Pipe gallery underground excavation primary lining plastic waterproof plate fixing device and waterproof plate laying method

A technology of fixing device and waterproof plate, which is applied in shaft lining, tunnel lining, mining equipment, etc., can solve the problems of small area of dark nail circle, weak welding, false welding and welding penetration, etc., so as to improve construction quality and save money. Cost, effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

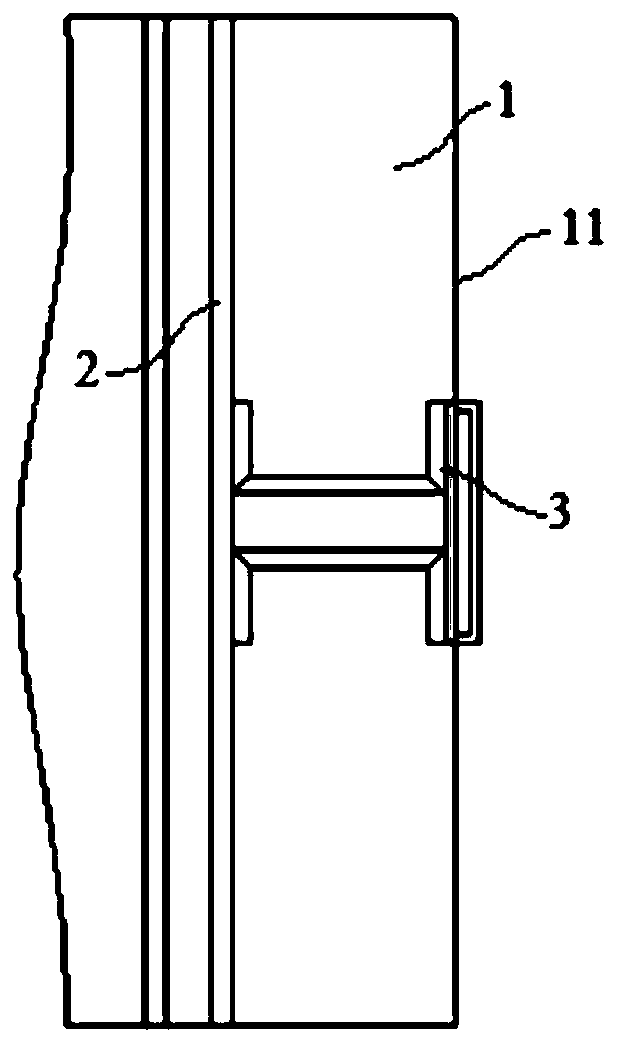

[0043] Such as figure 1 and Figure 4 As shown, a plastic waterproof board fixing device for the initial lining of the underground excavation of the pipe gallery in this embodiment includes a pre-embedded device 3, a fixed base plate 4 and a plastic waterproof board 5, and one end of the pre-embedded device 3 is welded and fixed On the grid steel arch 2 in the lining 1, a fixed base plate 4 is installed at the other end, and the plastic waterproof plate 5 is pasted and fixed through the fixed base plate 4, and the plastic waterproof plate 5 is fixed on the fixed base plate 4 by pasting. , effectively avoiding false welding, welding penetration and welding infirmity caused by the traditional use of hidden nail rings to weld and fix the waterproof board, ensuring the firmness of the laying and installation of the plastic waterproof board 5, avoiding water seepage in the pipe gallery, and improving the pipe gallery Flashing construction quality and durability of concrete structu...

Embodiment 2

[0049] In this embodiment, a method for laying a plastic waterproof board for the initial lining of a pipe gallery underground excavation uses the fixing device described in Embodiment 1 to lay the waterproof board, which specifically includes the following steps:

[0050] Step 1. Make a fixed substrate 4

[0051] Take the whole roll of waterproof board, cut it into several rectangular fixed substrates 4 with a size of 200mm×50mm, and prepare for construction.

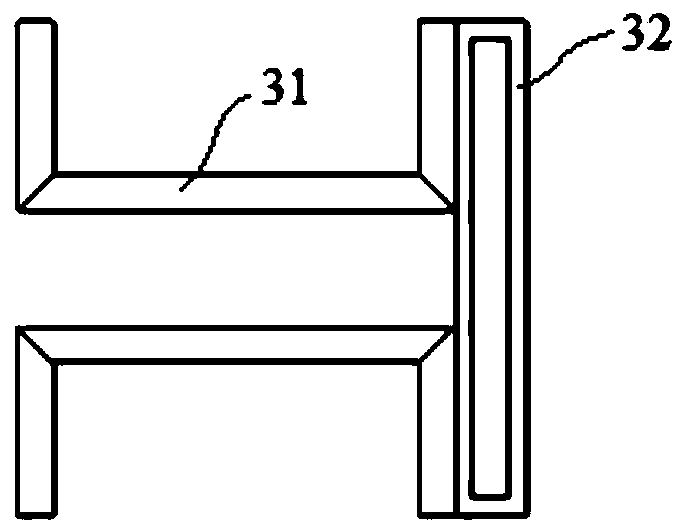

[0052] Step 2. Making the pre-embedded device 3

[0053] Use flat steel to make a hollow box 32, the width and height of the inner hole in the hollow box 32 match the width and thickness of the fixed substrate 4 respectively, to ensure that the rectangular fixed substrate 4 of 200mm×50mm can pass through the hole in the box; then The installation frame 31 is made by processing steel bar scraps on site into the shape of channel steel, ensuring that its processing length is equal to the distance from the initial lining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com