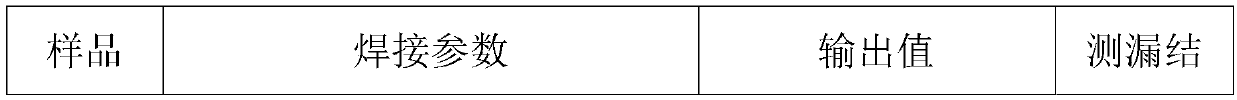

Patents

Literature

30results about How to "Avoid false welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

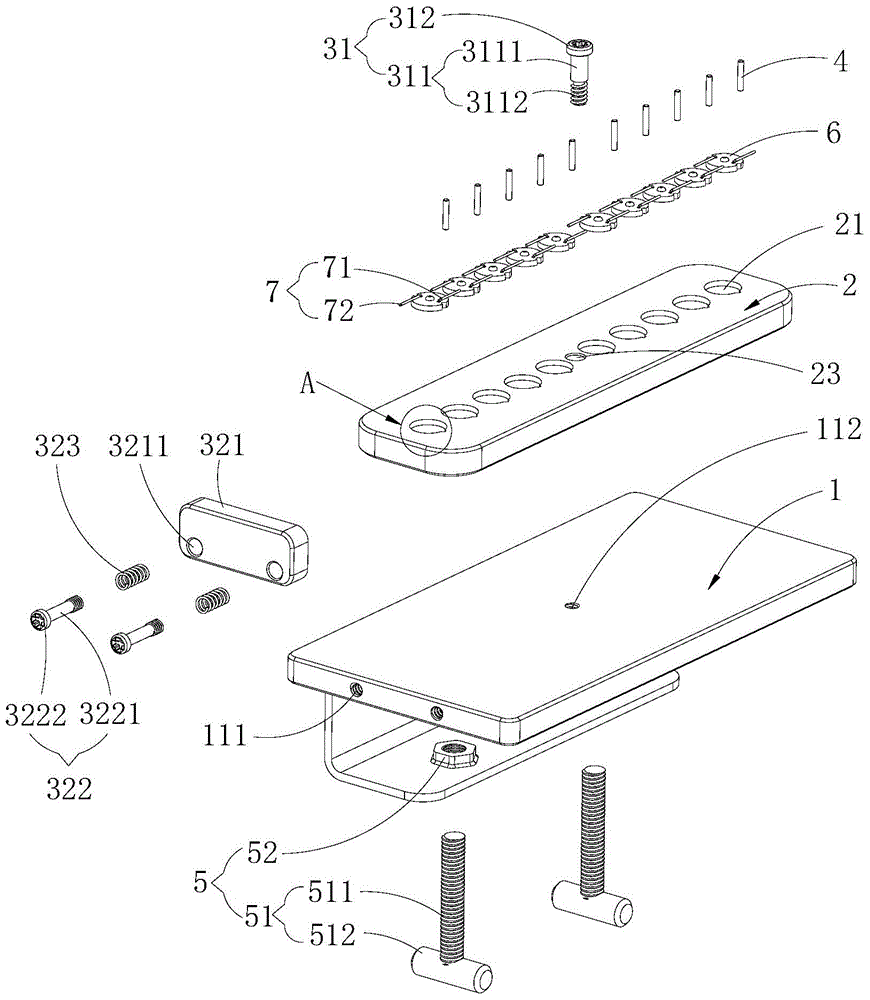

Spot soldering fixture and spot soldering process

InactiveCN102581458APrecise positioningHeight adjustableResistance welding apparatusEngineeringSoldering process

The invention belongs to the technical field of soldering, and particularly relates to a spot soldering fixture, which is used in a spot soldering process capable of avoiding pseudo soldering, false soldering and bursting, and is high in soldering efficiency. The spot soldering fixture comprises a fixture body, a cell storage area and a fuse storage area, and an avoidance hole is reserved between the cell storage area and the fuse storage area. Compared with the prior art, the spot soldering fixture has the advantages that a fuse and a metal strap can be effectively positioned, the height of a soldering pin can be adjusted, spot soldering quality can be improved, soldering reject ratio can be decreased, production efficiency can be improved, and cost can be saved. Besides, the invention further discloses the spot soldering process using the spot soldering fixture.

Owner:DONGGUAN NVT TECH

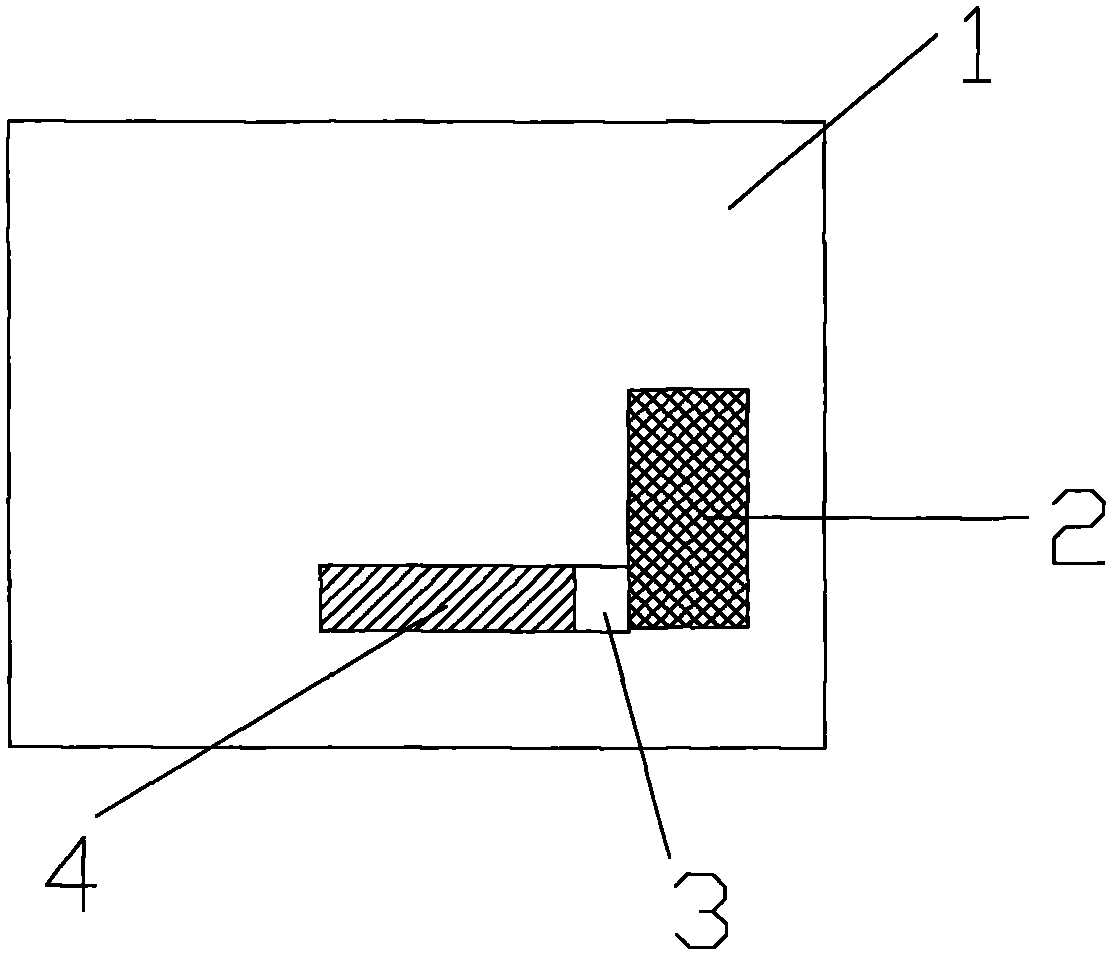

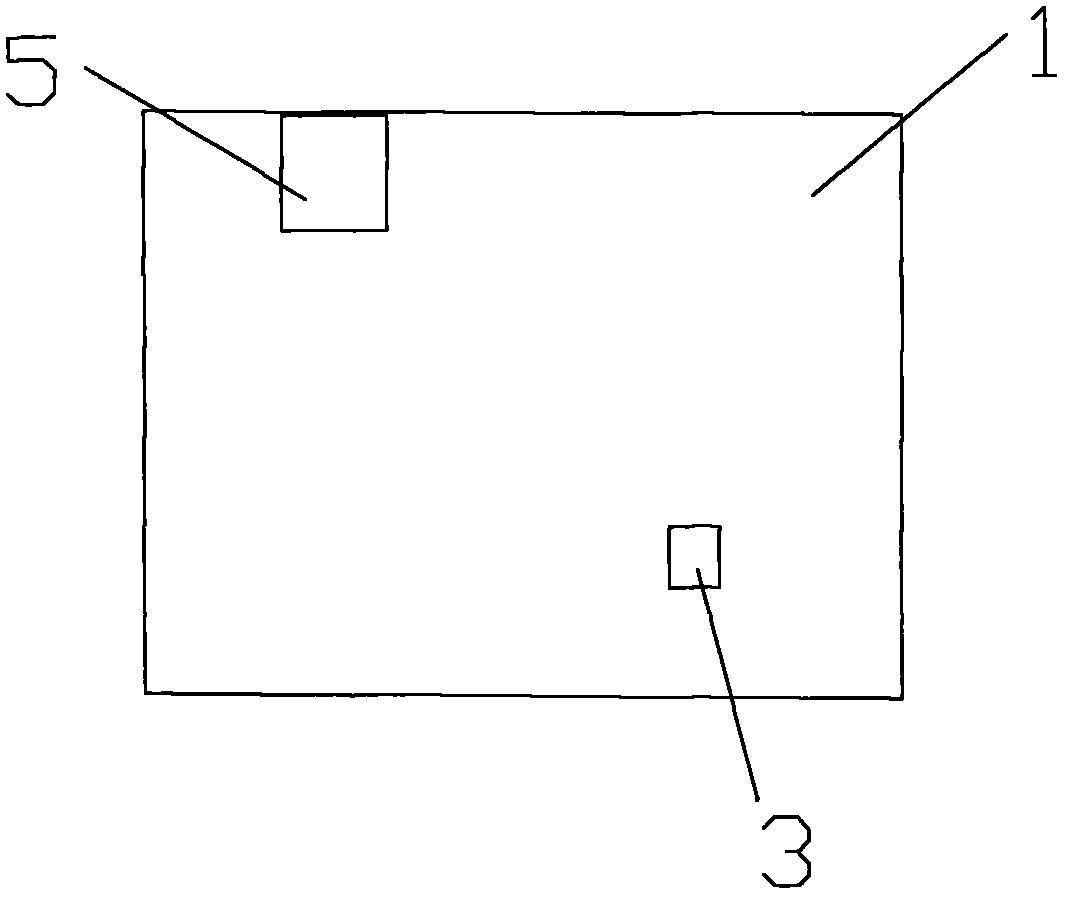

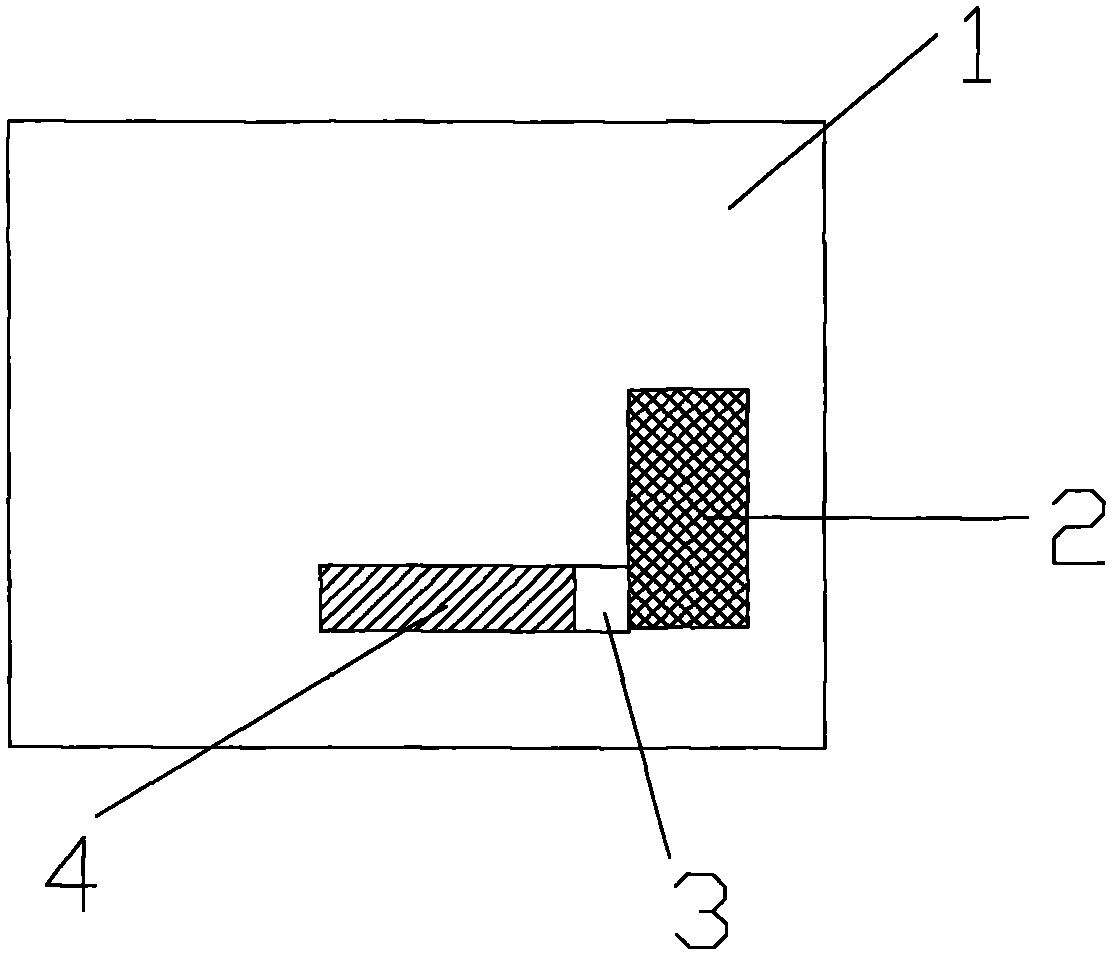

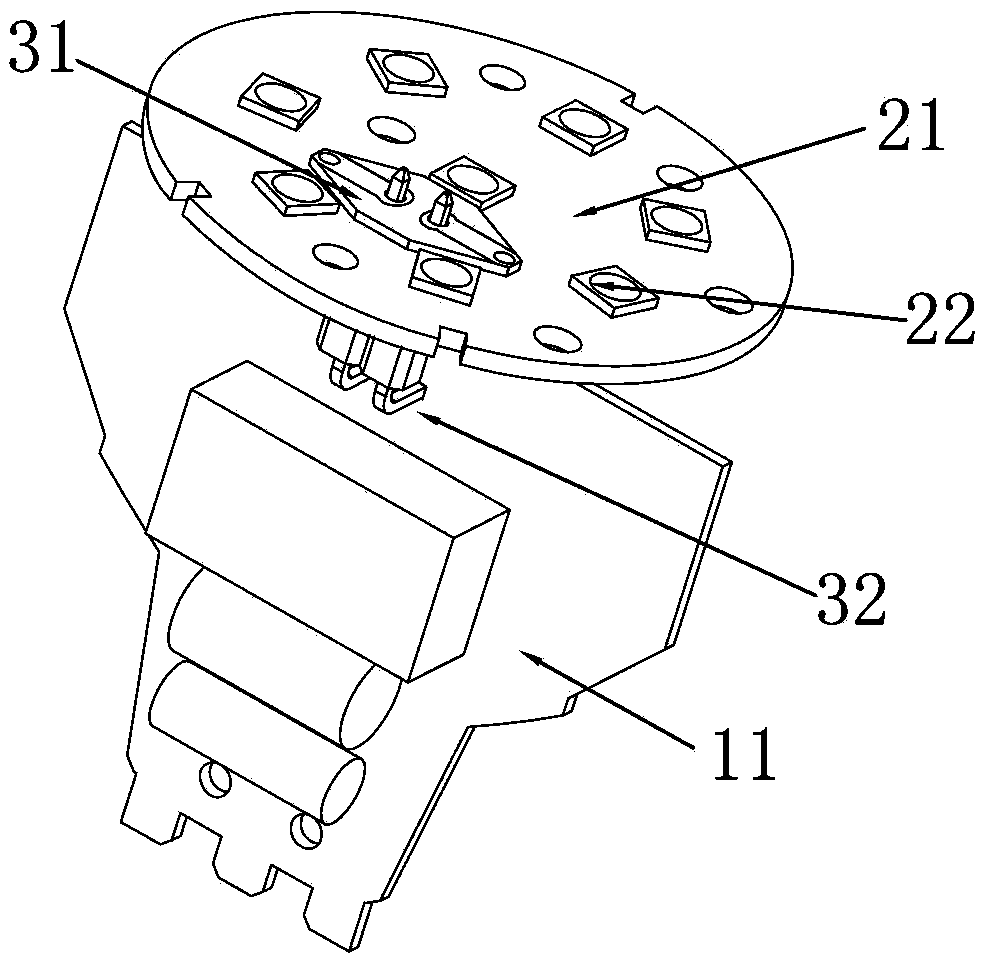

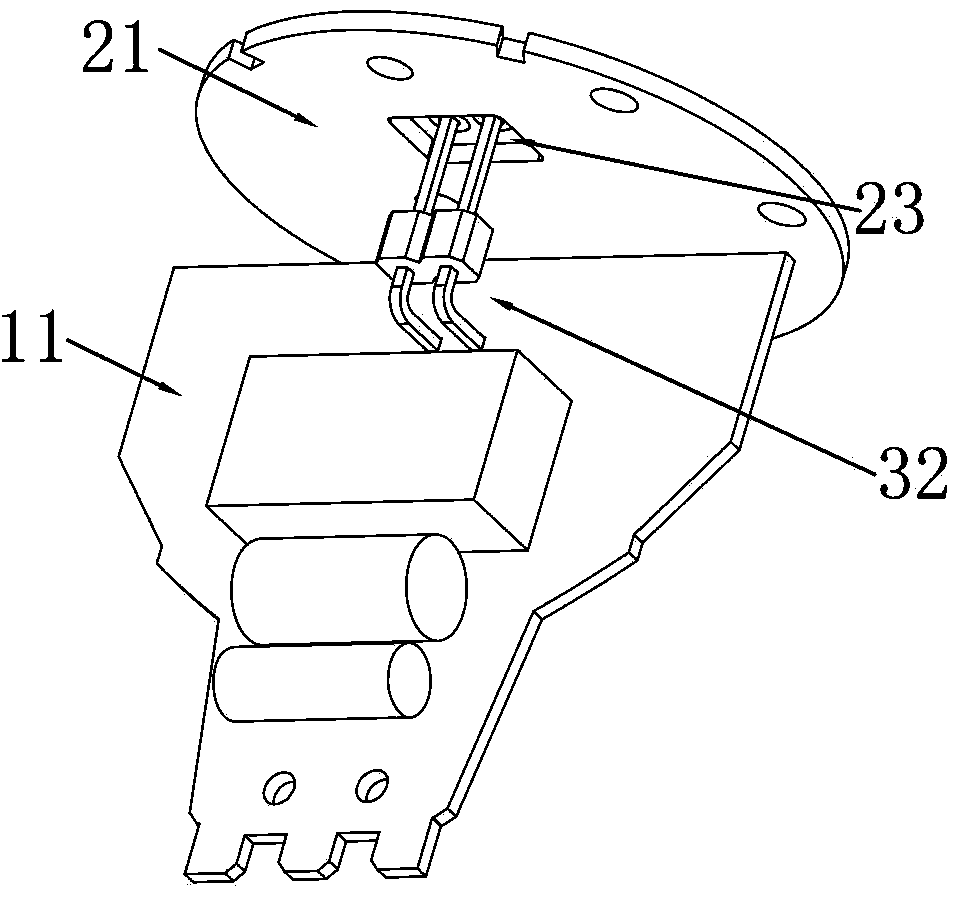

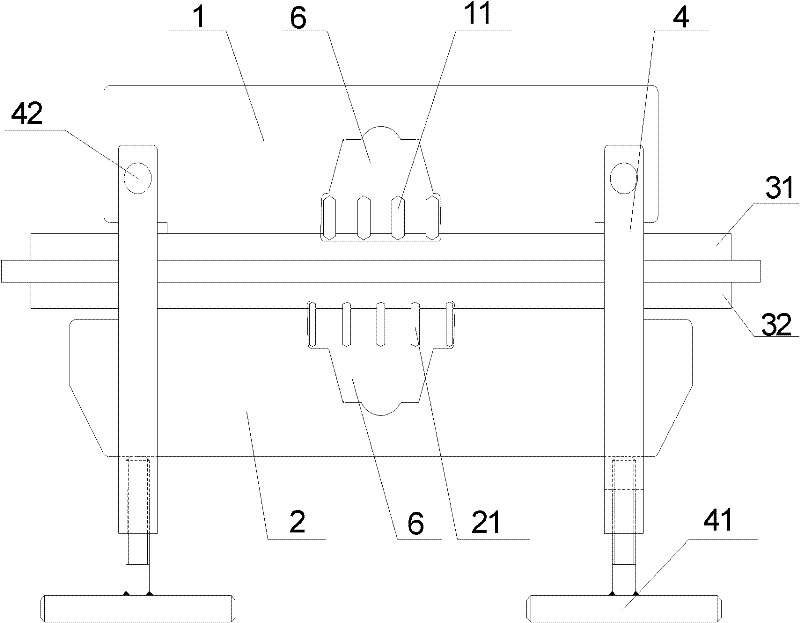

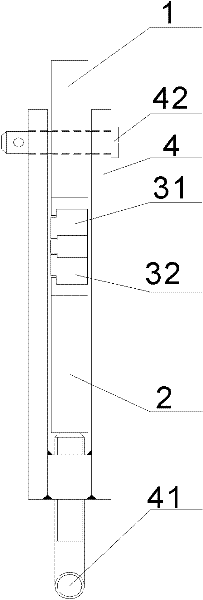

LED lamp and circuit connecting method thereof

InactiveCN103438370AAvoid short circuit conditionsAvoid false weldingPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention discloses an LED lamp and a circuit connecting method of the LED lamp. The LED lamp comprises a power supplying device and an LED light source module, the LED light source module comprises a metal substrate and an LED light source arranged on the metal substrate, the LED lamp further comprises a connecting board and a connecting pin, the connecting board is arranged on the metal substrate and is electrically connected with the metal substrate, one end of the connecting pin penetrates through the metal substrate and is welded to the connecting board, the other end of the connecting pin is fixedly connected with a power supplying device in a welding mode, and therefore the connecting pin is electrically connected with the power supplying device and the LED light source module. Compared with the prior art, according to the LED lamp and the circuit connecting method of the LED lamp, due to the fact that the connecting pin and the connecting board are connected with the power supplying device and the LED light source module and connecting welding points are arranged on the connecting board, false welding and cold joint caused by good heat dissipation performance of the metal substrate are avoided; in addition, the occurrence of short circuit due to the situation that conductive wires are broken caused by being scratched by the metal substrate can be avoided. The LED lamp is easy to weld and conductive wires to be welded are not needed to be fixed manually.

