Low-temperature single-component zinc series phosphating solution and preparation method thereof

A zinc-based phosphating solution, a single-component technology, applied in the coating process of metal materials, etc., can solve the problems of poor corrosion resistance, rust return, flooding, etc., and achieve excellent corrosion resistance, stable bath solution, and film formation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

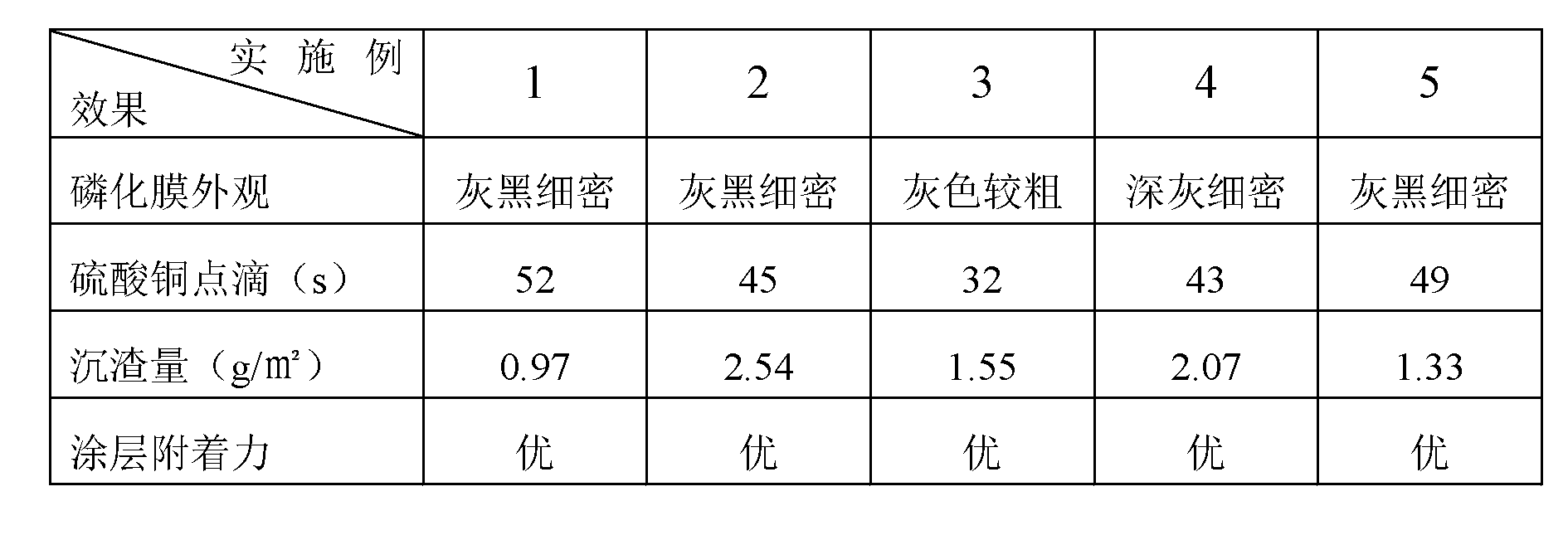

Examples

Embodiment 1

[0025] Low-temperature single-component zinc phosphating solution 1, in which the components and their contents are: zinc oxide 8g / L, phosphoric acid 24.7g / L, nitric acid 3.7g / L, nickel nitrate 0.3g / L, m-nitrobenzene sulfonate Sodium acid 0.8g / L, sodium chlorate 1.9g / L, hydroxylamine sulfate 1.2g / L, citric acid 1.3g / L, the balance is water.

Embodiment 2

[0027] Low-temperature single-component zinc-based phosphating solution 2, in which the components and their contents are: zinc oxide 5g / L, phosphoric acid 30g / L, nitric acid 3g / L, nickel nitrate 0.3g / L, sodium m-nitrobenzene sulfonate 1.5g / L, sodium chlorate 2.5g / L, hydroxylamine sulfate 2.5g / L, citric acid 1g / L, the balance is water.

Embodiment 3

[0029] Low-temperature single-component zinc phosphating solution 3, the components and their contents are: zinc oxide 9g / L, phosphoric acid 12.5g / L, nitric acid 6.2g / L, nickel nitrate 1g / L, m-nitrobenzene sulfonic acid Sodium 0.5g / L, sodium chlorate 1.5g / L, hydroxylamine sulfate 1g / L, citric acid 2g / L, the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com