An adaptive motor heat dissipation system and an adaptive motor heat dissipation method

A motor heat dissipation and self-adaptive technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of no monitoring and feedback adjustment system, and achieve the effects of simple structure, improved efficiency, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation plan

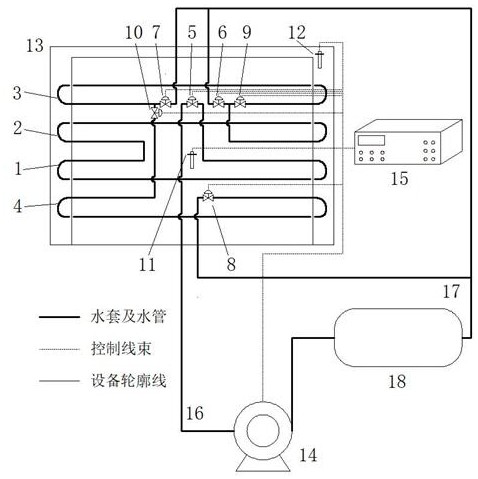

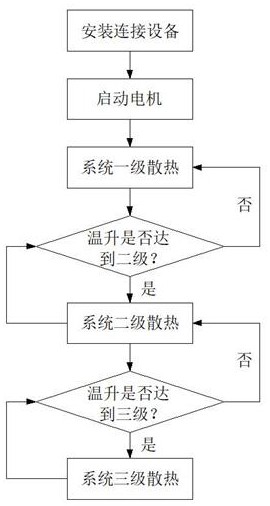

[0033] The present invention will be further described below in combination with schematic diagrams.

[0034] Such as Figure 1-6 As shown, the self-adaptive motor heat dissipation system of the present invention includes a first-level waterway 1, a second-level waterway 2, a third-level waterway 3, a fourth-level waterway 4, a water inlet solenoid valve 5, a first-level water outlet solenoid valve 6, and a second-level water outlet. Water outlet solenoid valve 7, third-stage water outlet solenoid valve 8, second-stage interlayer connection solenoid valve 9, third-stage interlayer connection solenoid valve 10, Pt100 embedded winding temperature sensor 11, surface-mounted casing temperature sensor 12, machine Shell 13, water inlet pump 14, cooling system controller 15, water inlet pipe 16, water outlet pipe assembly 17 at all levels, cooling water tank 18.

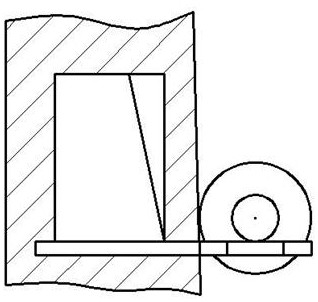

[0035] Such as Figures 3a-3d As shown, when the excitation coil is de-energized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com