Patents

Literature

50results about How to "Avoid welding through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

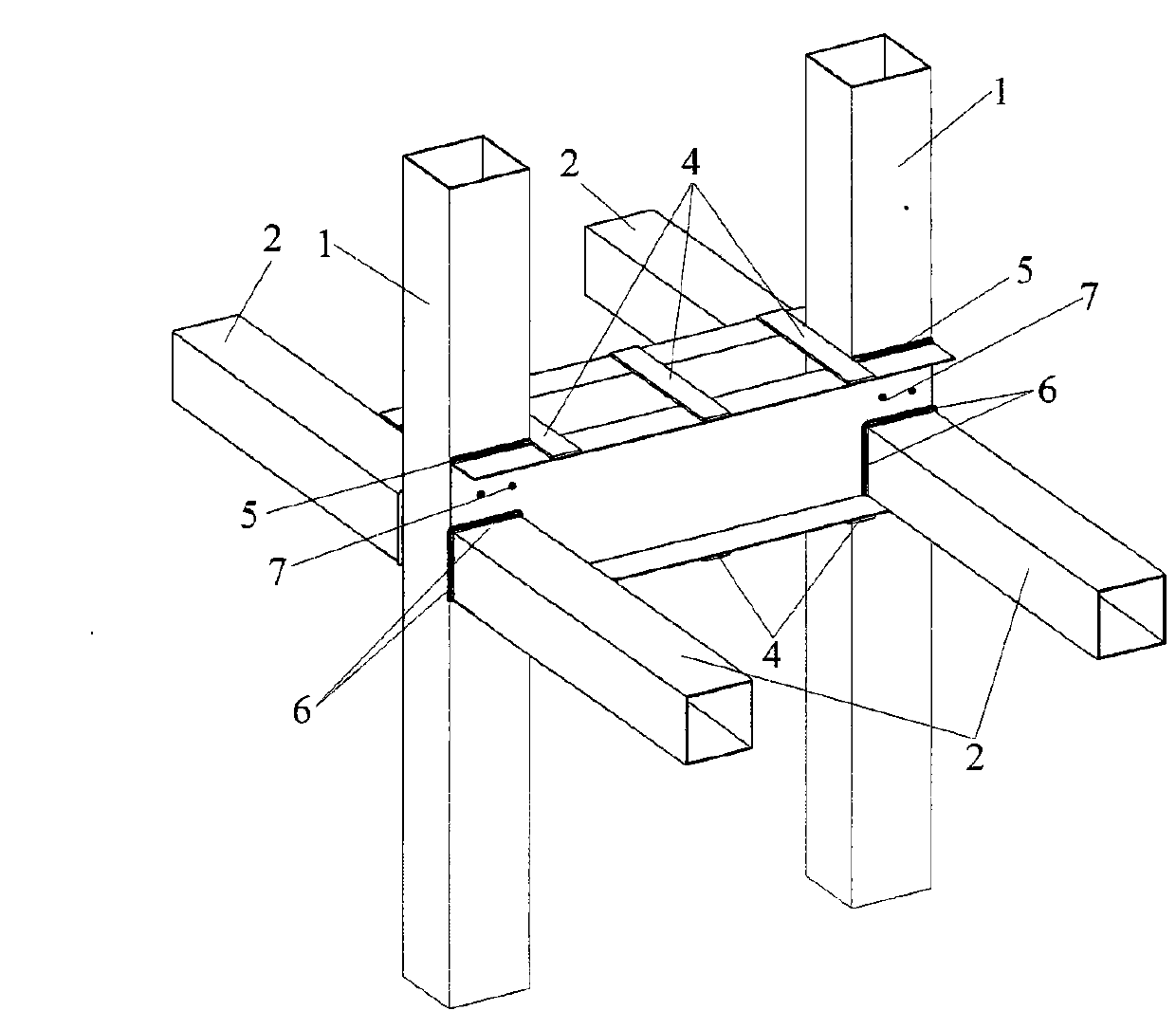

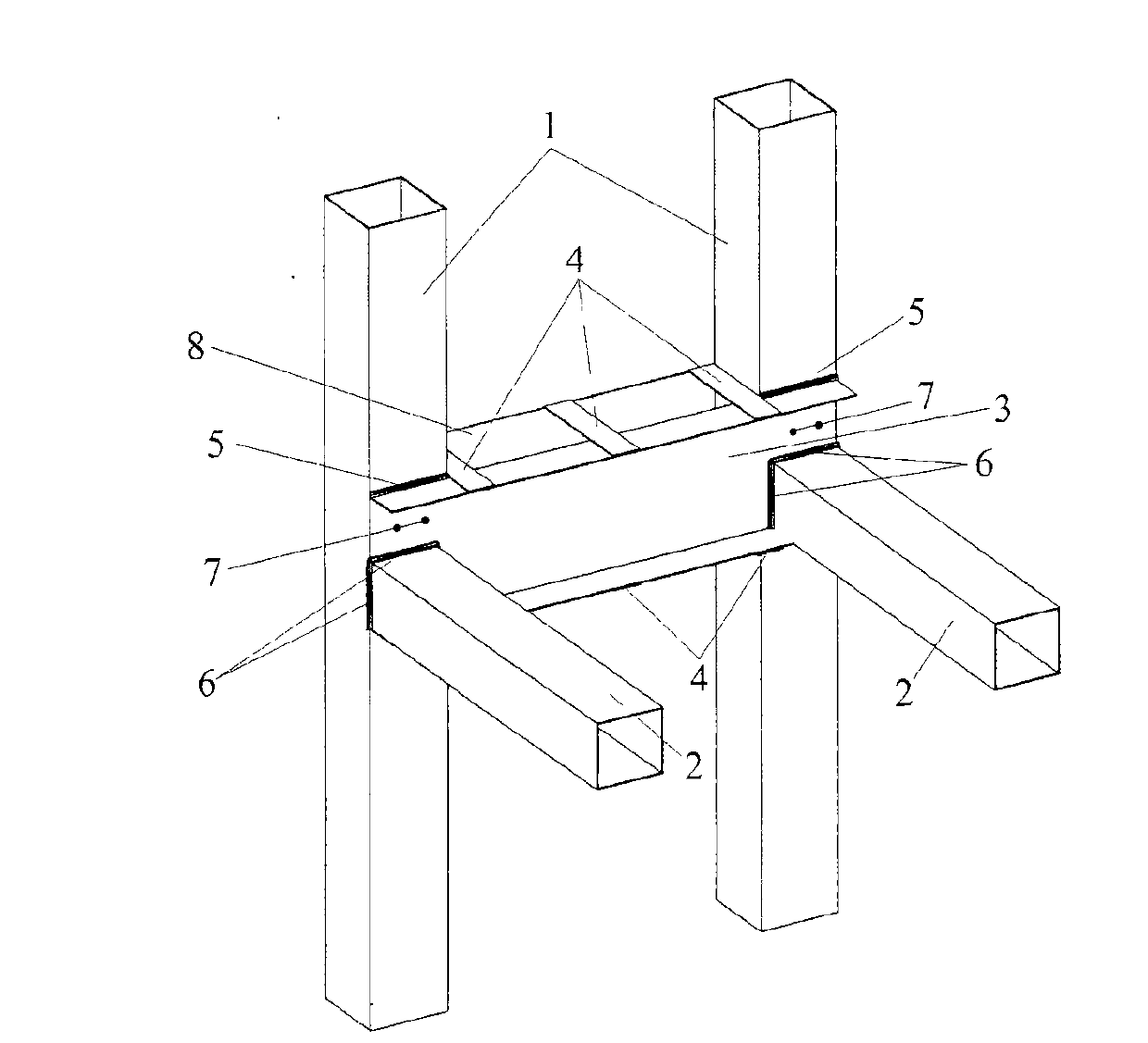

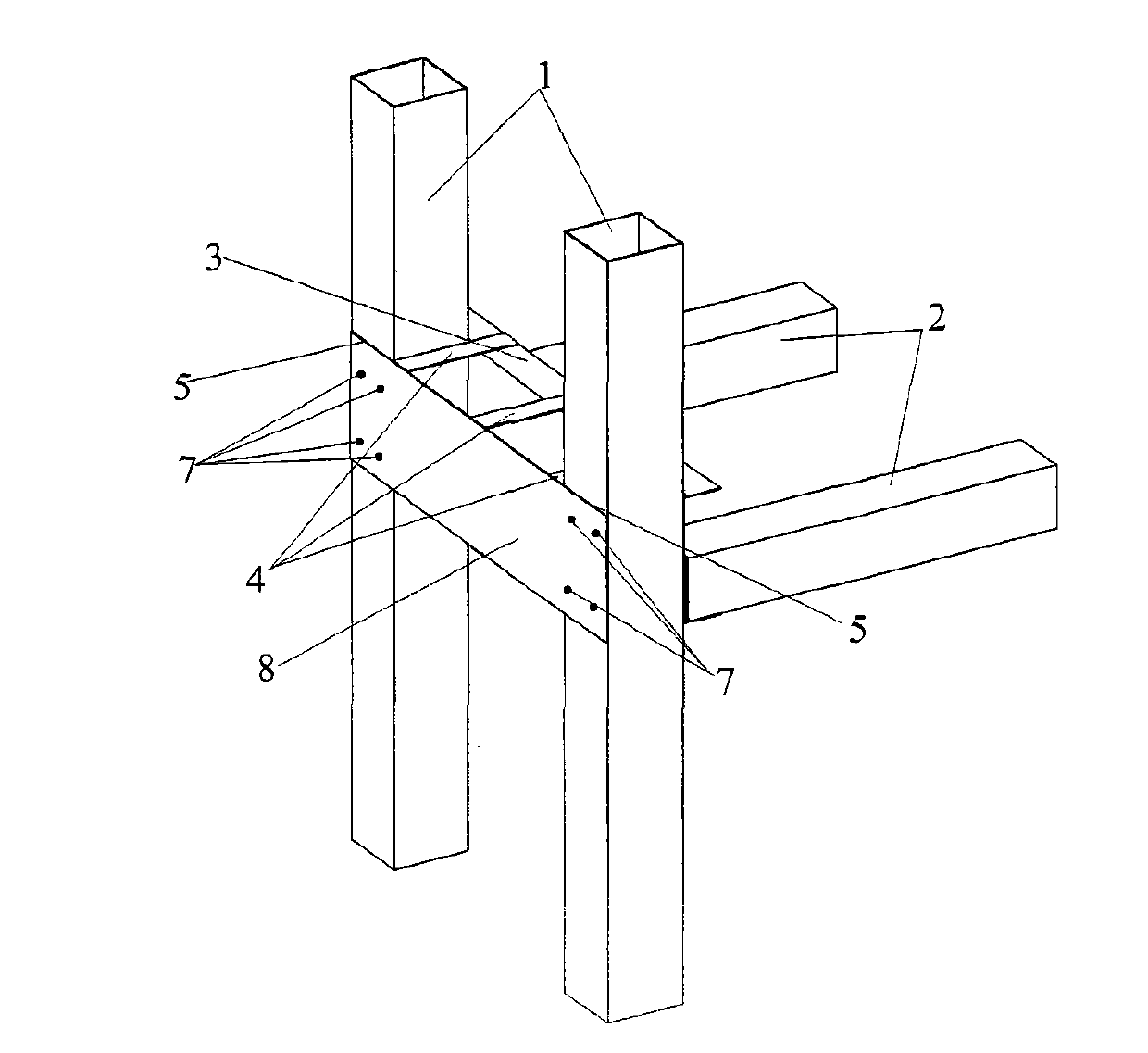

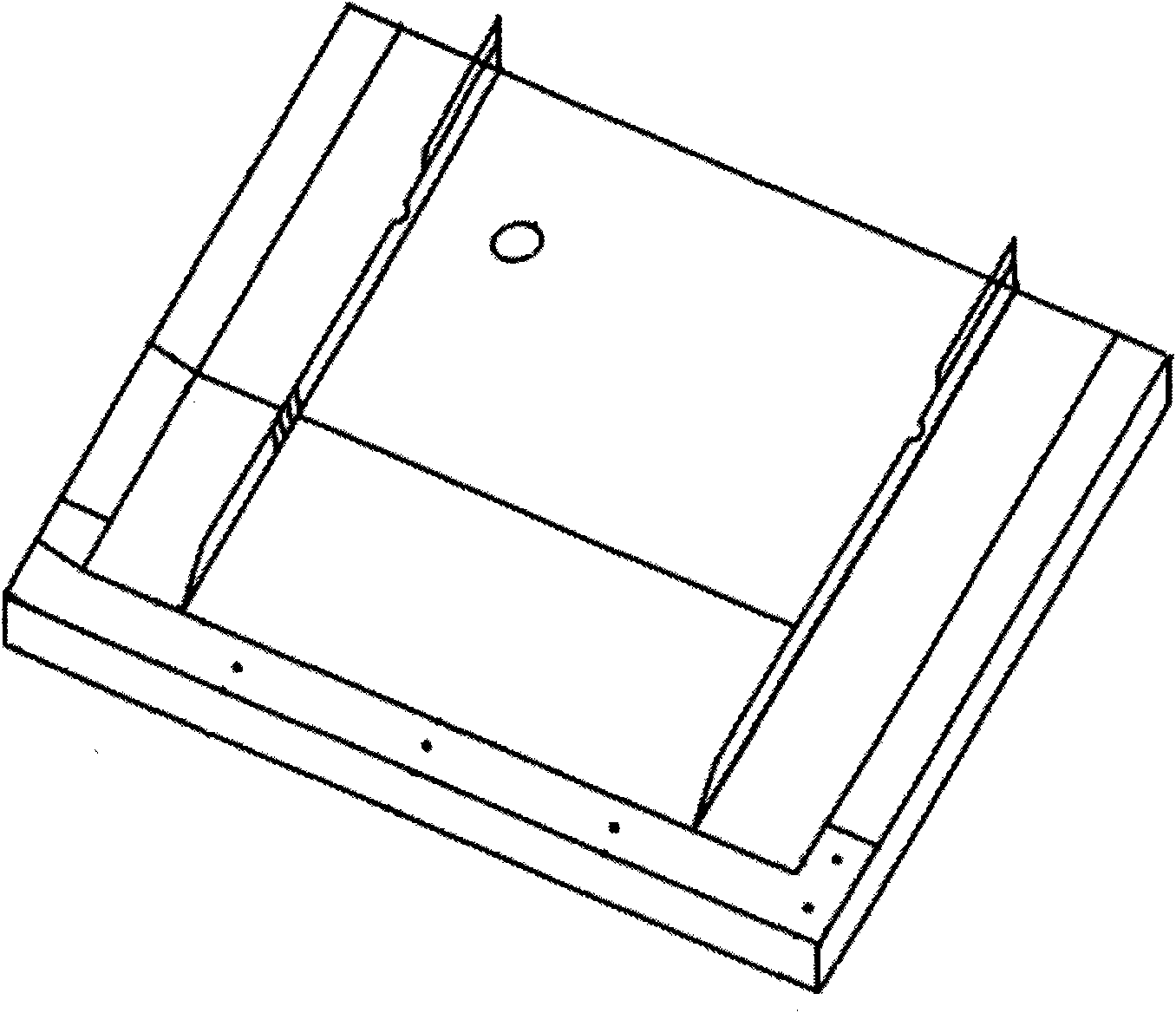

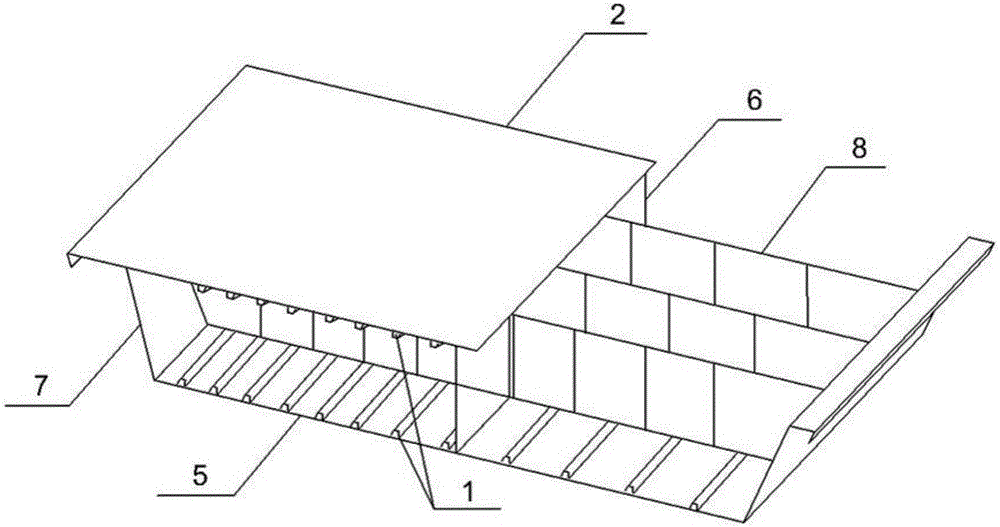

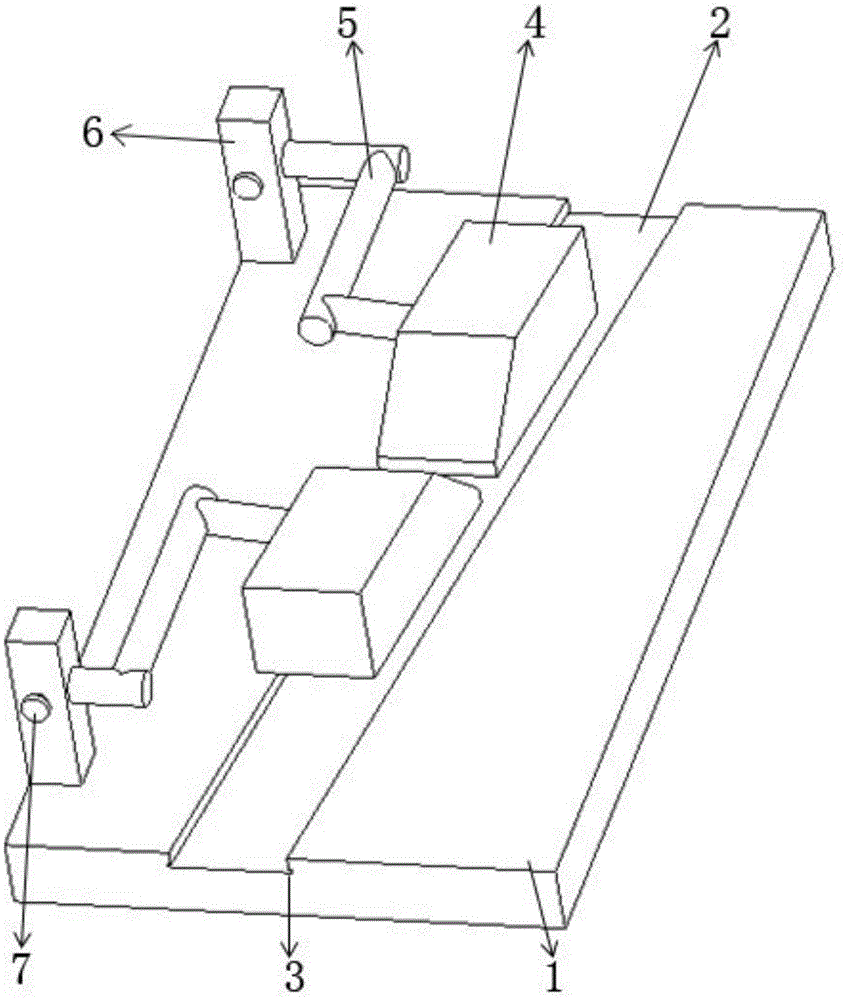

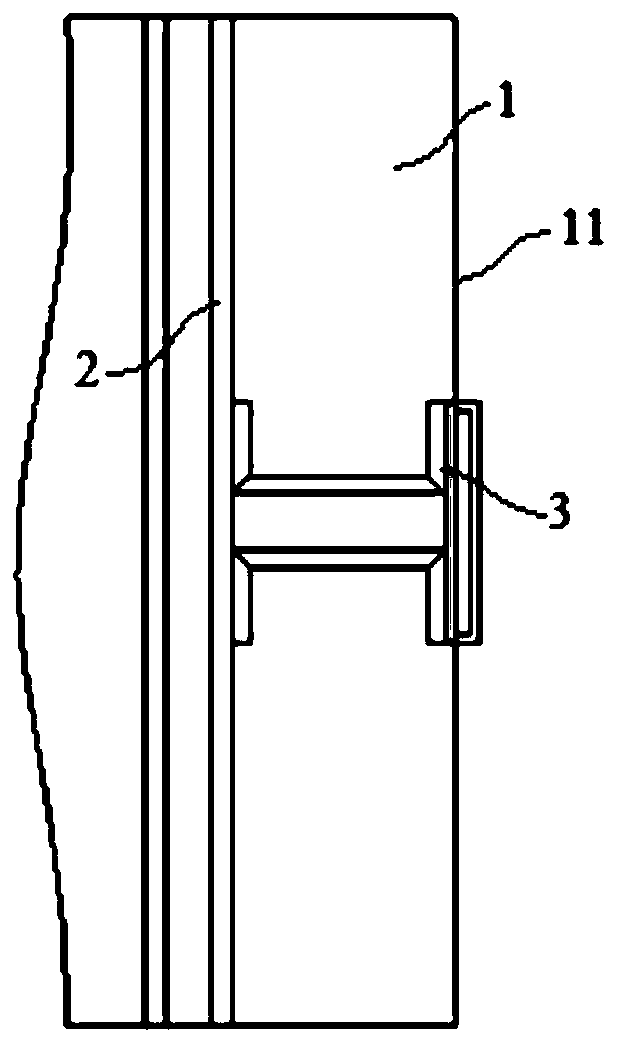

Cold bending thin-wall steel beam column node

InactiveCN101793059AImprove ductilityIncrease ultimate bearing capacityBuilding constructionsEarthquake resistanceStructural system

The invention discloses a cold bending thin-wall steel beam column node, which comprises a square steel tubular column (1), a square steel tubular beam (2) and a C-shaped steel beam (3). The steel beam column node is characterized in that the C-shaped steel beam (3) is welded on the square steel tubular column (1), and the square steel tubular beam (2) is welded on the C-shaped steel beam (3). The C-shaped steel beam (3) and the square steel tubular column (1) can be connected by self-tapping screws (7). The cold bending thin-wall steel beam column node overcomes the defect of the conventional cold bending thin-wall steel beam column node connection; and the node has the advantages of definite stress transfer pathway, predominant earthquake resistance and simple and feasible construction operation, can be widely applied to connection of sections of various cold bending thin-wall steel rods, and is particularly suitable for a structural system adopting a plug-in retaining wall.

