Production process of 200-220g/m<2> spun silk knitted garment fabric

A production process and spun silk technology, which is applied to the production process field of 200-220g/m2 spun silk knitted garment fabrics, can solve the problems of poor bending and torsional deformability, difficult to form uniform coils, poor flatness of the cloth surface, etc. The effect of reducing bending, small knots, and high flatness of the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

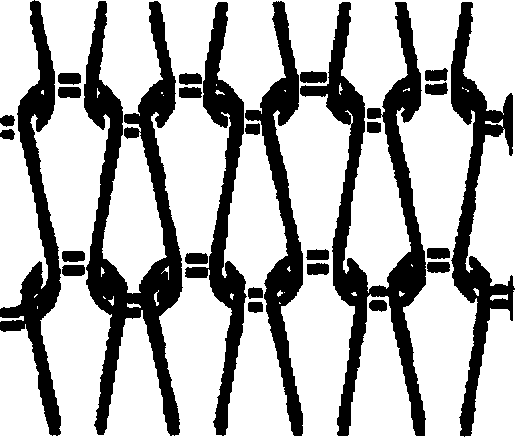

Image

Examples

Embodiment Construction

[0025] A kind of 200~220g / m 2 The production technology of the gram-weight spun silk knitted garment fabric comprises the following steps in turn:

[0026] (1) Process specification design

[0027] The raw material is 120N / 2 spun silk strands in a tube, and the weave design adopts a single-sided plain weave. The weight, transverse and longitudinal densities of the fabrics for printing are: 200-220G / M 2 , 62 mesh / 5cm, 82 mesh / 5cm.

[0028] (2) Spinning into a bobbin

[0029] The doubling and twisting operation is carried out on the doubling machine, the two spun yarns are combined and twisted into strands, and the twist of doubling is 700-800T / m, and the winding operation is carried out on the winding machine, and the winding tension is controlled by the tension sheet The weight is in the scope of 18~22g, and processing obtains the specification of packaged spun silk strand required by step (1), for braiding.

[0030] (3) Weaving process

[0031] 18G single-sided circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com