Aluminum alloy and applications and production method of aluminum alloy

A lead alloy, high purity technology, applied in the direction of electrical components, circuits, battery pack parts, etc., can solve the problems of false soldering, poor fluidity of Pb-Sn alloy, missing soldering, etc., to reduce scum, avoid false soldering, increase The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

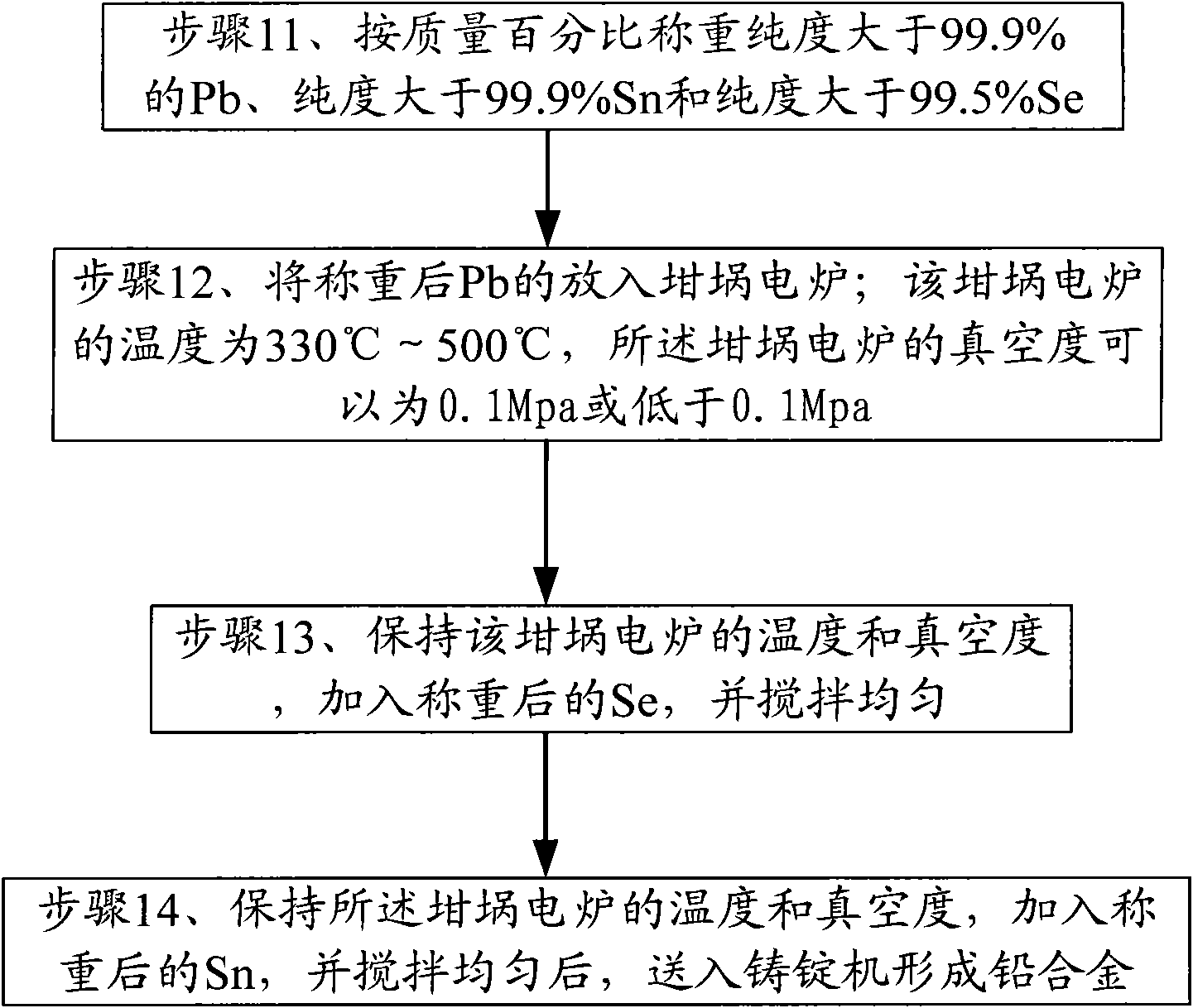

Method used

Image

Examples

Embodiment Construction

[0020] The invention improves the fluidity and corrosion resistance of the lead alloy by changing the material of the lead alloy in the prior art, can effectively reduce scum, and avoid problems such as virtual welding, false welding, and missing welding. The present invention will be described in detail through specific examples below. In the following description, unless otherwise specified, all percentages are percentages by weight.

[0021] The specific embodiment of the present invention provides a lead alloy. The composition and mass percentage of the lead alloy are as follows: tin Sn can be 0.1% to 2.0%; selenium Se can be 0.001% to 1.0%; the rest is lead Pb; the Sn The purity is 99.9% and above, the purity of Se is 99.5% and above, and the purity of Pb is 99.9% and above.

[0022] Preferably, the composition of the above-mentioned lead alloy and the specific mass percentage content of each composition are as shown in Table 1:

[0023] Table 1:

[0024] Unit: % (weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com