Method for treating highly-difficult-to-treat industrial wastewater through catalytic oxidation and micro-electrolysis

A technology for catalytic oxidation and industrial wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of increasing treatment costs, reducing treatment effects, and increasing workload in post-treatment processes, etc. , to achieve the effect of solving iron-carbon compaction, improving treatment effect, reducing sludge dewatering workload and treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

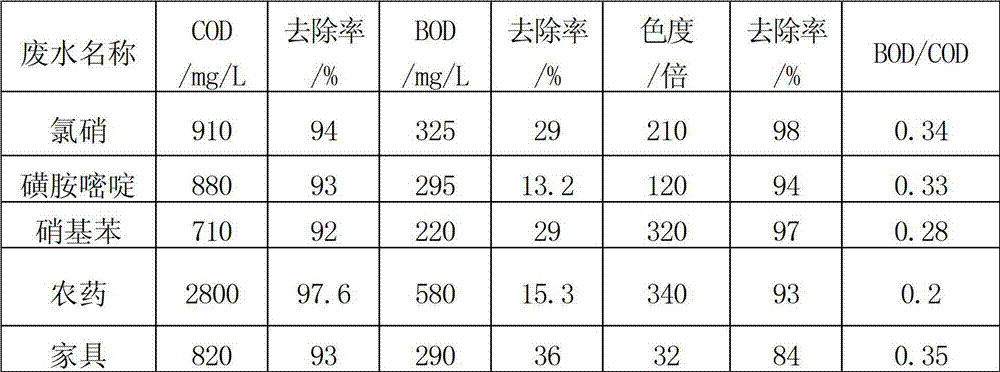

[0045] Utilize the method of the present invention to process the waste water that produces 5 kinds of different products, and initial index is shown in Table 1.

[0046] Table 1 Wastewater quality before treatment

[0047] wastewater name

COD / mg / L

BOD / mg / L

pH

Chroma / fold

SS / mg / L

15000

458

0.5

12000

2500

12000

340

7

2000

1500

9500

310

6

11000

2100

120000

685

6.5

5000

2050

furniture

11000

450

6.2

200

3000

[0048] Approach:

[0049] 1), iron carbon pretreatment

[0050] Soak cast iron chips in 10% NaOH solution for 10 minutes to degrease and clean them, then soak them in 3% dilute hydrochloric acid for 30 minutes to remove the surface passivation film and clean them for later use. Soak the granular activated carbon in water for 2 hours for later use.

[0051] 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com