Owner:SOUTHWEAT UNIV OF SCI & TECH

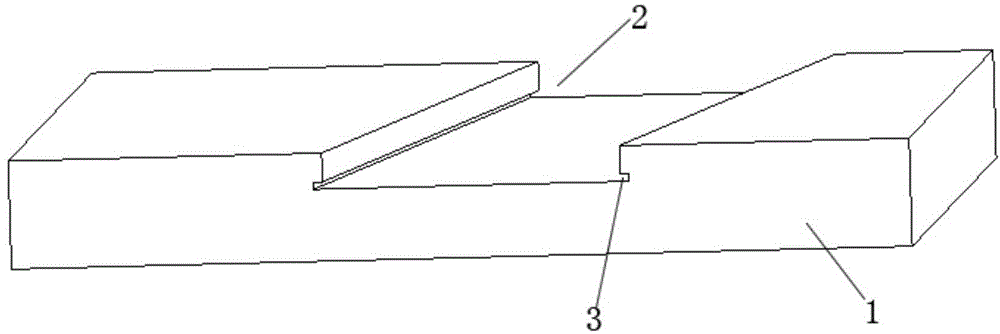

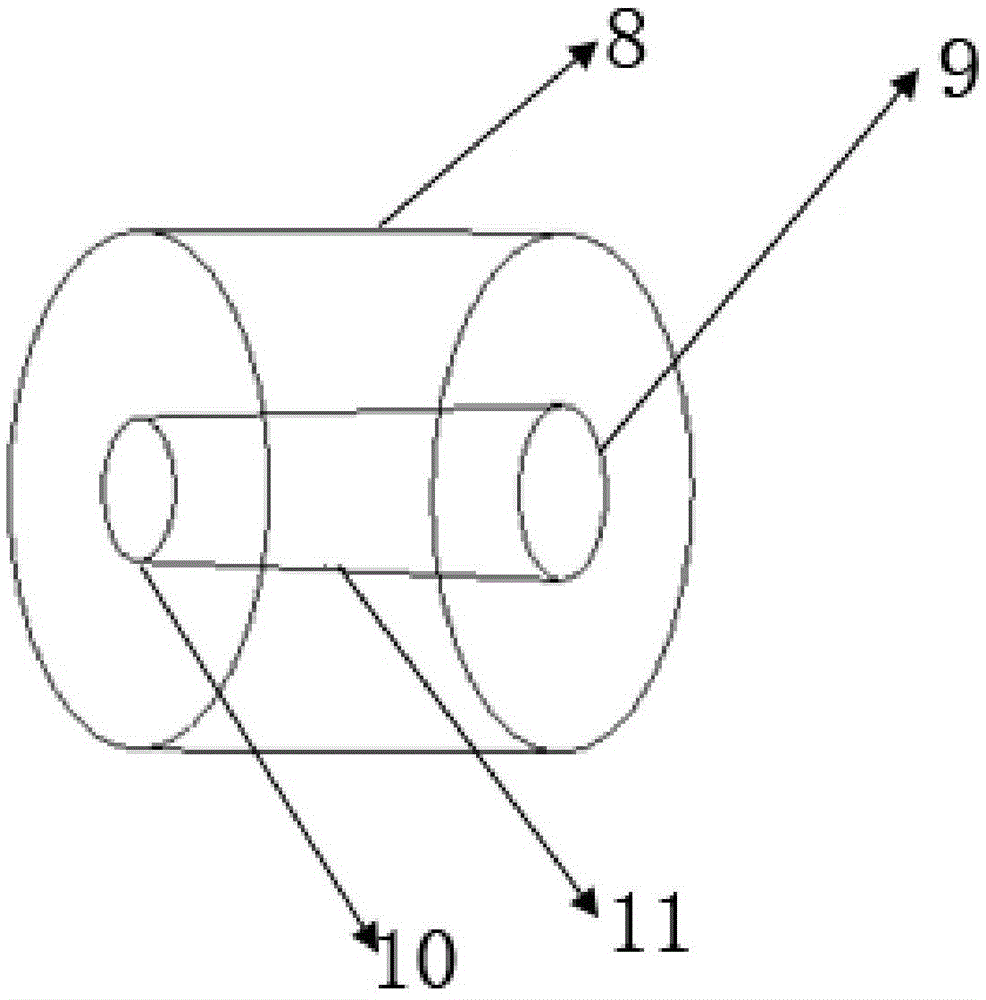

Method for carrying out simulated training of non-melt argon tungsten-arc welding on liquefied natural gas (LNG) carrier for welders

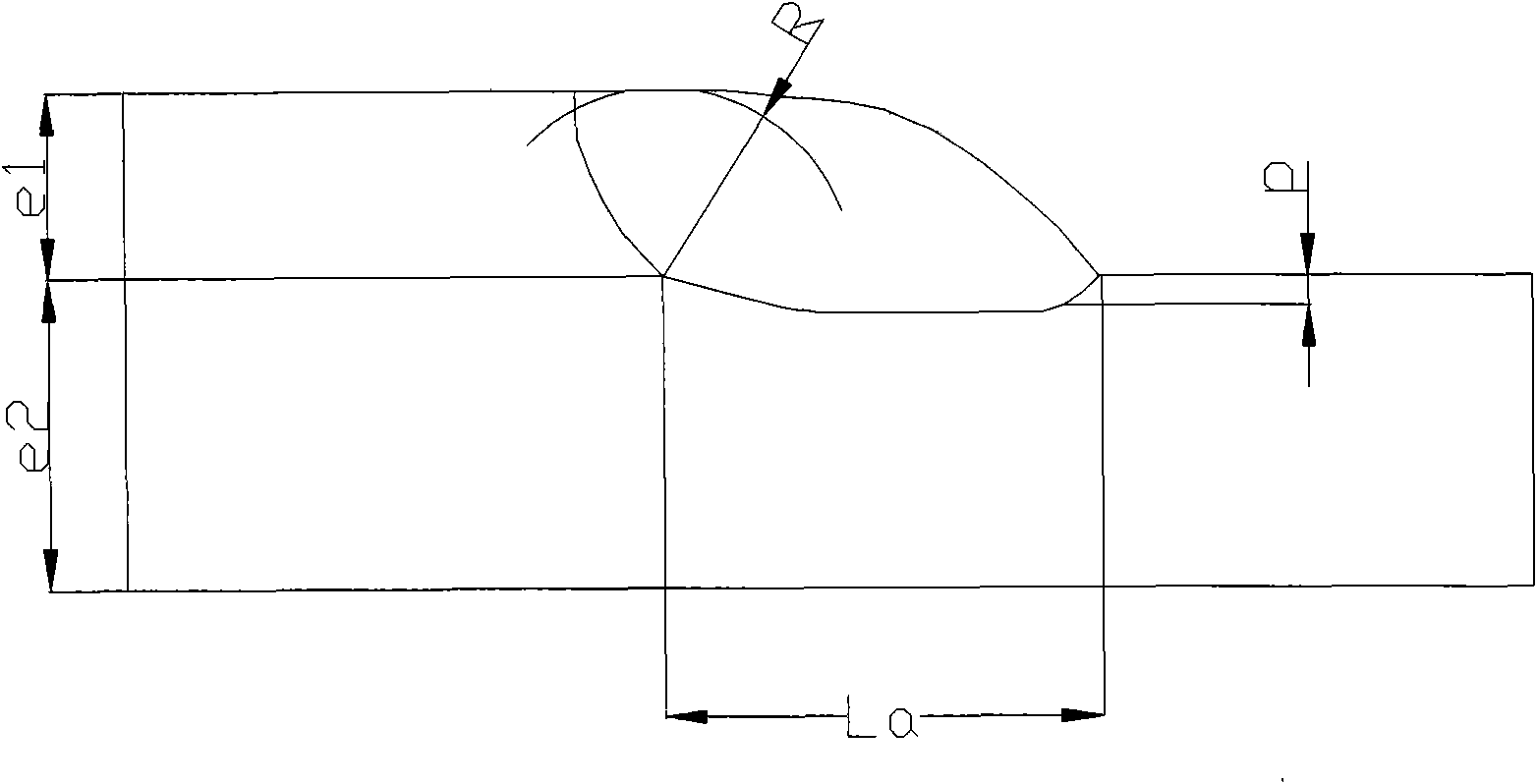

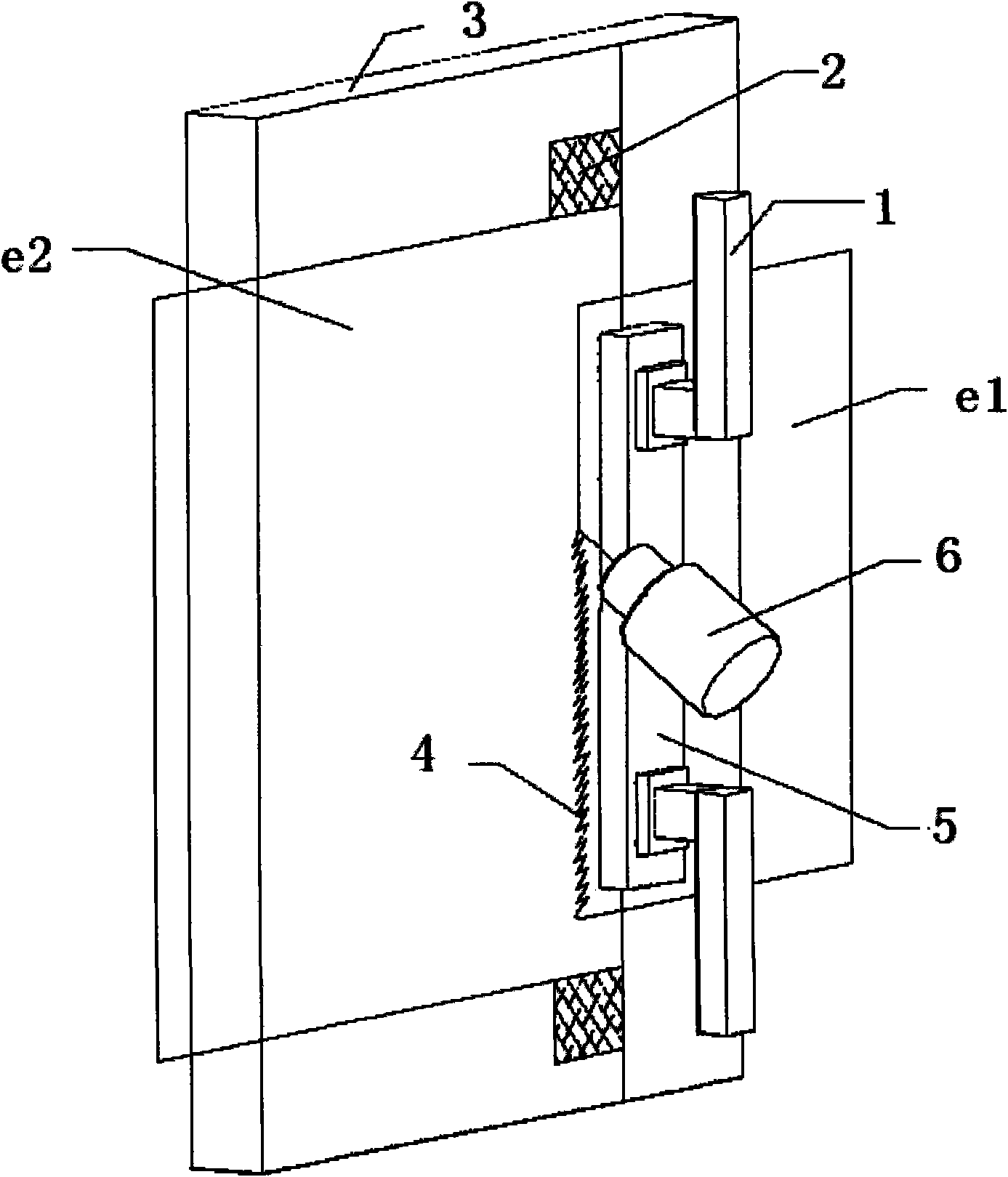

ActiveCN101898273AChange welding straightness differenceAvoid welding throughWelding/cutting auxillary devicesAuxillary welding devicesDistortionWeld seam

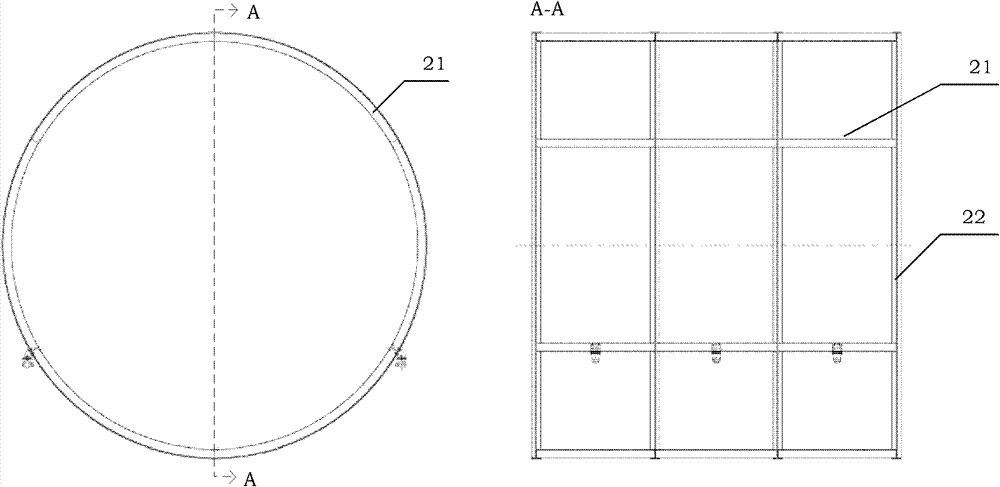

The invention relates to a method for carrying out a simulated training of non-melt argon tungsten-arc welding on a liquefied natural gas (LNG) carrier for welders, which needs to simulate the welding between film materials on a cargo tank containment system on the LNG carrier. The method comprises the following steps: firstly, clamping the welded seam of a specimen needing to be welded by using a clamping tool, and then, carrying out fixed-position welding; then, lining and pressing a radiating component at the edge of the welded seam, and clamping the radiating component by using the clamping tool; and finally, enabling the nozzle of a welding torch to be close to the edge of the radiating component for welding, and removing the clamping tool after welding. The method of the invention performs important functions of avoiding the weld penetration of invar film materials by welders in operation and controlling the post welding distortion, and greatly improves the training efficiency and effect of manual TIG welding.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

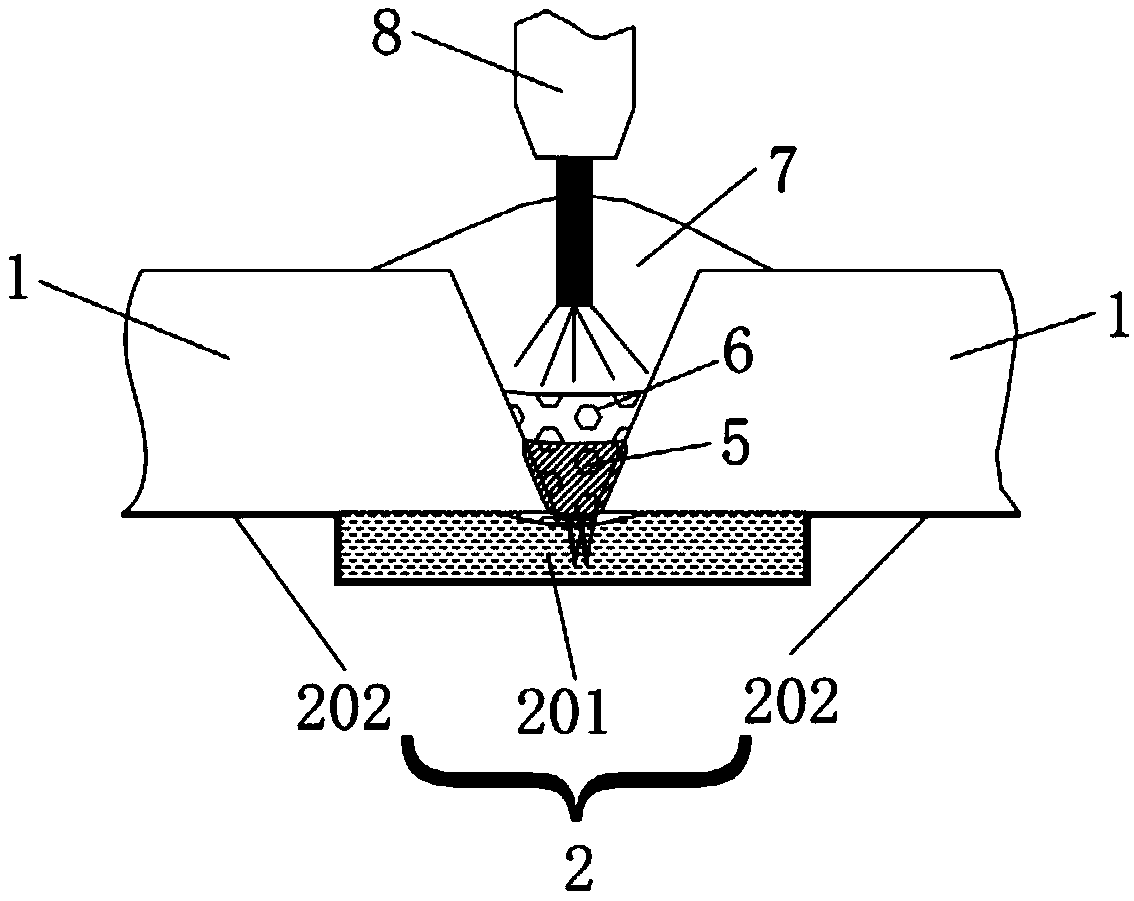

FGB-process single-sided submerged arc welding pad bonding method

InactiveCN108856993ASimplify the pasting processGuaranteed coincidenceWelding accessoriesWrinkle skinEngineering

The invention relates to the technical field of welding, and discloses an FGB-process single-sided submerged arc welding pad bonding method. A bonding layer of a flexible pad can be attached to the surface of a steel plate flatly and tightly, the bonding force between the flexible pad and the surface of the steel plate, and poor attachment such as wrinkles or air bubbles is avoided, thereby avoiding weld penetration due to loosening of the flexible pad, and reducing post-weld repair or repair work; meanwhile, since the flexible pad is fastened and bonded to the steel plate, there is no need toposition a card code, and there is also no need to use a thin flat iron bar or a wooden tip to perform the mounting and fastening process. The correct positioning welding can be directly performed ina butt seam groove, and a subsequent FGB arc is used to melt a positioning weld seam into the weld, thereby simplifying the processes of pad bonding and seam assembly, and improving the overall efficiency of an FGB welding process.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Full-penetration welding technology for fillet seams of U-shaped rib plate of steel structure

ActiveCN106112224AWell formedReduce the consumption of manpower and material resourcesArc welding apparatusWelding/cutting media/materialsEngineeringWeld penetration

The invention discloses a full-penetration welding technology for fillet seams of a U-shaped rib plate of a steel structure. A steel top plate and the U-shaped rib plate form the steel structure with narrow space, a welding gasket is installed on an internal fillet seam inside the narrow space, an external bevel fillet seam outside the narrow space is welded, and one side welding and double side forming of the steel top plate and the U-shaped rib plate can be realized. According to the full-penetration welding technology, the fillet seams of the U-shaped rib plate can be effectively protected against weld penetration, full penetration of the fillet seams of the U-shaped rib plate of the steel structure can be guaranteed, the front sides and the rear sides of the fillet seams can be well formed, the fatigue resistance of the fillet seams of the U-shaped rib plate of the steel structure can be improved, and the service life of the steel structure can be prolonged.

Owner:武汉天高熔接股份有限公司 +2

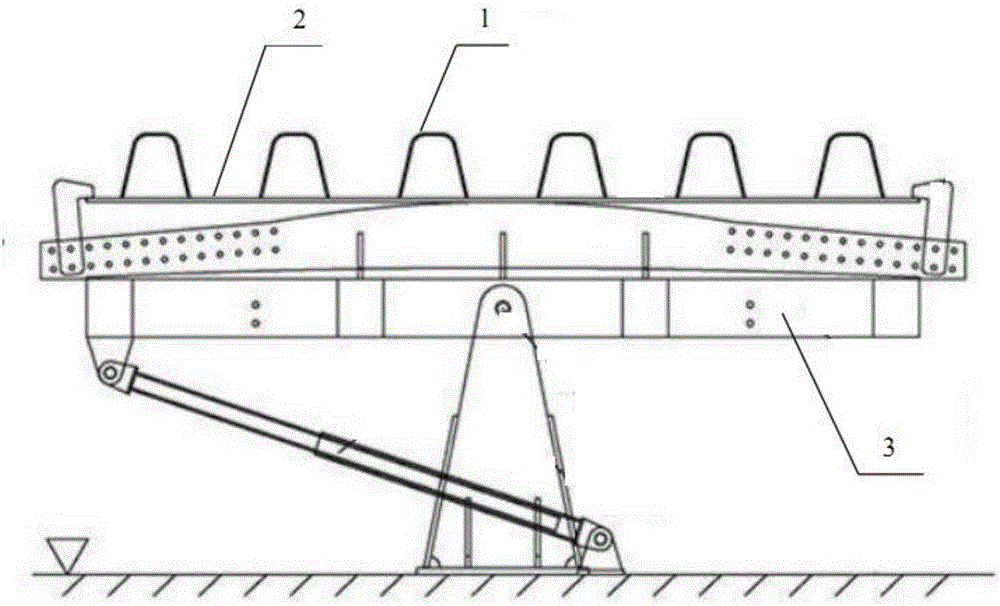

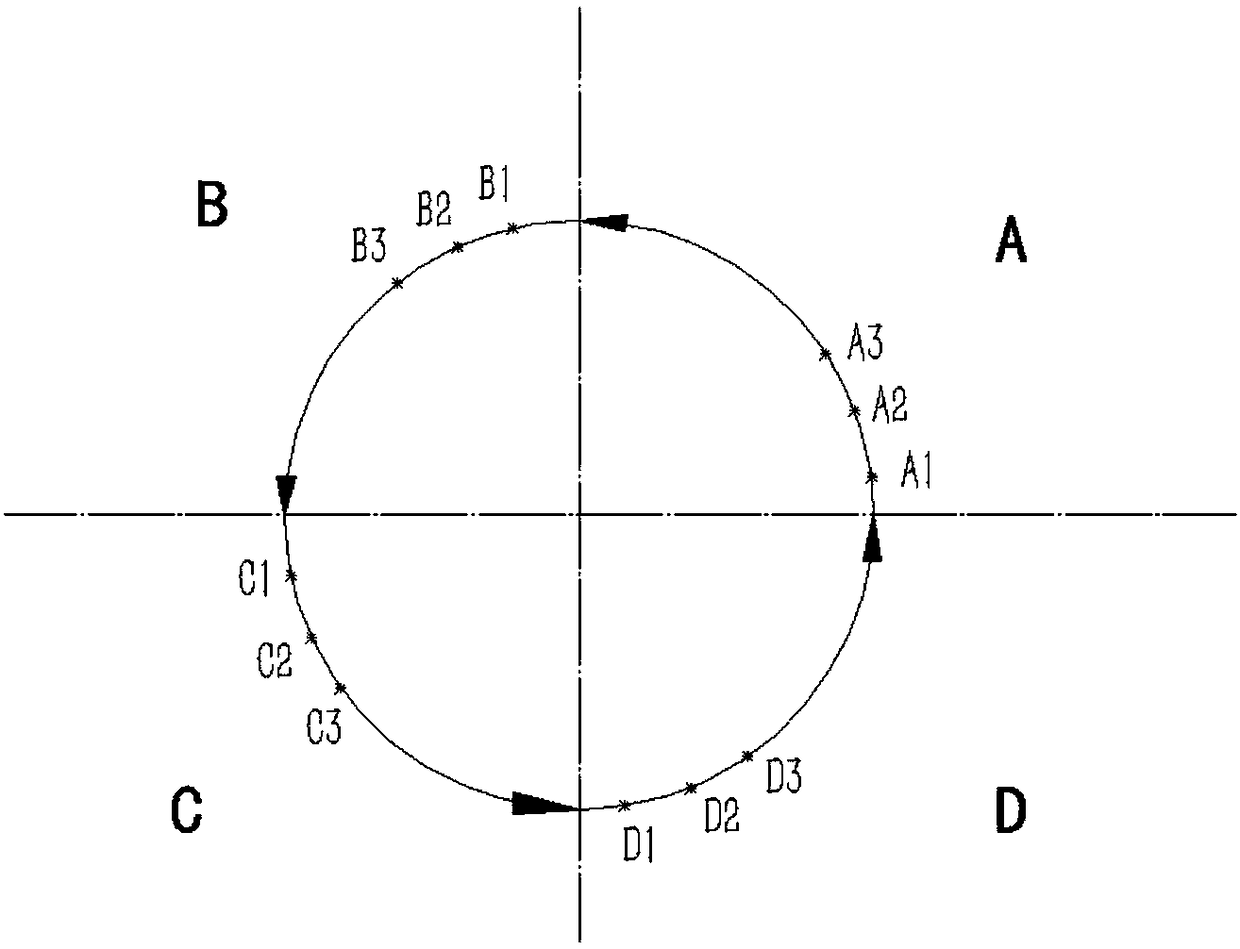

Construction method for single-side fusion-through welding of connection angle seams of closed longitudinal ribs and bridge deck slab

ActiveCN106334861ASimple structureEasy constructionArc welding apparatusWelding/cutting media/materialsFillet weldProduction line

The invention discloses a construction method for single-side fusion-through welding of connection angle seams of closed longitudinal ribs and a bridge deck slab. The construction method comprises the following construction steps that the multiple closed longitudinal ribs and the bridge deck slab are assembled so that a bridge deck slab unit can be formed, the bridge deck slab unit is installed on a bed-jig of a slab unit welding production line horizontally, and welding backings are installed at the two inside longitudinal angle seams; the longitudinal angle seam located on the outer portion is welded by rotating the bed-jig; the other longitudinal angle seam located on the outer portion is welded by rotating the beg-jig; and the bed-jig is rotated to be in the horizontal state, and the bridge deck slab unit subjected to welding is removed. By means of the construction method, the problems that due to incomplete penetration of one-side welding of closed longitudinal ribs and a bridge deck slab, a fatigue crack source exists, and consequently fatigue cracks are caused can be solved, welding penetration of fillet welds of the closed longitudinal ribs can be effectively prevented, the effect that the depth of fusion of the fillet welds of the closed longitudinal ribs meets the design requirement can be ensured, full penetration and excellent molding of the fillet welds of the closed longitudinal ribs of a steel structure are achieved while the production efficiency is improved, and the service life of the steel structure is prolonged.

