A method for preparing degummed mulberry silk products based on biological enzyme method

A mulberry silk and degumming technology, which is applied in the biochemical treatment of enzymes/microbes, animal fibers, textiles and papermaking, etc., can solve the problems of poor wettability and low whiteness of mulberry silk, and achieve good degumming effect, wettability and High whiteness, good degumming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing degummed mulberry silk products based on a biological enzyme method, comprising the steps of:

[0048] (1) Protease and cutinase degumming:

[0049]Immerse mulberry silk power-spun raw silk in a solution of alkaline protease and cutinase, and degumming at a temperature of 40°C and pH 8 for 0.5h to obtain a degumming system; wherein the alkaline protease in the solution of alkaline protease and cutinase The dosage is 2U / mL, and the dosage of cutinase is 5U / mL;

[0050] (2) Lipase catalyzed low temperature bleaching:

[0051] Add lipase, glyceryl triacetate and hydrogen peroxide to the degumming system obtained in step (1) to remove residual glycerides on the surface of silk fibroin, and at the same time carry out low-temperature bleaching of mulberry silk at a temperature of 40°C and a pH of 6.5 for 1 hour to obtain low-temperature Bleached mulberry silk products; wherein the amount of lipase relative to the degumming system is 2U / mL, the amount ...

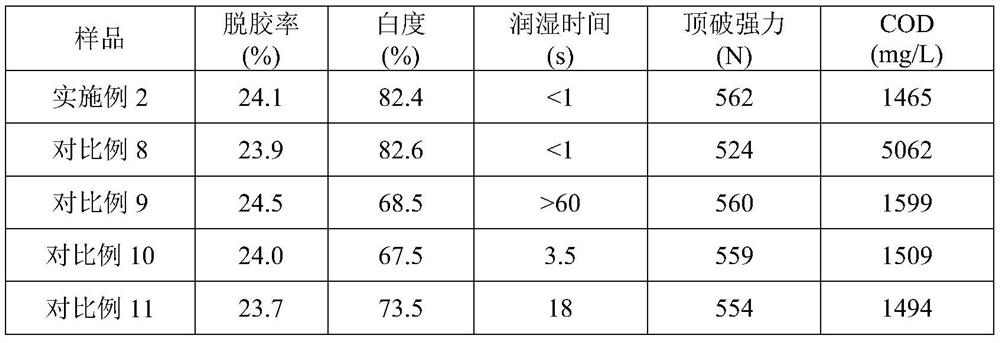

Embodiment 2

[0075] A method for preparing degummed mulberry silk products based on a biological enzyme method, comprising the steps of:

[0076] (1) Protease and cutinase degumming:

[0077] Soak mulberry silk knitted jersey raw silk in a solution of alkaline protease and cutinase, degumming at a temperature of 55°C and pH 9 for 1 hour to obtain a degumming system; the amount of alkaline protease in the solution of alkaline protease and cutinase 4U / mL, the dosage of cutinase is 10U / mL;

[0078] (2) Lipase catalyzed low temperature bleaching:

[0079] Add lipase, glyceryl triacetate and hydrogen peroxide to the degumming system obtained in step (1) to remove residual glycerides on the surface of silk fibroin, and at the same time carry out low-temperature bleaching of mulberry silk at a temperature of 55°C and a pH of 7.5 for 2 hours to obtain low-temperature Bleached mulberry silk products; wherein the amount of lipase relative to the degumming system is 4U / mL, the amount of triacetin r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com