Owner:ZHEJIANG SHENGHUI LIGHTING

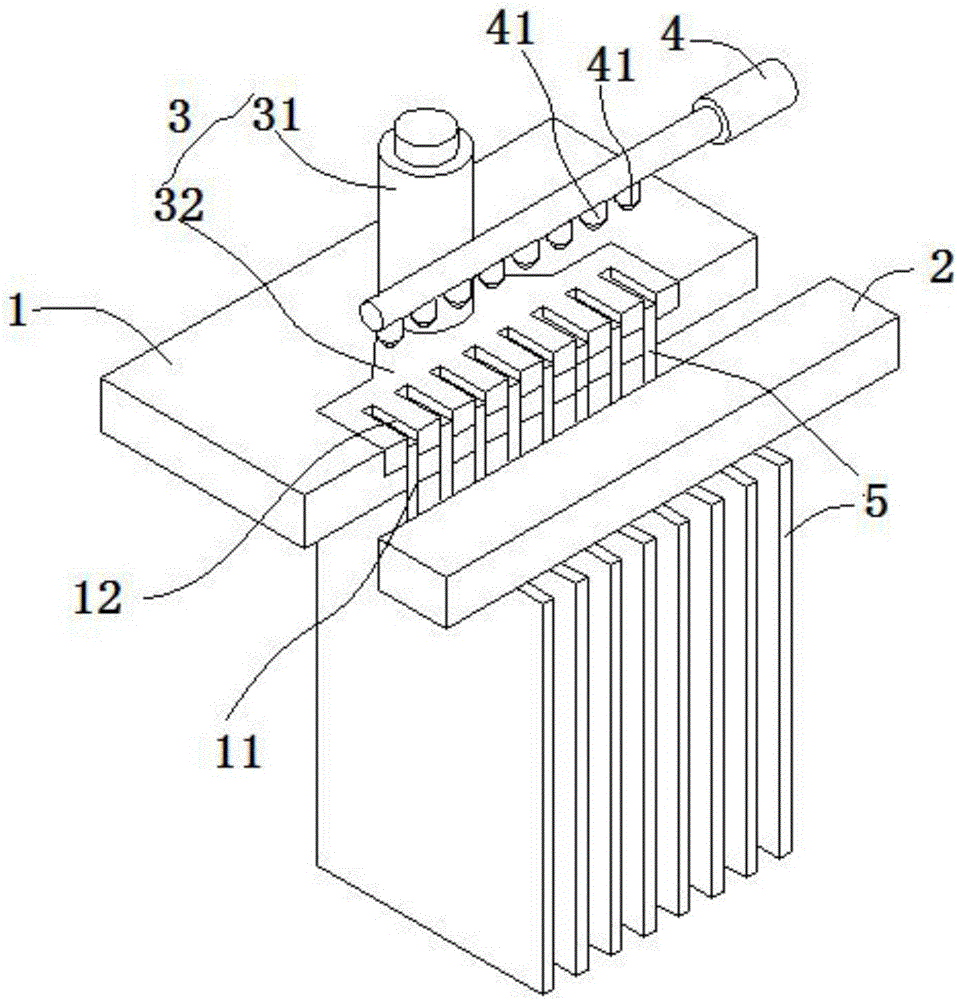

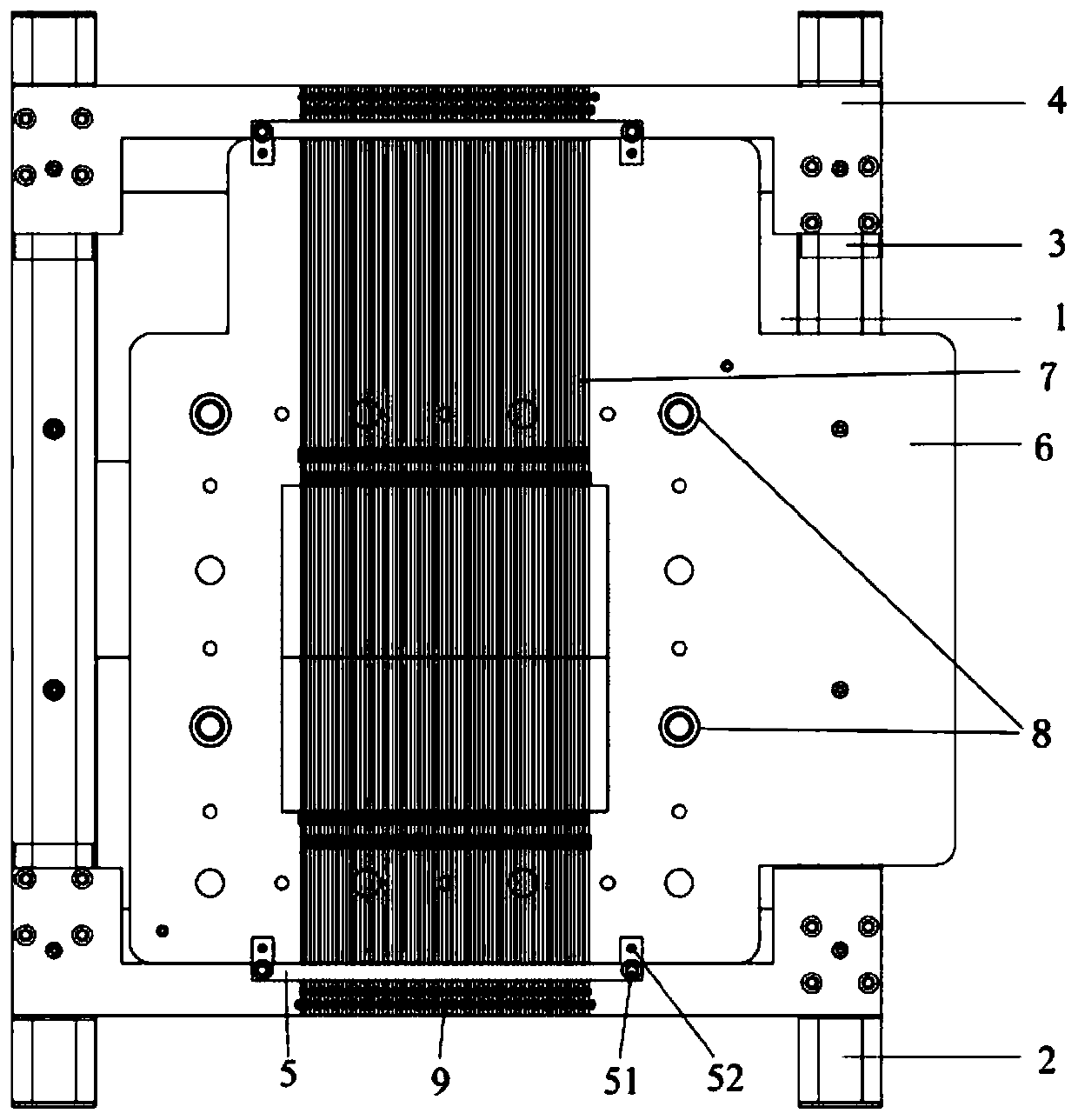

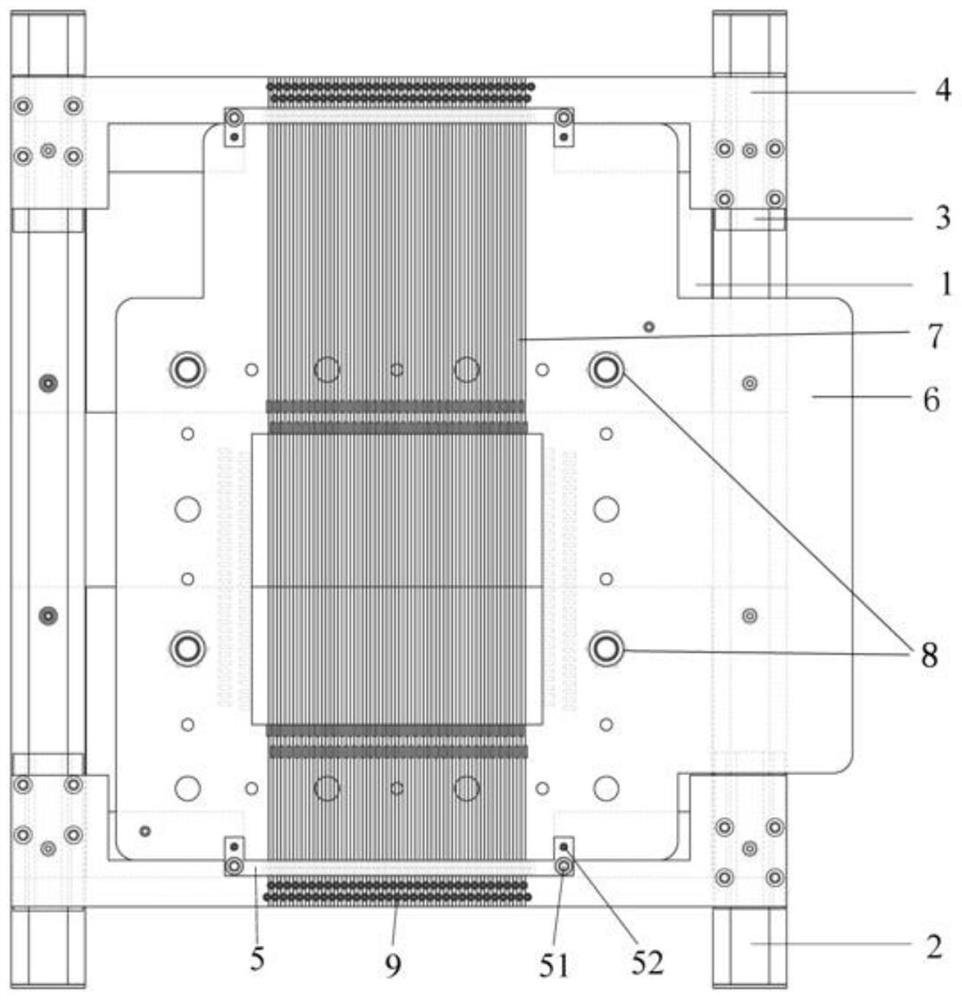

Burn-in pole lug clamping device

InactiveCN102303203AWon't slipAvoid false weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention provides a burn-in pole lug clamping device, which comprises a fastening piece, a positive pole comb plate, a negative pole comb plate and a press strip which is sandwiched between the positive pole comb plate and the negative pole comb plate, wherein the positive pole comb plate and the negative pole comb plate are tightly compressed through the fastening piece; two opposite surfaces of the positive pole comb plate and the negative pole comb plate are provided with a positive pole lug placing position and a negative pole lug placing position respectively; one side of the press trip towards the positive pole comb plate is provided with positive comb teeth, and one side of the press strip towards the negative pole comb plate is provided with negative comb teeth; a positive accommodating cavity matched with the shape of a positive pole lug is enclosed by the positive comb teeth and the positive pole lug placing position; and a negative accommodating cavity matched with the shape of a negative pole lug is enclosed by the negative comb teeth and the negative pole lug placing position. In the burn-in pole lug clamping device, the accommodating cavities matched with the pole lugs are correspondingly enclosed by one side of the press strip and the positive pole comb plate as well as the other side of the press strip and the negative pole comb plate respectively, so that the pole lugs cannot slip off from the cavities, and the phenomenon of false welding is prevented; and the accommodating cavities are tightly attached to the pole lugs without gaps, and lead leakage in the welding process can be prevented.

Owner:ZHAOQING LEOCH BATTERY TECH

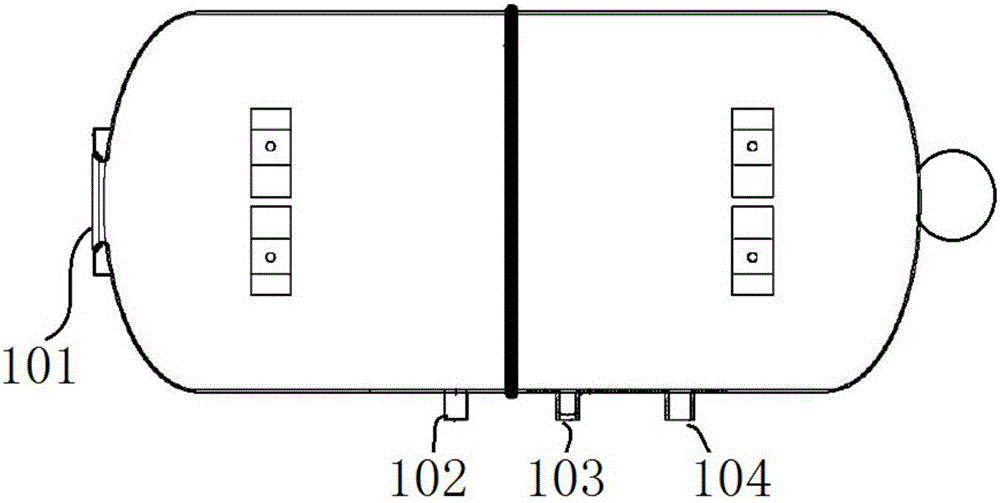

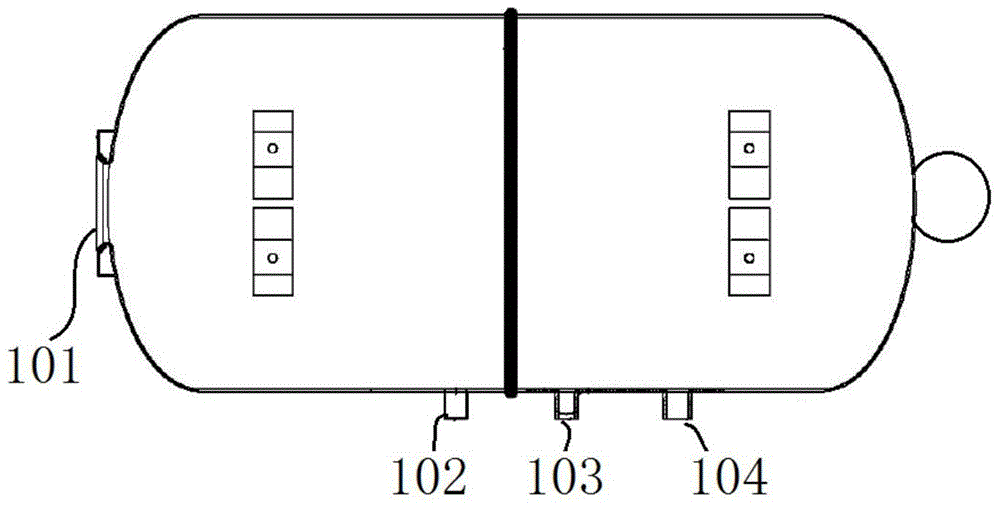

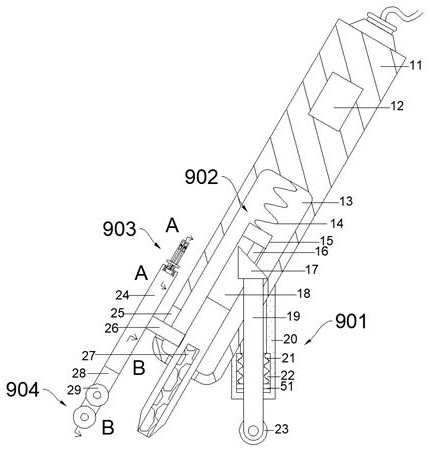

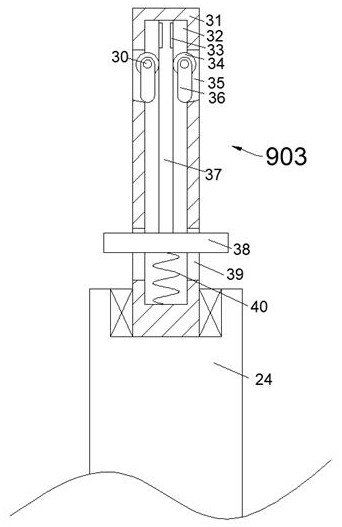

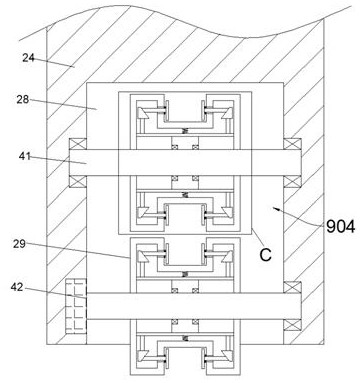

Welding device and welding method for bus-bar of lead-acid storage battery

ActiveCN106180958AAutomate operationAvoid WeldingGas flame welding apparatusEngineeringFusion welding

The invention discloses a welding device and a welding method for a bus-bar of a lead-acid storage battery. The characteristic that fusion welding through flame heating is full and thorough, so that inevitable quality problems of a cast-welding mode of fault welding, false welding, skip welding and the like are avoided, and the welding method and the welding device have the advantages of low production cost, simple operation, convenient maintenance, reliable welding quality and the like. On the basis, by adopting the welding device, automatic operation can be realized; the production efficiency is 10 times higher than that of manual welding operation; and welding quality and reliability are further improved.