Owner:武汉天高熔接股份有限公司 +3

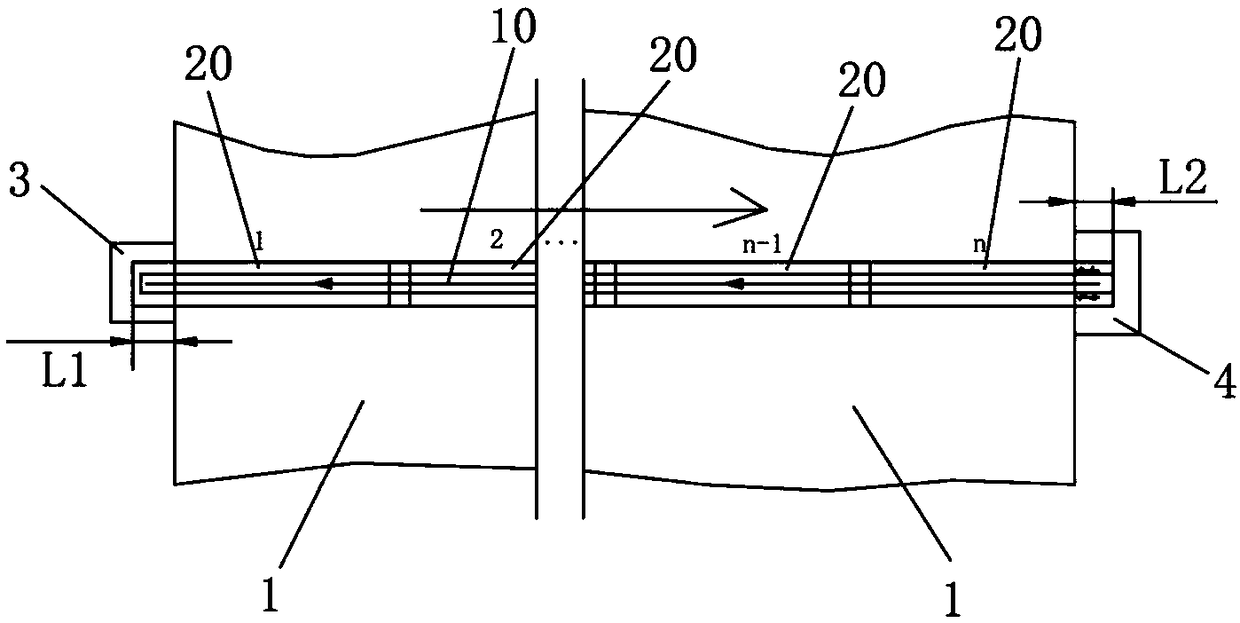

High-speed welding method of thin metal sheet

InactiveCN108326419APlay a fixed roleExtend cooling timeLaser beam welding apparatusThin metalThermal deformation

The invention relates to the field of welding, and provides a high-speed welding method of a thin metal sheet. The method comprises the steps of S1, dividing a welding track into a plurality of secondary welding sections; S2, arranging a plurality of welding points in each secondary welding section in advance; and sequentially marking the plurality of welding points; and S3, welding the first welding point in each welding section; then welding the second welding point in each welding section; sequentially welding in the same way until the N welding point in each secondary welding section is welded, and thus finishing sequential connection of the plurality of secondary welding sections and obtaining a complete welding line. According to the method, the thin metal plate can be fixed andprevented from welding deformation through the plurality of welding track sections; the alternative welding manner is performed, so that the heat dissipating time of the welding points can be increased, and the accumulated heat is decreased, and as a result, the weld penetration caused by thermal deformation and heat accumulation can be prevented; and meanwhile, low secondary section welding speedrealizes high overall welding speed.

