Soil conditioner for passivation of heavy metals and preparation method of soil conditioner

A soil conditioner and heavy metal technology, applied in soil conditioning materials, chemical instruments and methods, restoration of contaminated soil, etc., can solve the problems of affecting soil microorganisms and animal functions, destroying soil structure, high sodium ion content, etc., to achieve reserve Rich, widely distributed, the effect of eliminating waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Grind lignite from Shanxi, pass through a 10-mesh sieve, add to 0.1M NaOH solution and mix, the addition amount is 0.05g / mL; keep warm at 65°C and shake for 4 hours; put it at room temperature for 2 hours The upper humic acid extract is separated from the solid residue;

[0035] 2. Mix the solid residue with 0.1M NaOH solution, the addition amount is 0.05g / mL; keep warm at 65°C and shake for 4 hours; after standing at room temperature for 2 hours, separate the upper humic acid extract from the solid residue ;

[0036] 3. Repeat steps 2 and 3 times;

[0037] 4. Combine the humic acids obtained in steps 1, 2, and 3 together, and record the volume as V 腐殖酸 , add the calcium chloride solution that concentration is 1wt% successively, and the polyacrylamide (Tianjin Institute of Fine Chemical Industry) solution that concentration is 0.05wt%, leave standstill 1 hour to make humic acid flocculation and sedimentation after stirring; The supernatant (pH 11.1) was removed, and...

Embodiment 2

[0044] 1. Grind weathered coal from Xinjiang, pass through a 100-mesh sieve, add to 0.1M NaOH solution and mix, the addition amount is 0.1g / mL; keep warm at 40°C and ultrasonic for 1 hour; stand at room temperature for 4 hours, use The natural sedimentation method separates the upper humic acid extract from the solid residue;

[0045] 2. Mix the solid residue with 0.1M NaOH solution, the addition amount is 0.1g / mL; keep warm at 40°C and ultrasonic for 1 hour; let it stand at room temperature for 4 hours, and use the natural sedimentation method to mix the upper humic acid extract with the solid residue separation;

[0046] 3. Repeat steps 2 and 5 times;

[0047] 4. Combine the humic acids obtained in steps 1, 2, and 3 together, and record the volume as V 腐殖酸 , add the calcium chloride solution that concentration is 1wt% successively, and the polyacrylamide (Tianjin Institute of Fine Chemical Industry) solution that concentration is 0.05wt%, leave standstill 1 hour after stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