Owner:HUBEI RUNYANG NEW ENERGY

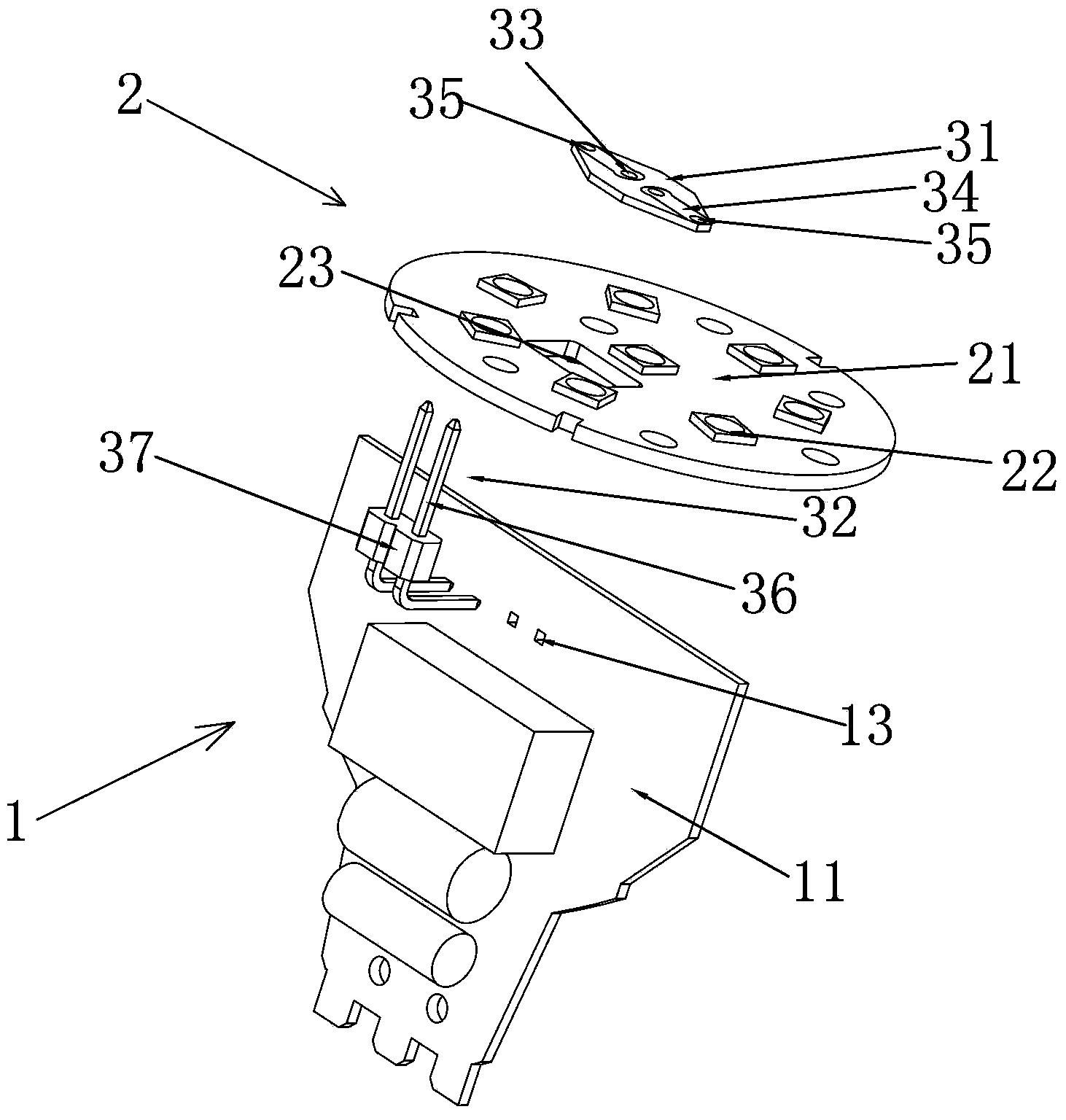

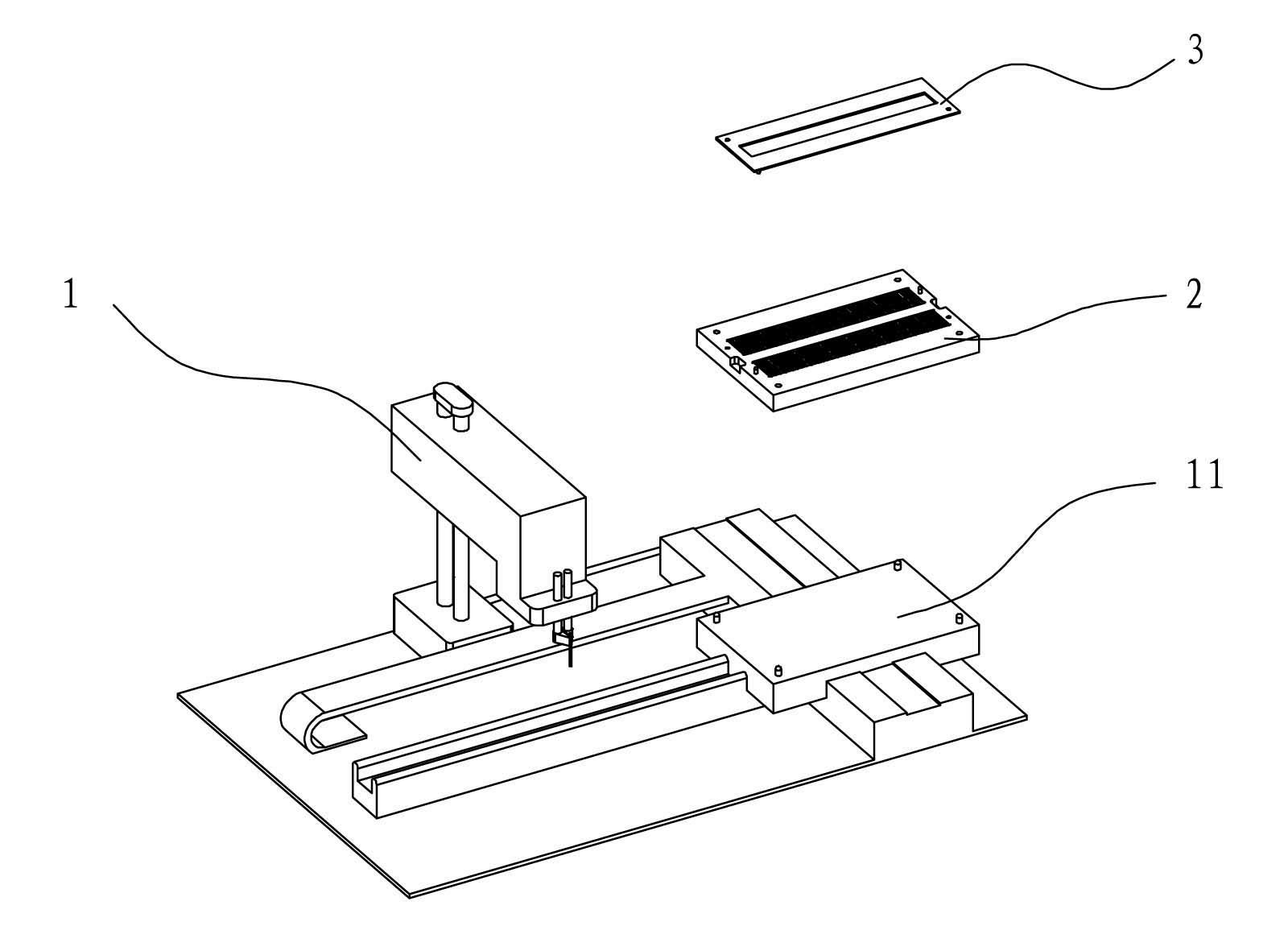

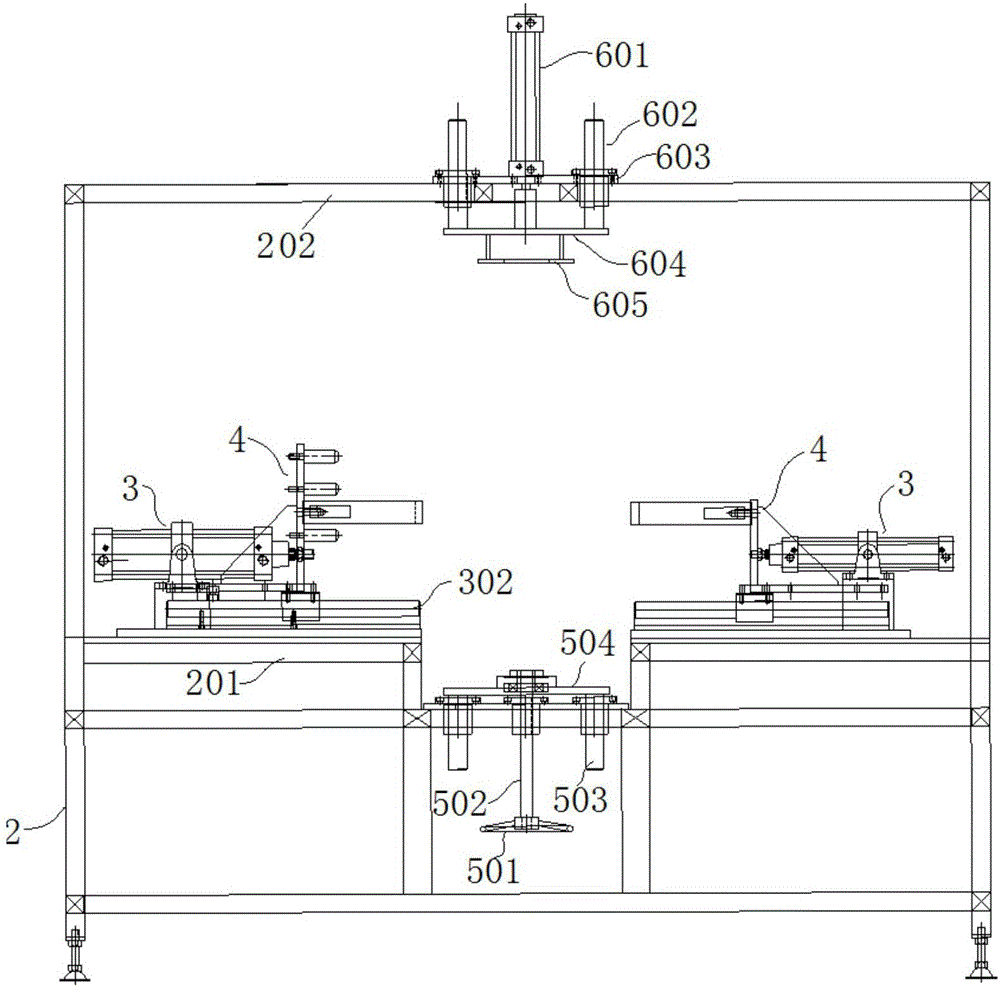

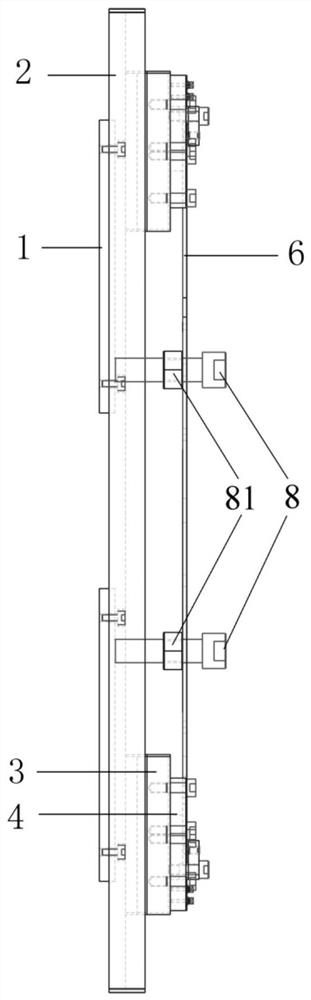

Equipment for automatically welding battery circuit board and using method of equipment

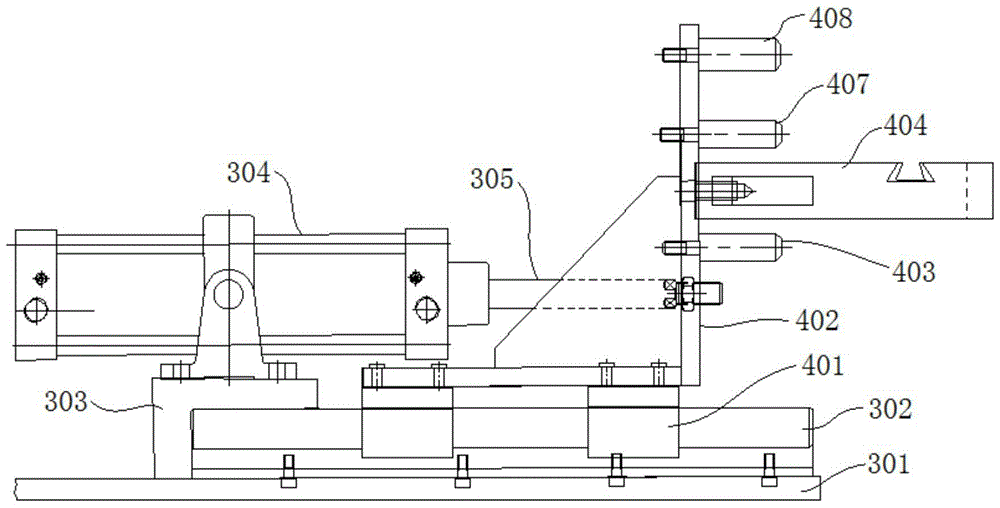

ActiveCN102205459AHealth effectsAvoid false weldingPrinted circuit assemblingWelding/cutting auxillary devicesElectrical batteryElectrical current

The invention discloses equipment for automatically welding a battery circuit board and a using method of the equipment. The equipment comprises an automatic spotweld machine with a two-dimensional numerically controlled sliding table; a clamp is arranged on the two-dimensional numerically controlled sliding table; a plurality of circuit board grooves for embedding the battery circuit board are formed on the clamp; a nickel sheet groove for accommodating a nickel sheet is formed at the corresponding position of the side of each circuit board groove; and a pressing board for fixing the batterycircuit board and the nickel sheets is arranged on the upper part of the clamp. In the equipment for automatically welding the battery circuit board, the fixed clamp and the pressing board are used for fixing the circuit board and the nickel sheets, the production cost is reduced by current welding, and problems of cold solder, loose weld and the like in the prior art can be avoided; therefore, the quality of a produced product is enhanced greatly; meanwhile, influence on the environment and the health of operators can be avoided.

Owner:ZHUHAI XUNDA TECH CO LTD

Lead and lead-free soldering method

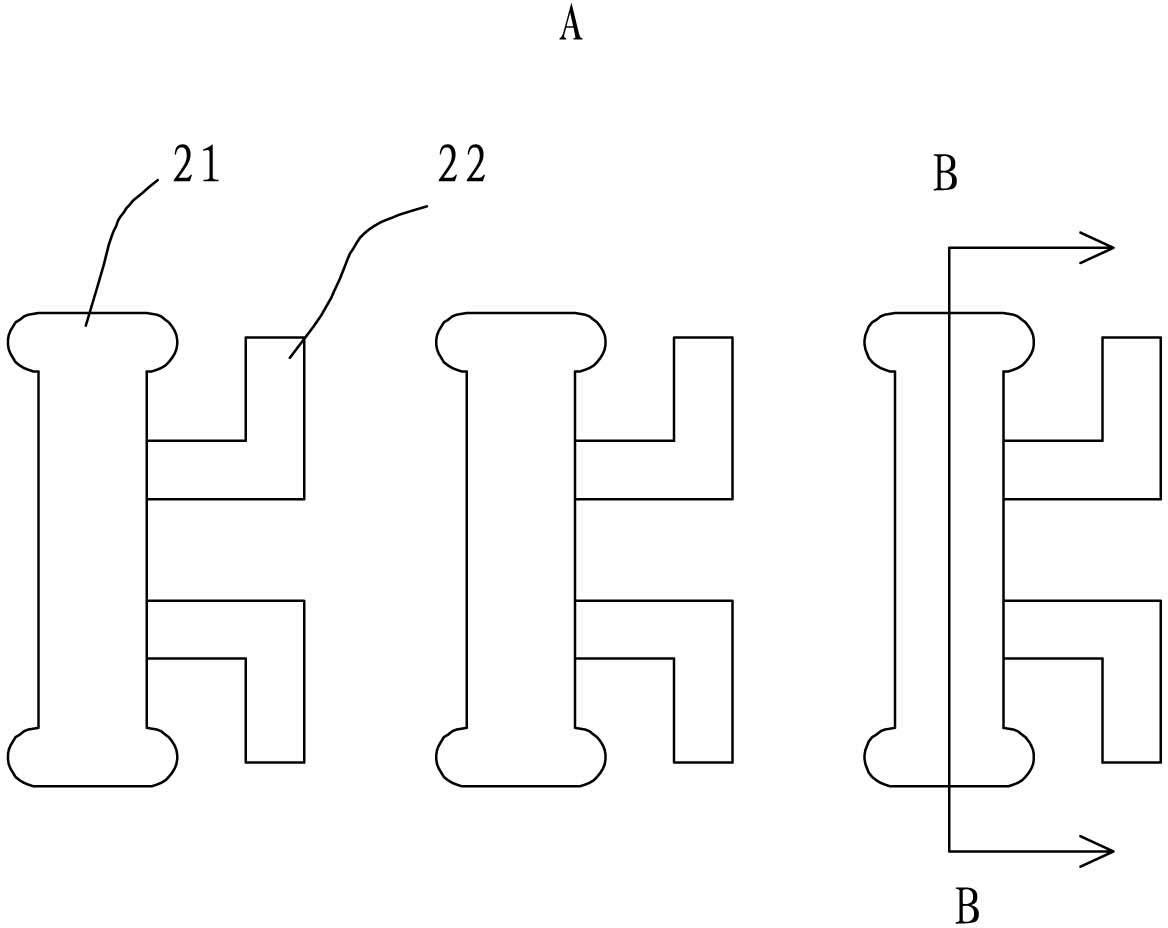

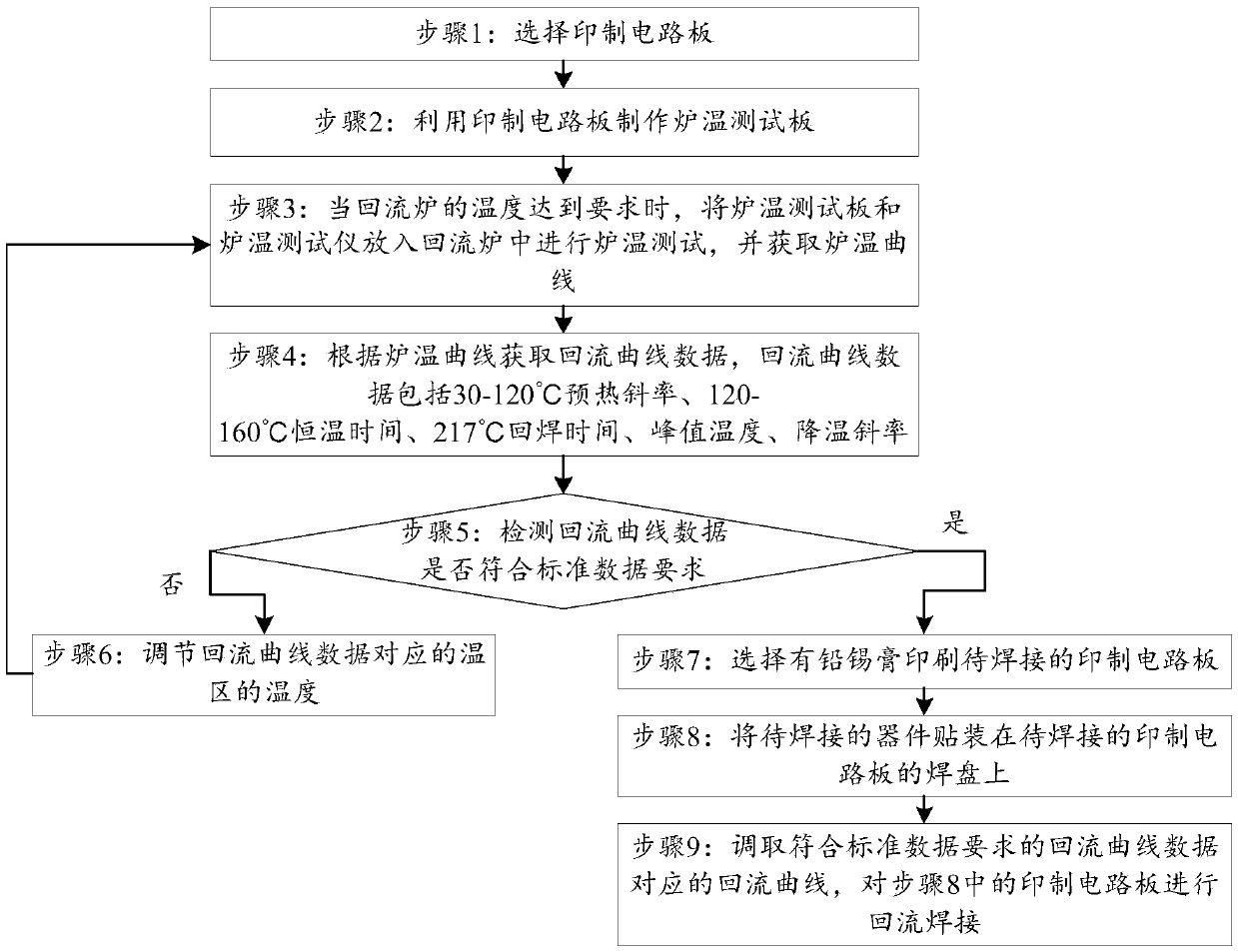

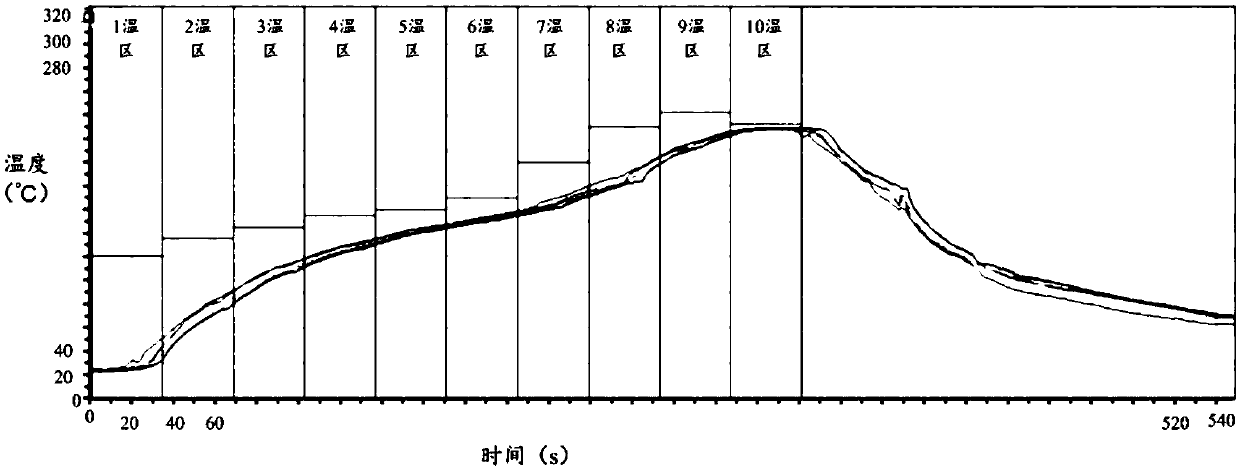

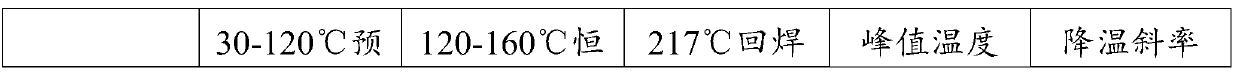

ActiveCN109688727ASolve problems prone to welding defectsAvoid WeldingPrinted circuit assemblingSoldering apparatusFurnace temperatureWelding defect

The invention discloses a lead and lead-free soldering method and belongs to the field of electronic assembly. The method comprises selecting a printed circuit board to make a furnace temperature testboard; when the temperature of a reflow furnace reaches the requirement, placing the furnace temperature test board and a furnace temperature tester in the reflow furnace for furnace temperature test, and obtaining a reflow profile; acquiring reflow profile data according to the reflow profile, and detecting whether the reflow profile meets standard data requirements; if the reflow profile does not meet standard data requirements, adjusting the temperature of a temperature zone corresponding to the reflow profile data; if the reflow profile meets standard data requirements, selecting lead solder paste to print the printed circuit board to be soldered; mounting a device to be soldered on a bonding pad of the printed circuit board to be soldered; and calling a reflow profile corresponding to the reflow profile data that meets the standard data requirements to perform reflow soldering. The problem that welding defects easily occur in current lead-free soldering is solved, and the effectsof ensuring soldering quality and avoiding defects such as pseudo soldering and bubbles at welding spots are achieved.