Owner:HANS LASER TECH IND GRP CO LTD

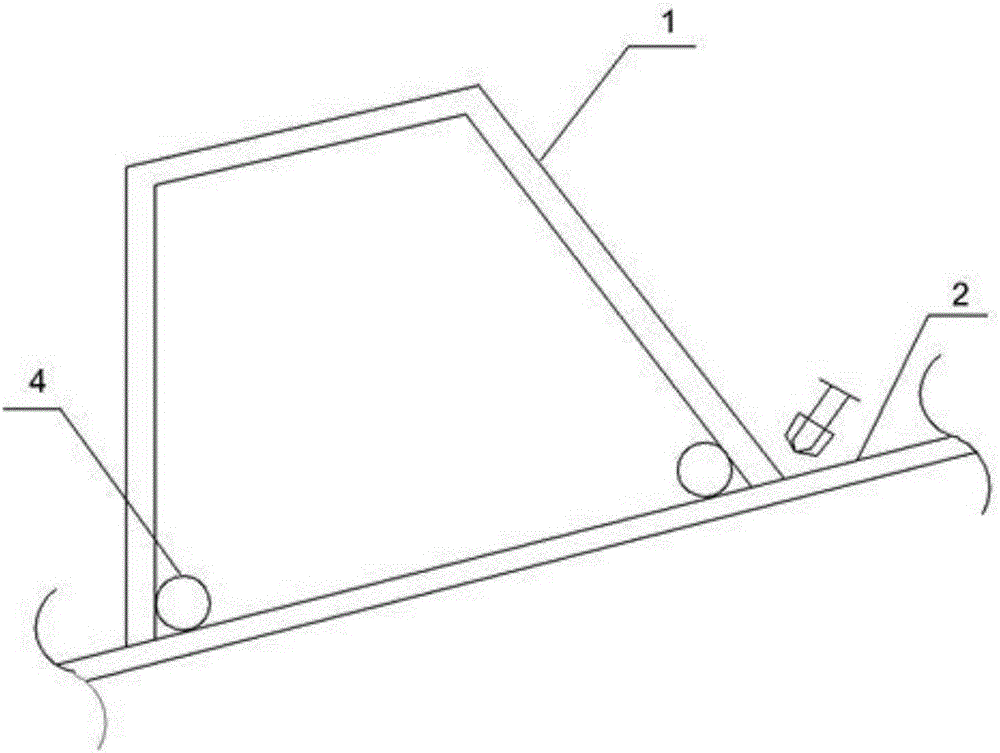

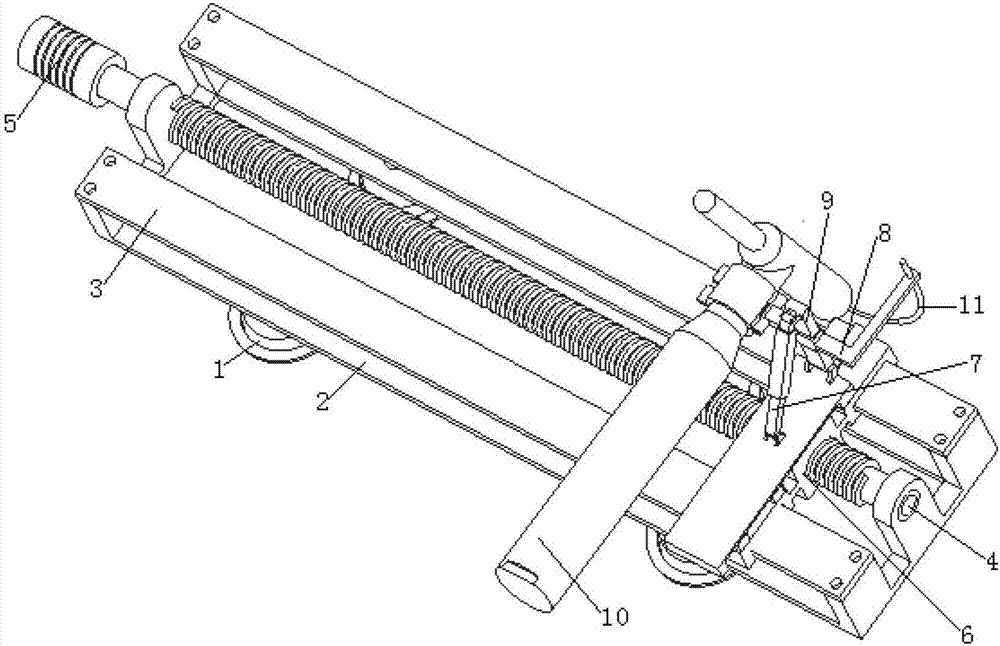

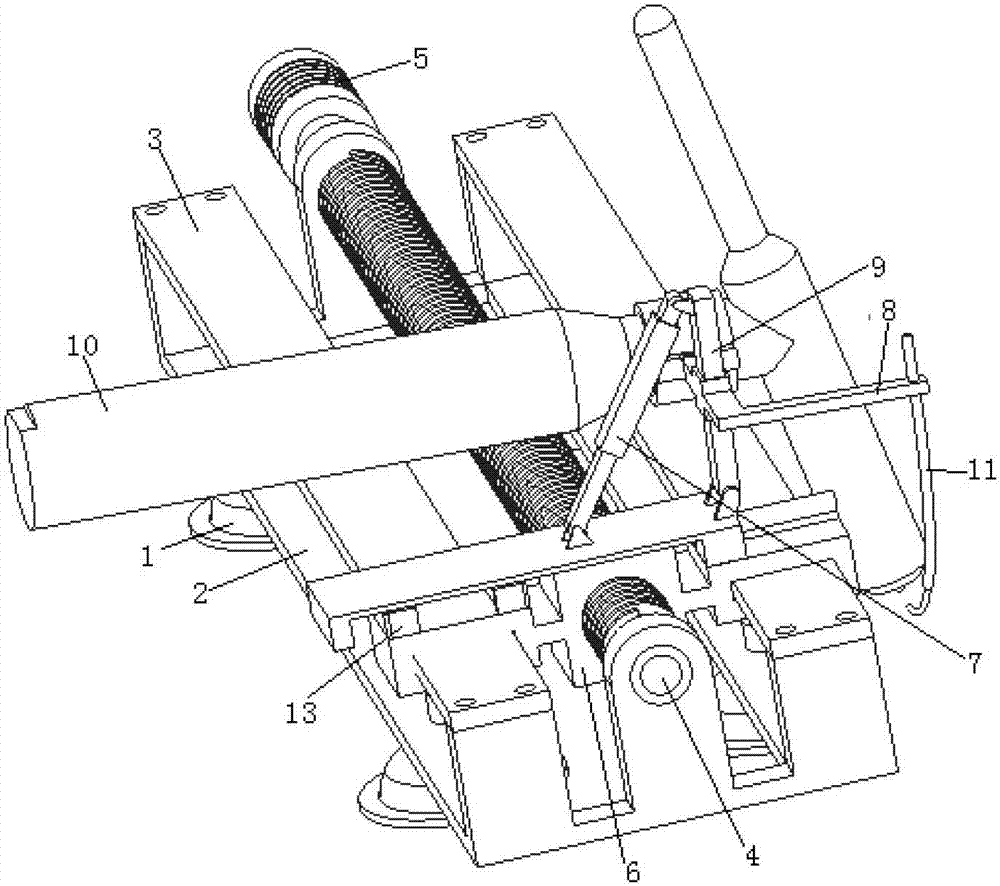

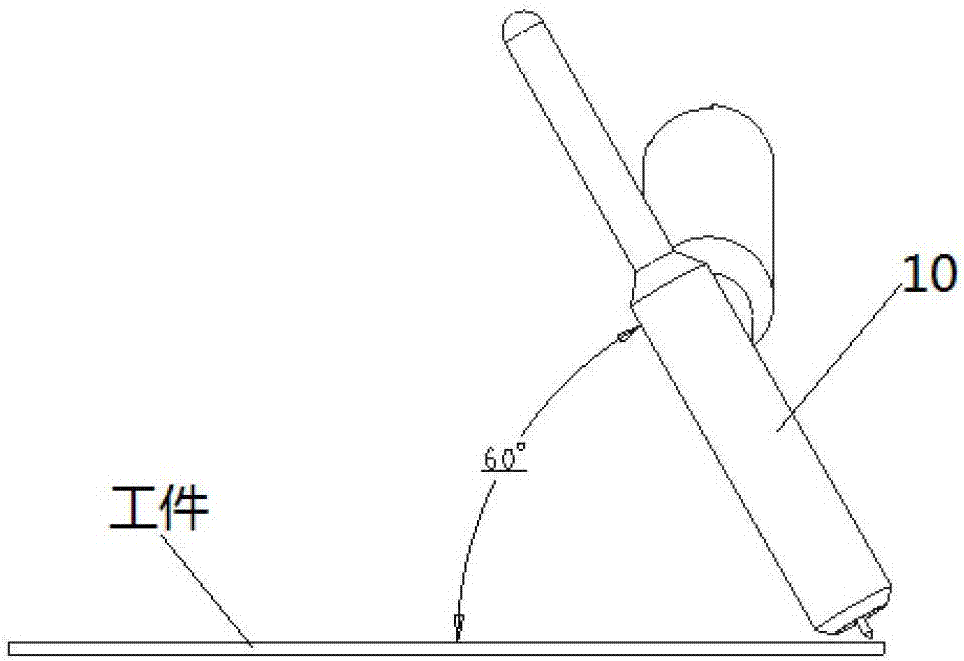

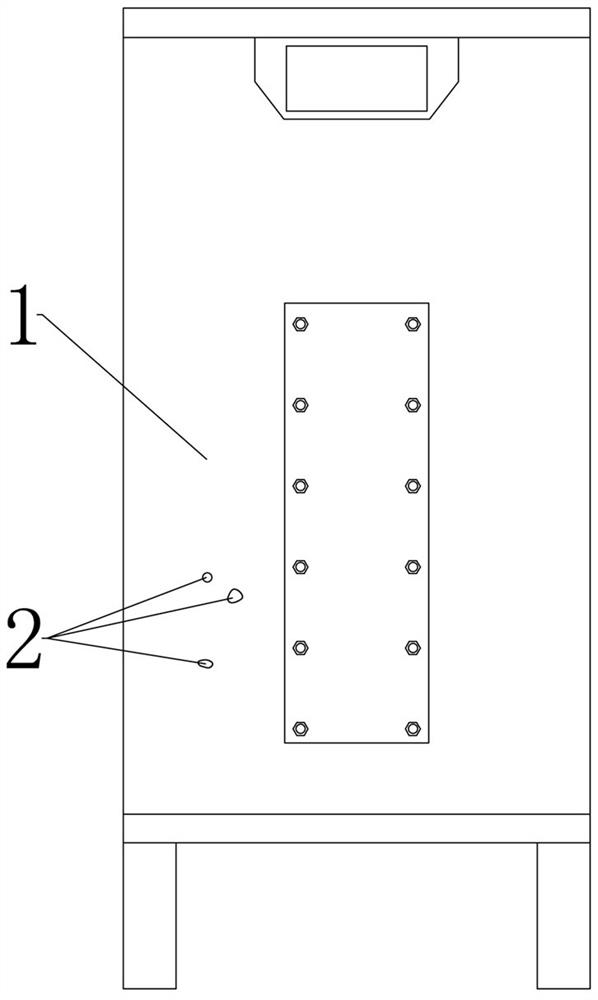

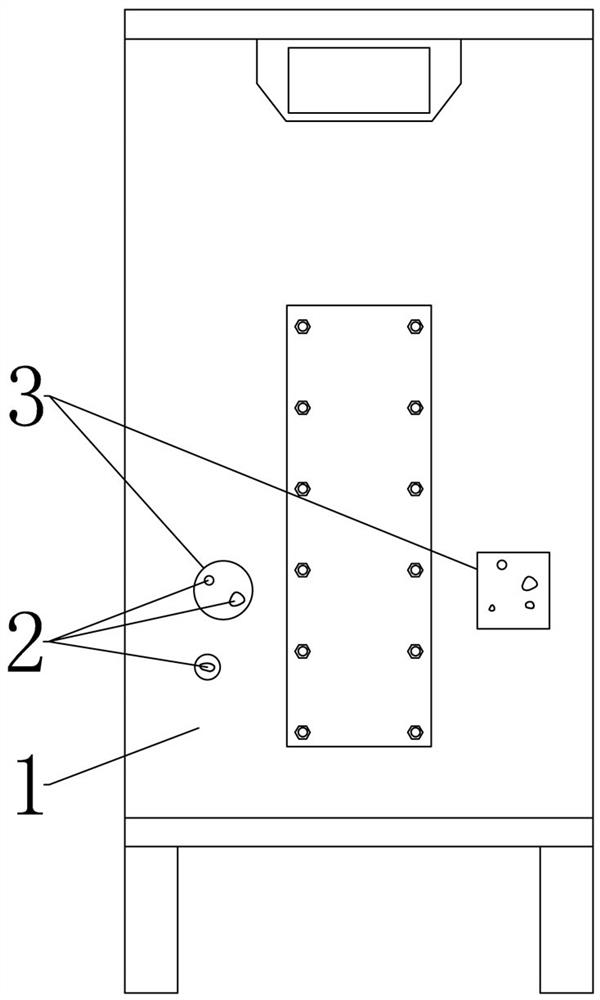

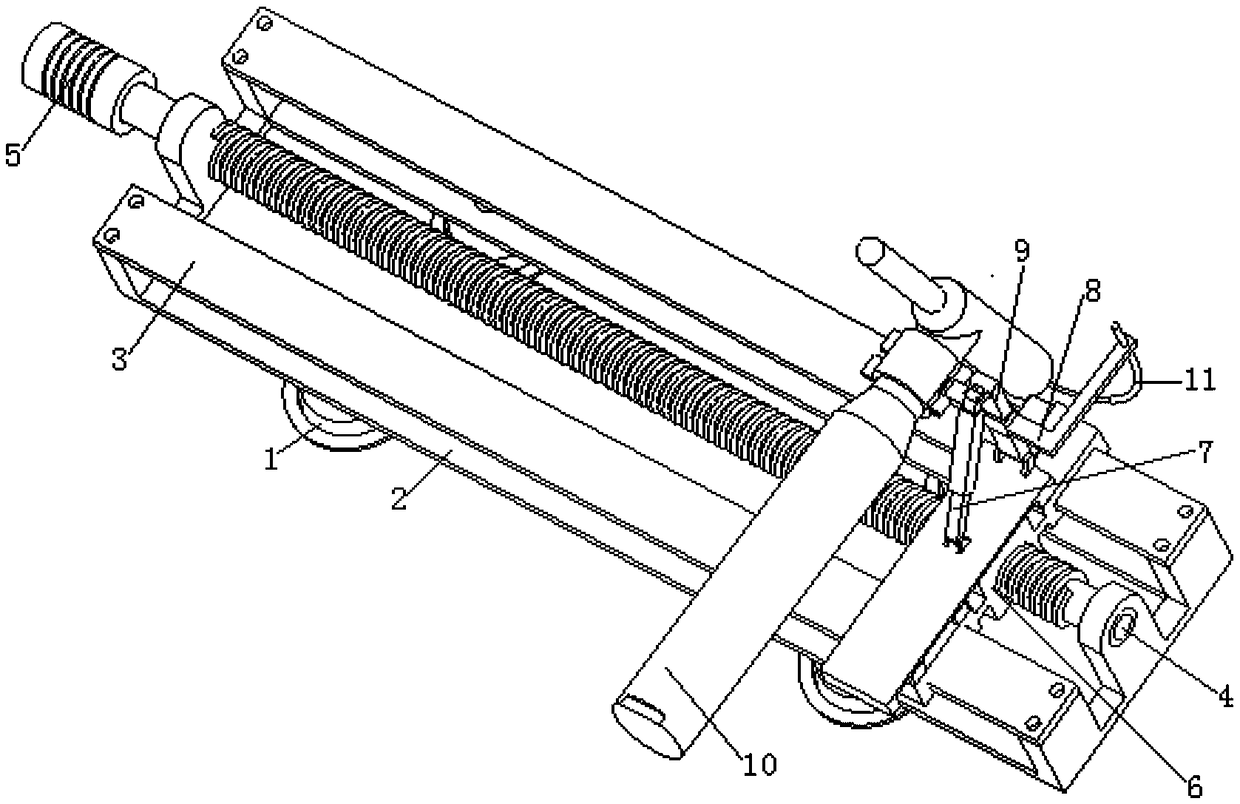

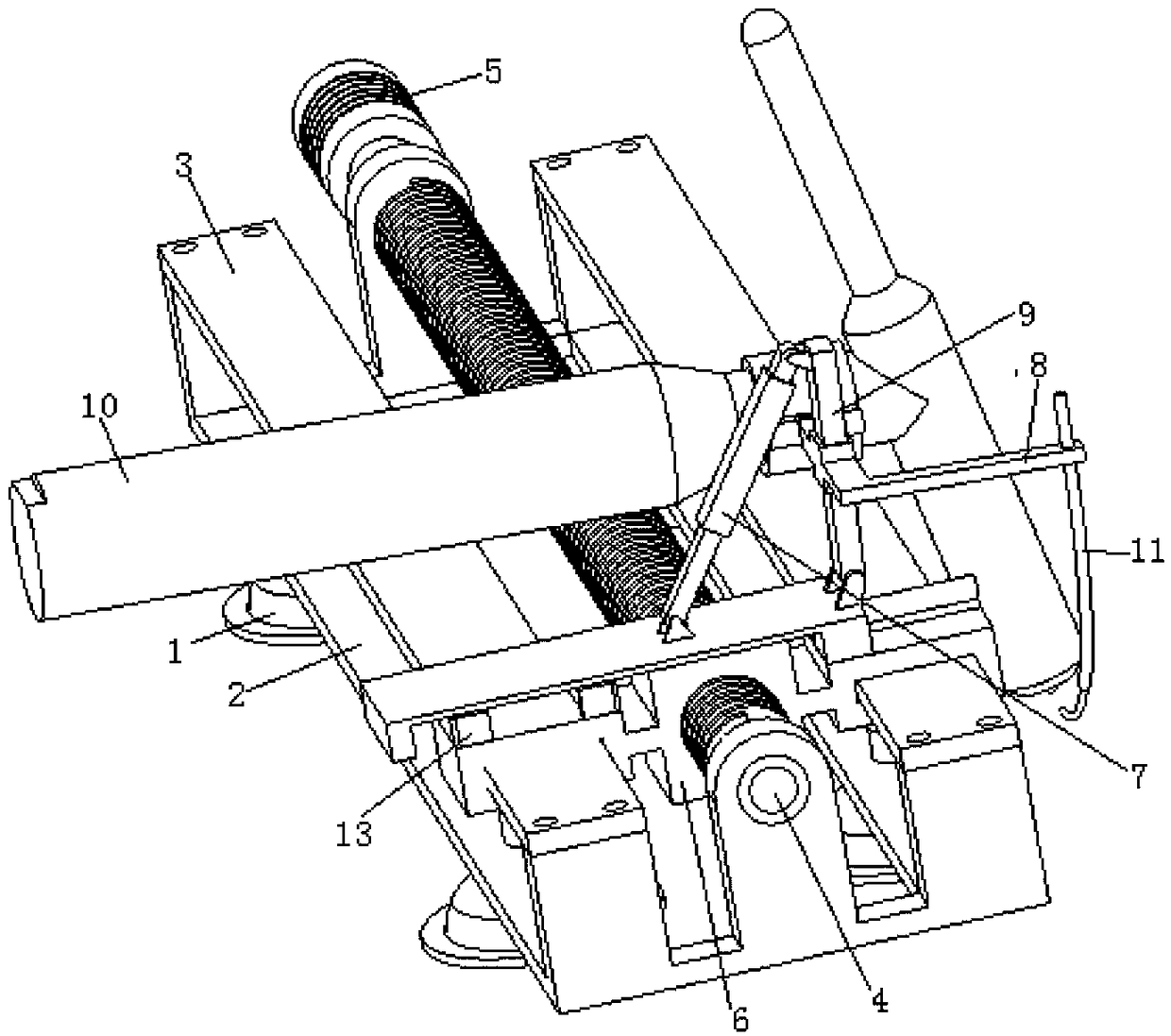

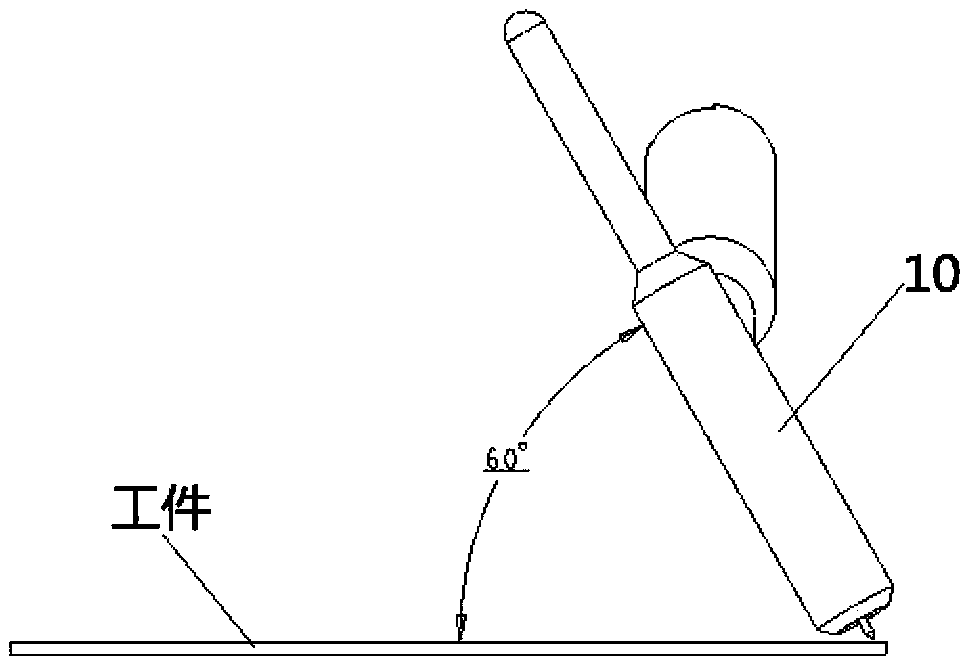

Semi-automatic welding fixture for sheet welding

ActiveCN107030430AGuaranteed smooth slidingEasy to useWelding/cutting auxillary devicesAuxillary welding devicesSemi automaticEngineering

The invention discloses a semi-automatic welding fixture for sheet welding. The semi-automatic welding fixture for sheet welding comprises a fixture frame body, wherein a lead screw and a slide rail parallel to the axis of the lead screw are arranged at the top of the fixture frame body, a nut slide block is in threaded connection to the lead screw, the end part of the nut slide block is arranged on the slide rail in a sleeving manner, and the nut slide block is driven through the lead screw to slide along the slide rail; and a welding gun clamping device used for fixing a welding gun is installed on the nut slide block. The semi-automatic welding fixture for sheet welding is light in weight, capable of being adsorbed onto a weldment, and applicable to semi-automatic welding for a straight welding joint; the fixture is capable of conveniently moving and is moved after one section is welded, and then the next section is welded, so that the long and straight welding joint can be welded; the height and the angle of the welding gun can be randomly adjusted; and a welding tractor is simulated to complete welding in combination with a wire feeding mechanism.

