Lignocellulose anaerobic methane-producing pretreatment and fermentation technology

A technology of lignocellulose and fermentation process, applied in the field of lignocellulose anaerobic fermentation, can solve problems such as difficult biodegradation, secondary pollution, etc., and achieve the effects of enhancing cellulase content, no secondary pollution, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

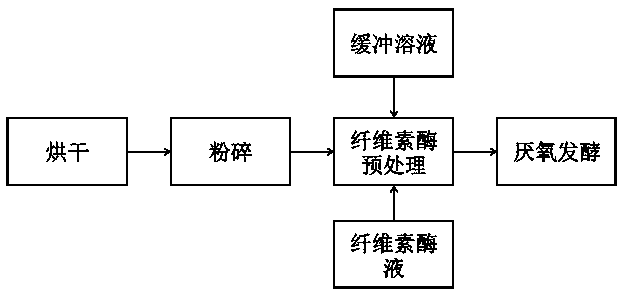

[0030] The embodiment adopts rice straw as the substrate of this process. For specific implementation process steps, see figure 1 .

[0031] 1) The collected rice straw has a high moisture content, and it is placed in a glass greenhouse for drying. After drying, the moisture content is about 6.5%;

[0032] 2) Use a screw extrusion crusher to crush the dried rice straw, sieve after crushing, sieve out the materials with a particle size larger than 1cm and then crush them again, and collect the materials with a particle size smaller than 1cm;

[0033] 3) Add cellulase to the broken rice straw, the amount of cellulase added is about 200U per gram of cellulose. In this example, the cellulose content of rice straw is 36.8%, so the amount of cellulase added is about 74U / g. Fully mix cellulase with straw;

[0034] 4) Add acetic acid-sodium acetate buffer solution with a pH of 5.0 to the mixture of cellulase and rice straw, and use the buffer solution to adjust the moisture conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com