Owner:无锡市同步电子制造有限公司

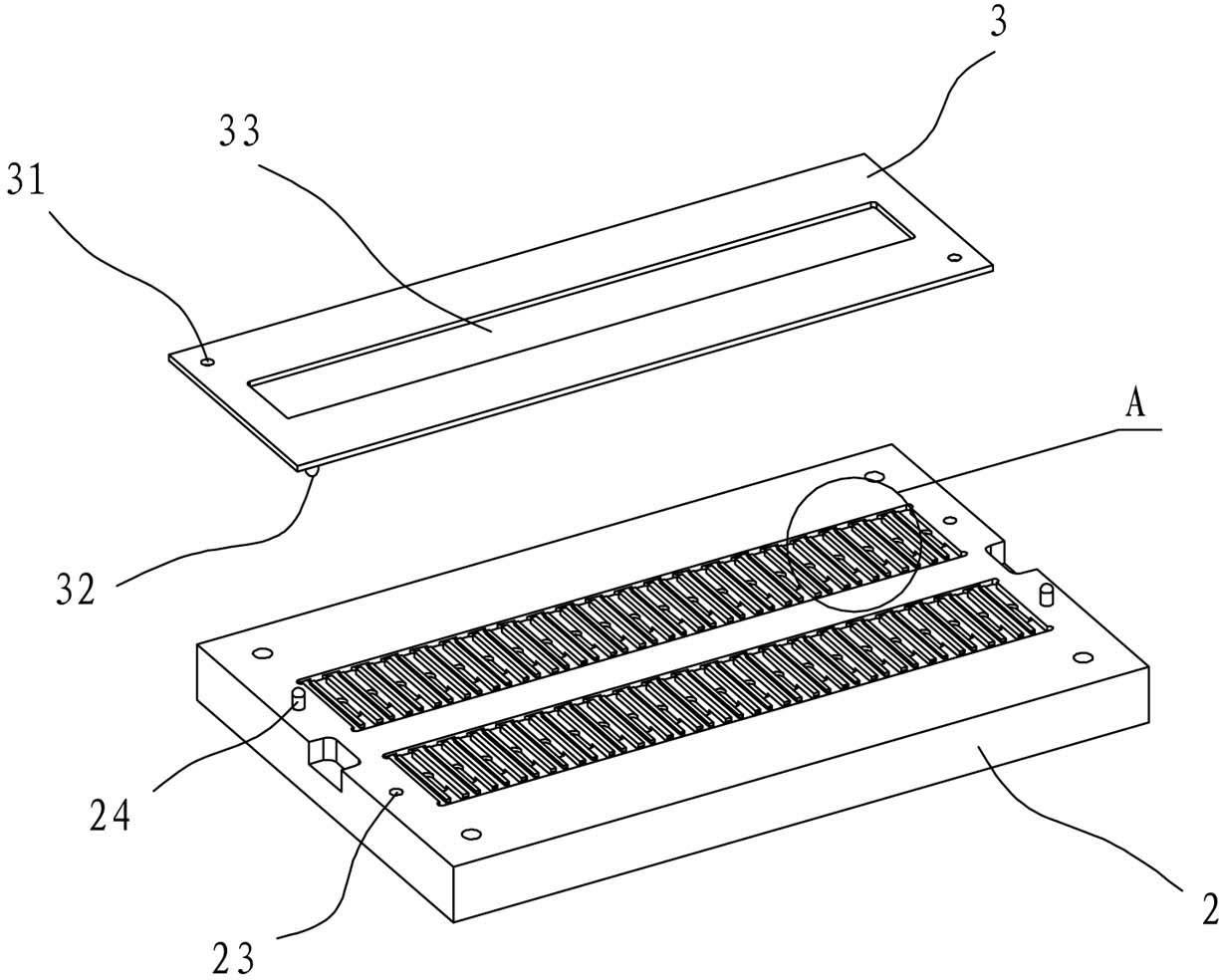

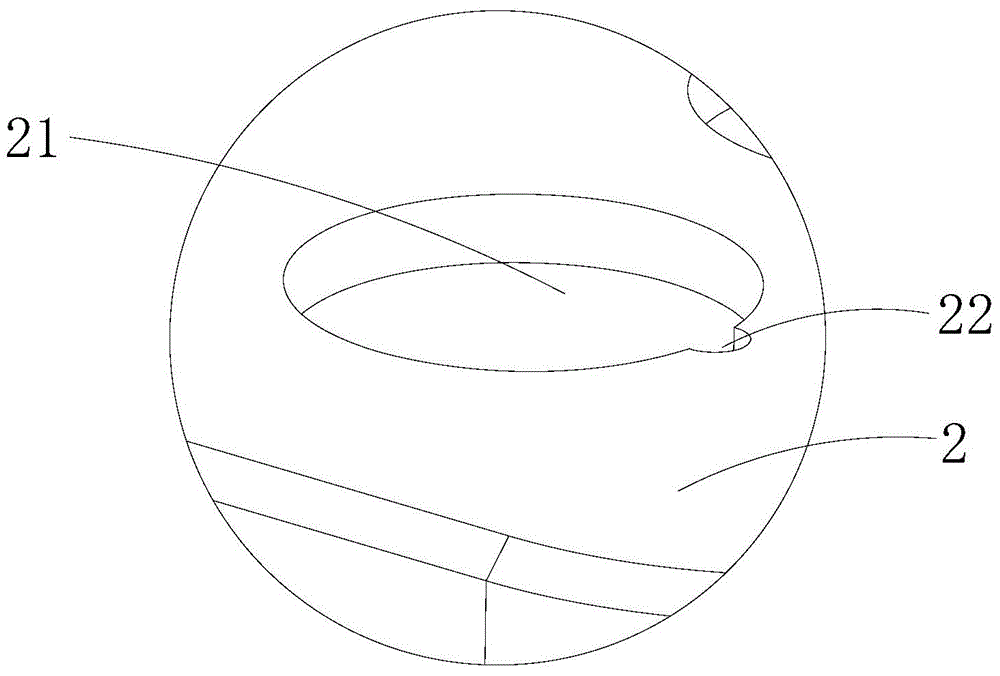

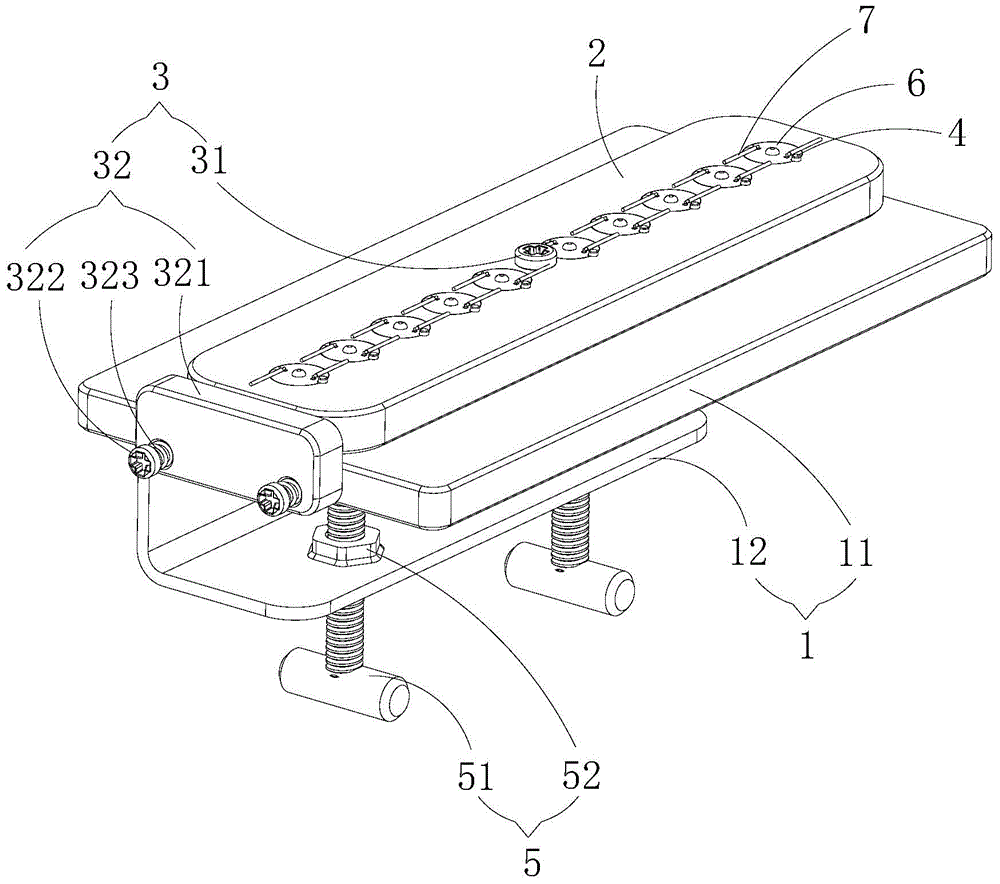

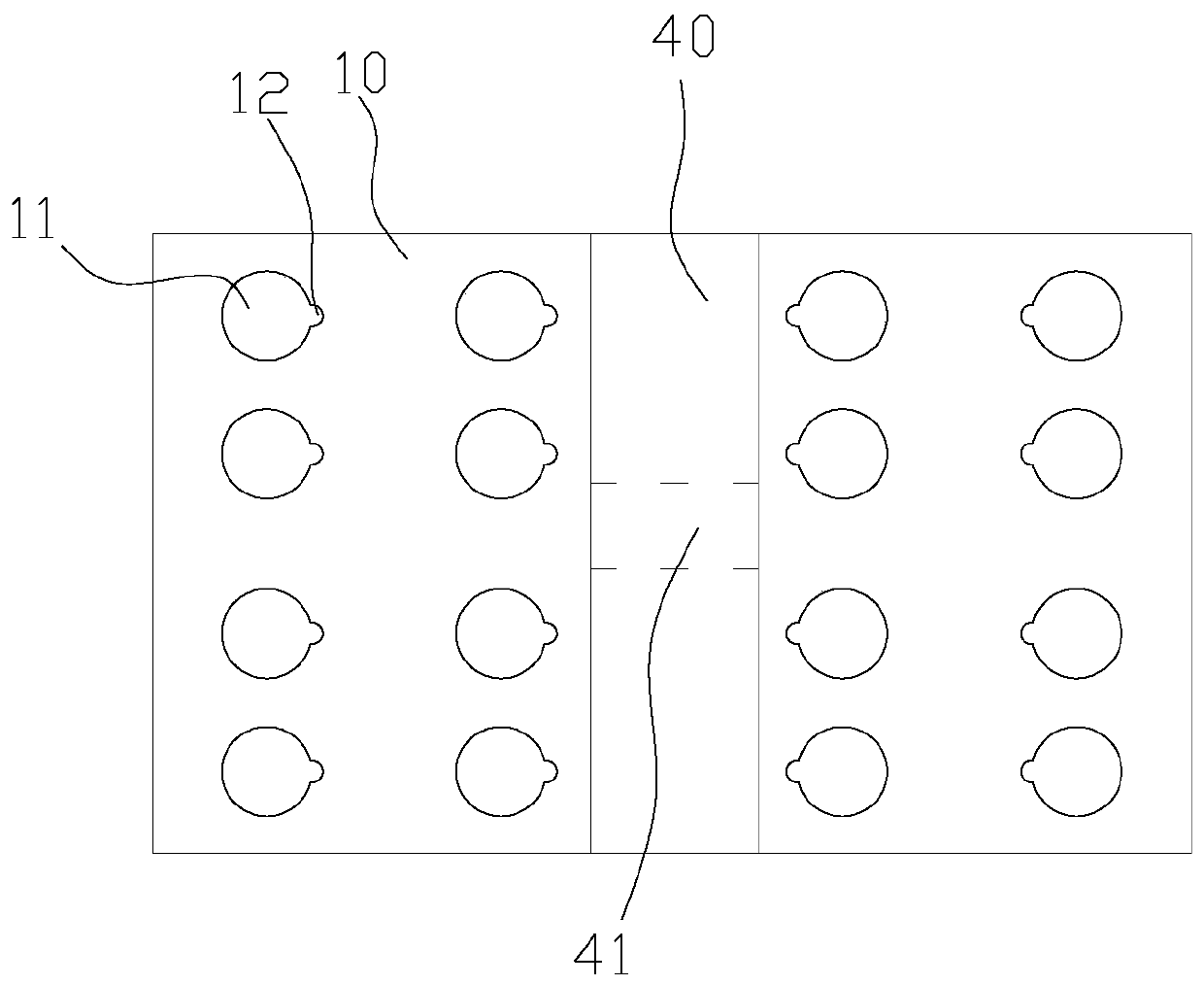

Machining locating device for LED light-emitting plates

InactiveCN104439817ARealize the installation and fixationEffective installation and fixationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLED lamp

The invention is suitable for the field of LED lamp production equipment and discloses a machining locating device for LED light-emitting plates. The machining locating device is used for locking and locating the LED light-emitting plates with first limiting grooves formed in the outer side walls in a protruding mode during machining. The machining locating device comprises a base, a locating plate, a locking assembly and limiting posts, wherein the base is used for being connected with a workbench, the locating plate is arranged on the base, the locking assembly is used for locking and fixing the locating plate to the base, and the limiting posts are used for locking the LED light-emitting plates to the locating plate; at least one locating hole used for containing the LED light-emitting plates is formed in the locating plate in a spaced mode, the inner side wall of each locating hole is provided with a second limiting groove in a protruding mode, each second limiting groove and the corresponding first limiting groove are used for forming a limiting hole in an enclosed mode, and the limiting posts are fixed in the limiting holes in an inserted mode. When a wire welding sequence is conducted, the machining locating device is adopted for locking and locating the LED light-emitting plates, so the work fatigue degree of production staff can be lowered, wire welding efficiency is improved, and welding quality of wires on the LED light-emitting plates is guaranteed.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

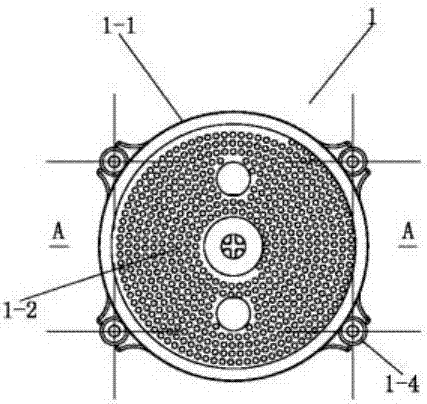

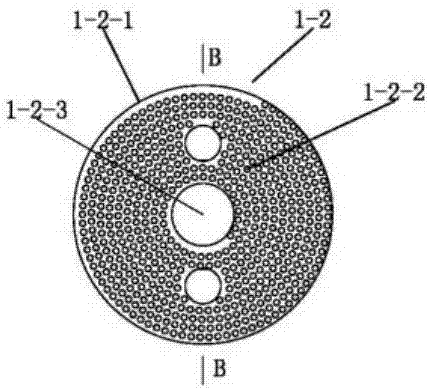

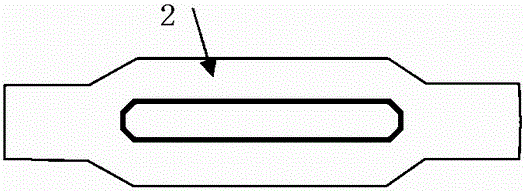

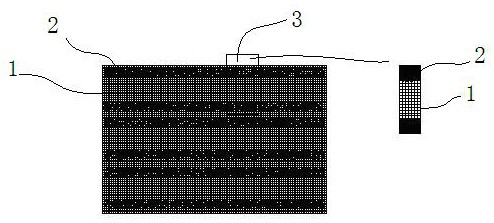

Tool clamp for screen mesh measuring sensor and using method

The invention discloses a tool clamp for a screen mesh measuring sensor. The tool clamp comprises a bottom plate, two clamping plates, clamping plate fixing devices, two positioning strips and tightening bolts; clamping grooves which are adjustable in depth and are the same as a circuit board of the screen mesh measuring sensor in thickness are formed in the surfaces of the clamping plates; the clamping plate fixing devices are used for fixedly connecting the clamping plates and the bottom plate, the two clamping plates are fixed in parallel, and the directions of the clamping grooves are opposite; the two positioning strips of sawtooth-shaped grooves are arranged at the positions in contact with to-be-welded metal wires of the screen mesh measuring sensor, and the distance between the adjacent sawtooth centers is the metal wire array to-be-controlled distance; and the tightening bolts are located on the clamping plates, used for tensioning the metal wires, used for determining the metal wire positions and used for adjusting the metal wire tightening force. The invention also discloses a using method based on the tool clamp. The tool clamp is simple and practical, the positions ofthe metal wires on a circuit board can be positioned with high accuracy, the pretightening force of the metal wire and the distance between the metal wire and a bonding pad can be adjusted, false welding and virtual welding are avoided, meanwhile, pre-winding and primary welding can be carried out, and manpower and welding time can be greatly saved.

Owner:SHANGHAI JIAO TONG UNIV

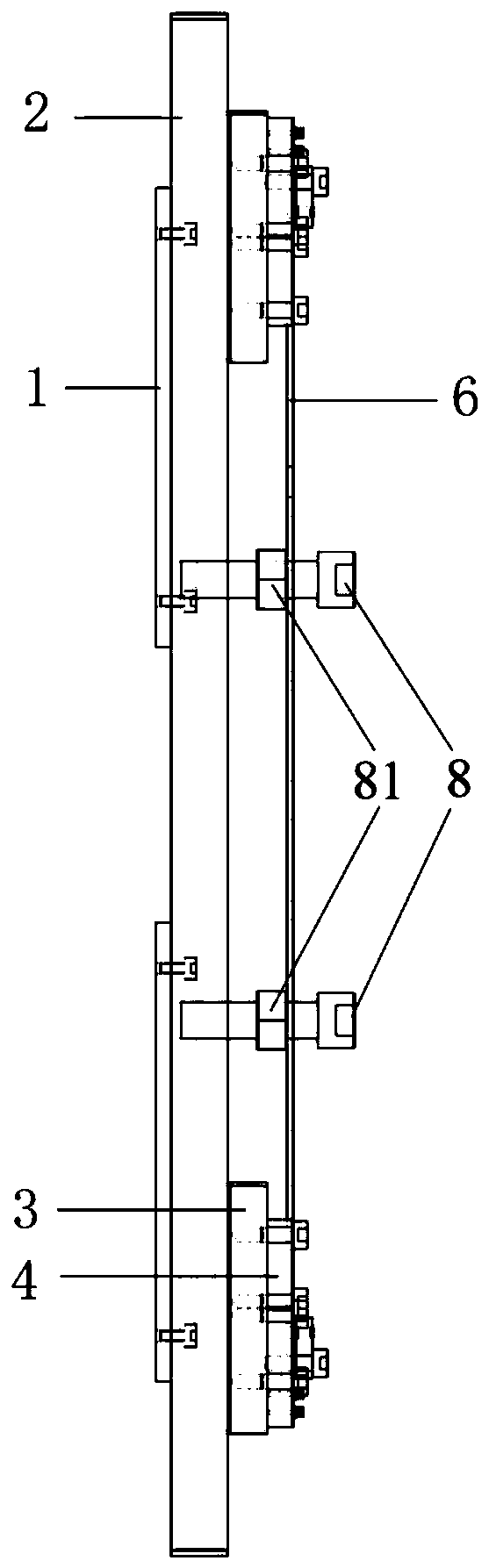

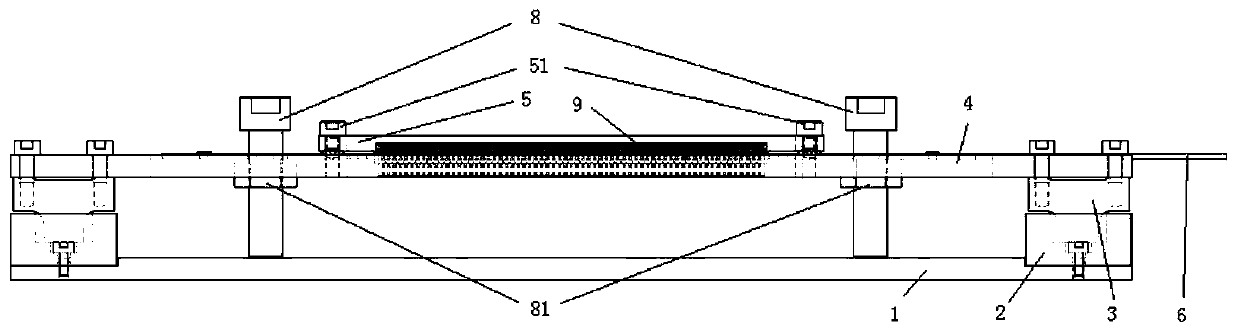

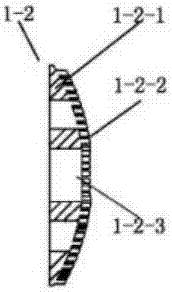

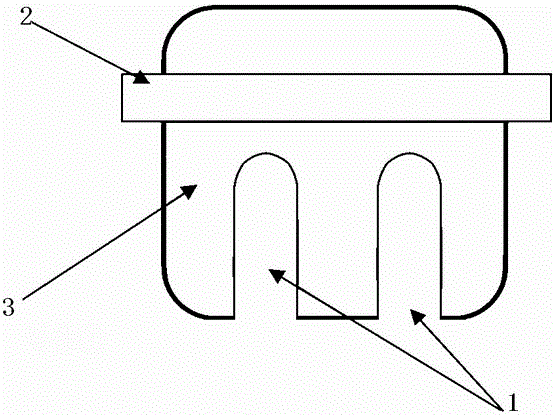

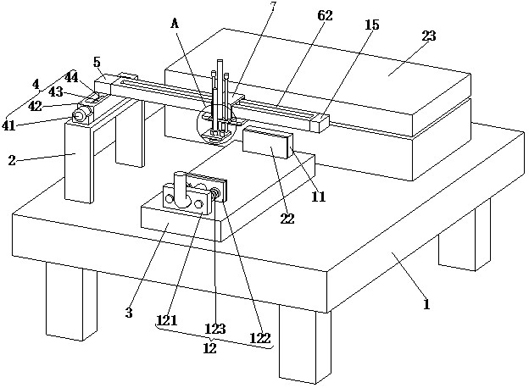

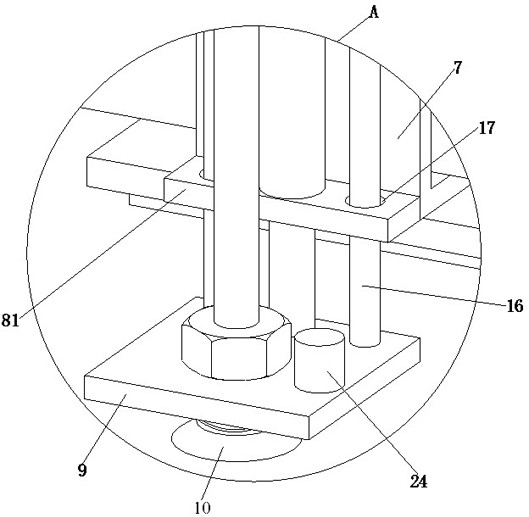

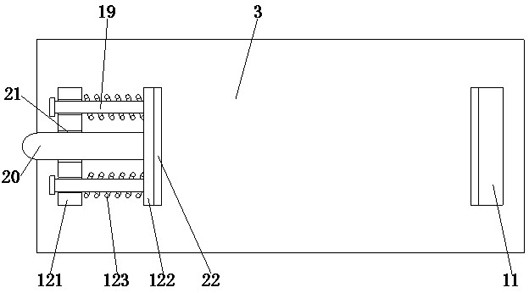

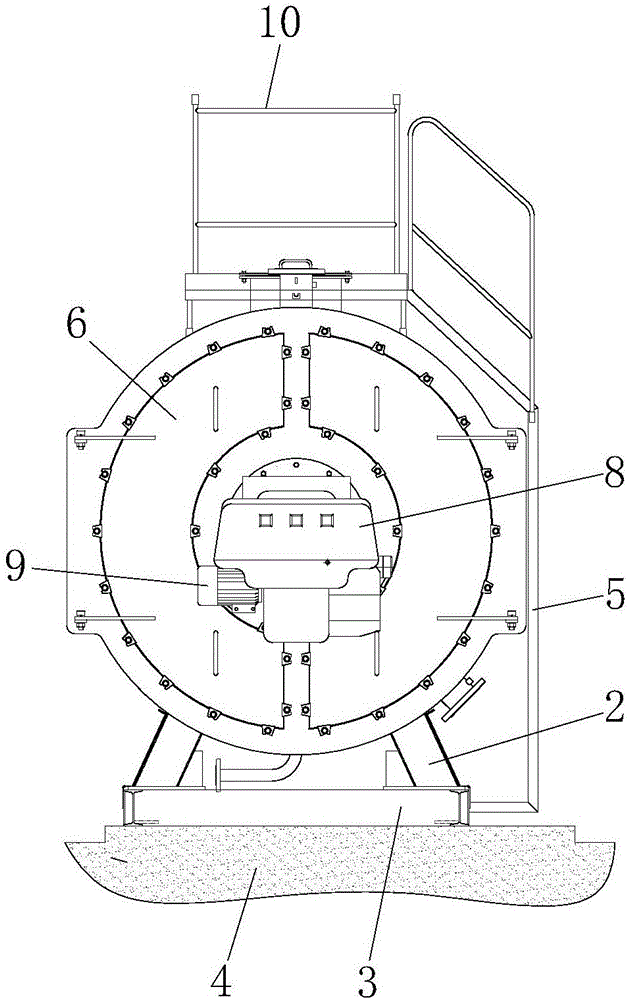

Water heater liner welding fixture used for spot welding positioning

ActiveCN104959773ACooperate accuratelyNot easy to shakeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a water heater liner welding fixture used for spot welding positioning, and belongs to the field of welding and positioning devices. The welding fixture comprises a support, clamping devices installed on two sides of the support and a supporting table located between the two clamping devices; the clamping devices are oppositely installed and comprise compressing components and centering components, the compressing components are internally provided with sliding rail connecting plates, and the sliding rail connecting plates are fixedly connected with a workbench; the centering components are slidingly connected with the compressing components, and the centering components arranged on two sides of the supporting table are controlled by the compressing components to carry out mutual clamping, and a top compressing device is arranged on the support to reduce welding gaps. According to the water heater liner welding fixture, by means of longitudinal compressing and transverse centering, the spot welding quality is improved, the welding efficiency is high, and the welding fixture is suitable for position spot welding of water heater liners with different sizes.

