Treatment method of organic industrial wastewater

A technology of industrial wastewater and treatment methods, applied in water/sewage treatment, water treatment parameter control, water/sludge/sewage treatment, etc., can solve problems such as increasing treatment costs, affecting use effects, increasing workload, etc. Achieve the effect of reducing treatment cost, improving treatment effect and solving iron-carbon hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

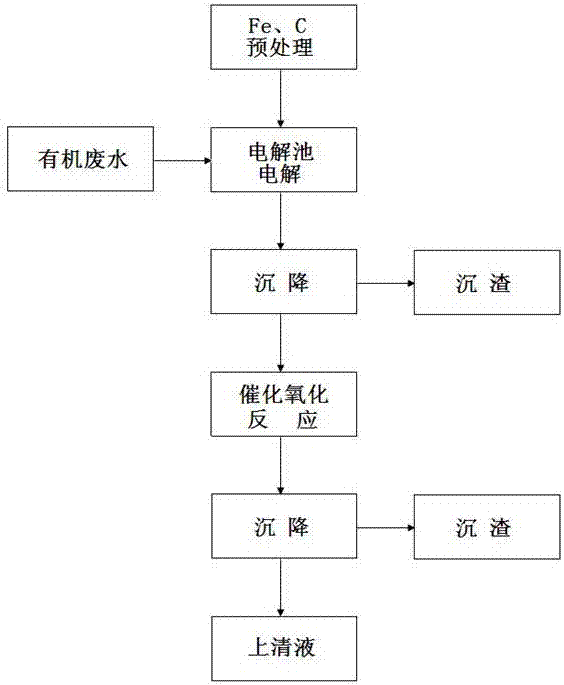

Method used

Image

Examples

Embodiment 1

[0068] The sample was taken from a chemical company's nitric chloride wastewater. The measured COD value was 15000mg / L, BOD value was 458mg / L, pH value was 0.5, chromaticity was 12000, and SS was 2500mg / L.

[0069] A. Pretreatment: Soak cast iron scraps in 10% NaOH solution for 10 minutes to degrease and clean them, then soak them in 3% HCl solution for 30 minutes to remove the surface wax film and wash them for later use; soak activated carbon for 2 hours for later use;

[0070] B. Electrolysis: add a composite electrolyte containing 40% of the volume of wastewater in the electrolysis tower containing wastewater. The composite electrolyte is a combination of pretreated cast iron filings and activated carbon at a volume ratio of 1:1; supplemented by compressed air aeration React for 40 minutes, measure the pH value as 4.5, add 1‰H 2 o 2 Continue to react for 25 minutes, measure the pH value as 6, stop the reaction, put the waste water into the intermediate pool and add the se...

Embodiment 2

[0073] The sample was taken from the sulfadiazine wastewater of a pharmaceutical company. The measured COD value was 12000mg / L, BOD value was 340mg / L, pH value was 7, chromaticity was 2000, and SS was 1500mg / L.

[0074] A. Pretreatment: Soak cast iron chips in 8% NaOH solution for 8 minutes to degrease and clean them, then soak them in 2% HCl solution for 25 minutes to remove the surface waxy film and wash them for later use; soak activated carbon for 1 hour for later use;

[0075] B. Electrolysis: add a composite electrolyte containing 25% of the volume of wastewater in the electrolysis tower containing wastewater. The composite electrolyte is a combination of pretreated cast iron filings and activated carbon at a volume ratio of 0.5:1.5; supplemented by compressed air aeration React for 30 minutes, measure the pH value as 4, add 0.5‰H 2 o 2 Continue to react for 20 minutes, measure the pH value to be 6.5, stop the reaction, put the waste water into the intermediate pool and...

Embodiment 3

[0078] The sample was taken from nitrobenzene wastewater from a chemical company. The measured COD value was 9500mg / L, BOD value was 310mg / L, pH value was 6, chromaticity was 11000, and SS was 2100mg / L.

[0079] A. Pretreatment: Soak cast iron chips in 12% NaOH solution for 12 minutes to degrease and clean them, then soak them in 4% HCl solution for 35 minutes to remove the surface waxy film and wash them for later use; soak activated carbon for 3 hours for later use;

[0080] B. Electrolysis: Add a composite electrolyte containing 50% of the volume of wastewater in the electrolysis tower containing wastewater. The composite electrolyte is a combination of pretreated cast iron filings and activated carbon at a volume ratio of 0.8:1.2; supplemented by compressed air aeration React for 50 minutes, measure the pH value as 5, add 1.5‰H 2 o 2 Continue to react for 30 minutes, measure the pH value to 5.5, stop the reaction, put the waste water into the middle pool and add the sedim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com