Owner:SHAANXI SCI TECH UNIV

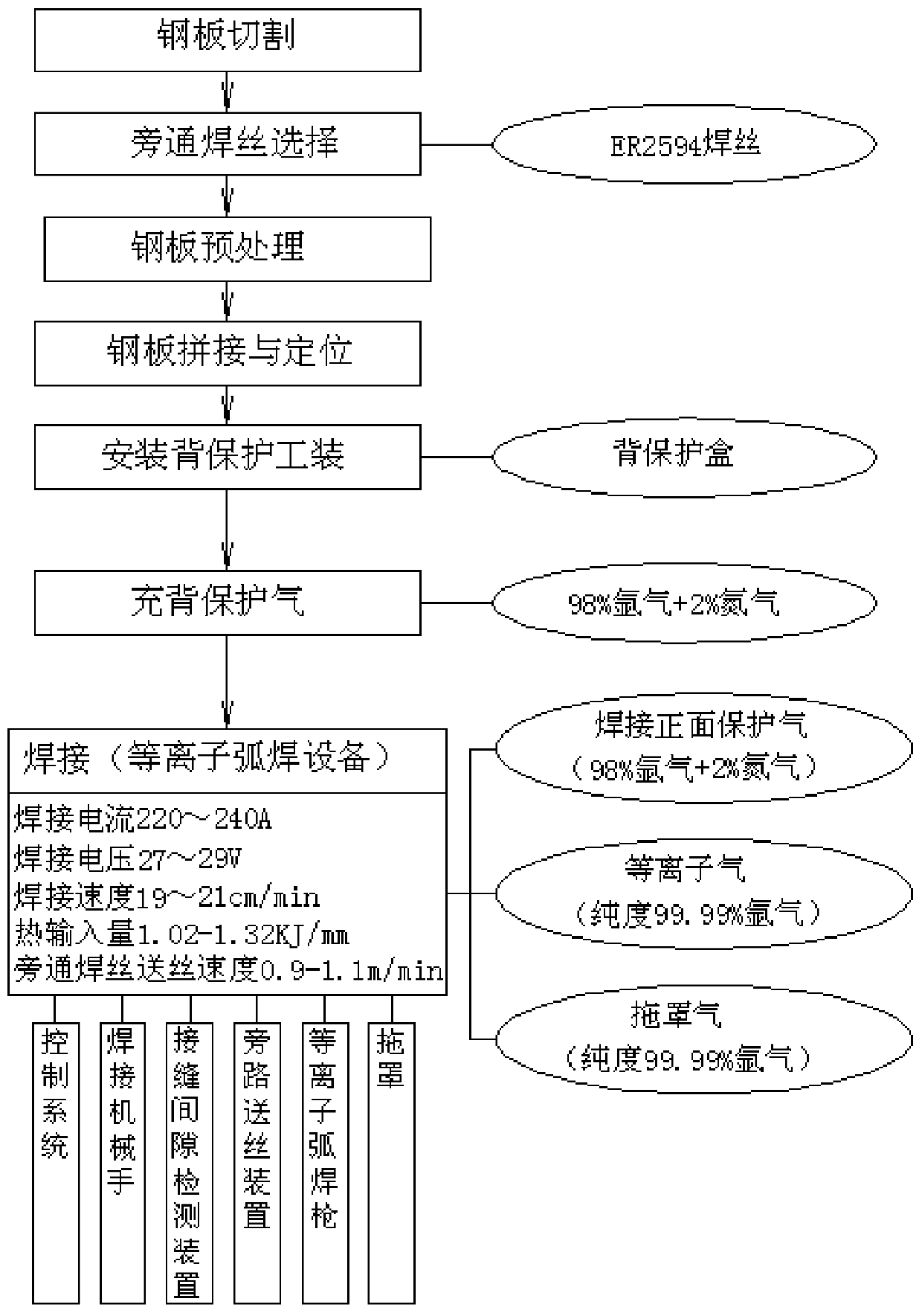

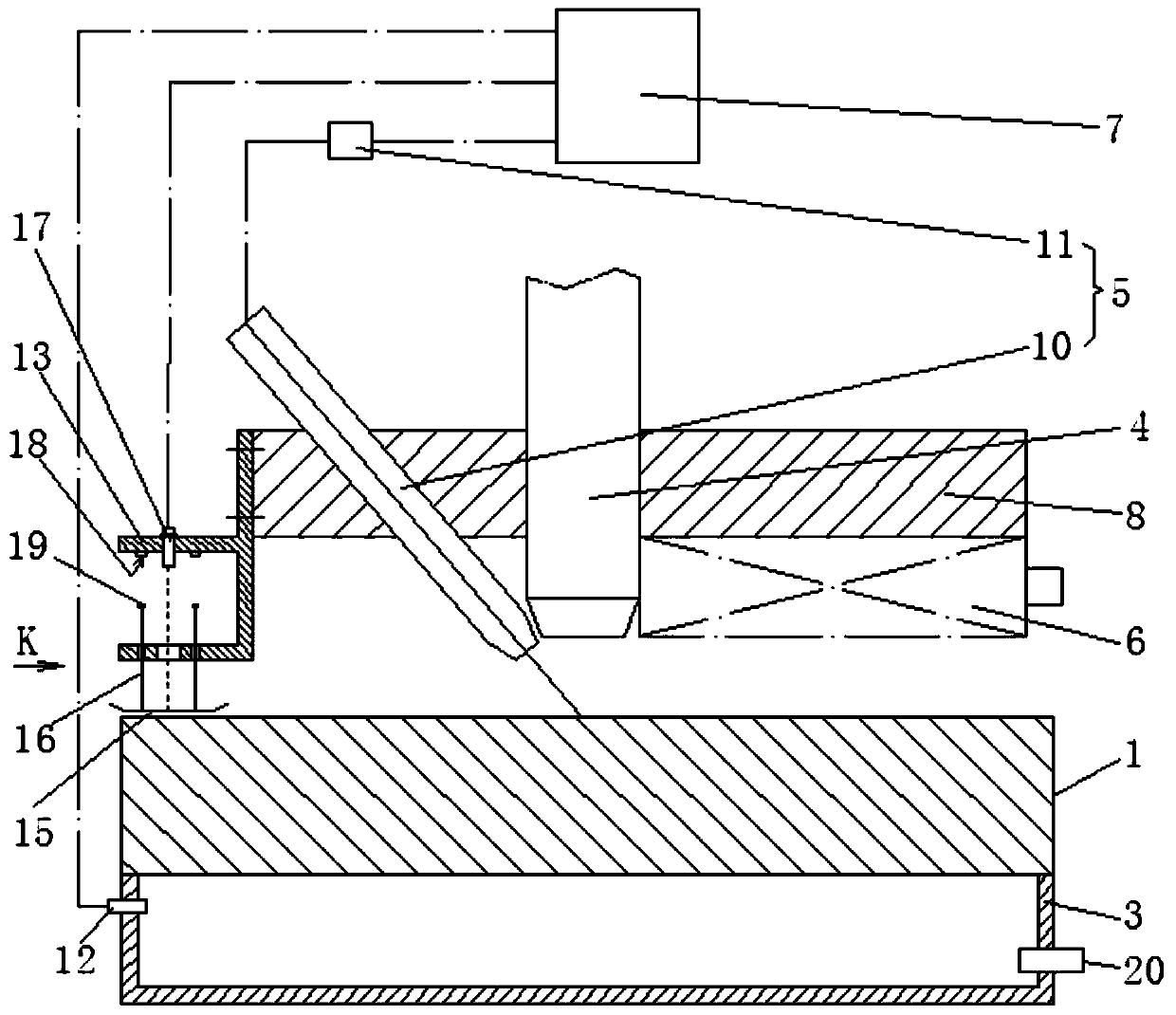

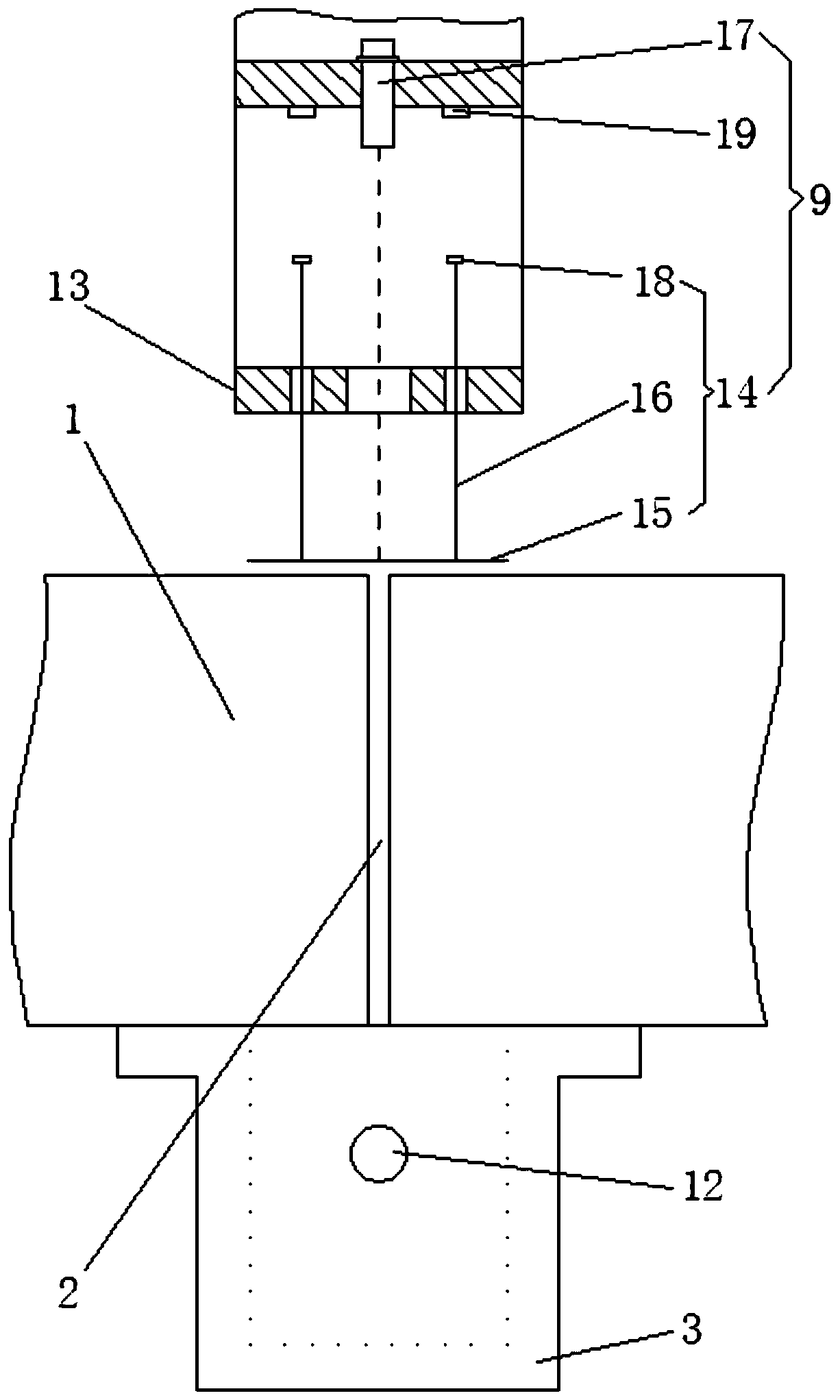

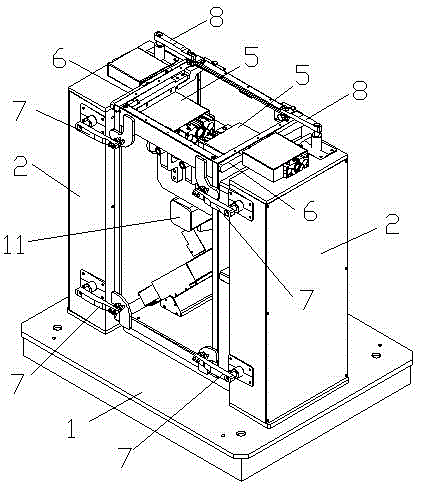

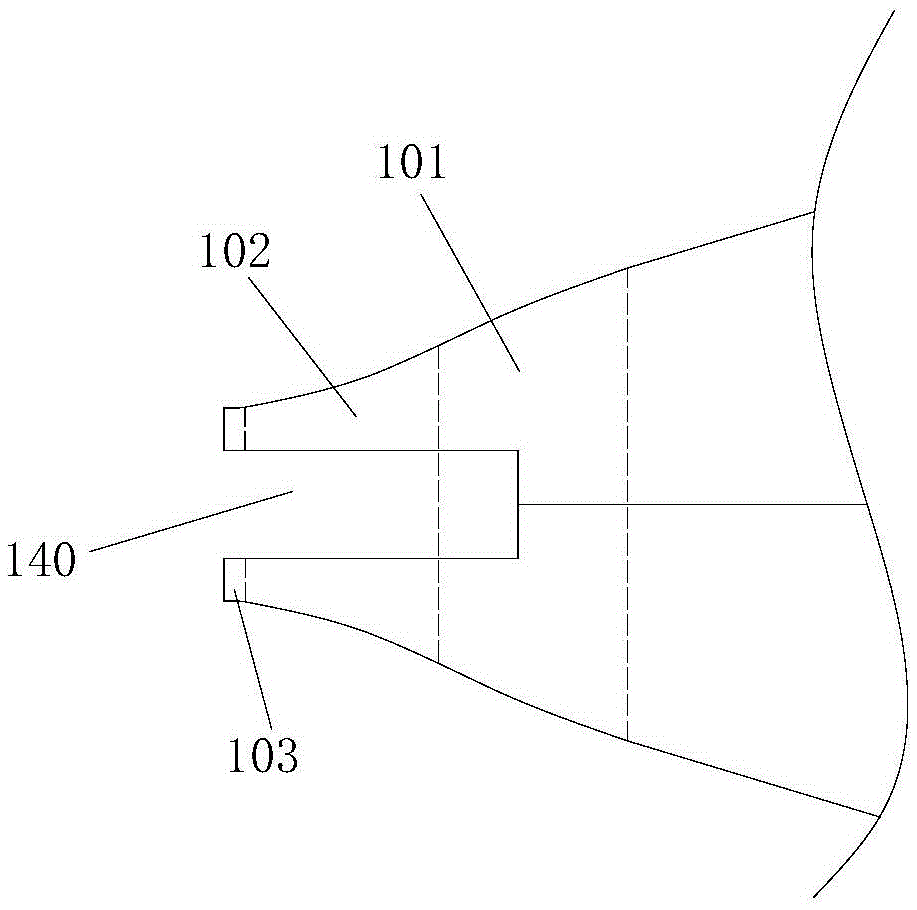

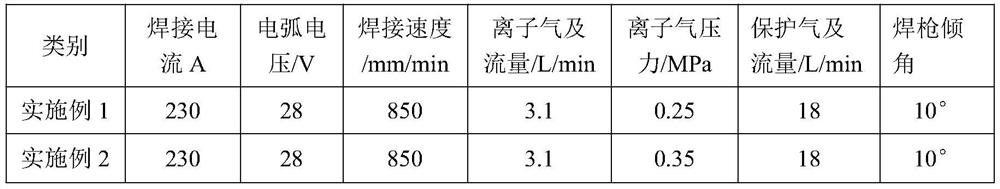

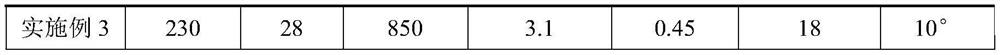

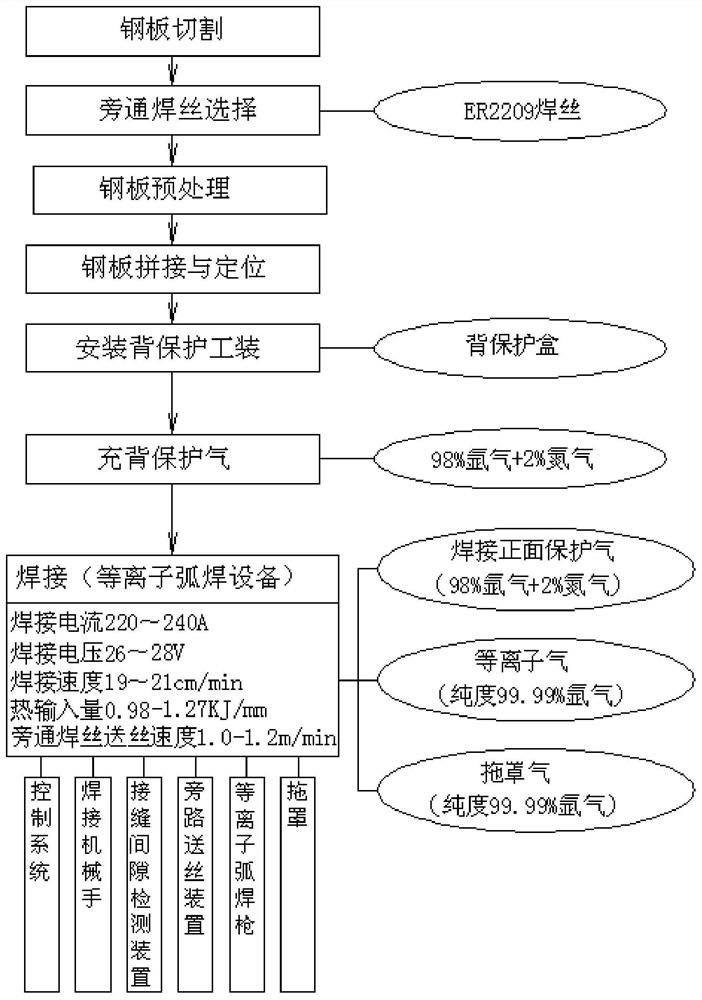

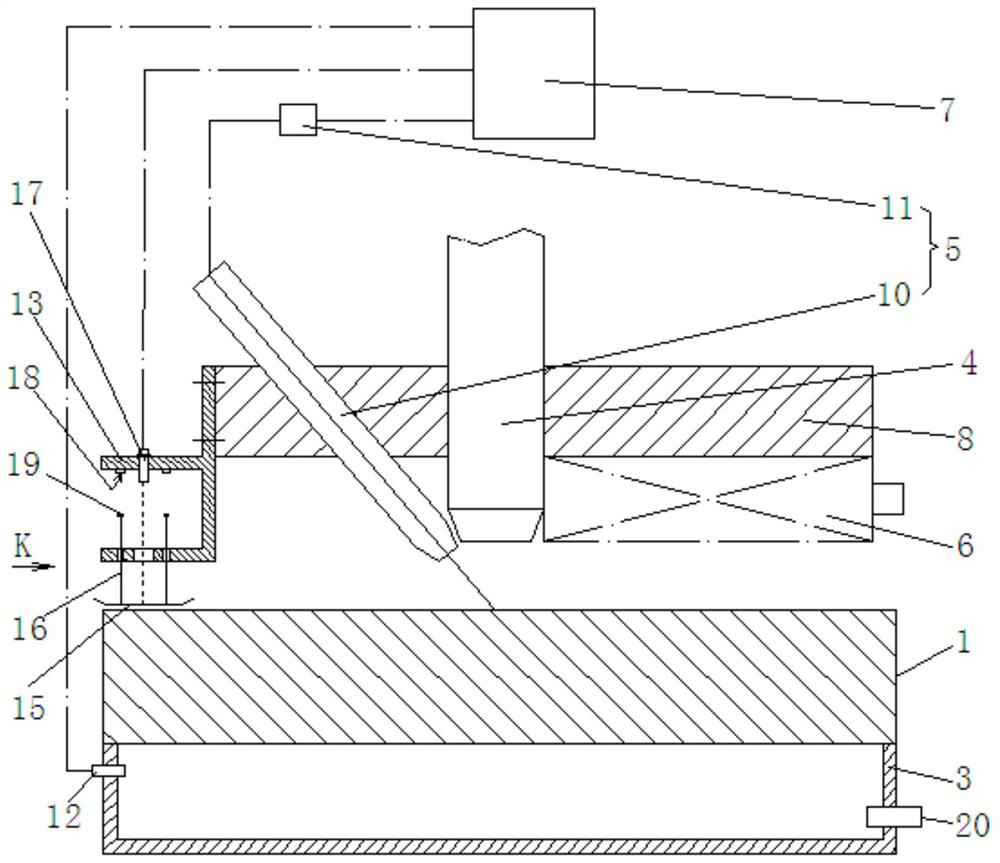

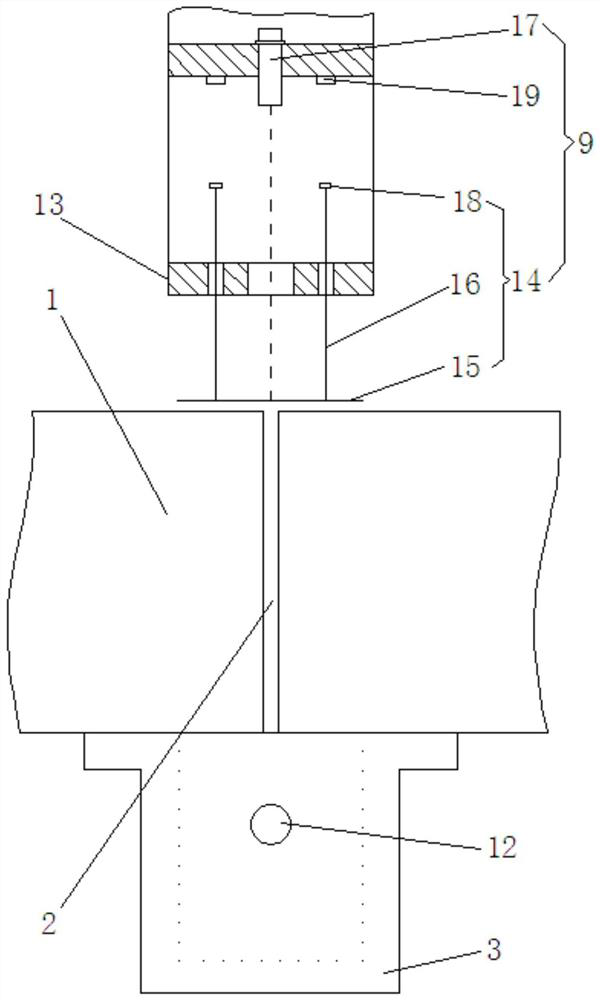

Plasma welding technology of duplex stainless steel 2507 with bypass wire feeding

ActiveCN110253123AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelShielding gas

The invention relates to the technical field of welding, and discloses a plasma welding technology of duplex stainless steel 2507 with bypass wire feeding. The plasma welding technology comprises the following process steps of: step (1), cutting steel plates; step (2), selecting welding wires; step (3), pretreating the steel plates; step (4), splicing and positioning the steel plates; step (5), installing a back protective tooling; step (6), filling a back protective gas; and step (7), welding, wherein the welding process parameters are as follows: the polarity of a power supply of plasma-arc welding equipment is straight polarity direct current; the tungsten electrode of a plasma-arc welding gun is cerium-tungsten electrode WCe-20, and the diameter Phi of the plasma arc welding gun is 4.0mm; the back protective gas and the welding front protective gas are the mixed gas of 98% of argon and 2% of nitrogen; plasma gas and drag cover gas are argon with the purity grade of 99.99%; the flow rate of the plasma gas is 5.5-6.0L / min; the flow rate of the welding front protective gas and the drag cover gas is 25-30L / min; the welding current is 220-240A; the voltage is 27-29V; the welding speed is 19-21cm / min; and the heat input is 1.02-1.32KJ / mm. The plasma welding technology can improve the welding efficiency, reduces the production cost, and meanwhile improves the quality of welding.

Owner:CHENGXI SHIPYARD XINRONG

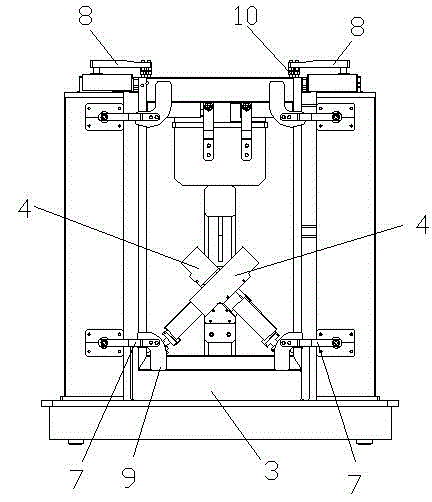

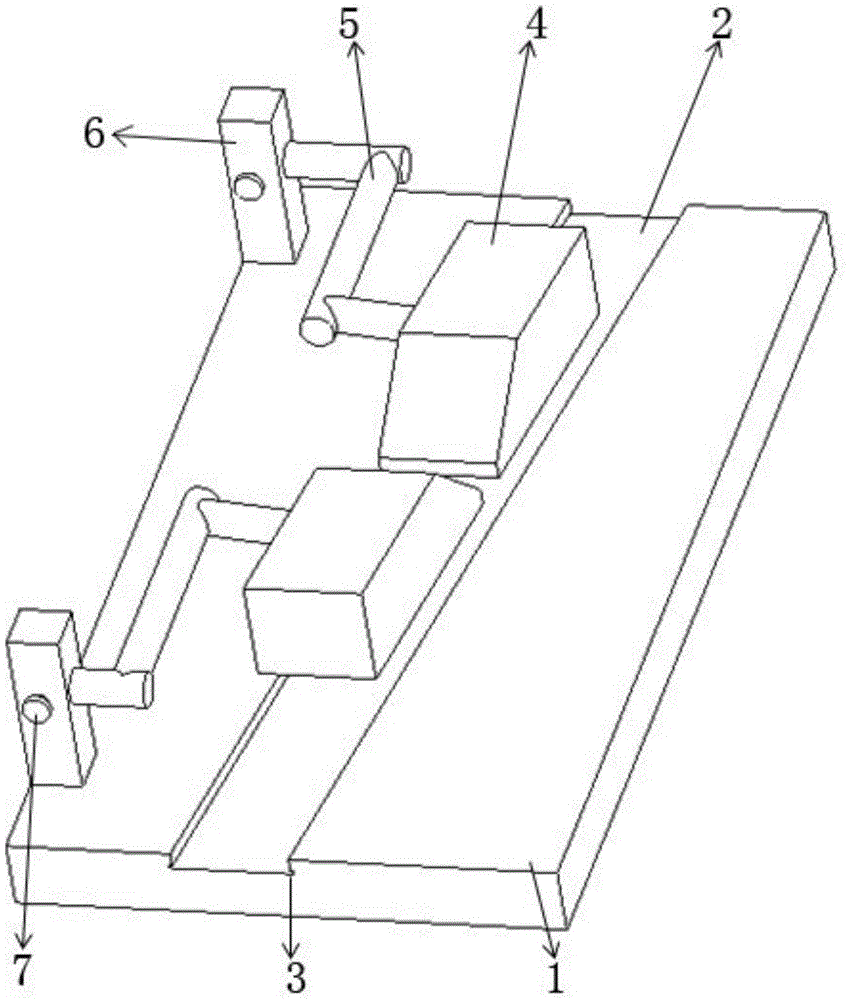

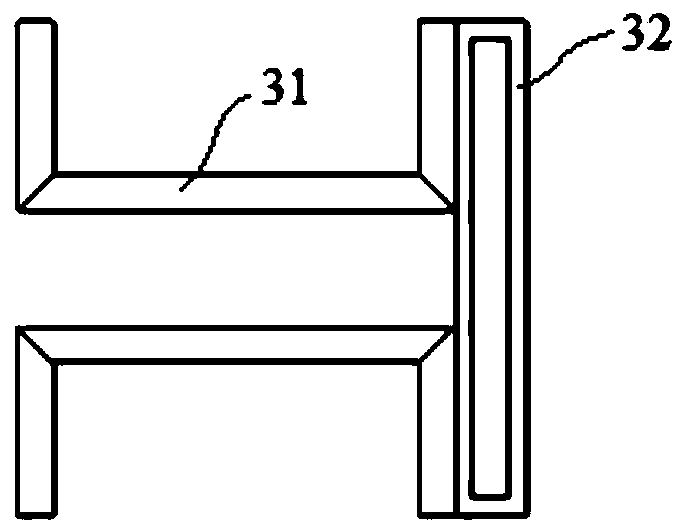

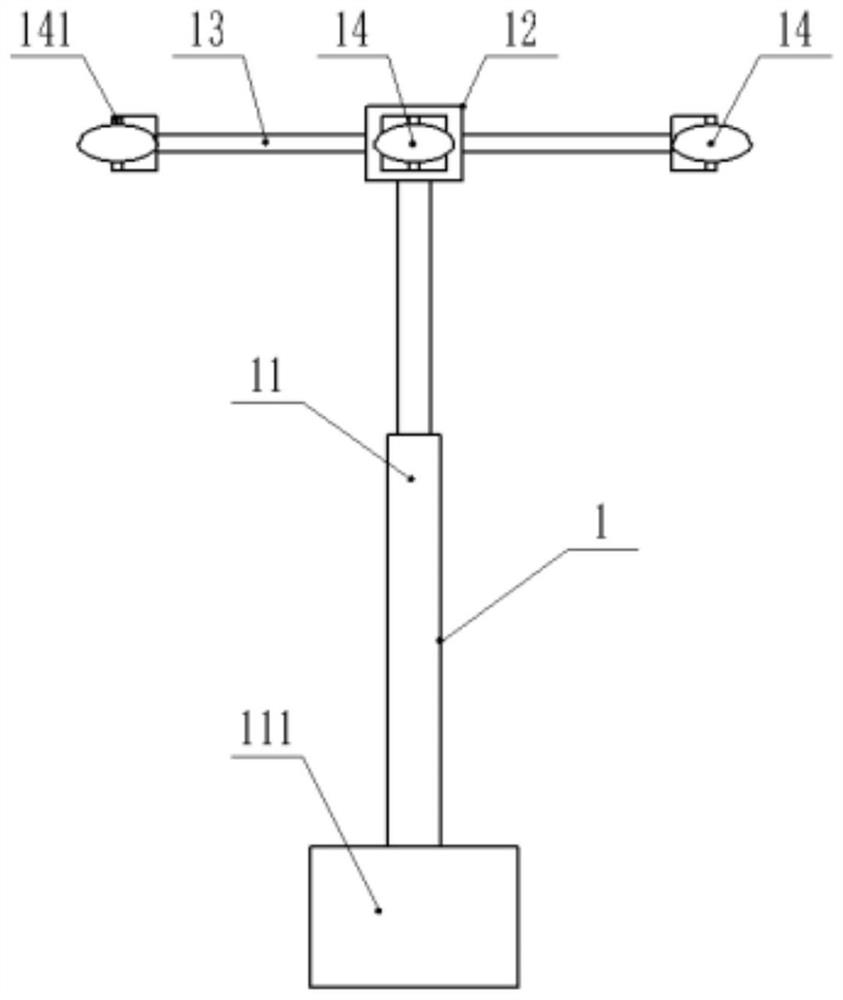

Workpiece welding clamp

ActiveCN104588946AAchieve fixationAvoid Welding ThroughWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld penetration

The invention discloses a workpiece welding clamp which comprises a base and two stand columns fixed to the base. A U-shaped seat is further arranged on the part, between the two stand columns, of the base. Two lower inner spacer parts which are perpendicular to each other and two upper inner spacer parts which are oppositely arranged are arranged between the two stand columns, the included angles between the lower inner spacer parts and the bottom face of the U-shaped seat are 45 degrees, and limiting parts used for limiting workpieces and matched with the upper inner spacer parts are arranged on the tops of the two stand columns. The workpieces are comprehensively fixed through multiple clamping air cylinders in different stations, the welding precision can be ensured while a robot carries out welding, especially the weld penetration phenomenon of the workpieces with very thin materials can be avoided, and the welding quality and the welding efficiency are improved.

Owner:SUZHOU AOGUAN ROBOTIZATION EQUIP

Submerged-arc welding method for K-shaped groove of low-temperature high-manganese austenite steel

The invention discloses a submerged-arc welding method for a K-shaped groove of low-temperature high-manganese austenite steel. The method comprises the following steps: forming the K-shaped groove ina steel plate to be welded at a unilateral angle of 45 degrees, flatly placing the steel plate on a welding platform, and not preheating before welding; adopting a forced forming welding process forbacking welding, and after backing welding is completed, adopting the same welding process for filling cover faces of the front face and the back face of the K-shaped groove; adopting a front-surfaceand back-surface alternate welding process for the submerged-arc welding , and carrying out back-surface welding after front-surface welding is carried out for two times; carrying out cosmetic weldingon the front surface after carrying out back-surface welding for two times, and finally carrying out cosmetic welding on the back surface; and after welding is completed, controlling the deformationdegree to be below 2 degrees. The method is a matched welding process of a matched welding material of the low-temperature high-manganese austenite steel, stable use of the matched welding material isguaranteed, it is guaranteed that the performance of the matched welding material is not inconsistent due to mismatching of the welding process, and a gap is filled in the welding process of the matched submerged-arc welding material of the low-temperature high-manganese austenite steel.

Owner:NANJING IRON & STEEL CO LTD

Method for welding stainless steel optical units without cutting steel belt and corresponding tool structure

The invention provides a method for welding stainless steel optical units without cutting steel belt, and has the advantages of overcoming the defects at the butting parts, satisfying the requirements of laser welding and directly welding without cutting steel belts so as to reduce the production cost. The method comprises the following steps: shielding the border positions on two sides of two steel belts needing opposite side connection; welding the exposed opposite side connection positions through welding equipment to complete the opposite side connection of the two steel belts; placing the integrated steel belt on two steel belt placing frames; forming stainless steel pipes through a longitudinal tubing die after the two steel belt placing frames discharge the steel belts at the same time; welding the shielded border positions on the two sides of the steel belts by a laser continuous welding device in the process of forming the stainless steel pipes in the longitudinal tubing die.