Owner:马鞍山粤美智造电子科技有限公司

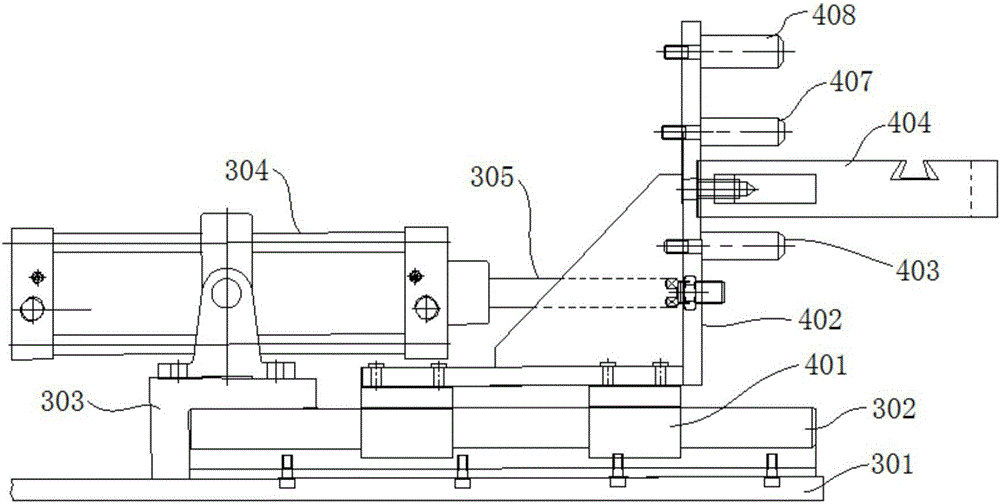

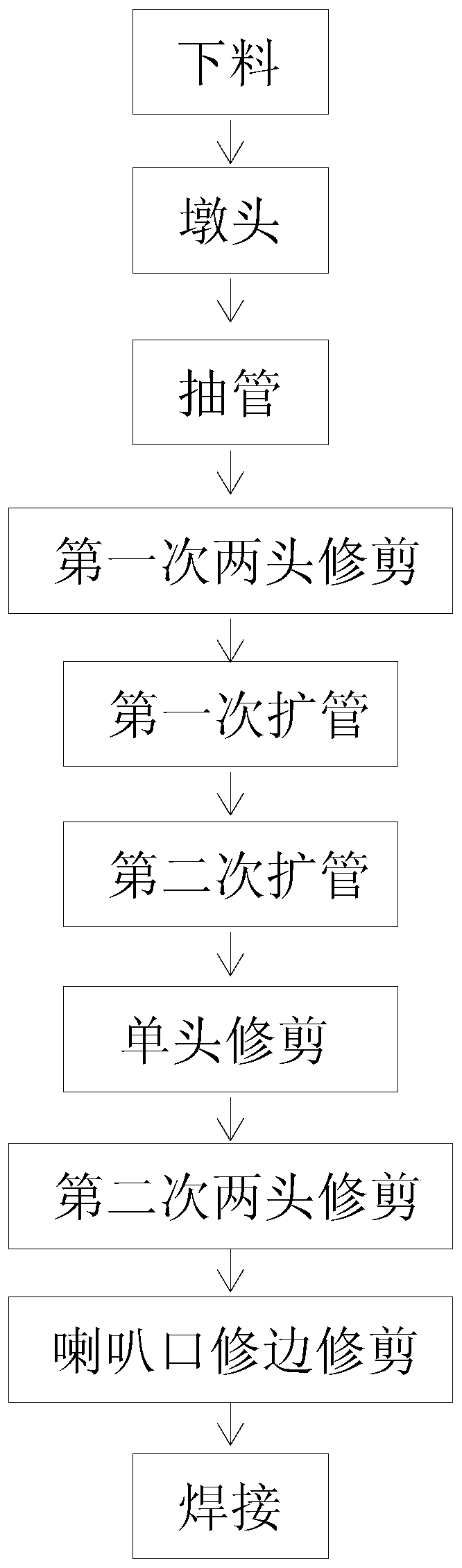

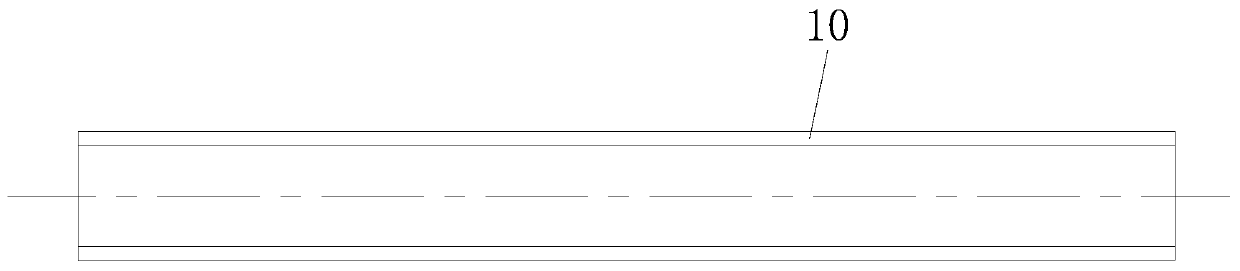

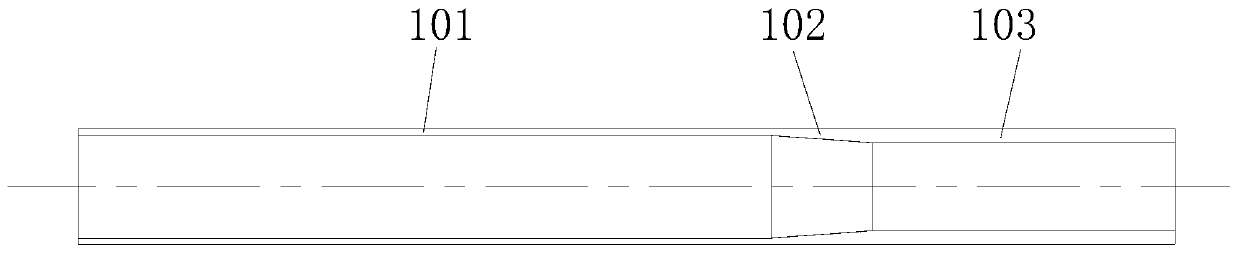

Manufacturing process and structure of pipe manufactured integrated horn sleeve front fork vertical pipe

PendingCN109967978ASolve the problem of false welding at the bottomSolve the problem of false weldingSteering deviceVertical tubeWelding

The invention discloses a manufacturing process and structure of a pipe manufactured integrated horn sleeve front fork vertical pipe. The process comprises the following steps of A, performing blanking; B, performing heading; C, performing pipe drawing; D, performing two-end trimming for the first time; E, performing pipe expanding for the first time; F, performing pipe expanding for the second time; G, performing one-end trimming; H, performing conical forming; I, performing two-end trimming for the second time; J, performing horn mouth edge-trimming and trimming; and K, performing welding. The manufacturing process has the beneficial effects that the problem of false welding between a sleeve and the bottom of the vertical tube is solved, and the potential safety hazard that falling off is prone to occurrence during riding is avoided.

Owner:李祝东

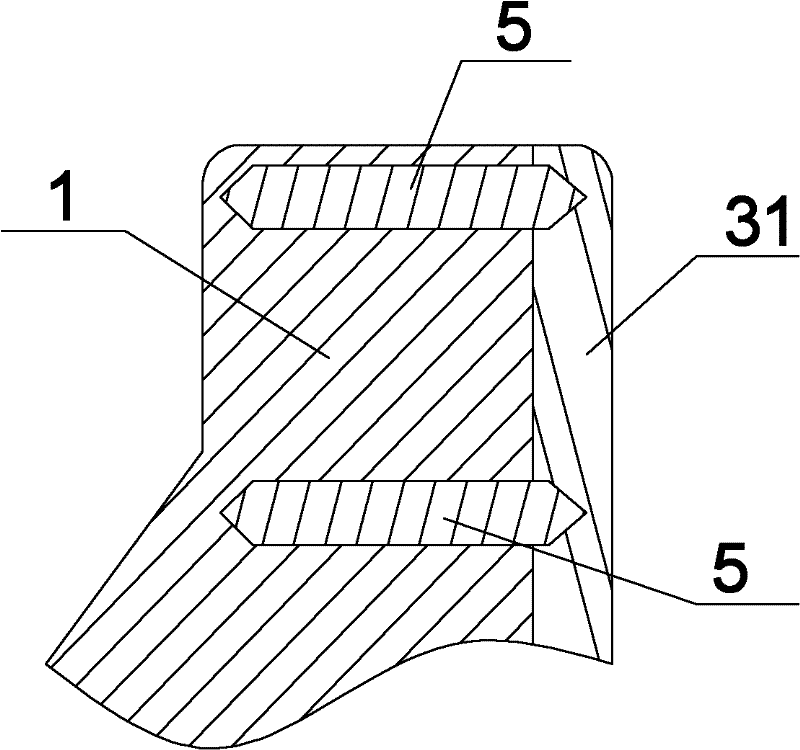

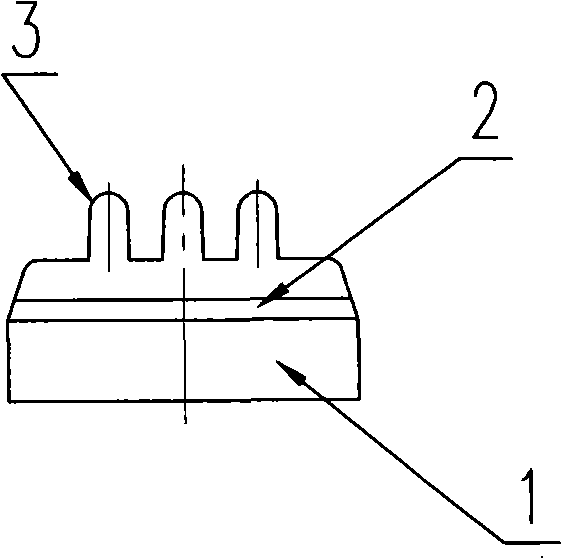

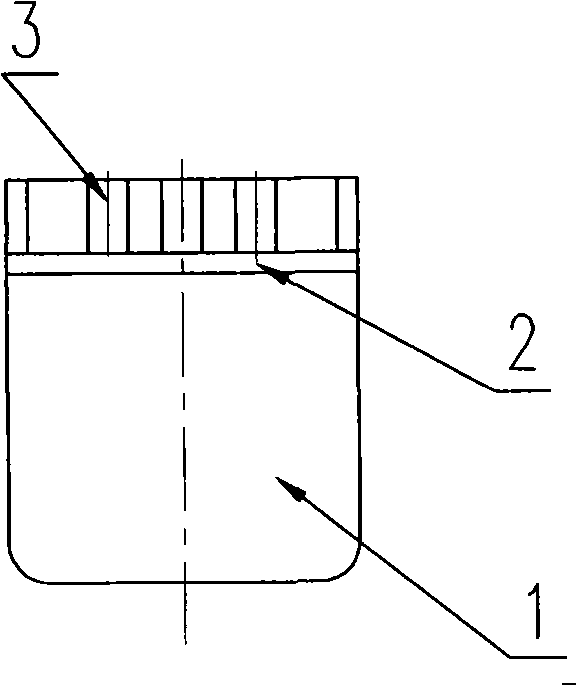

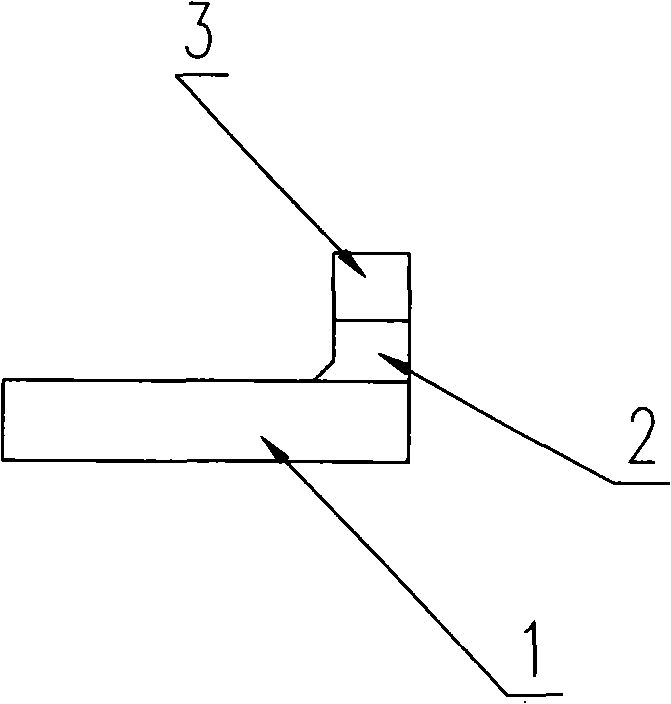

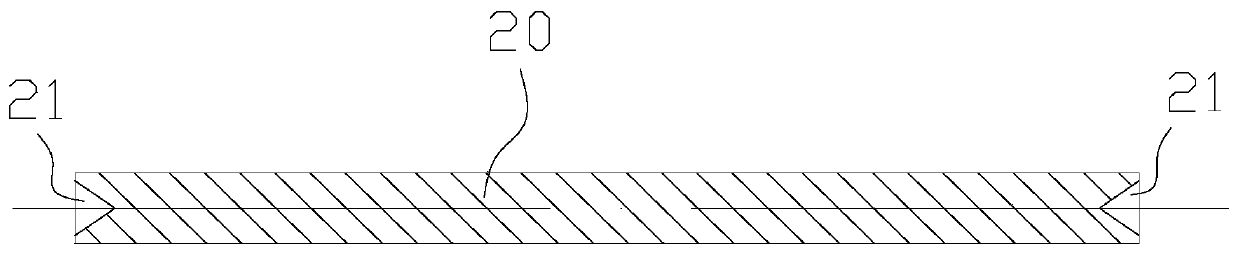

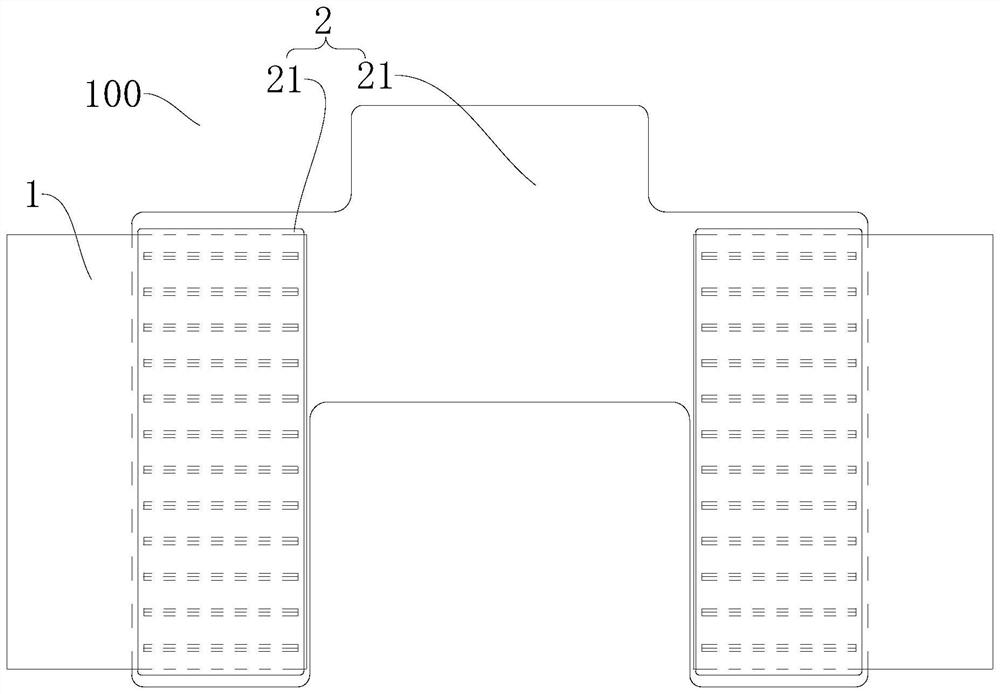

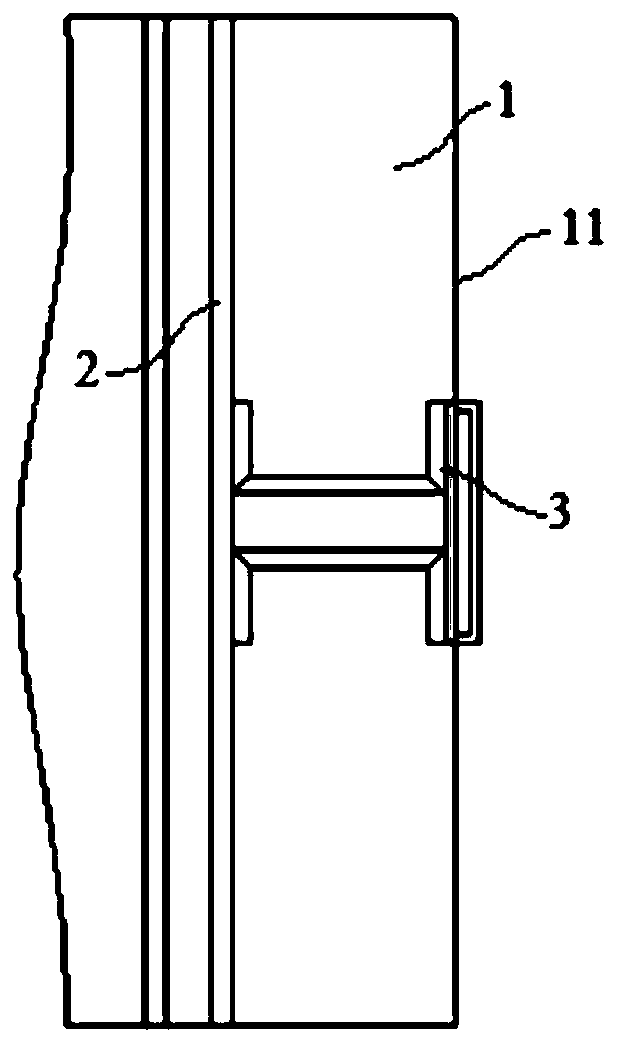

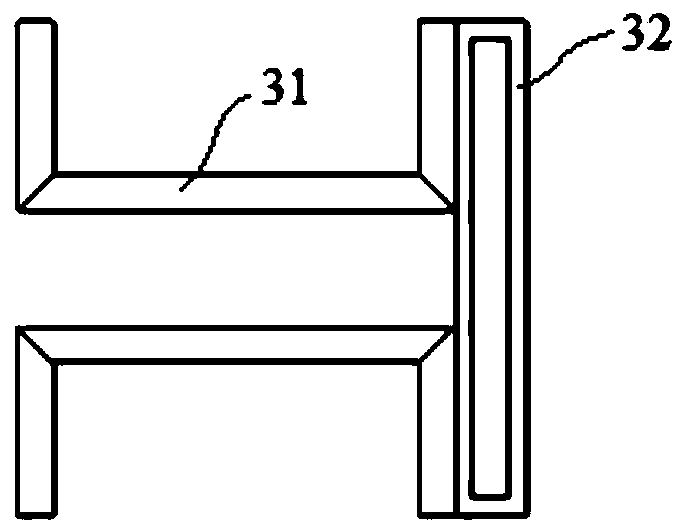

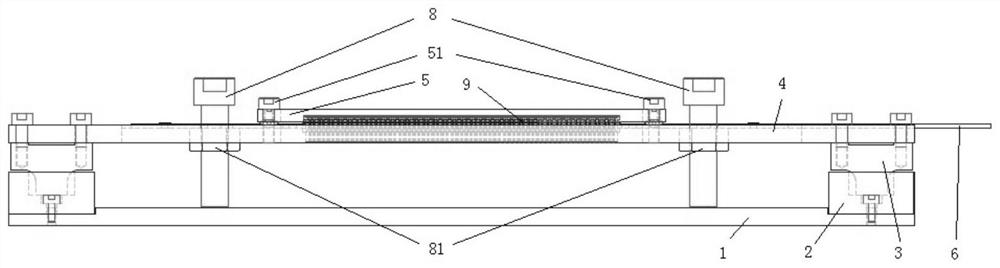

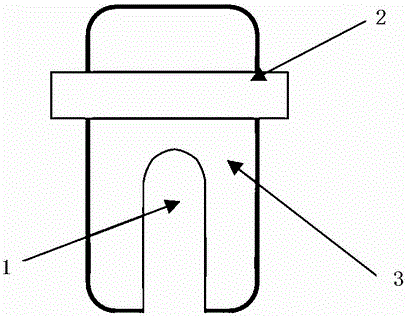

Comb type polar post for accumulator through-hole welding

InactiveCN101359730AReasonable structural designAvoid false weldingCell component detailsManufacturing technologySoldering

Disclose is a comb-shaped terminal post used in a through-wall welding of storage battery, belonging to the field of lead-acid storage battery manufacturing technology, which essentially comprises a terminal post conductive electrode (1), a short step (2) which is disposed on one end of the terminal post conductive electrode (1) and small comb-shaped teeth (3) which are arranged on the short step (2), and the like, wherein the number of teeth of the small comb-shaped teeth (3) is 3 to 6; and the using process is that as long as the comb-shaped terminal post is placed on the welding mold (5), the small comb-shaped teeth (3) which are disposed at the bottom thereof are melted together with the plate lugs (4) of the polar plate so as to form a cylinder manifold. The overall structure is rational in design, so that the comb-shaped terminal post can be firmly combined together with the cylinder manifold by making use of the small comb teeth part of the terminal post without affecting the designed size of the battery, so as to improve the performance of the storage battery; and false soldering and inveracious soldering of the terminal post can be effectively prevented, so as to improve the high current discharge capacity of the storage battery and extend the service life of the battery.

Owner:WOLONG ELECTRIC GRP CO LTD +1

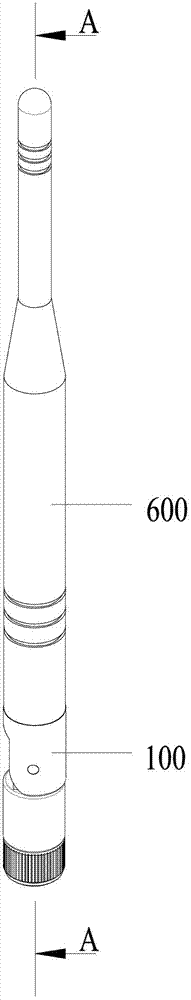

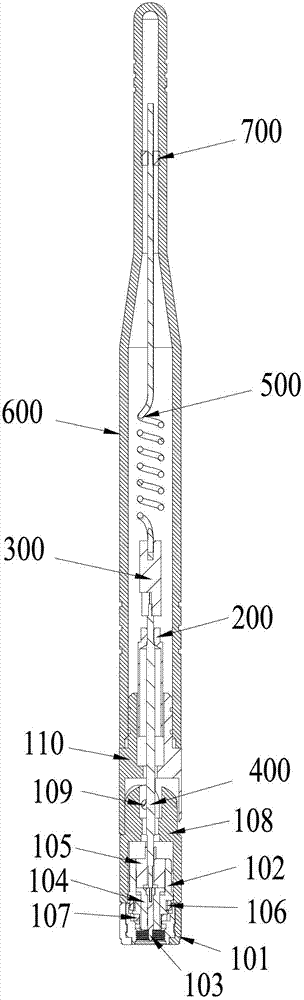

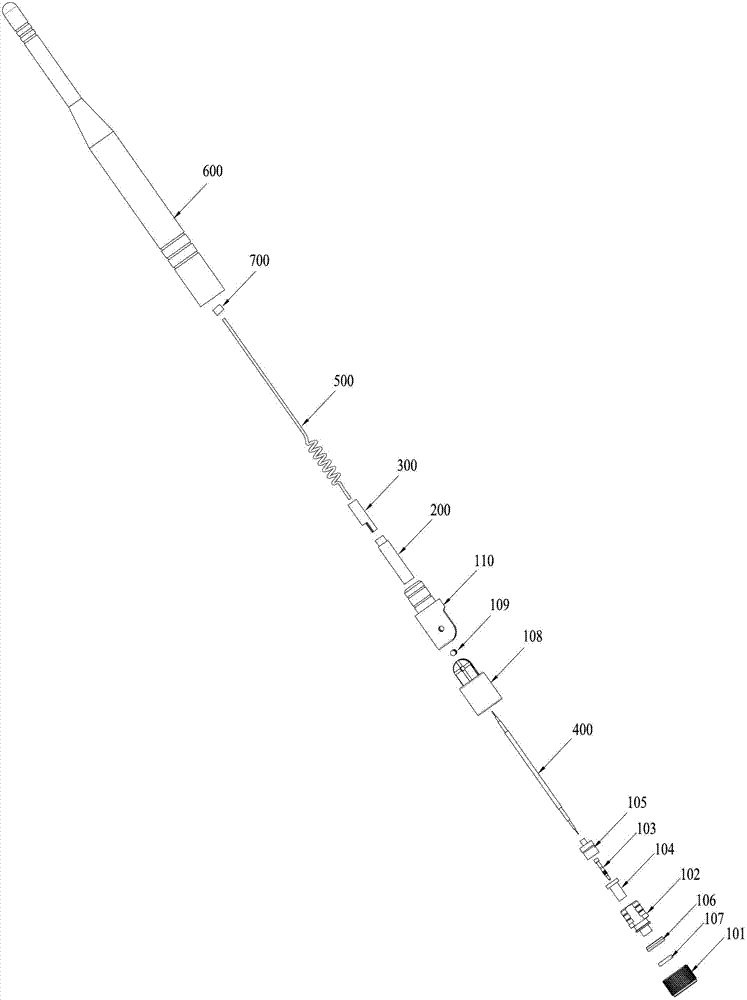

Dipole antenna

ActiveCN102856625AImprove qualityEasy to controlAntenna supports/mountingsRadiating elements structural formsDipole antennaMetal

The invention discloses a dipole antenna, which comprises a connector, a metal pole, a wire, a coil, a sheath and a metal tube which is embedded on the connector in a matching way. The wire comprises a signal wire and a shielding wire, wherein the shielding wire of the wire penetrates through the metal tube and is connected with the metal tube, the axial center of one end of the metal pole is provided with a stepping surface, the axial center of the stepping surface is provided with a first through hole, the signal wire of the wire is welded in the through hole, the axial center of the other end of the metal pole is provided with a second through hole, and the coil is riveted in the second through hole of the metal pole; and the coil, the metal pole, the metal tube and the wire are sleeved in the sheath, the sheath is fixedly connected with the connector, and a fixing plug is arranged between the coil and the sheath. The dipole antenna has the advantages that the frequency and signal of transmission are stable, and the product quality can be improved.

