Cationic polyacrylamide-modified Fe3O4 magnetic flocculant and preparation method thereof

A technology of polyacrylamide and magnetic flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, organic materials/organic magnetic materials, etc., and can solve the secondary pollution of magnetic flocculant application range, complex flocculation process, high cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Take 20 mg of cationic polyacrylamide with a weight average molecular weight of 3 million and an ion degree of 15, and add 100 g of it at a concentration of 0.1 mol L -1 , a phosphate buffer solution with a pH of 9.0, stirred at 100rpm for 60min to dissolve it completely; then add 100mg of magnetic nano-Fe to the reaction system 3 o 4 Particles, react at 20°C, 300rpm stirring speed for 5min;

[0050] (2) After absorbing the product with a permanent magnet, remove the supernatant, then add deionized water 800 times the weight of the product to wash for 5 times, then redisperse the washed product in deionized water, and ultrasonically treat it for 10 minutes to disperse it , forming a stable suspension to obtain cationic polyacrylamide-modified Fe 3 o 4 magnetic flocculant.

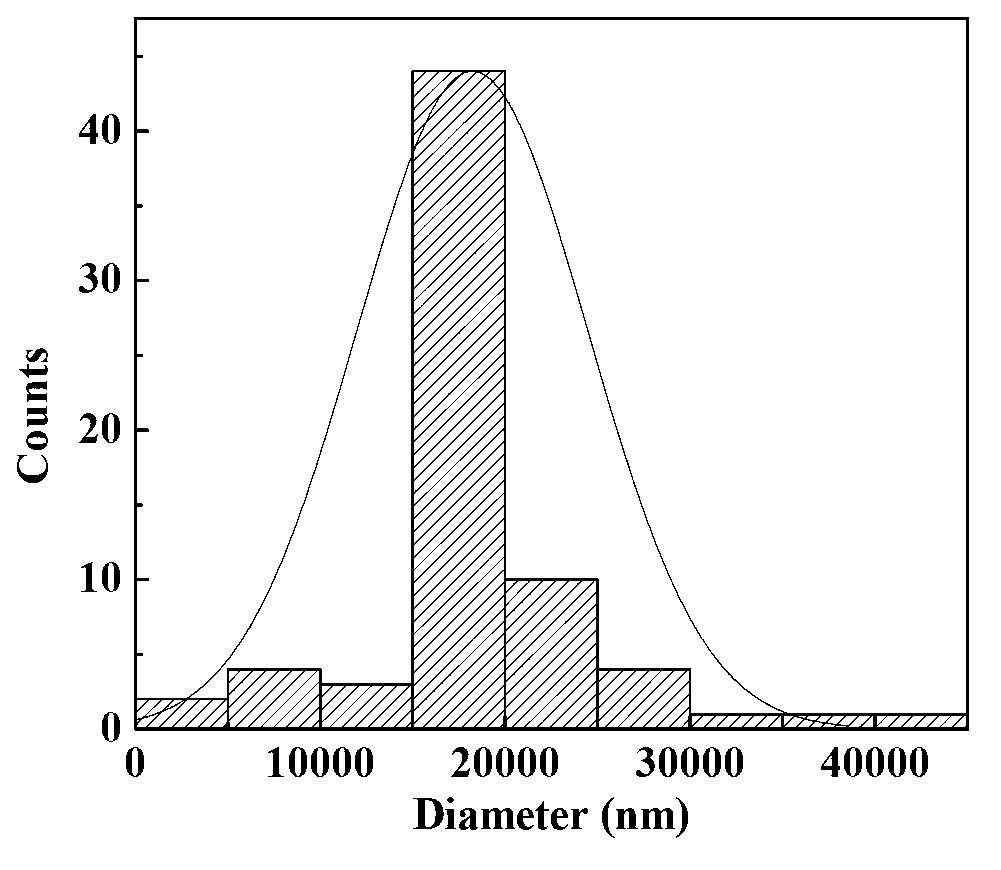

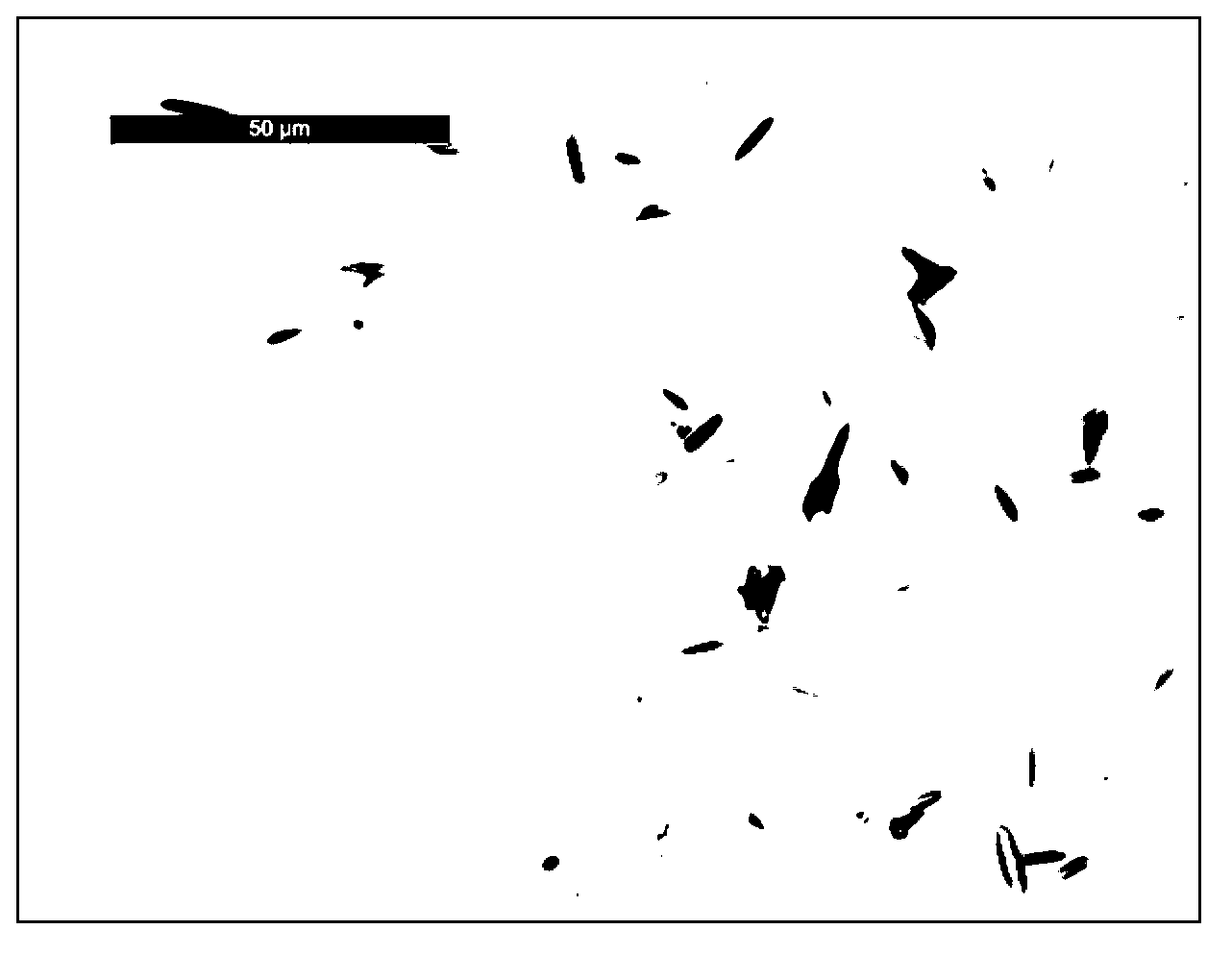

[0051] The average particle size of the obtained magnetic flocculant was 160 μm, the saturation magnetization was 68.4 emu / g, and the coercive force was 2.3 Oe.

[0052] Flocculation effect ...

Embodiment 2

[0055] (1) Take 60 mg of cationic polyacrylamide with a weight average molecular weight of 12 million and an ion degree of 30, add 100 g of it at a concentration of 0.15 mol L -1 , acetic acid buffer solution with a pH of 7.5, stirred at 200rpm for 80min to dissolve it completely; then add 100mg of magnetic nano-Fe to the reaction system 3 o 4 Particles were reacted at 28°C for 40 minutes at a stirring speed of 50 rpm;