Owner:FUJIKURA HENGTONG AERIAL CABLE SYST +2

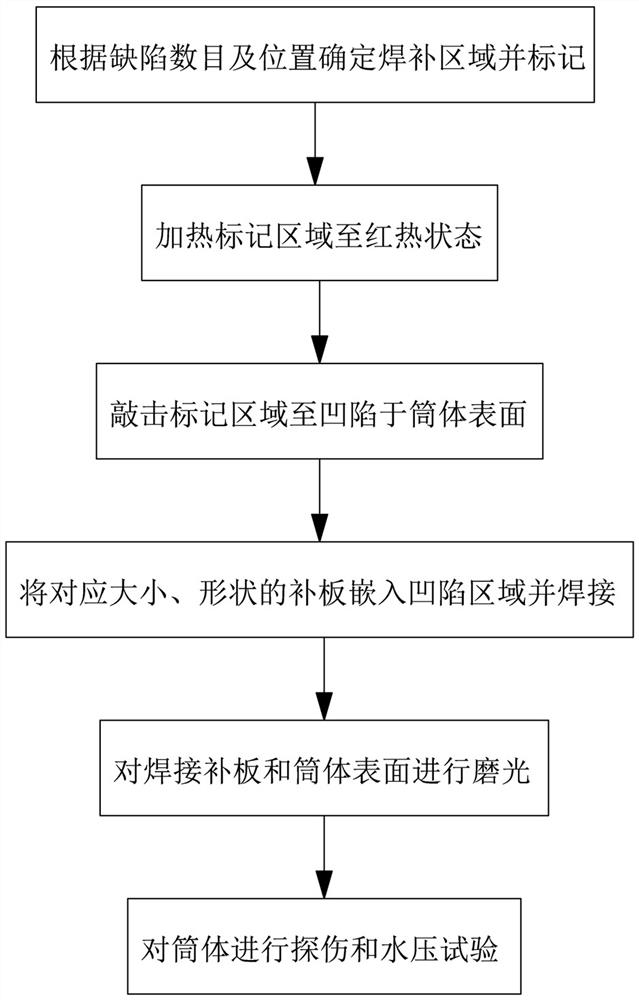

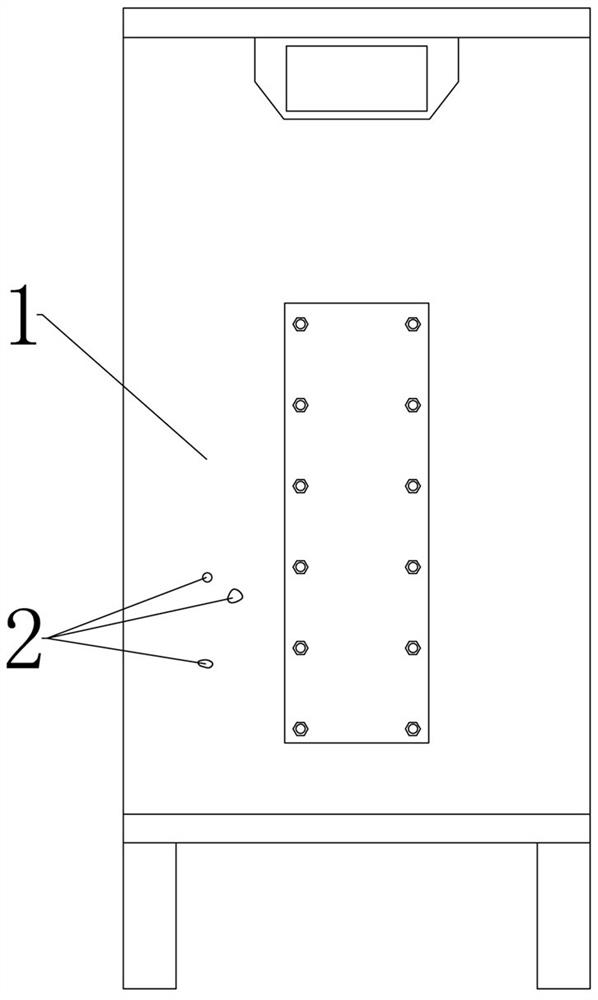

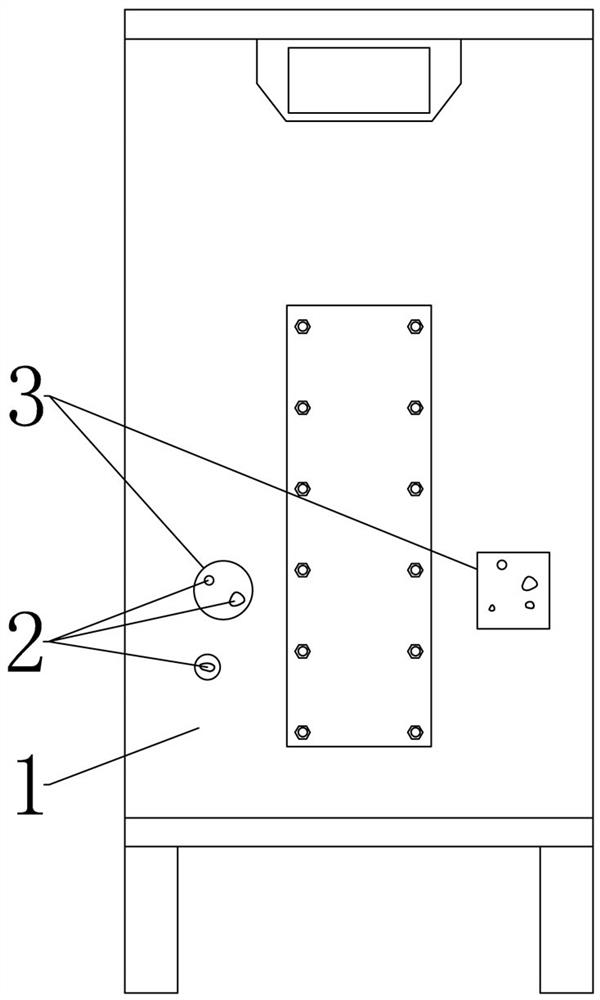

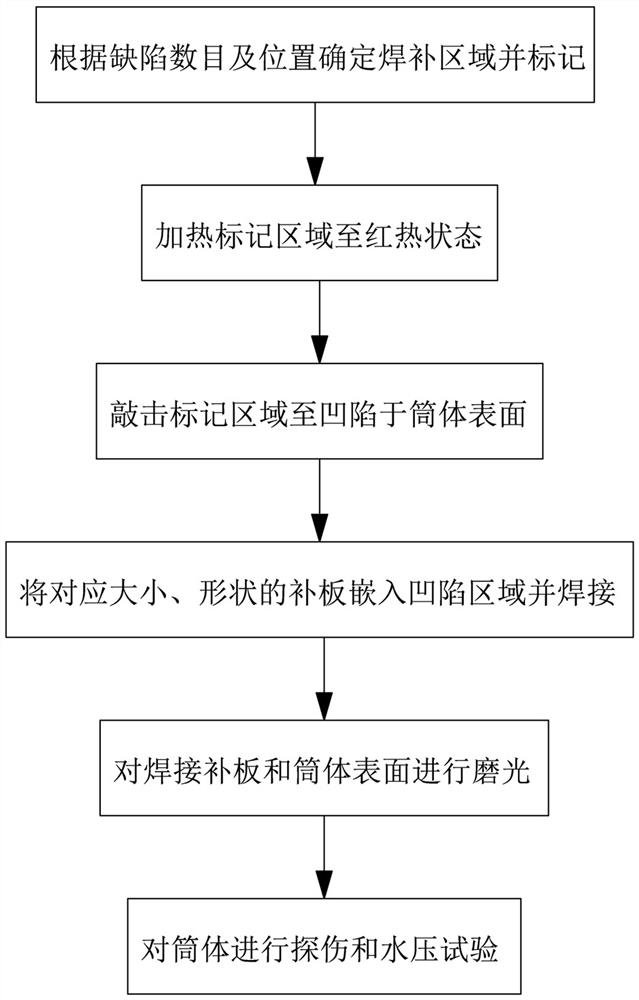

Preheating boiler outer cylinder welding repair method

The invention relates to the technical field of boiler welding repair, in particular to a preheating boiler outer cylinder welding repair method. The preheating boiler outer cylinder welding repair method comprises the following steps of determining the position of a defect, cleaning the periphery of the defect, determining a repair welding area according to the shape and size of the defect, and marking the repair welding area; heating the marked area, wherein the size of the heating area is 10-15mm from the repair welding area as the center; knocking the marking area in a red hot state to enable the marking area to be concave on the surface of the cylinder body; according to the size of the sunken area, embedding the corresponding repair plate into the sunken area, and welding the repair plate into the sunken area; smoothing the weld joint; and carrying out flaw detection on a weld zone of the boiler outer cylinder, and carrying out a hydrostatic test after flaw detection. The method solves the problems that in the prior art, when corrosion spots of the boiler outer cylinder are welded and repaired, repair plates are directly added for welding, consequences such as welding leakage, poor welding and weld penetration at the welding position are likely to be caused, and even larger defects are caused, the welding effect is good, and the efficiency is high.

Owner:CRRC LUOYANG CO LTD

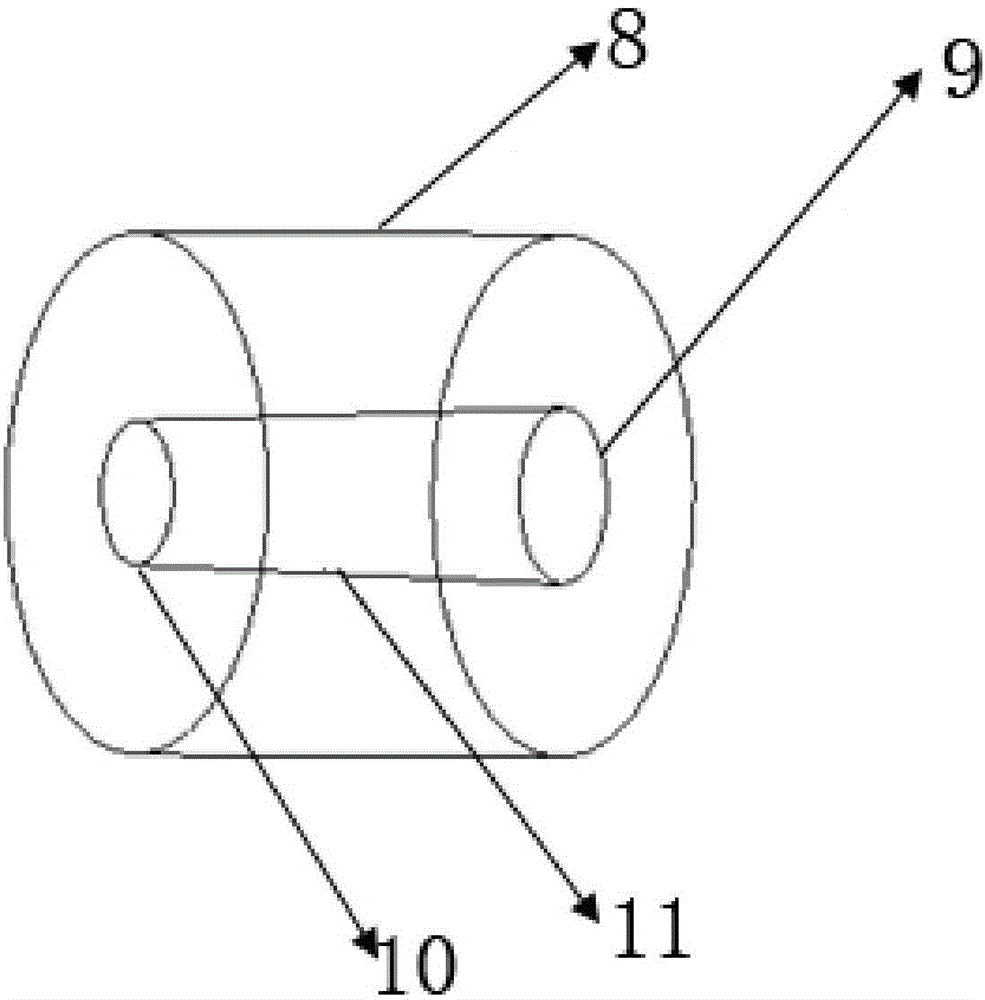

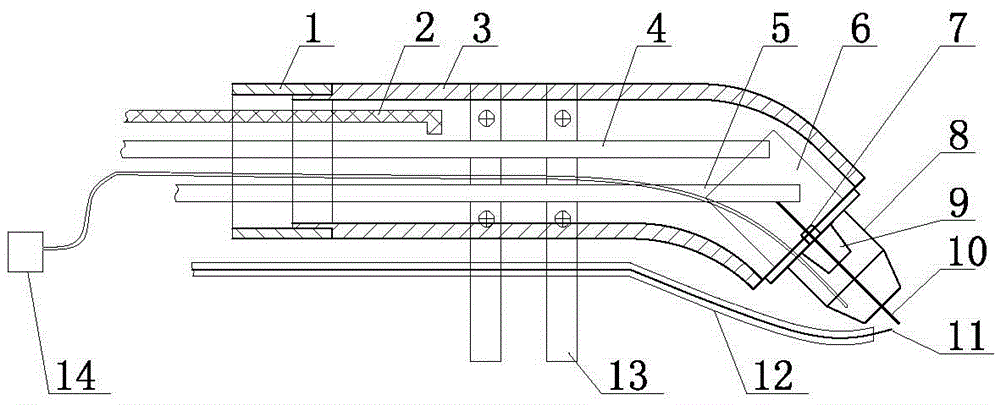

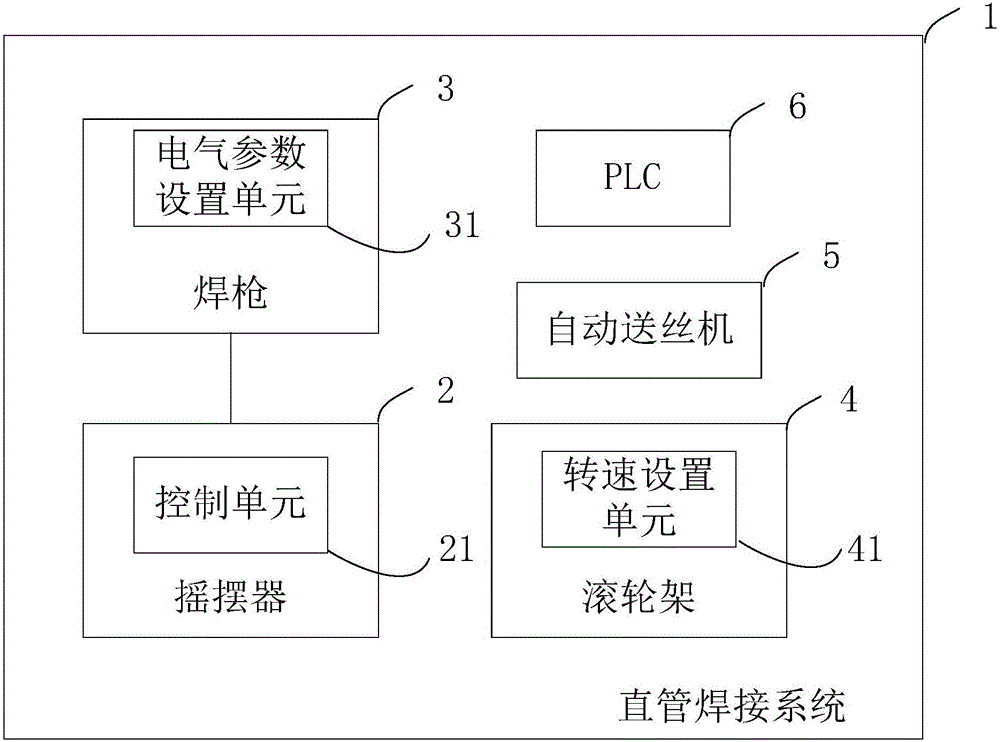

Automatic welding gun head for tube-shell thin tube plate embedded deep hole welding

InactiveCN106735785AFacilitates deep hole weldingFast penetrationCooled electrode holdersElectrode accessoriesSpray nozzleEngineering

The invention discloses an automatic welding gun head for tube-shell thin tube plate embedded deep hole welding. The structure comprises a guide cavity tube, an insulation cavity tube and a nozzle module; one end of the insulation cavity tube is fixedly connected with the end part of the guide cavity tube; the length of the welding gun head is elongated through the guide cavity tube to conveniently realize deep hole welding of a tube plate; a copper base is fixedly connected into a cavity at the other end of the insulation cavity tube, and is fixedly connected with the nozzle module; the nozzle module includes a tungsten pole; a tip part of the tungsten pole includes a first smoothing angle and a second smoothing angle; the second smoothing angle is larger than the first smoothing angle; and the double smoothing angles of the tip of the tungsten pole can centralize arcs to facilitate quick through welding of the tube plate and a heat exchange tube. The automatic welding gun head further comprises an arc pressure tracker; and the arc pressure tracker can detect the arc voltage change during welding to adjust the position of the tungsten pole so as to effectively prevent the through welding phenomenon under the condition of through welding as far as possible.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

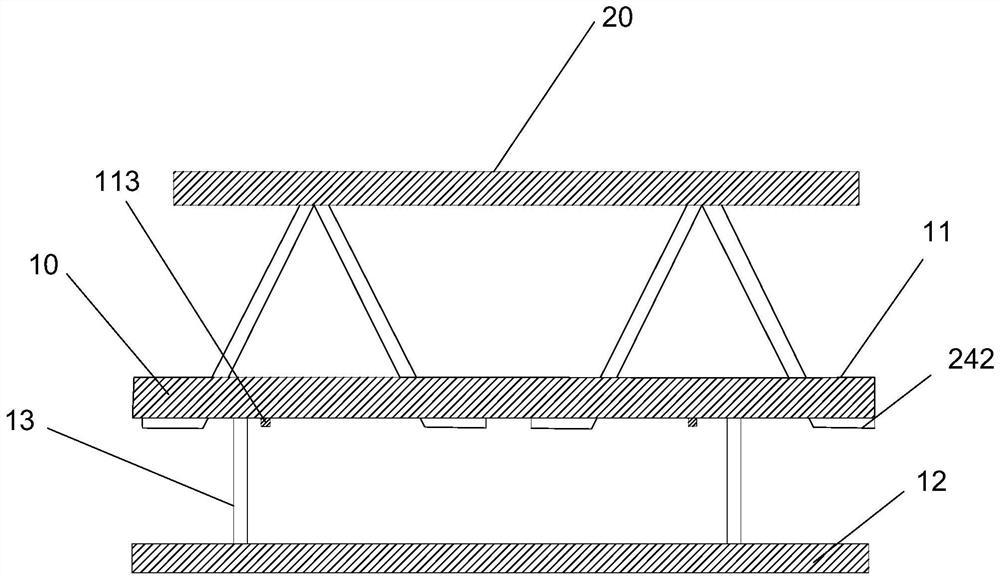

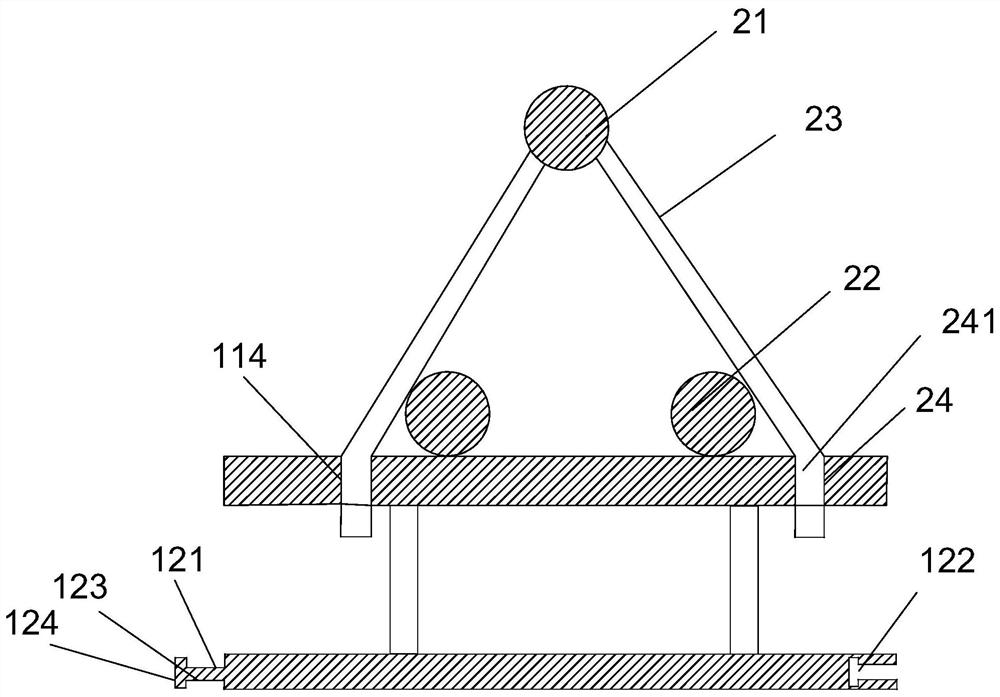

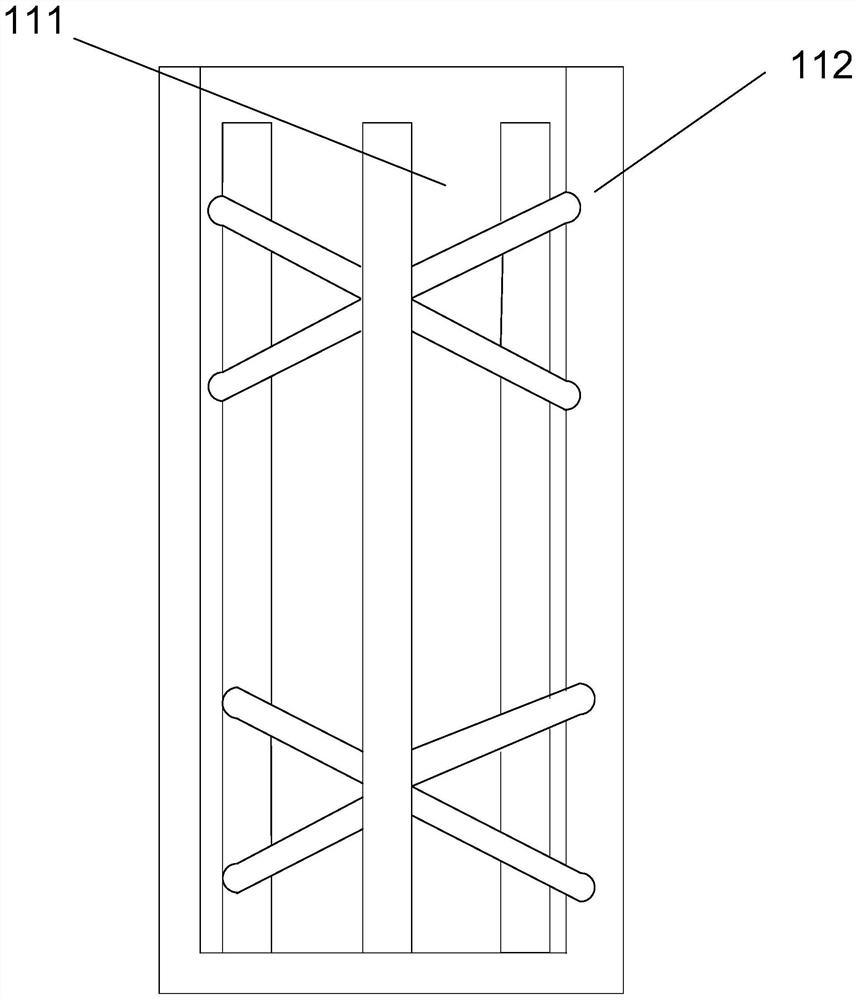

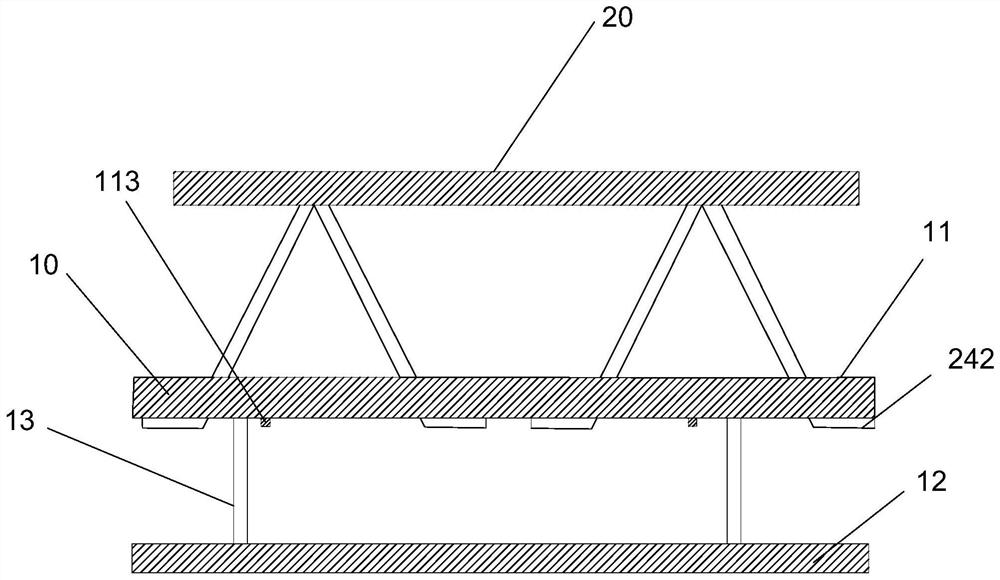

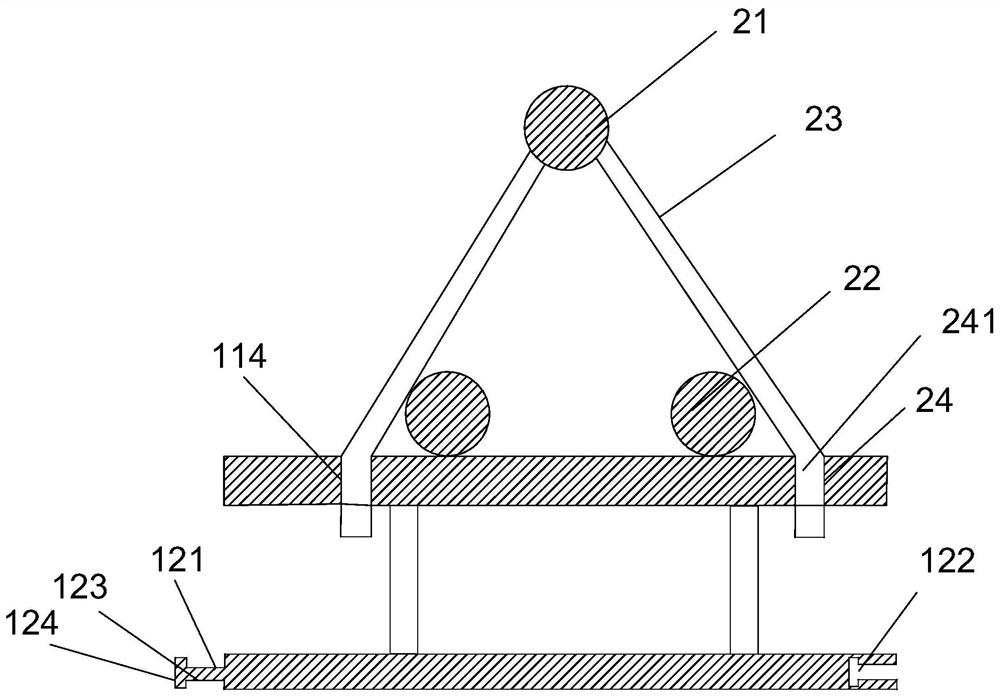

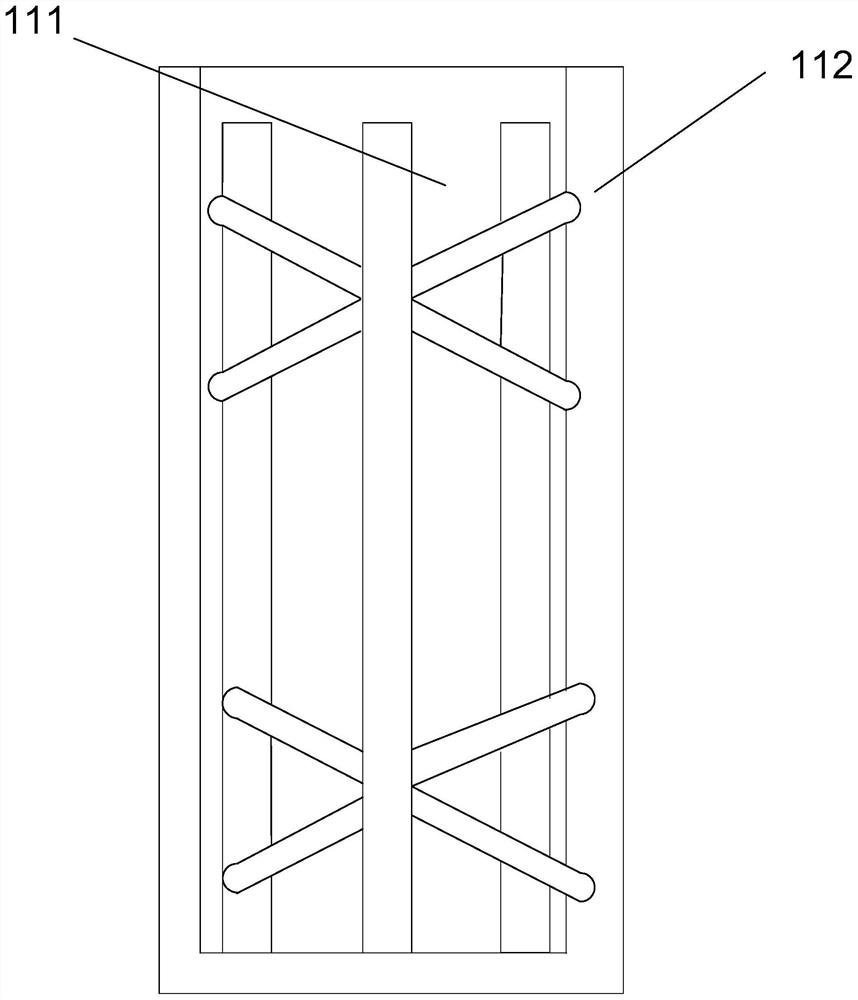

High-rise building long-span steel bar truss floor deck and production technology thereof