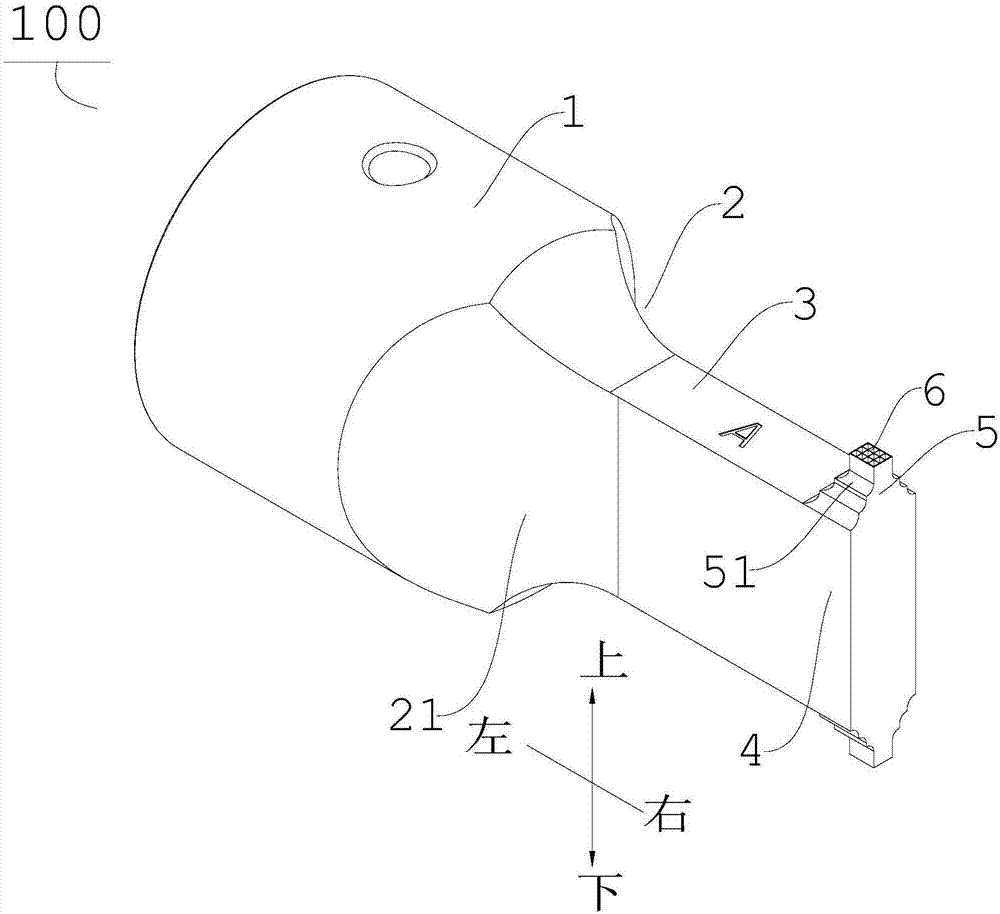

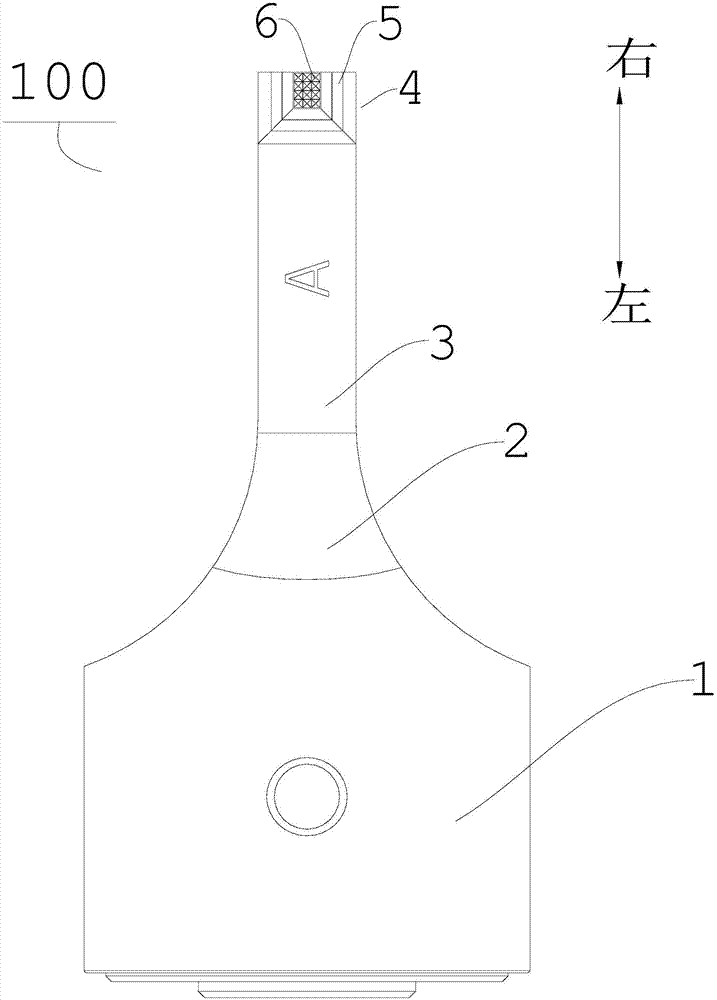

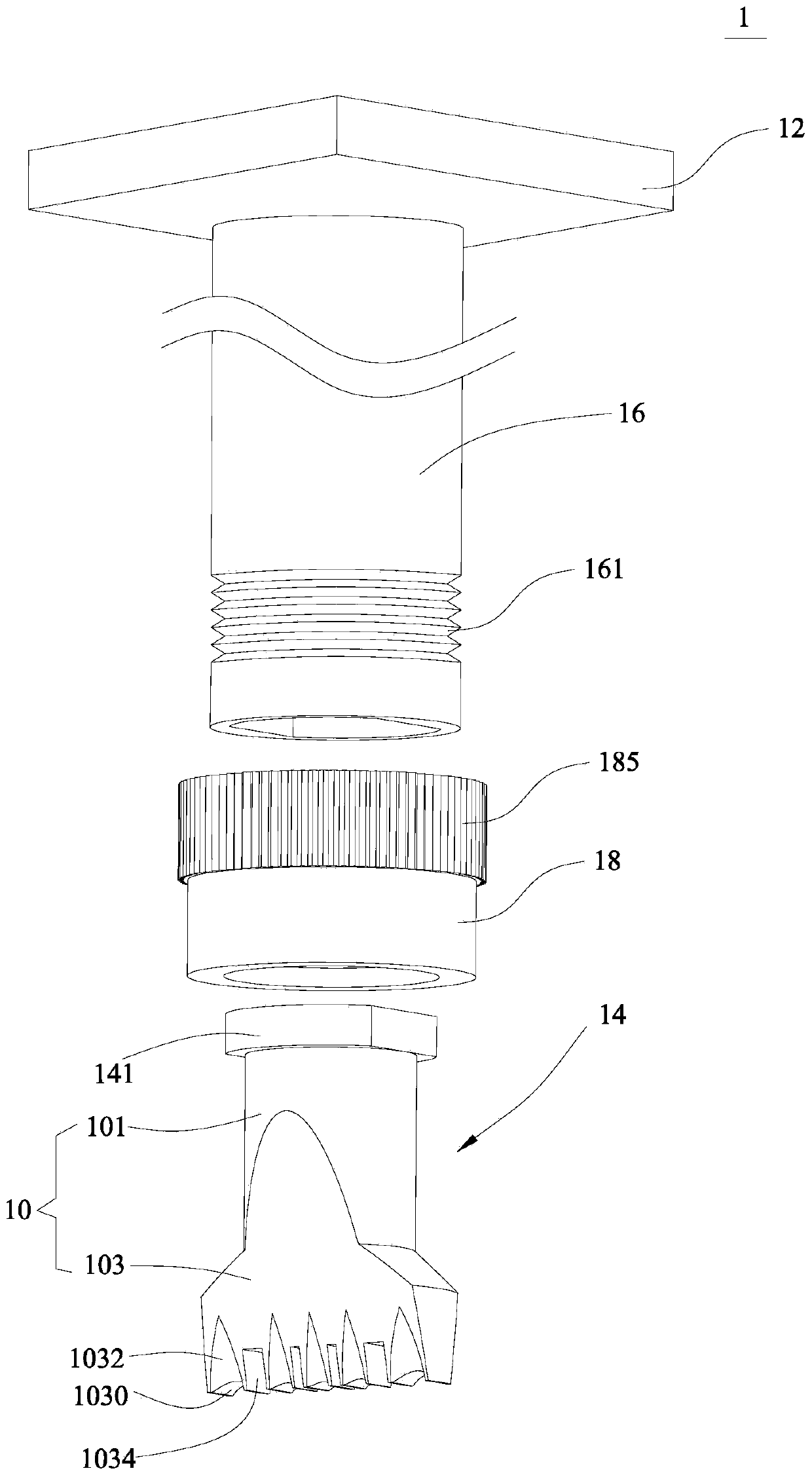

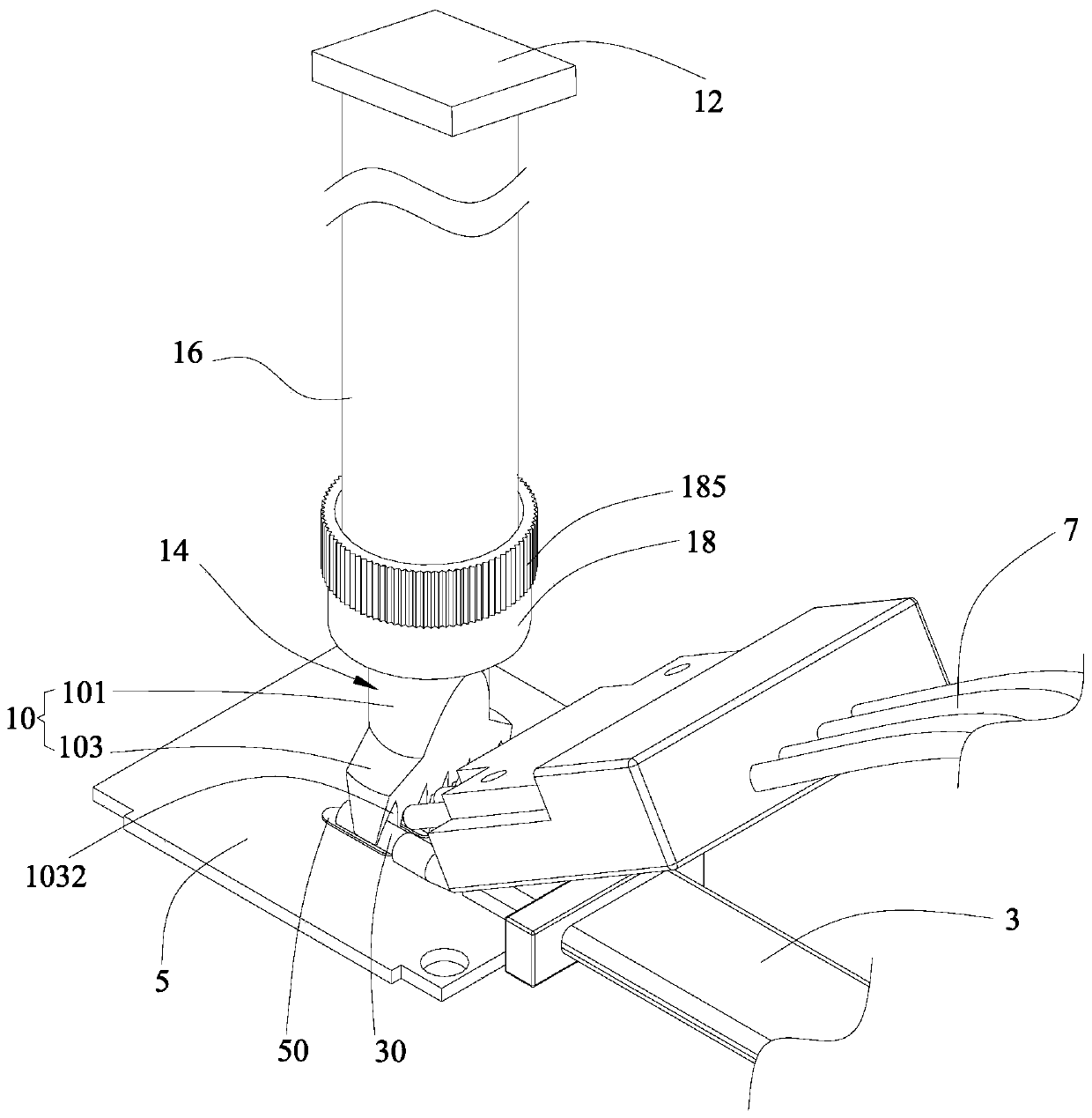

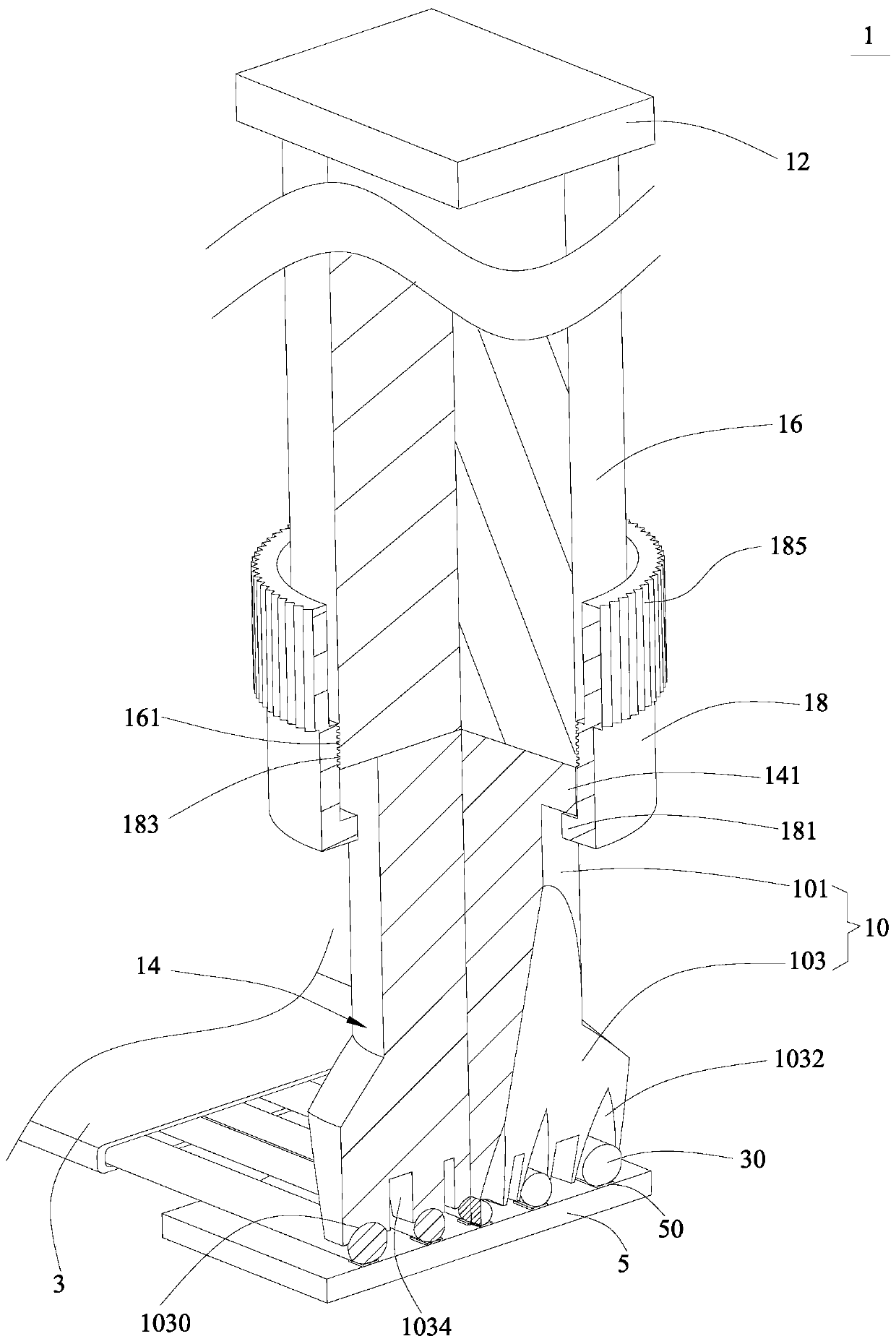

Ultrasonic welding head

ActiveCN107511581AExtend your lifeReduce energy lossNon-electric welding apparatusUltrasonic weldingEnergy loss

The invention discloses an ultrasonic welding head. The ultrasonic welding head comprises a handle, a variable arc rod, a swinging arc rod, a reducing part and welding teeth, wherein the variable arc rod is connected to one end of the handle, and the cross-sectional area of the variable arc rod is less than that of the handle; the swinging arc rod is connected to one end, which is far from the handle, of the variable arc rod, and the cross section of the swinging arc rod is approximately in a rectangular shape; the reducing part is arranged on at least one side surface of the swinging arc rod, in the direction from the free end of the reducing part to the swinging arc rod, the cross-sectional area of the reducing part is gradually increased, and one side surface, which is far from the handle, of the reducing part is flush with the end surface of the free end of the swinging arc rod; and the welding teeth are arranged on the end surface of the free end of the reducing part. According to the ultrasonic welding head, the reducing part is arranged, so that energy loss during ultrasonic welding can be reduced, the service life of the ultrasonic welding head is prolonged, and bad defects of false welding, over welding and the like when products are welded are avoided.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

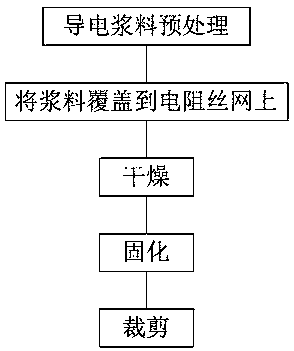

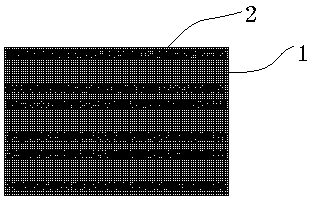

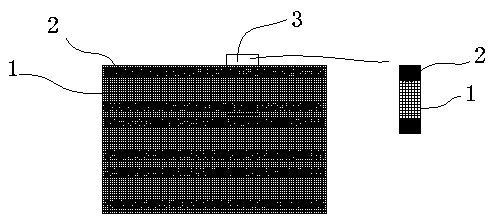

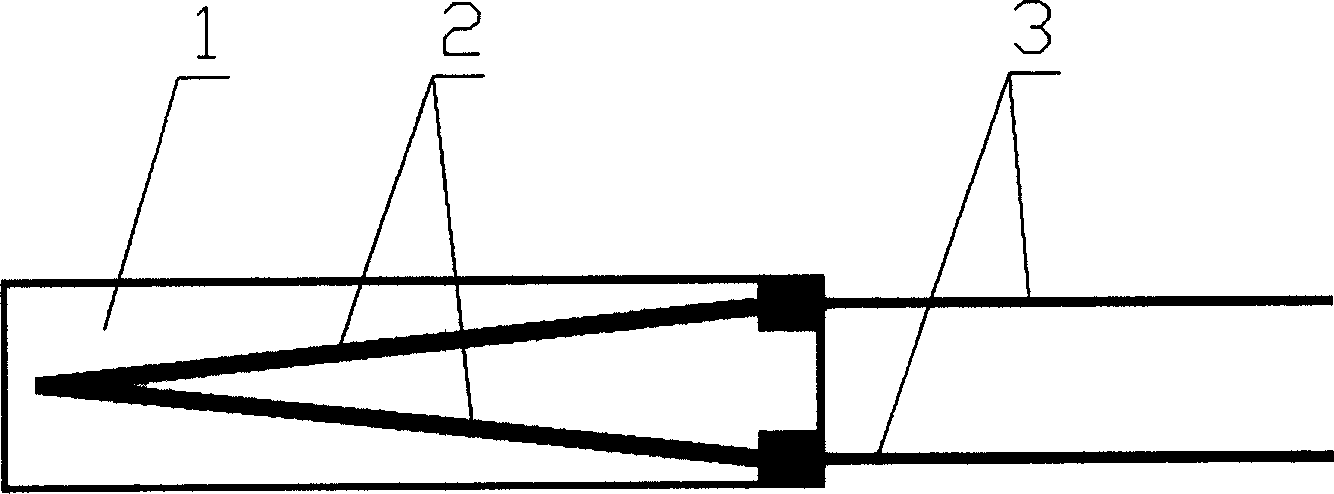

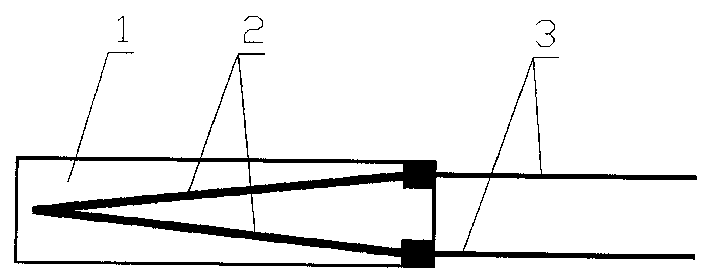

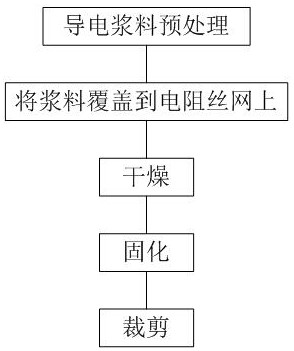

Preparation method of netty heating body for electronic cigarette

ActiveCN109348548AAvoid false weldingIncrease productivityOhmic-resistance electrodesTobacco devicesElectronic cigaretteSlurry

The invention relates to a preparation method of a netty heating body for an electronic cigarette. Firstly, a resistance wire is woven into a resistance wire net, and then an electrode is prepared onthe resistance wire net; and the electrode is prepared on the resistance wire net by covering the resistance wire net with conductive slurry. The method comprises a step of pre-treating the conductiveslurry, a step of covering the resistance wire net with the conductive slurry, a step of drying, a step of curing and a step of cutting. For the defects of an existing netty heating body preparationprocess, the invention provides the preparation method of the netty heating body for the electronic cigarette, which is simple in preparation process, high in stability and low in cost and is suitablefor industrial production.