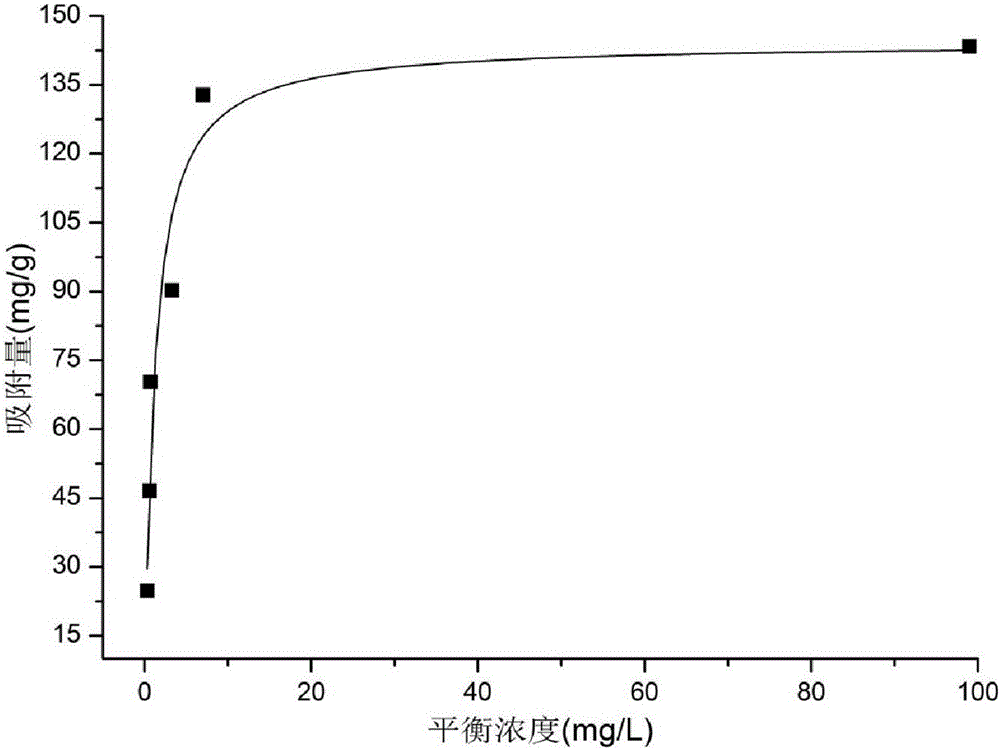

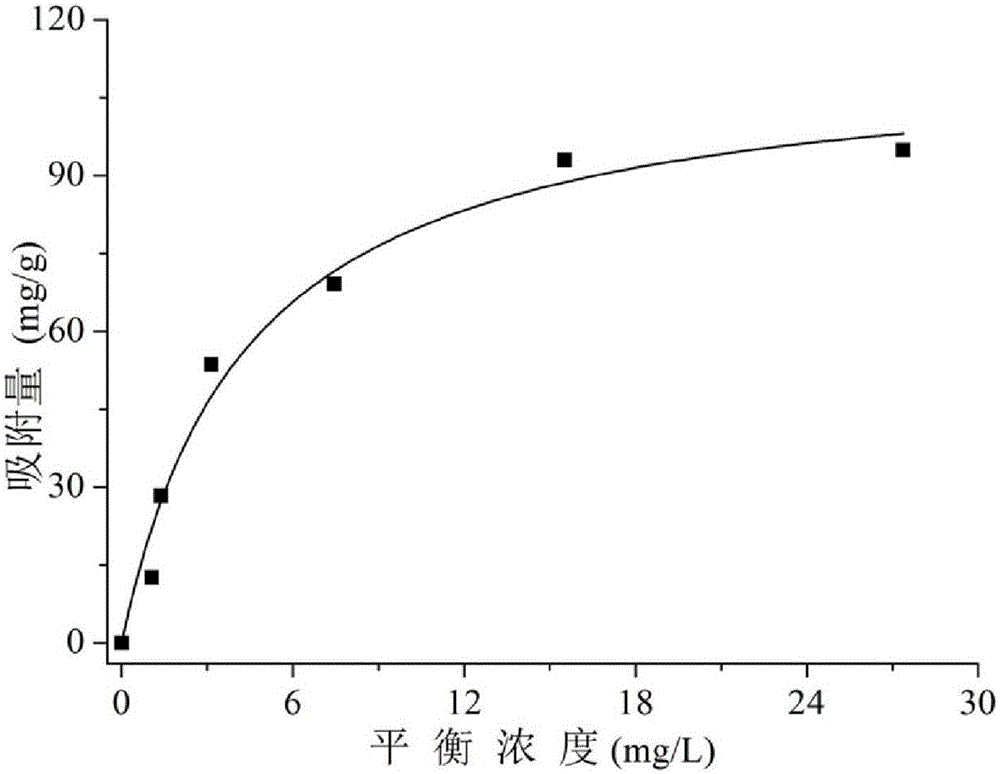

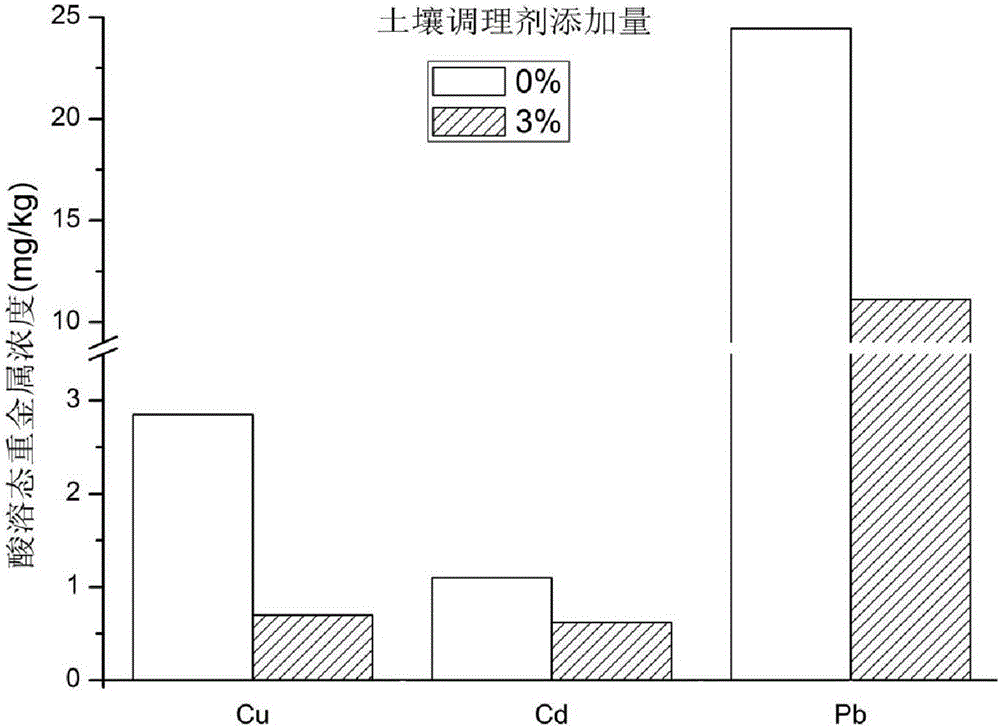

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com