Lead and lead-free soldering method

A lead-free soldering and surface soldering technology, used in welding equipment, electrical components, printed circuit manufacturing, etc., can solve the problems of high melting temperature, fast oxidation speed and poor wettability of lead-free soldering, so as to ensure the welding quality and avoid The effect of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

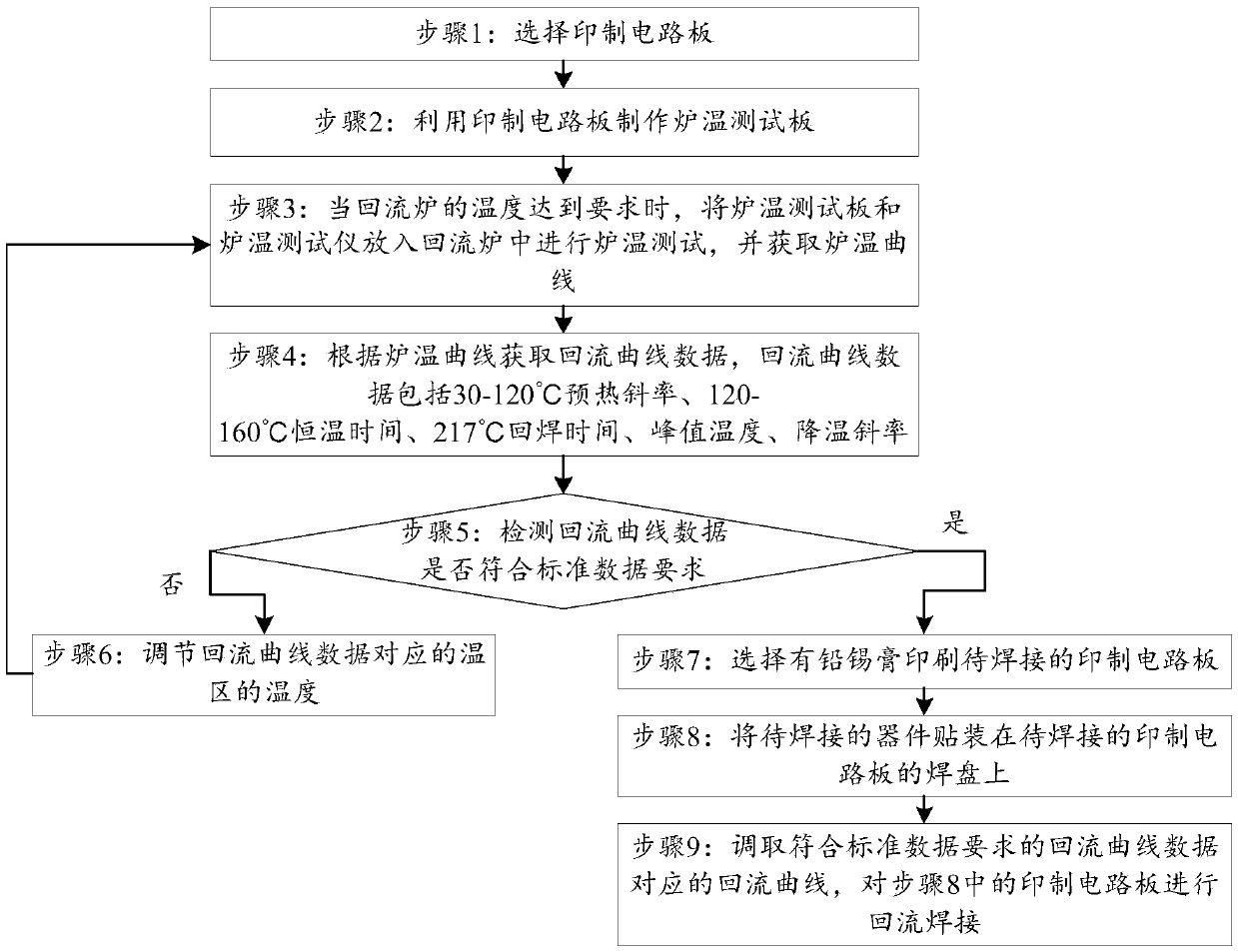

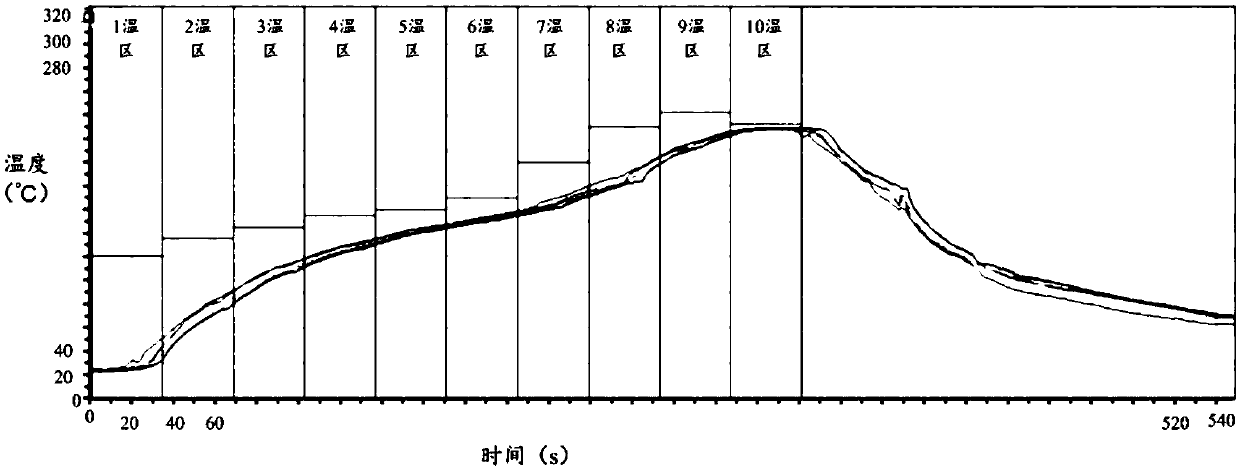

[0039] Please refer to figure 1 , which shows a flowchart of a lead-free lead-free soldering method provided by an embodiment of the present invention. like figure 1 As shown, the lead-free lead-free soldering method may include the following steps:

[0040] Step 1: Select the PCB.

[0041] The TOP side of the printed circuit board is soldered with lead-free BGA.

[0042] Step 2: Make a furnace temperature test board using a printed circuit board.

[0043] Select 5 temperature-sensing lines, and arrange 4 temperature-sensing lines evenly around the printed circuit board;

[0044] Drill a hole on the printed circuit board, and bury the remaining 1 temperature sensing line to the bottom of the BGA.

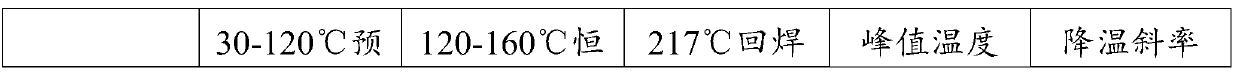

[0045] Step 3: When the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com