Owner:ALD GRP

Heating head capable of detecting hot-melting piece and heater

PendingCN107580382AEasy to find the correct positionAvoid missing solderInduction heating apparatusType metalElectromagnetic induction

The invention discloses a heating head capable of detecting a hot-melting piece. The heating head is provided with at least one hot-melting piece detector. The hot-melting piece detectors are metal detectors. The metal detectors are electro-magnetic inducted metal detectors or X-ray detection type metal detectors or ultrasonic detection type metal detectors. The hot-melting piece detectors are cylindrical. The number of the hot-melting piece detectors is four. The four hot-melting piece detectors are distributed on the side face of the heating head. The distribution shape of the four hot-melting piece detectors is rectangular. The detection heads of the hot-melting piece detectors are fixedly connected with the heating head through fixing racks. The hot-melting piece detectors are identical to the heating head in orientation. A heater comprises a heating head, wherein the heating head is the heating head capable of detecting the hot-melting piece. The correct position of the hot-melting piece is easy to find, and caused solder skips, false solder and solder deviations are avoided.

Owner:高雄

A water heater liner welding tool for spot welding positioning

ActiveCN104959773BCooperate accuratelyNot easy to shakeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a water heater liner welding fixture used for spot welding positioning, and belongs to the field of welding and positioning devices. The welding fixture comprises a support, clamping devices installed on two sides of the support and a supporting table located between the two clamping devices; the clamping devices are oppositely installed and comprise compressing components and centering components, the compressing components are internally provided with sliding rail connecting plates, and the sliding rail connecting plates are fixedly connected with a workbench; the centering components are slidingly connected with the compressing components, and the centering components arranged on two sides of the supporting table are controlled by the compressing components to carry out mutual clamping, and a top compressing device is arranged on the support to reduce welding gaps. According to the water heater liner welding fixture, by means of longitudinal compressing and transverse centering, the spot welding quality is improved, the welding efficiency is high, and the welding fixture is suitable for position spot welding of water heater liners with different sizes.

Owner:马鞍山粤美智造电子科技有限公司

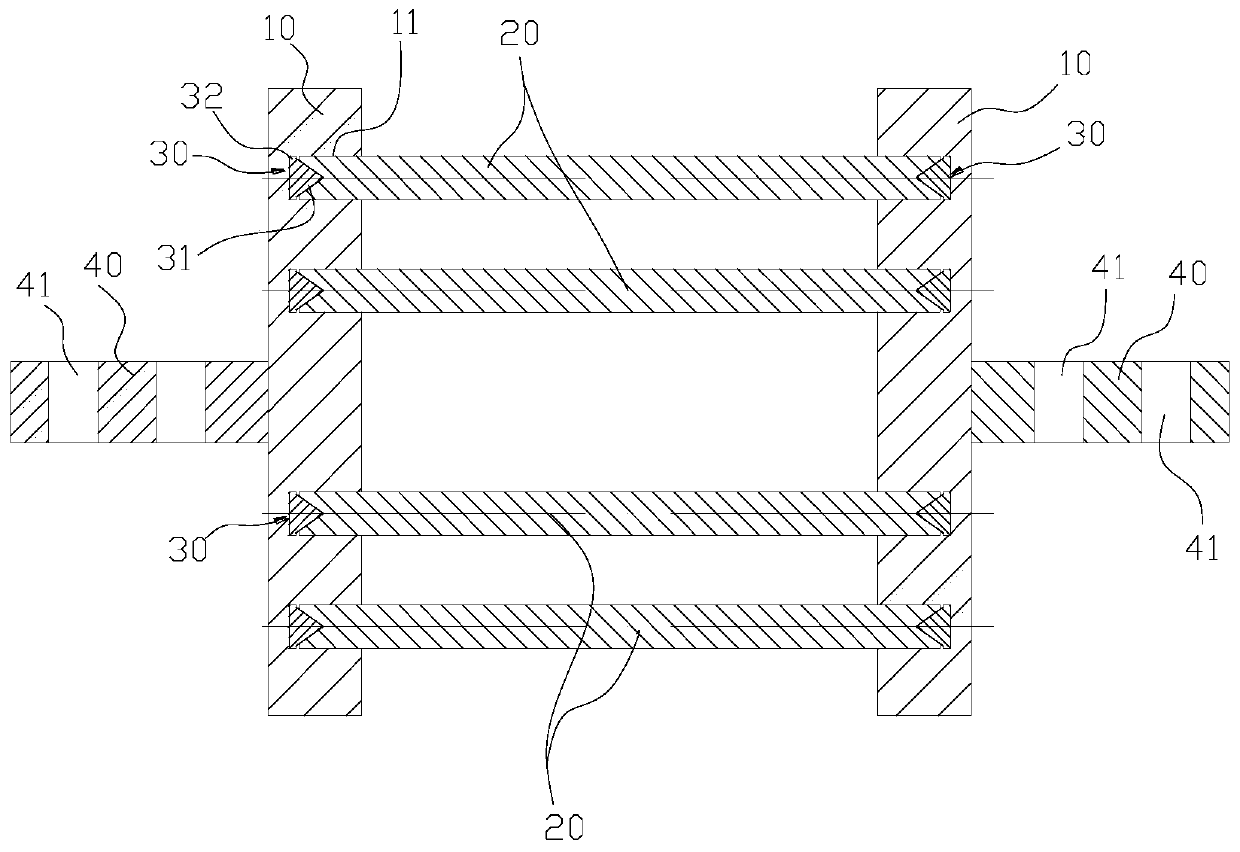

Shunt and manufacturing method thereof

ActiveCN110034418AQuick connectionFirmly connectedContact member manufacturingRiveted connectionsEngineeringRivet

The invention discloses a shunt and a manufacturing method thereof. The shunt comprises plate-shaped wiring terminals, resistance rods and rivets, wherein the two plate-shaped wiring terminals are oppositely arranged; the two plate-shaped wiring terminals are provided with insertion holes in matrix arrangement, and the insertion holes are blind holes formed in the inner side plate surfaces of theplate-shaped wiring terminals; the multiple resistance rods are in one-to-one correspondence with the insertion holes, wherein the two ends of each resistance rod are provided with mortise holes respectively, and the mortise holes are conical; each rivet comprises a head part and a cap part, wherein the head part of the rivet extends into the corresponding mortise hole; and the two ends of each resistance rod are pressed into corresponding insertion holes of the two plate-shaped wiring terminals respectively, so that the tail part of the rivet is extruded by the hole bottom of the corresponding insertion hole.

Owner:陈敏

A welding device for avoiding false soldering and poor contact during circuit board soldering

ActiveCN111246681BTransport moreAvoid false weldingPrinted circuit assemblingSolder feeding devicesHand partsContact failure

The invention discloses a welding device for avoiding false soldering and poor contact when soldering a circuit board. The delivery point, the thermal melting point of the tin bar, and the contact point with the circuit board move synchronously among the three points, avoiding the change of the distance between the contact iron and the circuit board when the force exerted by the hand cannot maintain a stable value. As a result, poor contact occurs. At the same time, the tin bar is conveyed in an active and uniform manner to avoid the false soldering phenomenon of connecting multiple soldering points together when the tin bar is transported too much. In addition, freeing one hand can facilitate the use of other auxiliary tools. , the operation is more convenient.

Owner:秦皇岛通宝光电科技有限公司

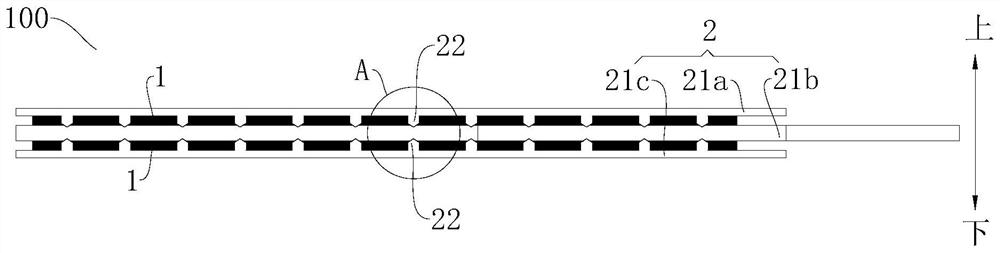

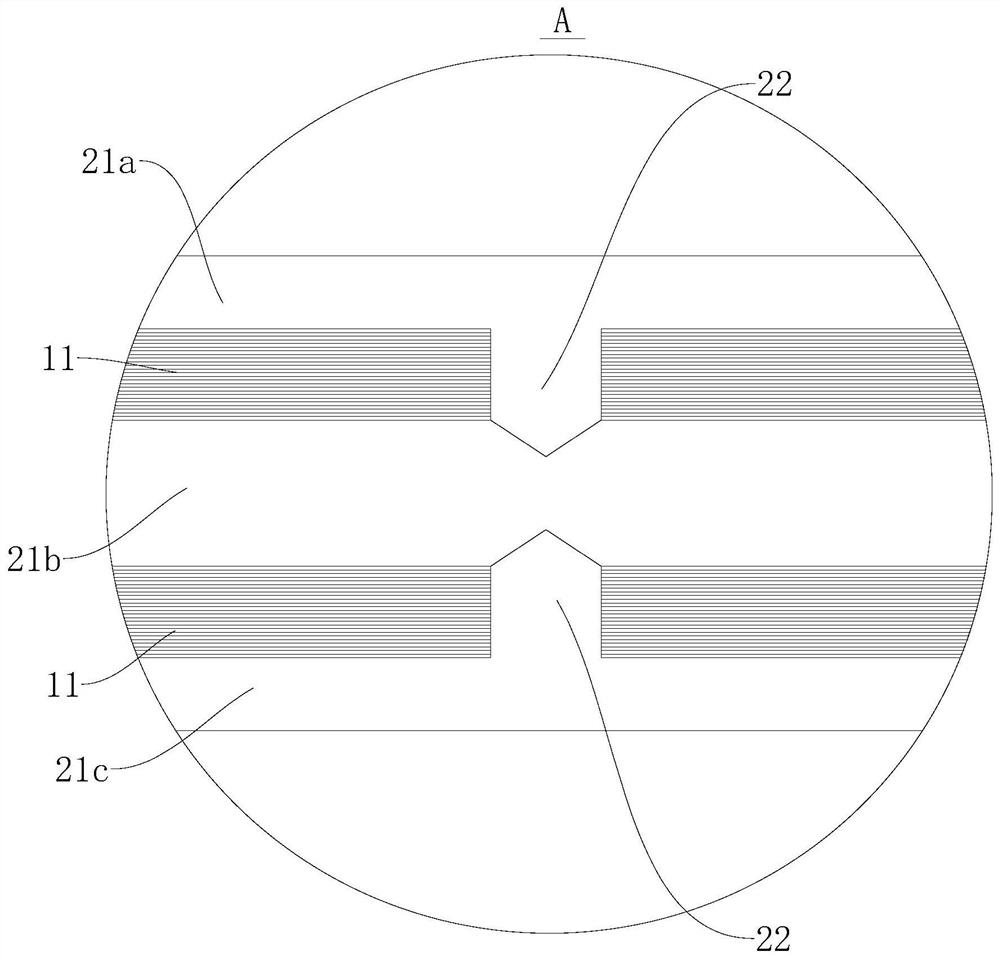

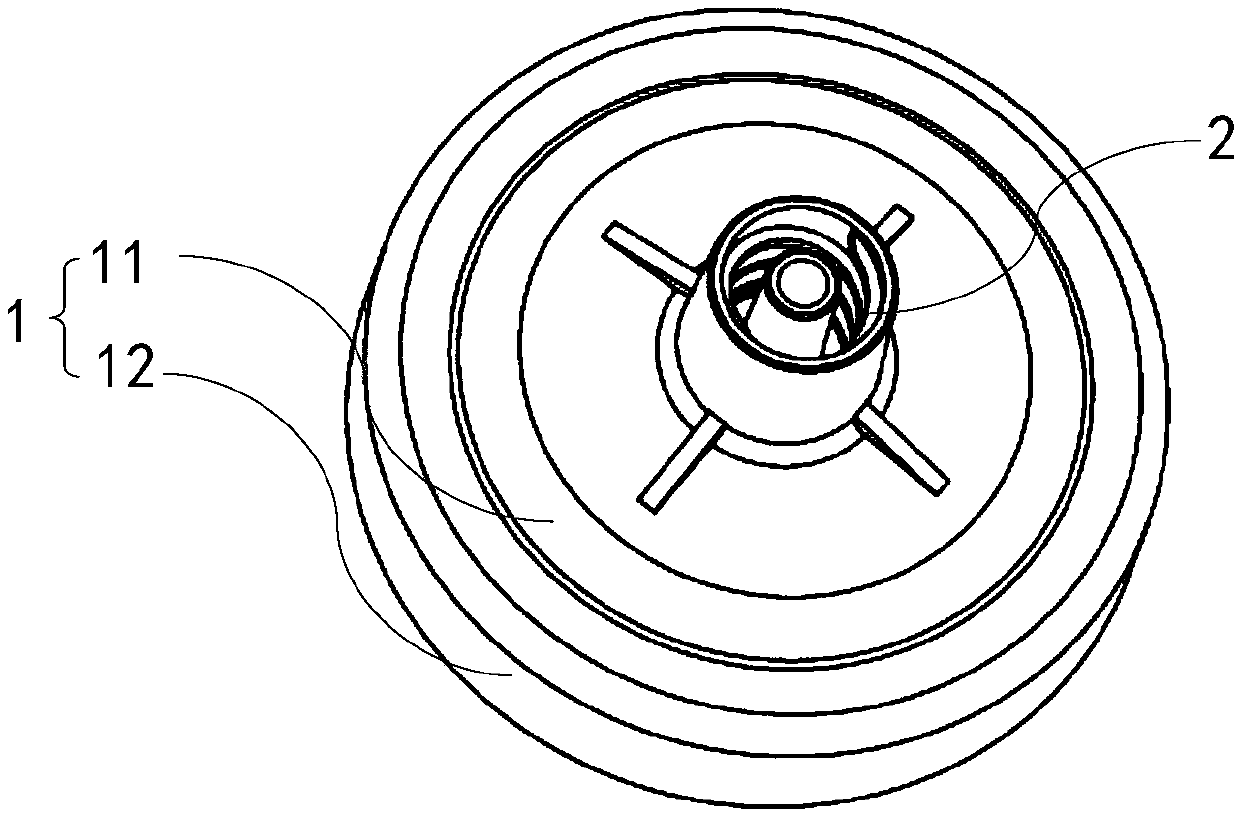

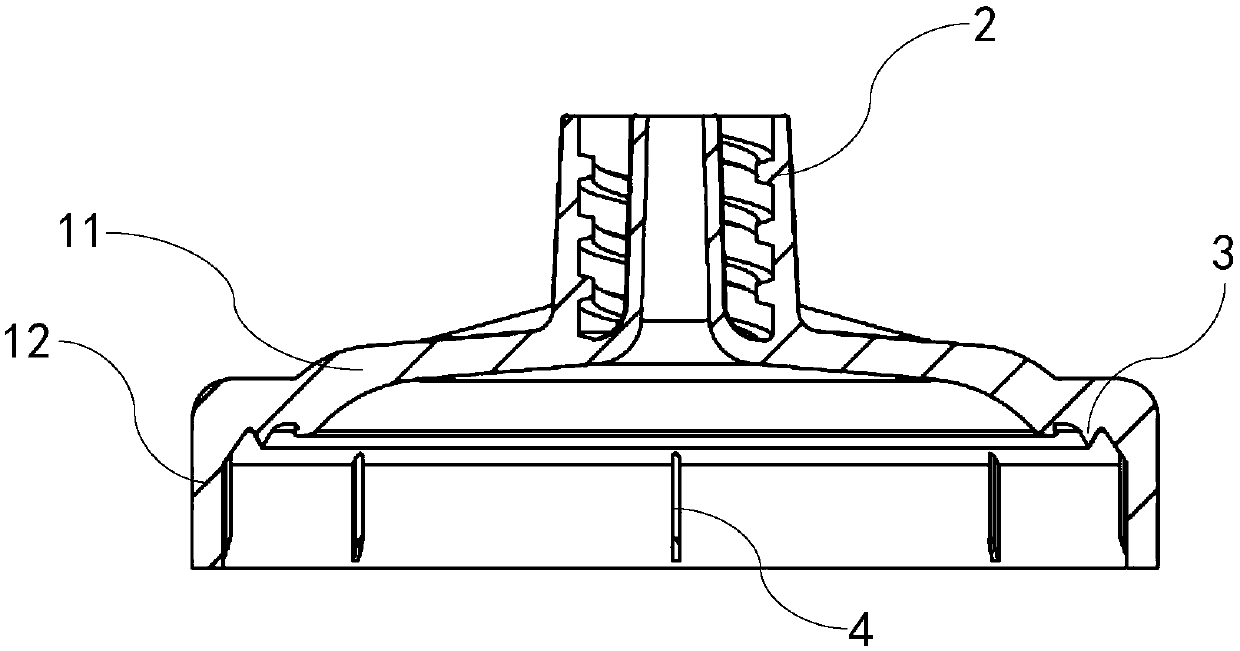

Current collector assembly, battery cell and battery pack

PendingCN113422162AReduce thicknessSimplifies electrical connectionsElectrode carriers/collectorsCell component detailsElectrical connectionSoldering

The invention discloses a current collector assembly, a battery cell and a battery pack. The current collector assembly comprises at least two tab groups, wherein each tab group comprising a plurality of tabs arranged in a stacked manner; a conductive connection component which comprises at least three conductive connection sheets, wherein the at least three conductive connection sheets are arranged at intervals in the thickness direction of the conductive connection sheets, and one tab group is stacked between every two adjacent conductive connection sheets; and at least one of the two adjacent conductive connecting sheets is electrically connected with each tab in the tab group. According to the current collector assembly provided by the embodiment of the invention, the welding difficulty of the conductive connecting sheet and the tab group can be reduced, false soldering or pseudo soldering is avoided, the welding effect is ensured, and the overcurrent capability of current is improved.

Owner:XIAMEN HAICHEN NEW ENERGY TECH CO LTD

Dialyzer end cover and welding technology thereof

The invention discloses a dialyzer end cover. The dialyzer end cover comprises a cover body, wherein a cover mouth for a Luer interface is arranged on the cover body in a manner of extending upwards from the cover body; the cover body comprises a cover top and a cover wall, wherein a cavity is formed between the cover top and the cover wall; the cover mouth is connected to the cover top and communicates with the cover top; and an annular welding line which has the same axis as the cover top is arranged on one side close to the cover wall, of the inner surface of the cover top, the width of thewelding line is 0.7-0.8mm, and the width of the welding line is 0.5-1.0mm. The invention also provides a welding technology. The welding technology comprises a welding technology of the dialyzer endcover. The welding technology of the dialyzer end cover comprises the following steps of step 1, enabling the dialyzer end cover and a dialyzer body to be in cooperation and alignment; and step 2, performing welding work on the dialyzer end cover by an ultrasonic welding head, the welding depth is 0.8mm, the amplitude is maintained to be 85%, the pressure maintaining time is 2 seconds, the weldingtime is 0.3-0.8 seconds, and the output energy is 300-700 Joule. According to the dialyzer end cover and the welding technology thereof disclosed by the invention, the welding intensity between the dialyzer end cover and the dialyzer body is improved, and side leakage is avoided.

