Water-taking mechanism of sewage source heat pump system and sewage source heat pump system with same

A sewage source heat pump and heat exchange mechanism technology, which is applied to the configuration of water supply pipeline systems, heat pumps, and water supply tanks, can solve problems such as difficult cleaning, heavy workload, and high cleaning and maintenance costs, so as to ensure system flow and reduce sedimentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

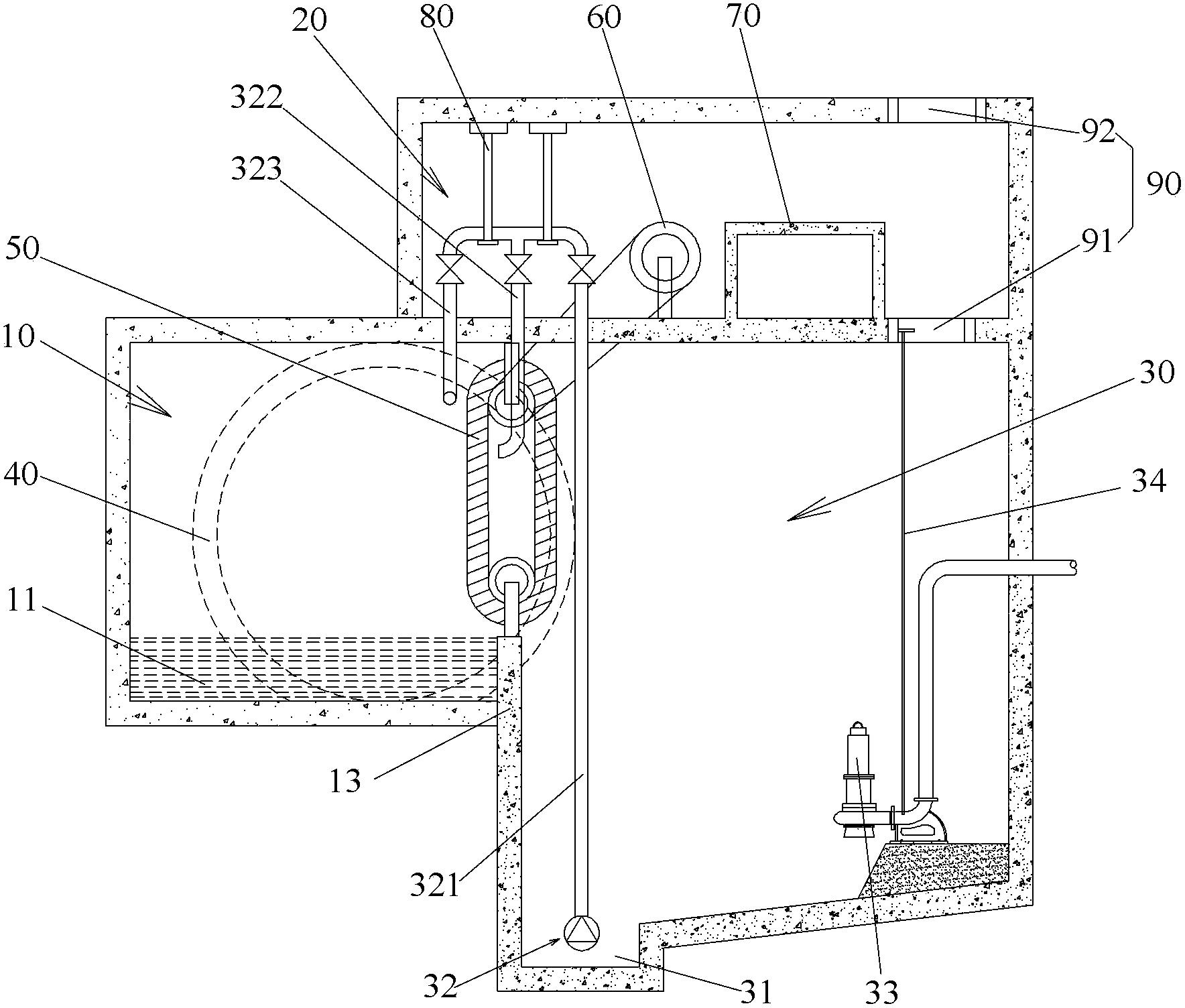

[0020] Such as figure 1 As shown, the present invention provides a water intake mechanism for a sewage source heat pump system, comprising a sewage intake pool 10, which communicates with the main sewage canal 40, and part of the sewage in the main sewage canal 40 is discharged into the sewage intake pool 10; The water intake pool 10 is connected, and there is a sewage passage between the buffer pool 30 and the sewage water intake pool 10. There is a submersible sewage pump 33 in the buffer pool 30, and the submersible sewage pump 33 is connected with the heat exchange mechanism of the sewage source heat pump.

[0021] The water intake mechanism of the sewage source heat pump system includes a sewage intake pool 10 and a buffer pool 30 connected to each other, and the sewage is introduced from the main sewage channel 40 . In this embodiment, a sewage inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com