion and wear test is real. By setting the flow rate, flow rate, pressure, temperature, and switch times of the internal blowout prevention tool in the pipeline, the test environment can be changed to conduct erosion tests under various setting conditions.

[0016] refer to Figure 1 to Figure 7 Describe this embodiment. This embodiment provides an erosion resistance pressure test device for internal blowout prevention tools, including a simulated pipe flow erosion test system loop 31, a simulated pressure jet erosion test system loop 32, and an electrical assembly control cabinet 33. and an automated experiment data monitoring sampling record...

specific Embodiment approach 2

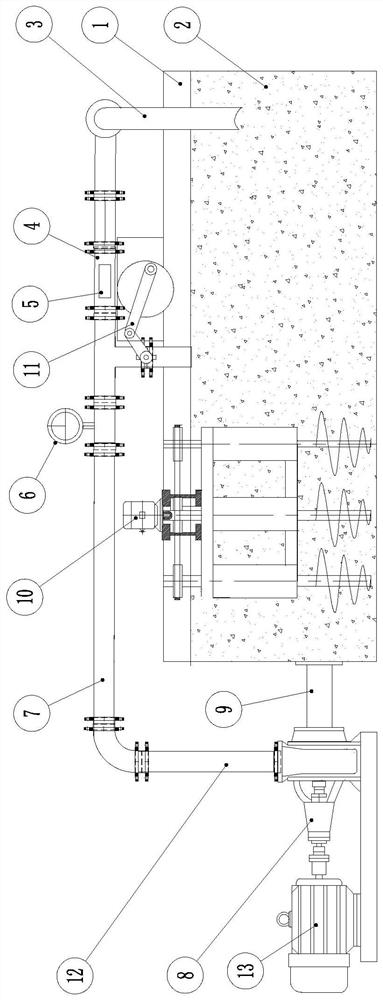

[0017] Specific implementation mode two: refer to Figure 1 to Figure 3 Describe this embodiment, this embodiment is to further limit the simulated pipe flow erosion test system circuit 31 described in the first specific embodiment, in this embodiment, the simulated pipe flow erosion test system circuit 31 includes a mud pump 13. Test pipeline 7, mud box 2, exhaust device 3, visible experiment cabin 4 and test valve core 5; the visible experiment cabin 4 is installed on the test pipeline 7, and the slurry outlet of the test pipeline 7 It is communicated with the inner cavity of the mud box body 2, and the slurry inlet 12 of the test pipeline 7 is communicated with the outlet of the mud pump one 13, and the inlet of the mud pump one 13 is connected with the slurry outlet one of the mud box body 2, and the test The valve core 5 is installed in the visual experiment cabin 4 and communicated with the test pipeline 7 on which the exhaust device 3 is arranged. Other compositions an...

specific Embodiment approach 3

[0019] Embodiment 3: Through the mud flow control device 11 in this device, the opening and closing of the internal blowout prevention tool in the erosion state is realized, and the dynamic erosion test of the internal blowout prevention tool during the working process is realized.

[0020] refer to Figure 1 to Figure 6 Describe this embodiment, this embodiment is to further limit the circuit 31 of the simulated pipe flow erosion test system described in the second specific embodiment, in this embodiment, the circuit 31 of the simulated pipe flow erosion test system also includes a mud flow control device 11 and a discharge pipe 15; a discharge pipe 15 is communicated between the test pipeline 7 and the mud box 2, and a mud flow control device 11 is arranged on the discharge pipe 15 for controlling the flow in the test pipeline 7. Other compositions and connection methods are the same as those in the second embodiment.

[0021] In this embodiment, the discharge pipe 15 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com