Quick precipitator for clarifying during sugar making

A settler and fast technology, applied in the direction of settling tank, using physical method to purify, etc., can solve the problems such as unseparated flocculation area and clear juice area, unsmooth flow rate of filtered juice, and inconspicuous clarification effect, achieving obvious clarification effect, Good flocculation effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

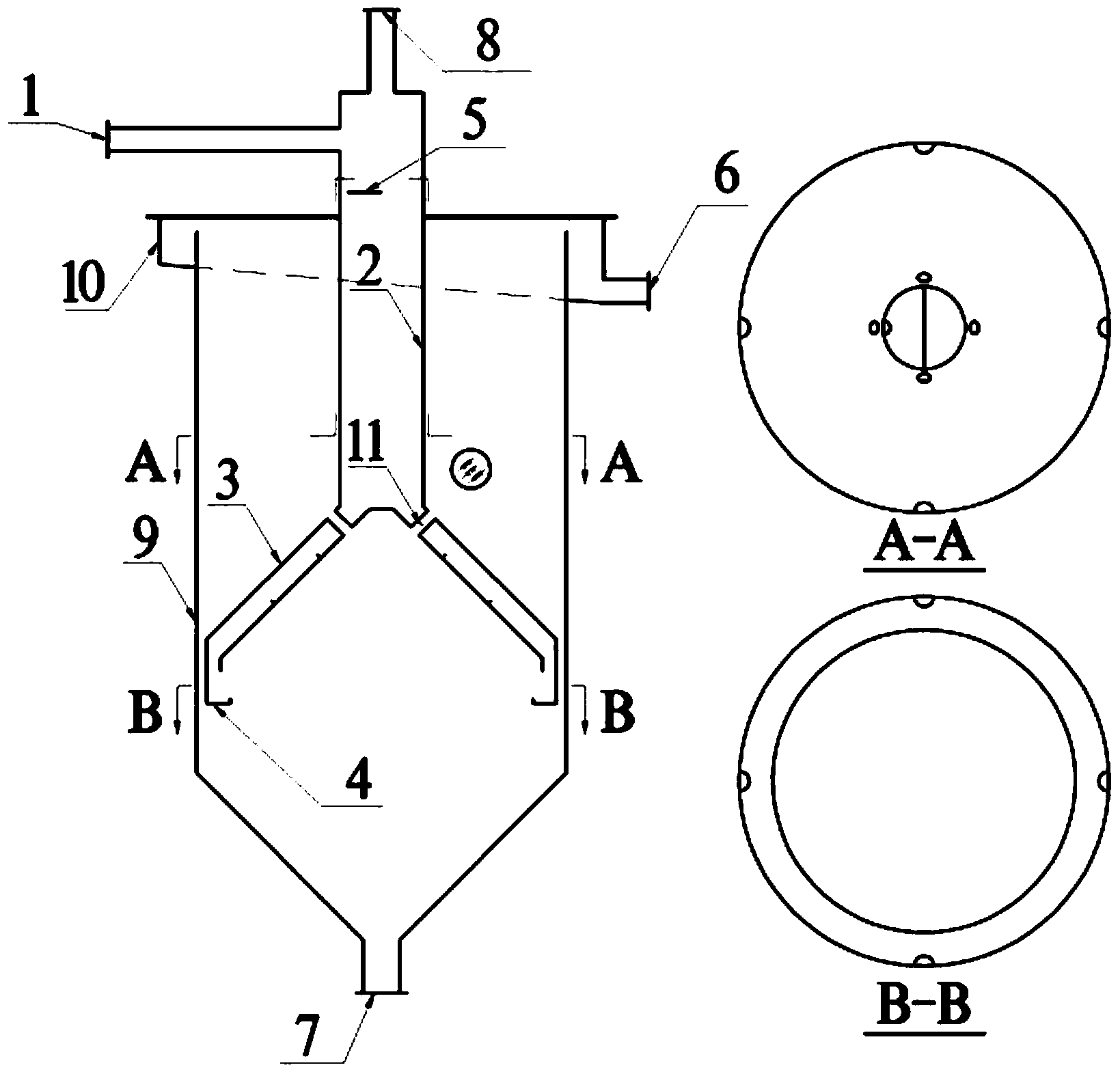

[0020] see figure 1 , the specific embodiment adopts the following technical scheme: the cylinder body 9 has a cavity inside, and is composed of a cylinder and a conical bucket. Connected, the lower end of cylinder 9 is connected with mud juice outlet pipe 7;

[0021] Sugarcane juice deflector, which includes diffuser pipe 2 and speed-reducing distributor 3, said diffuser pipe 2 and reducer distributor 3 are fixedly connected, cylinder 9 is divided into clear liquid area and flocculation sedimentation area, diffuser pipe 2 A through hole 11 is designed between the upper end of the speed reduction distributor 3 and the lower end of the speed reduction distributor 3 is fixedly connected with the inner wall of the cylinder 9;

[0022] sugarcane juice inlet pipe 1, said sugarcane juice inlet pipe 1 is fixedly connected to the side wall at the upper end of the diffuser pipe 2; and

[0023] Air diffuser outlet pipe 8, said air diffuser outlet pipe 8 is fixedly connected with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com