Owner:贝恩医疗设备(广州)有限公司

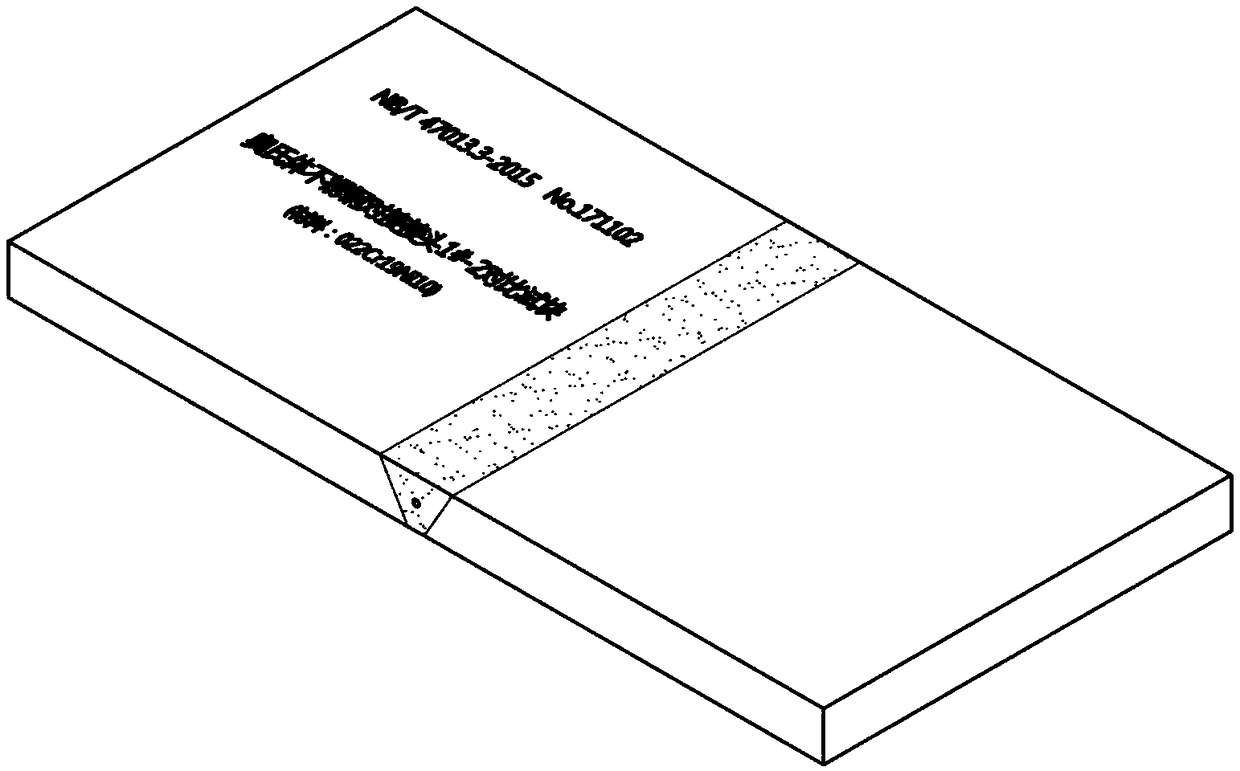

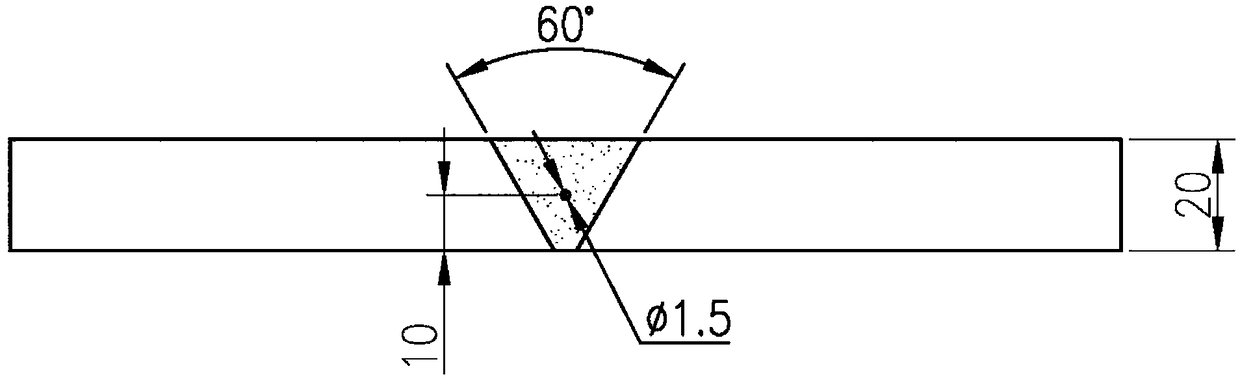

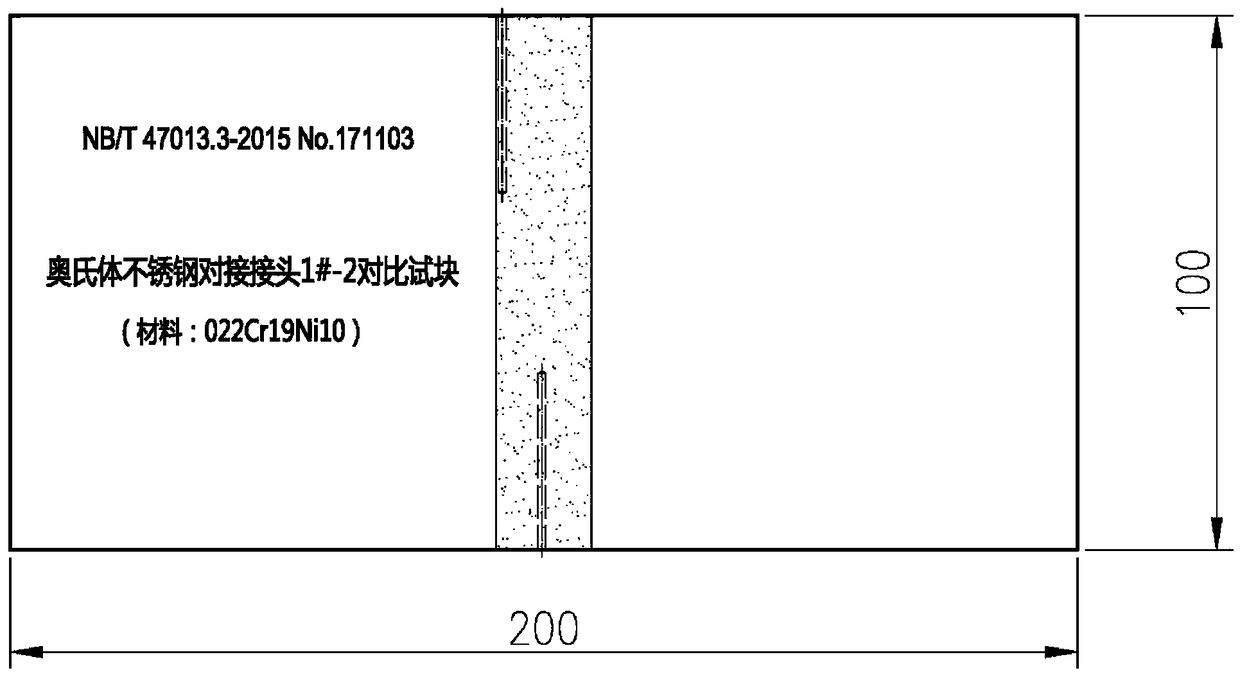

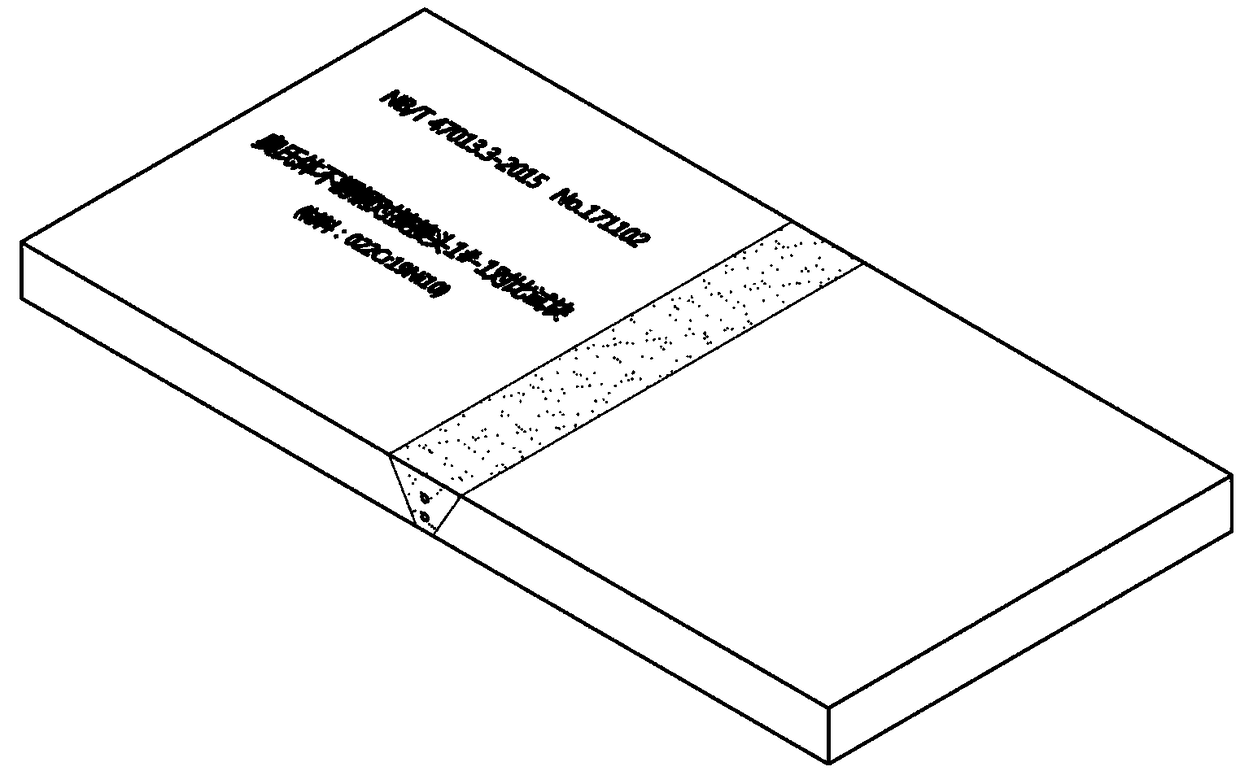

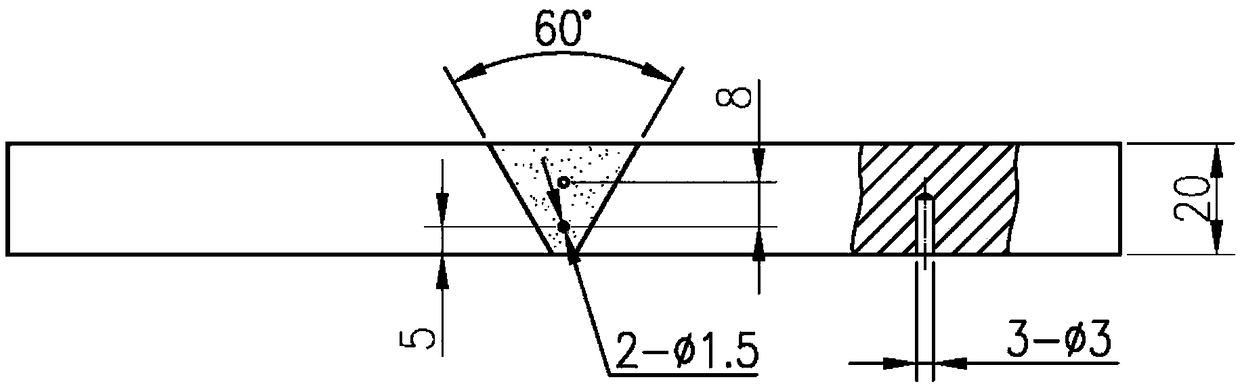

Heavy water reactor spent fuel basket welding center column butt joint welding 1#-2 comparison test block

The invention belongs to the technical field of spent fuel transmission of nuclear power plants, in particular to a heavy water reactor spent fuel basket welding center column butt joint welding 1#-2comparison test block. The purpose is to research and develop a set of heavy water reactor spent fuel basket welding center column butt joint 1#-2 comparison test block so that the welding quality ofa fuel basket can be ensured to be verified, safety and reliability in the hoisting process of the fuel basket can be ensured to be achieved, and the existence of the risk of occurrence of falling inthe hoisting process due to the problem of the welding quality of a center column can be effectively avoided. The heavy water reactor spent fuel basket welding center column butt joint welding 1#-2 comparison test block is characterized by being in a cuboid shape integrally, a first detection hole is formed in the center of the front end face of the test block, a second detection hole is formed inthe left side of the center of the rear end face of the test block, and the detection holes are used for simulating the defects existing in the weld joint. According to the described center column butt joint 1#-2 comparison test block, the effects of being safe and reliable are achieved, the use is convenient, the stability is high, the economic benefit is high, the welding quality of the centercolumn of the fuel basket is ensured, and the problem of the center column of the fuel basket is avoided.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Pipe gallery underground excavation primary lining plastic waterproof plate fixing device and waterproof plate laying method

PendingCN111502709AImprove construction qualityGuaranteed firmnessUnderground chambersTunnel liningArchitectural engineeringPipe

The invention discloses a pipe gallery underground excavation primary lining plastic waterproof plate fixing device and a waterproof plate laying method, and belongs to the technical field of buildingconstruction. The pipe gallery underground excavation primary lining plastic waterproof plate fixing device comprises an embedded device, a fixing base plate and a plastic waterproof plate, wherein one end of the embedded device is welded and fixed to a grating steel arch frame in an underground excavation primary lining, the other end of the embedded device is provided with the fixing base plate, and the plastic waterproof plate is pasted and fixed through the fixing base plate. The invention further provides a laying method of the pipe gallery underground excavation primary lining plastic waterproof plate, and the fixing device is adopted for laying the waterproof plate. By the adoption of the technical scheme, the phenomena that in a traditional method, the waterproof plate is missed in welding, penetrated in welding and infirm in welding in the laying process can be effectively avoided, the firmness of installation and fixation of the plastic waterproof plate is guaranteed, and the construction quality of the pipe gallery waterproof plate and the durability of a concrete structure are improved.

Owner:CHINA MCC17 GRP

Tooling and fixture for wire mesh measuring sensor and usage method

ActiveCN110340483BAccurate placementImprove accuracySoldering auxillary devicesStructural engineeringContact position

The invention discloses a tooling fixture for a wire mesh measuring sensor, which comprises a bottom plate; two splints, the splint surface has a slot whose depth can be adjusted to be the same as the thickness of the circuit board of the wire mesh measuring sensor; it is used for fixing the splint and The splint fixing device of the bottom plate, and the two splints are fixed in parallel and the direction of the slot is opposite; the position that is in contact with the wire to be welded of the wire mesh sensor is the two positioning strips of the zigzag groove, and the distance adjacent to the center of the sawtooth is metal The spacing of the wire array to be controlled; the pretension bolts on the clamping plate for tensioning the wire, determining the position of the wire and adjusting the pretension of the wire. The invention also discloses a using method based on the tooling fixture. The invention is simple and practical, can locate the position of the metal wire on the circuit board with high precision, and the pre-tightening force of the metal wire and the distance from the pad can be adjusted, avoiding false welding and virtual welding, and can be pre-wound and welded at one time , greatly saving manpower and welding time.

Owner:SHANGHAI JIAO TONG UNIV

Lithium-ion power battery tab

InactiveCN105006543AEasy to operateImprove performanceSecondary cellsCell component detailsLithiumPower battery

The invention relates to a lithium-ion power battery tab, which comprises a metal conductor strip and a tab rubber block. The edge part of the longer end of the metal conductor strip is provided with a hole. The hole is U-shaped and the two sides of the U-shaped hole are parallel to each other. The top end of the U-shaped hole is circular arc-shaped. One or more U-shaped holes can be arranged to fix battery tabs according to the width of the metal conductor strip. No laser welding operation is required in an electrical core factory when batteries are to be grouped, wherein screws directly pass through U-shaped holes and pressing plates to tightly lock the tabs of the batteries as a whole. In this way, the equipment investment of large laser welding equipment is saved. Meanwhile, the operation is convenient and the effect is obvious. The virtual welding is avoided, and the production cost is lowered. The production efficiency is improved.

Owner:WUXI BAISHIJIE METAL PROD TECH

Thick-film thermocouple for quickly measuring temp of molten steel and its making method

InactiveCN1144029CAvoid false weldingReduce consumptionThermoelectric device with peltier/seeback effectThermometers using electric/magnetic elementsScreen printingWire gauze

A thick-film thermocouple for quickly measuring the temp. of molten steel is made up of superfine Pt powder and Rh powder or Pt-Rh alloy powder through mixing with glass powder and transparent thick liquid to obtain print slurry, then silk screen printing on ceramic substrate, after baking, high-temp. sintering, and soldering two compensating lines on the thick film temp.-sensing bulb. Its advantages include simple structure, high stability and reliability, high productivity, and low cost.

Owner:CHONGQING MATERIALS RES INST

A preparation method of an electronic cigarette mesh heating body

ActiveCN109348548BAvoid false weldingIncrease productivityOhmic-resistance electrodesTobacco devicesConductive pasteEngineering

Owner:ALD GRP

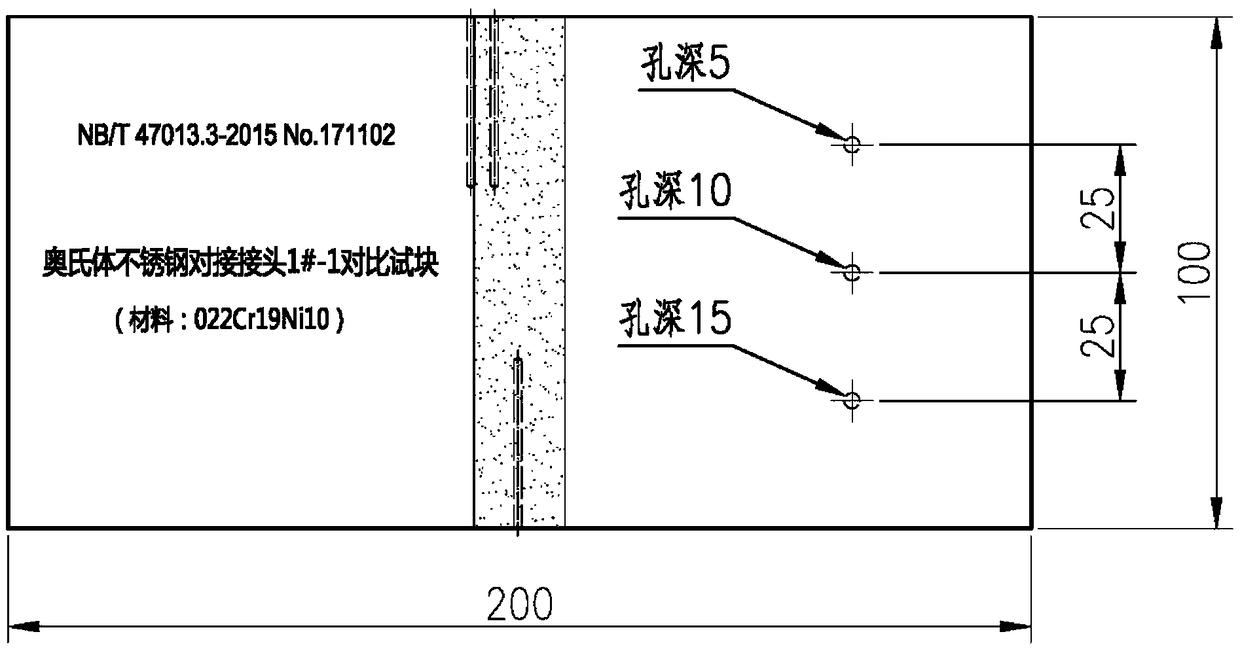

Heavy water reactor spent fuel basket welding center column butt joint welding 1#-1 comparison test block

PendingCN108941964AGuarantee welding qualityAvoid Weld PorosityWelding apparatusButt jointNuclear power

The invention belongs to the technical field of spent fuel conveying of nuclear power plants, and in particular relates to a heavy water reactor spent fuel basket welding center column butt joint welding 1#-1 comparison test block. According to the comparison test block, welding quality of the fuel basket can be ensured, safety and reliability in hoisting of the fuel basket can be guaranteed, andthe risk of falling during hoisting due to the problem that welding quality of the central column is defective is effectively avoided. The comparison test block is characterized in that the comparisontest block is of a cuboid shape wholly; a first detection hole and a second detection hole are sequentially formed in the center line of the front end surface of the test block from bottom to top; athird detection hole and a fourth detection hole are sequentially formed in the rear end surface of the test block along the oblique direction from bottom to top; a fifth detection hole, a sixth detection hole and a seventh detection hole are sequentially formed in the right portion of the lower end surface of the test block from back to front; and the detection holes are used for simulating defects existing in weld joints. According to the comparison test block, the welding quality of the center column of the fuel basket is ensured.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Defective product maintenance platform for semiconductor processing

PendingCN114309870AEasy to adjustEasy to weldWork benchesSoldering auxillary devicesControl engineeringSemiconductor chip

The invention relates to the technical field of semiconductors, and discloses a defective product maintenance table for semiconductor processing, which comprises a working table, and the top of the working table is fixedly connected with a bracket and a fixed table. According to the defective product maintenance platform for semiconductor processing, the guide mechanism, the transverse guide mechanism and the vacuum chuck are arranged, a semiconductor chip is sucked through the vacuum chuck, a first motor of the guide mechanism is started, an output shaft of the first motor rotates to drive a first threaded rod to rotate, and the first threaded rod rotates to adjust the position of a guide block; a second motor of the transverse guide mechanism is started, an output shaft of the second motor drives a second threaded rod to rotate, the second threaded rod rotates to adjust the position of a sliding block, the sliding block drives a connecting ring to move, the connecting ring drives a lifting mechanism and a moving plate to move, and then the position of the chip can be adjusted; therefore, the position of the semiconductor chip is adjusted, and the position of the chip is convenient to adjust.

Owner:深圳市赢创智联科技有限公司

LED point light source wire welding machine and welding abutting mechanism thereof

PendingCN110773834AAvoid multiple alignment operationsAvoid WeldingMetal working apparatusSoldering auxillary devicesWire rodPoint light

The embodiment of the invention provides an LED point light source wire welding machine and a welding abutting mechanism thereof. The welding abutting mechanism comprises an abutting part used for abutting against the welding ends of wire cores of a to-be-welded wire and a driving part used for driving the abutting part to move to correspondingly compress the welding ends to a welding disc of a PCB which is correspondingly connected with the welding ends in a welding manner; and the abutting part comprises a main body portion relatively fixed to the output end of the driving part and an abutting portion formed in the mode of extending from one end of the main body portion, and the end face of the end, far away from the main body portion, of the abutting portion is concaved to form a plurality of wire pressing grooves which are distributed at preset distances in parallel so as to correspondingly position and abut against the welding ends of the wire cores of the to-be-welded wire. According to the LED point light source wire welding machine and the welding abutting mechanism thereof, in the specific welding process, any one wire pressing groove of the abutting part only needs to bealigned with the corresponding welding disc of the PCB, repeated alignment is avoided, only the specific abutting part needs to be replaced for different specifications of wires, great convenience isachieved, the welding efficiency is high, and false welding and pseudo welding are avoided.

Owner:SHENZHEN EX LIGHTING TECH HLDG

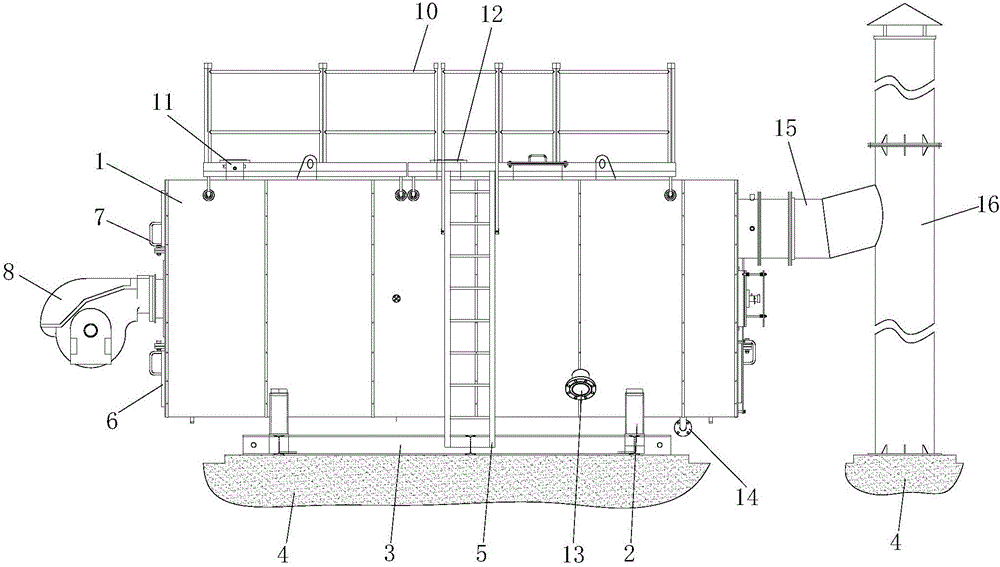

Novel boiler

The invention discloses a novel boiler. The novel boiler comprises a boiler body, wherein the bottom of the boiler body is mounted on a base through a bracket, the boiler body is fixedly connected with the bracket, and the base is mounted on a foundation through screws; one side of the boiler body is provided with a climbing ladder, one end of the boiler body is connected with two semicircular end covers through screws, and handles are arranged on the end covers; and a fan mounted on the boiler body is arranged at the inner side of the end covers, and a motor is arranged on the fan. According to the novel boiler, by arranging the boiler body of which the welding parts are all fully welded, dummy welding and air leakage phenomena of the original boiler body are avoided, heat dissipation is reduced, and energy is saved; and by arranging sealing gaskets between the end covers and the boiler body and carrying out sealing gasket treatment on all of the other pipeline joints of the boiler body, a great sealing effect is ensured at the parts, in contact with the boiler body, of the end covers, air leakage is prevented, heat dissipation is reduced, and energy is saved.

Owner:湖北扬天节能环保股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com