ActiveCN111794428AAvoid WeldingPrevent leakageFloorsCeramic shaping apparatusArchitectural engineeringLong span

The invention discloses a high-rise building long-span steel bar truss floor deck, and the high-rise building long-span steel bar truss floor deck comprises several soffit formworks and several steelbar trusses, wherein the soffit formworks are in buckled connection with the steel bar trusses, the soffit formwork comprises an upper bearing plate, a lower loading plate and a connection column, thesteel bar trusses pass through the upper bearing plate, the upper bearing plate comprises a buckling plate, a splicing plate and a buckle, and the splicing plate and the buckling plate are in cooperation with the steel bar trusses through the buckle; the invention also discloses a production technology of the high-rise building long-span steel bar truss floor deck, and the technology comprises the following steps: preparing the soffit formworks; assembling the steel bar trusses; and assembling a steel bar truss floor deck. On the basis of the prior art, a structure of the steel bar truss floor deck is improved, the existing single-layer soffit formworks is changed into be double-layer, thereby, leakage of grout is avoided, further, the buckling plate and the splicing plate are mutually fitted, thus, the upper bearing plate can be fixed with the steel bar trusses, then, an aim of avoiding weld penetration of the soffit formworks, a risk of leakage of grout is avoided, and the steel bartruss floor deck can be used in high-rise buildings.

Owner:南京耀丰新材料科技有限公司

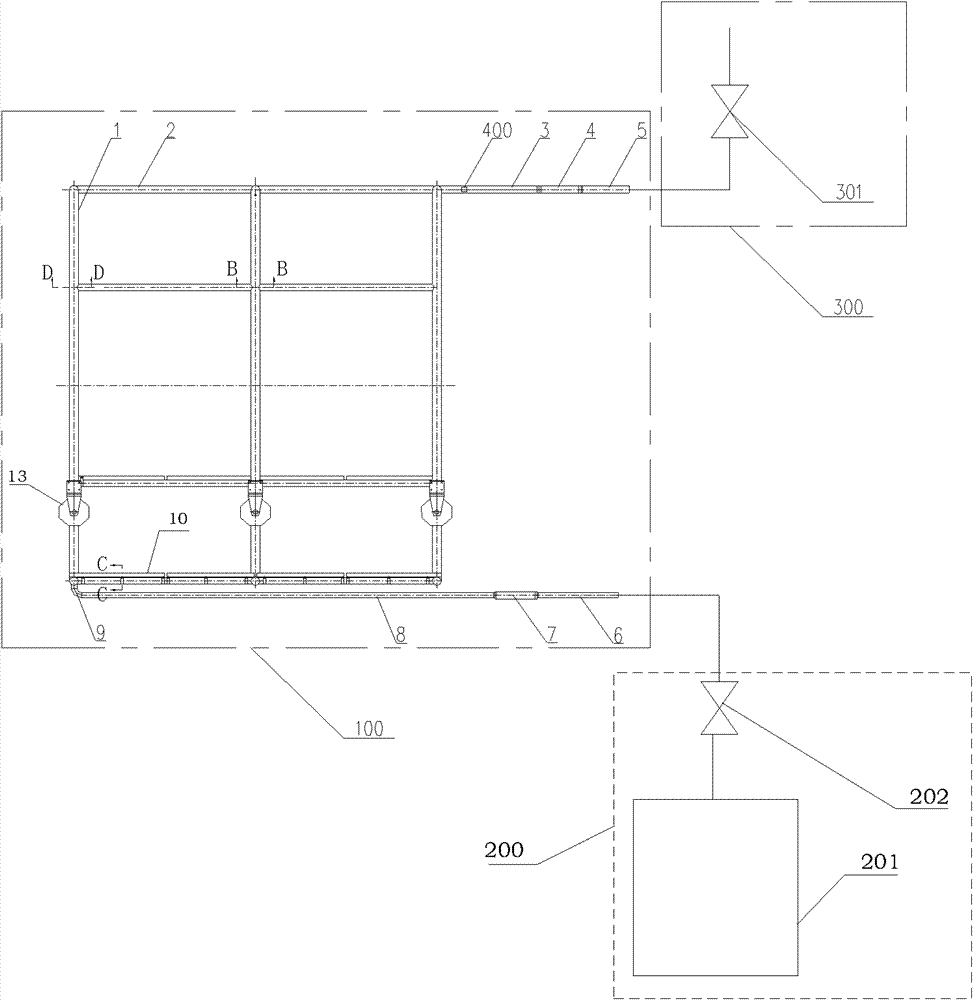

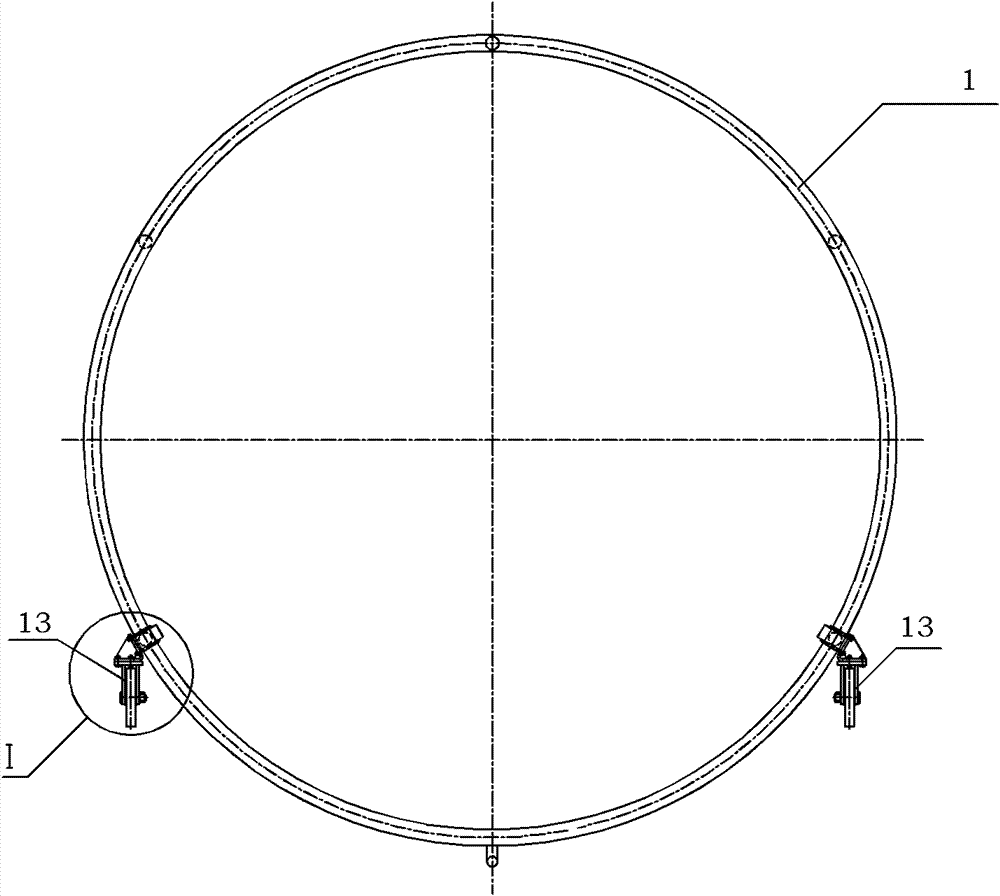

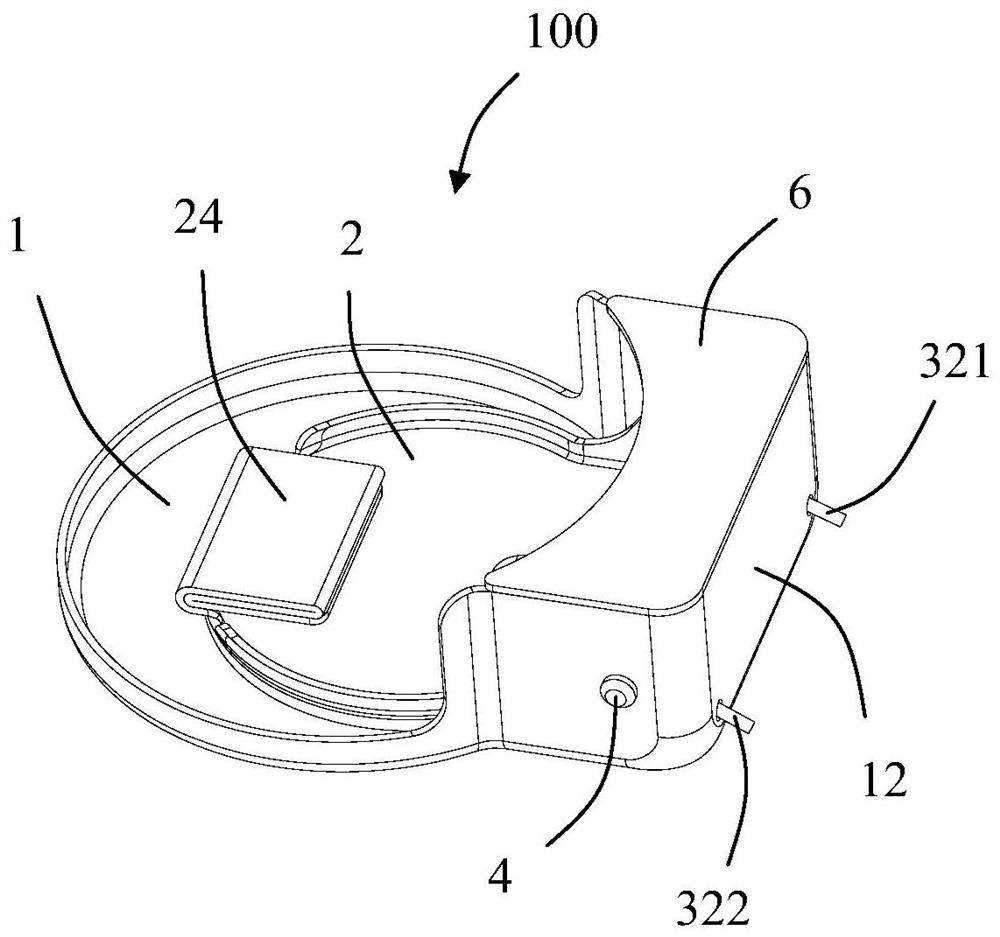

Pressure-resisting welding method for circular seam of pressure container

ActiveCN110039266AAvoid scrappingAvoid deformationWelding/cutting auxillary devicesArc welding apparatusEngineeringWeld seam

The invention discloses a pressure-resisting welding method for a circular seam of a pressure container. The pressure-resisting welding method includes the following steps that firstly, a pressure container cylinder is assembled on a supporting rotating frame, insertion connection openings are formed in the end faces of the two sides of the pressure container cylinder in a hitting manner, and an edge milling machine is used for conducting grooving on the outer side of a sealing head of the pressure container and the outer side of the pressure container cylinder; secondly, the sealing head of the pressure container is inserted into the tail end of the pressure container cylinder, a pressure device is applied to the tail end of the sealing head of the pressure container, and positioning welding is conducted on the circular seam; thirdly, a double-wire submerged arc welding machine is arranged at the upper portion of the pressure container, a gas shield welding machine is arranged at theinner bottom of the pressure container, a rotating frame begins to rotate after preheating, and welding is conducted at the same time; fourthly, a pressure container connecting pipe and the pressure container cylinder are assembled and welded; and fifthly, stress-relief annealing is conducted, all-directional detection is conducted on the weld seam, and the interior and exterior surfaces of the pressure container are treated.

Owner:宜兴市压力容器厂有限公司

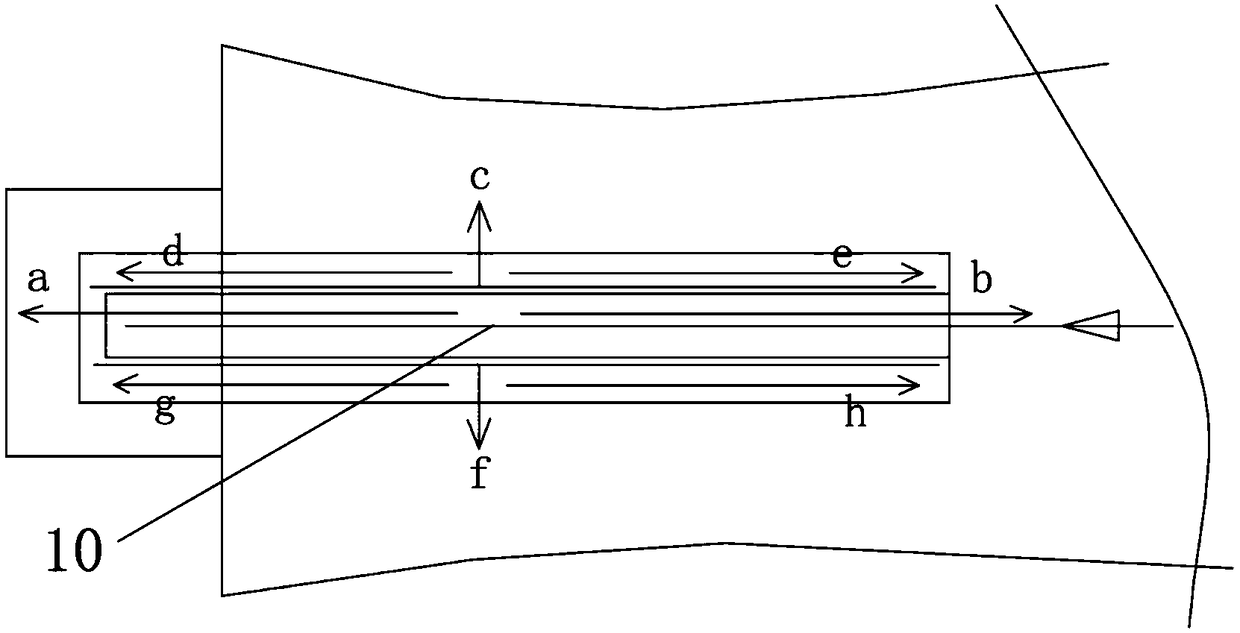

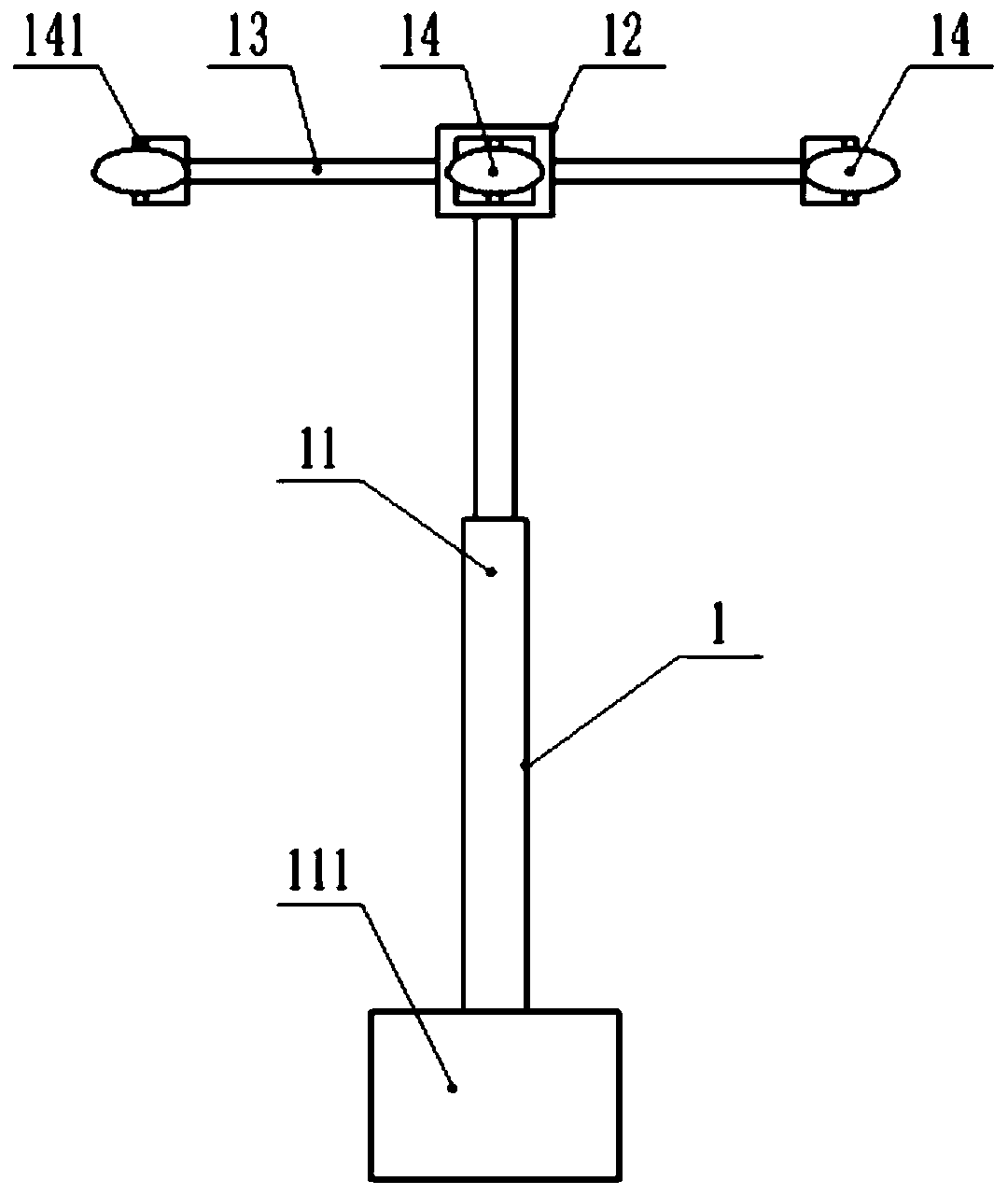

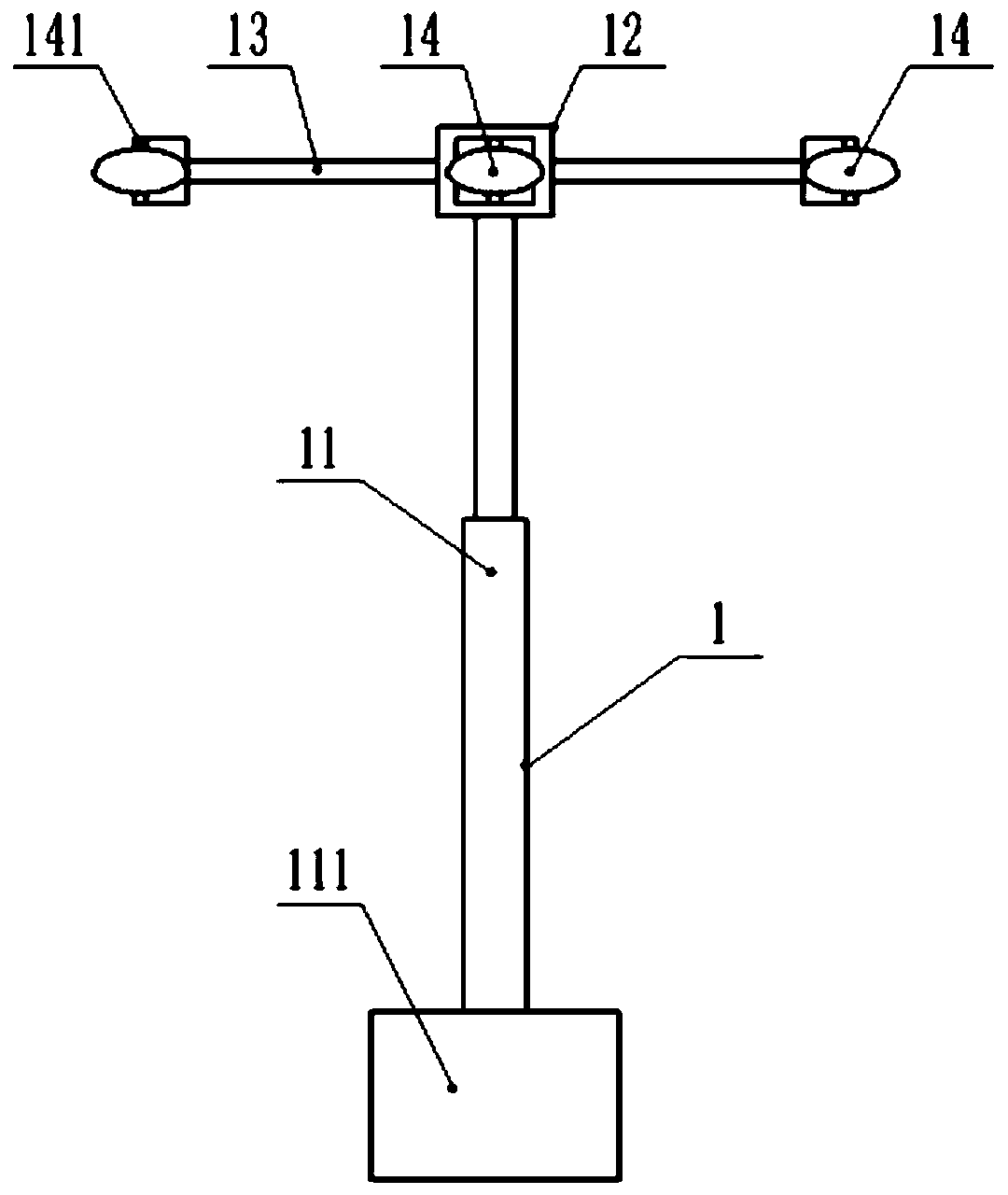

Straight pipe welding system

InactiveCN106002062ARotate at a constant speedUniform swingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a straight pipe welding system. The straight pipe welding system comprises a welding gun, a wiggler, an automatic wire feeding machine and a roller wheel frame, wherein the welding gun is fixedly connected with the wiggler and comprises an electric parameter setting unit which is used for setting electric parameters when a motor of the welding gun works; a straight pipe to be welded is arranged on the roller wheel frame, and the roller wheel frame is used for driving the straight pipe to be welded to rotate; the wiggler is used for driving the welding gun to swing along the welding joint between the to-be-welded end of the straight pipe to be welded and a component to be welded; the wiggler comprises a control unit which is used for controlling the swinging period of the wiggler; and the automatic wire feeding machine is used for feeding a solder wire to a welding gun head, and the welding gun is used for welding the welding joint through the welding gun head. The straight pipe welding system provided by the invention can improve the welding efficiency of the straight pipe, reduce air pores, lower the weld penetration probability, improve the uniformity of the welding joint, and guarantee the welding quality.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