[0056] (2) After absorbing the product with a permanent magnet, remove the supernatant, then add deionized water 900 times the weight of the product to wash for 3 times, redisperse the washed product in deionized water, and ultrasonically treat it for 5 minutes to disperse it. A stable suspension was formed to obtain cationic polyacrylamide-modified Fe 3 o 4 magnetic flocculant.

[0057] The average particle size of the obtained magnetic flocculant was 200 μm, the saturation magnetization was 71.0 emu / g, and the coercive force was 2.5 Oe.

[0058] Floccul...

Embodiment 3

[0061] (1) Take 10 mg of cationic polyacrylamide with a weight average molecular weight of 8 million and an ion degree of 40, and add 100 g of it at a concentration of 0.05 mol L -1 , a phosphate buffer solution with a pH of 7.0, stirred at 100rpm for 90min to dissolve it completely; then add 100mg of magnetic nano-Fe to the reaction system 3 o 4 Particles were reacted at 25°C for 10 minutes at a stirring speed of 150rpm;

[0062] (2) After absorbing the product with a permanent magnet, remove the supernatant, then add deionized water 1000 times the weight of the product to wash for 4 times, redisperse the washed product in deionized water, and ultrasonically treat it for 15 minutes to disperse it. A stable suspension was formed to obtain cationic polyacrylamide-modified Fe 3 o 4 magnetic flocculant.

[0063] The average particle size of the obtained magnetic flocculant was 120 μm, the saturation magnetization was 64.3 emu / g, and the coercive force was 2.1 Oe.

[0064] Fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com