Apparatus for treating sewage containing oil, and processing technique

A treatment device and technology for oily sewage, applied in water/sewage treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high investment cost, large floor area, high energy consumption and material consumption , to achieve the effect of less scum, high degree of automation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

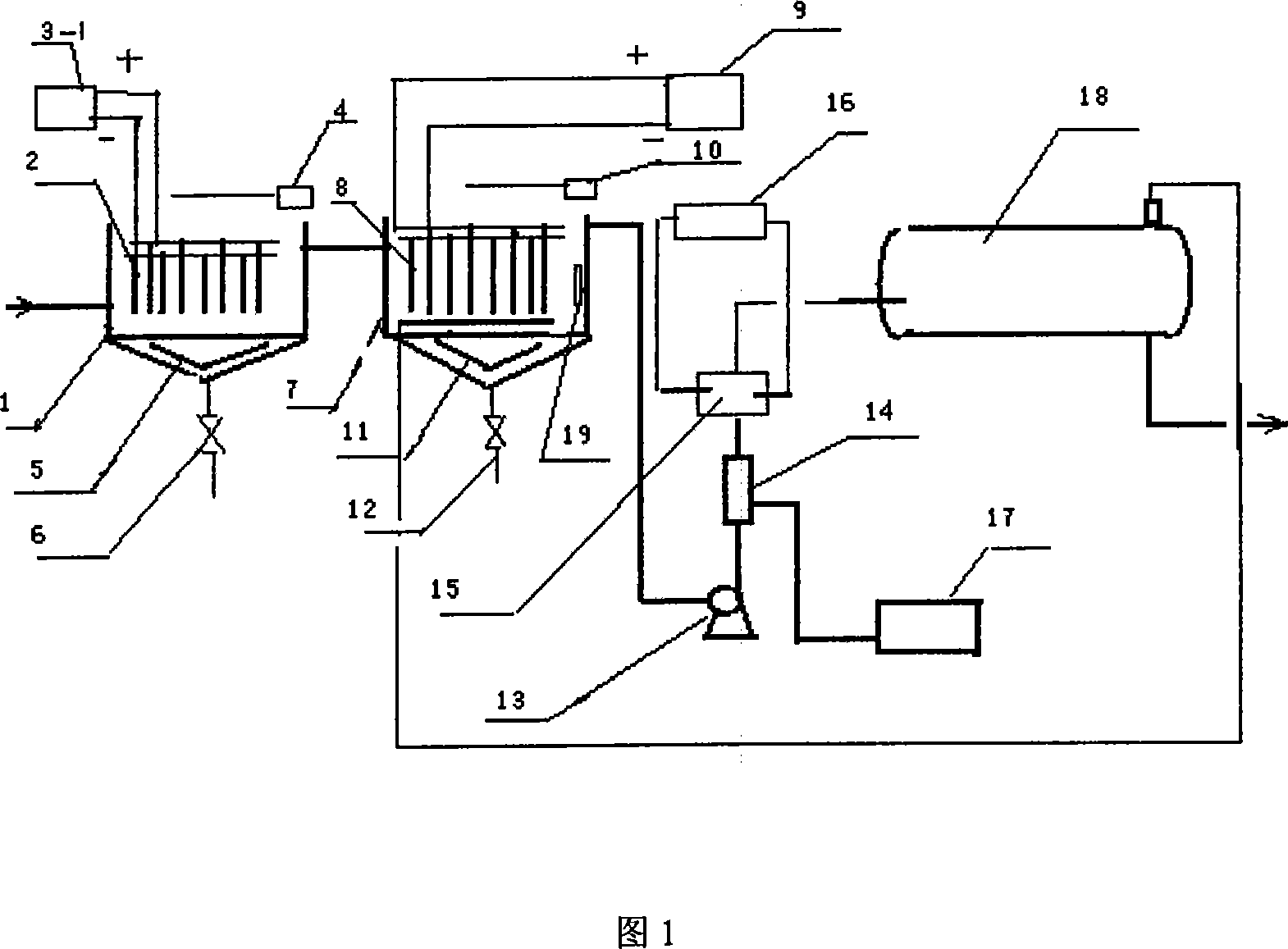

[0018] This technology is used in the industrial sewage of an oil refinery. The water quality before treatment is: oil 100mg / l, COD 1211mg / l. The treatment capacity is 2 tons / hour, using the device shown in Figure 1, the voltage of the electrocoagulation tank is 500V, the hydraulic retention time is 15 minutes, the voltage of the electric floating tank is 500V, the hydraulic retention time is 15 minutes, the power of the ultrasonic scale inhibitor is 10 watts, and the pump outlet Pressure 0.3 MPa, ozone flow rate 10 g / h, gas-liquid mixer mixing pressure difference 0.03 MPa, ultrasonic enhanced oxidizer 0.3 W / cm 2 , The residence time of the reaction tank is 10 minutes, and the water quality after treatment is COD100mg / l and oil 5mg / l.

Embodiment 2

[0020] Oily sewage in an oilfield, oil 510mg / l, COD2210mg / l, suspended solids 130mg / l before treatment, using the device shown in Figure 1, the voltage of electrocoagulation tank 1 is 5V, the voltage of electric floating tank is 5V, and the power of ultrasonic scale inhibitor is 10 Watts, pump outlet pressure 0.8 MPa, ozone flow rate 15 g / h, gas-liquid mixer mixing pressure difference 0.08 MPa, ultrasonic enhanced oxidizer 5W / cm 2 , The residence time of the reaction tank is 10 minutes, and the water quality after treatment is COD100mg / l and oil 5mg / l. The water quality after treatment is: oil 4.5mg / l, COD 80mg / l, suspended matter 18mg / l.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com