Method for processing fabric of surgical gown with permeability-resisting protection function

A processing method and technology with protective function, applied in the processing field of surgical gown fabrics, can solve the problems of low consumption level, unfavorable environmental protection, decreased mechanical strength, etc., and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

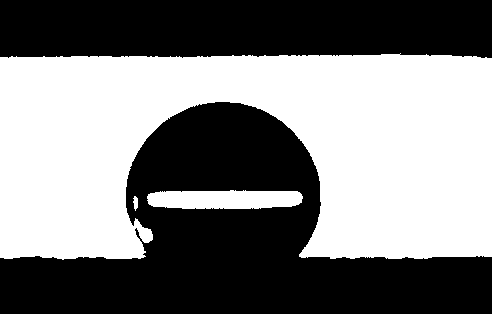

Image

Examples

Embodiment Construction

[0019] A method for processing a surgical gown fabric with anti-seepage protection function, comprising the following steps in sequence:

[0020] (1) Nano-sol pretreatment:

[0021] Preparation of nano-sol: Mix tetraethyl orthosilicate, ammonia water, and ethanol at a molar ratio of 1:16:60, stir magnetically at 50°C for 4 hours, and place at 25°C for 124 hours;

[0022] Treatment method: The surgical gown fabric is subjected to two-dipping and two-rolling treatment in nano-sol, with a liquid retention rate of 100%, and ventilation for 15 minutes;

[0023] (2) Low temperature and atmospheric pressure air plasma treatment:

[0024] The surgical gown fabric treated in step (1) was subjected to plasma treatment under the following treatment conditions: DC voltage 400 V, power 1 kW, frequency 200 Hz, treatment time 1 min, gas: air;

[0025] (3) Chemical anti-seepage agent treatment:

[0026] The surgical gown fabric treated in step (2) is dipped and rolled in the anti-seepage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com