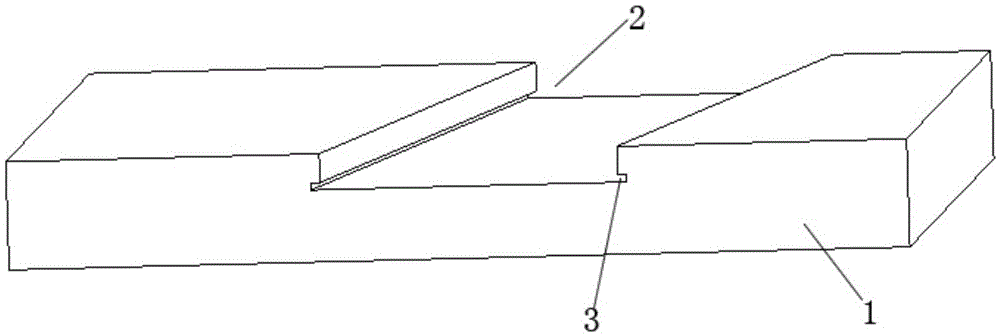

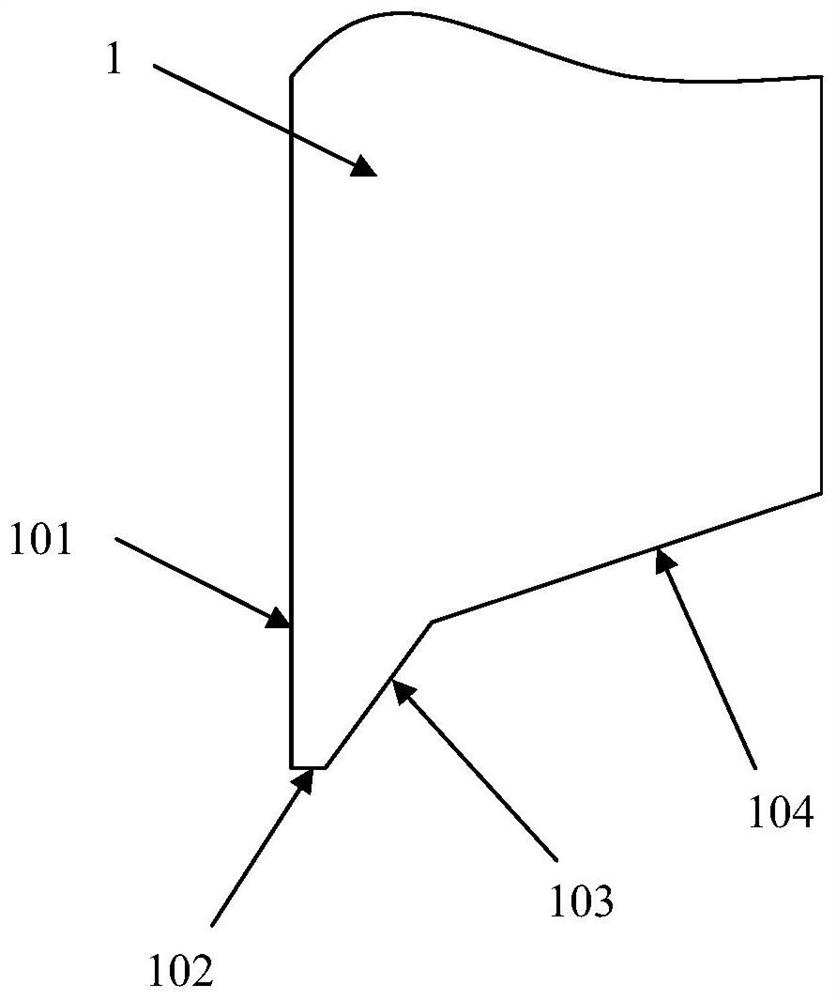

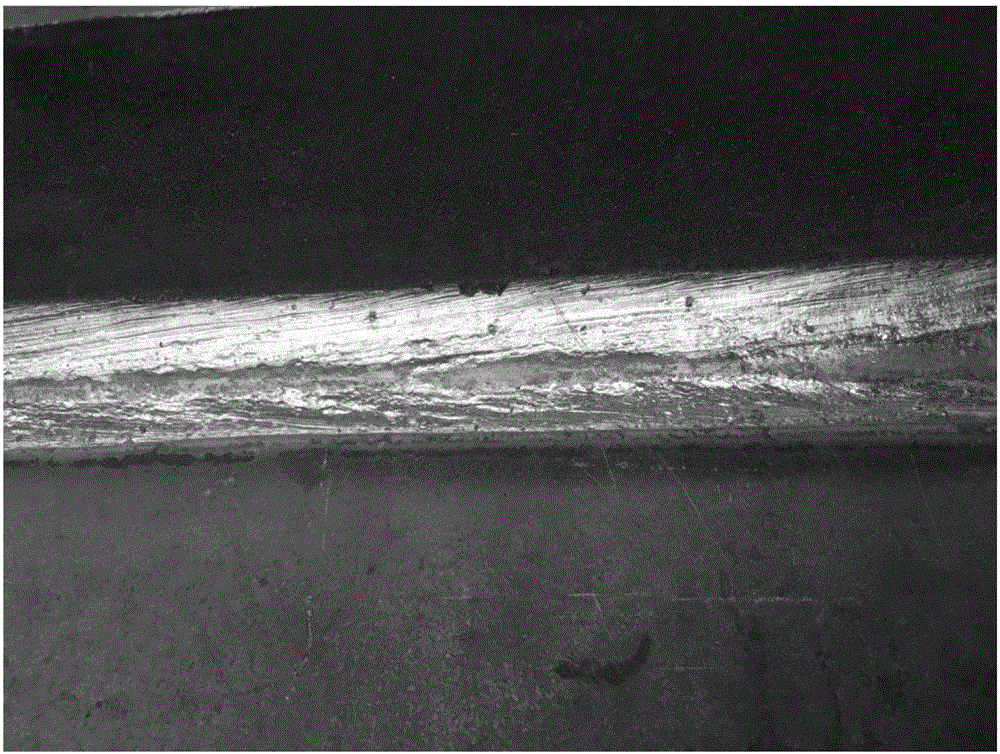

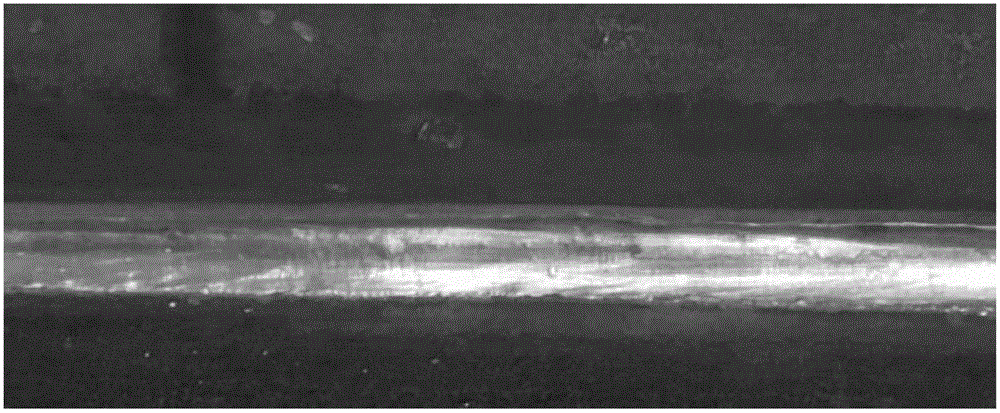

Knife handle and welding method of the knife handle and cutter body

ActiveCN104191420BAvoid welding throughSufficient space for subsequent grindingArc welding apparatusMetal-working hand toolsEngineeringThermal treatment

The invention relates to a welding process for cutter handles, in particular to a cutter handle and a welding method for the cutter handle and a cutter body. The head end of a cutter handle body is in a gradual contraction tapered portion, and a handle plug is encapsulated at the tail end of the cutter handle body; the tapered portion is provided with an outer convex area, an inner concave area and a straight stretching area in sequence along the axis of the cutter handle, and the outer convex area, the inner concave area and the straight stretching area are connected smoothly; a positioning groove concaved along the axis of the cutter handle is formed in the center of the handle plug. The welding method includes the steps that the cutter body is inserted into the cutter groove of the cutter handle, thermal treatment, welding and tempering heat preservation are conducted in sequence, and weld joint grinding and cutter handle surface antiskid treatment are carried out. The cutter handle solves the technical problem that the structure of a traditional cutter handle affects welding quality and welding efficiency; the technical problem that deformation is prone to occurring in a traditional welding method is solved through the provided welding method.

Owner:阳江十八子刀剪制品有限公司

Method used for efficiently welding straight seams of air conditioner compressor shell

InactiveCN112475571AMeet the requirements of production rhythmReduce volume fractionWelding/cutting auxillary devicesAuxillary welding devicesWeld seamSmall hole

The invention discloses a method used for efficiently welding straight seams of an air conditioner compressor shell. The technical problems that when straight seams of an existing air conditioner compressor shell blank are welded, welding quality is poor, and welding efficiency is low are mainly solved. The method used for efficiently welding the straight seams of the air conditioner compressor shell comprises the steps that (1) the to-be-welded surface of a steel plate is cleaned; (2) an air conditioner compressor shell blank is prepared; and (3) the air conditioner compressor shell blank iswelded, a small hole type plasma welding process is adopted, the butt joint straight seams of the rolled steel plate are welded, a plasma welding process is adopted, in the welding process, the shellblank is controlled to move along the center of a welding seam to achieve welding, the welding current is 200-240 A, the arc voltage is 25-31 V, and the welding speed is 750-850 mm / min. The method ishigh in welding efficiency, good in welding quality, easy and convenient to operate and low in welding cost.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A plasma welding process of duplex stainless steel 2205 with bypass wire feeding

ActiveCN110253125BImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesShielding gasEngineering

Owner:CHENGXI SHIPYARD XINRONG

Welding and Repairing Method for the Outer Cylinder of the Preheating Boiler

The invention relates to the technical field of boiler welding repair, in particular to a welding repair method for preheating the outer cylinder of a boiler, which includes the following steps: determining the position of the defect, cleaning around the defect, and determining the welding repair area according to the shape and size of the defect, Mark the repaired welding area; heat the marked area, the size of the heated area is centered on the repaired welding area plus an area of 10~15mm; tap the marked area in a red hot state to make the marked area concave on the surface of the cylinder; according to the dent According to the size of the area, the corresponding repair plate is embedded in the recessed area, and the repair plate is welded in the recessed area; the weld is smoothed; the weld area of the outer cylinder of the boiler is inspected, and the hydraulic test is carried out after the inspection is free of defects. The invention solves the problems in the prior art that when welding repairs to the corrosion points of the outer cylinder of the boiler, directly adding a repair plate welding is likely to cause welding leaks, poor welding, welding penetration and other consequences at the welding place, and even cause larger defects, and the welding effect is good. ,efficient.

Owner:CRRC LUOYANG CO LTD

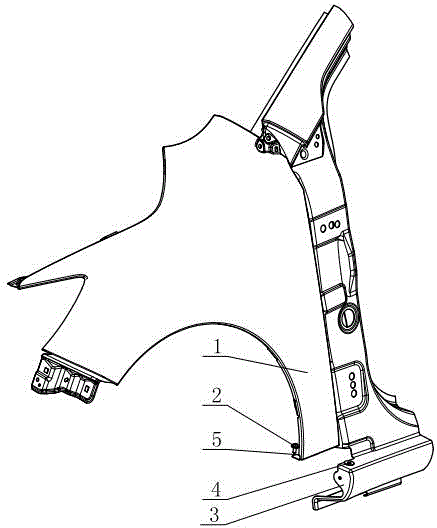

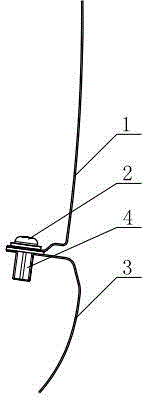

Lower mounting structure of automobile fender

InactiveCN104443059APlay the role of anti-rotationReduce quality impactSuperstructure subunitsEngineeringWeld penetration

The invention relates to a lower mounting structure of an automobile fender. The lower mounting structure comprises a side wall outer plate and a fender connected to the side wall outer plate, wherein a hexagonal hole is formed in the side wall outer plate, a hexagonal rivet is driven into the hexagonal hole; a notch is formed in the lower part of the fender; a fitting surface at the notch in the lower part of the fender is fastened with the side wall outer plate by virtue of a bolt. The lower mounting structure is compact and reasonable in structure, and convenient to operate and mount; the hexagonal hole is formed in the lower part of the side wall outer plate, and the hexagonal rivet is driven into the hexagonal hole and can be used for achieving the effects of preventing rotation; meanwhile, a riveting nut is used to replace a welding nut, so that welding penetration can be prevented, and the influences on the appearance surface quality are lowered. The fitting surface of the fender is designed into a form of the notch for regulating the gap between the fender and the side wall outer plate. The lower mounting structure of the automobile fender can be used for effectively overcoming the problem that the fender is difficult to mount when the parting seams in the lower parts of the door and the side wall, and the parting seams in the fender and the lower part are an integral body.

Owner:WUXI TONGJIE AUTO DESIGN

Automatic cooling heat sink framework and refrigeration method thereof

InactiveCN102228845BSolve the problem of not being able to automatically cool downRealize automatic coolingHeating or cooling apparatusIndirect heat exchangersEngineeringHeat sink

Owner:BEIHANG UNIV

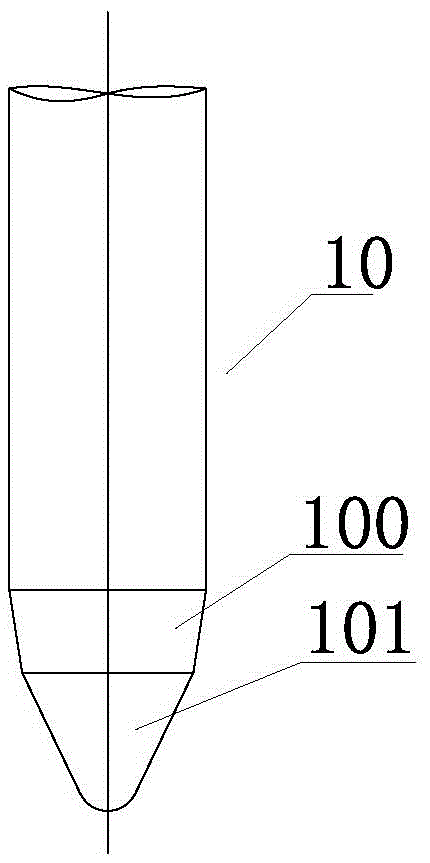

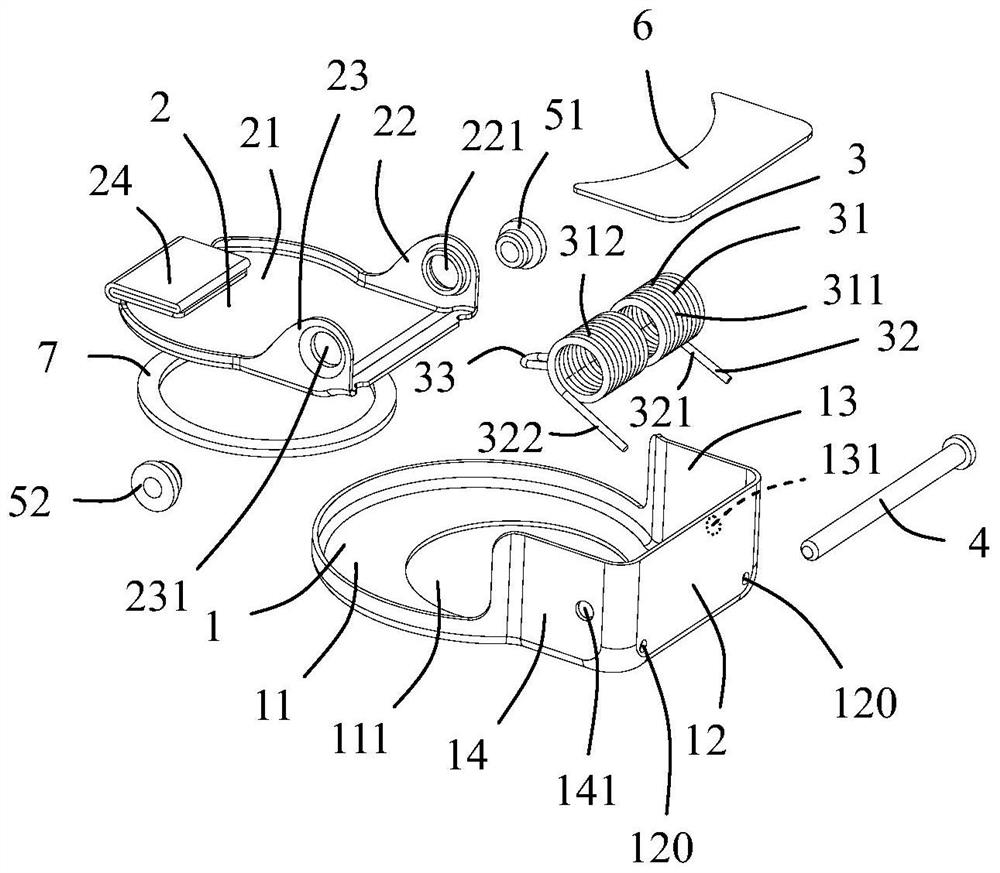

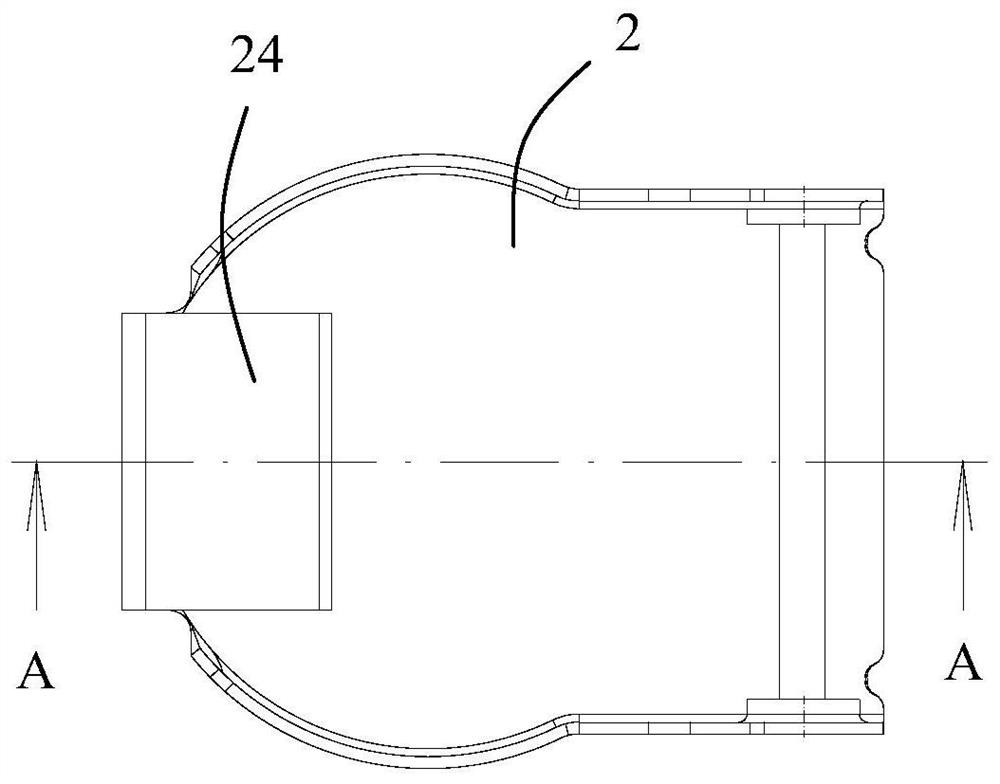

Exhaust valve

PendingCN113738890AWeight increaseEasy to openEngine controllersMachines/enginesExhaust valveLow speed

An exhaust valve comprises a valve seat, a valve cover capable of rotating relative to the valve seat and an elastic piece used for abutting against the valve cover. The valve seat is provided with a first body part, the first body part is provided with an air inlet hole, the valve cover is provided with a second body part matched with the air inlet hole, the valve cover is further provided with a balancing weight which is integrally formed with the second body part and formed by folding, and the balancing weight is located at the end of the valve cover. Compared with the prior art, the balancing weight which is integrally formed with the second body part and is formed by folding is arranged on the valve cover, so that the weight of the valve cover is increased, and the valve cover is not prone to being opened by pulse airflow when an engine rotates at a low speed; and in addition, the integrally-arranged balancing weight is convenient to manufacture, and the quality problems of weld penetration, splashing and the like caused by welding are solved.

Owner:SHANGHAI TENNECO EXHAUST SYST

A method of welding stainless steel light unit without cutting strips and corresponding tooling structure

The invention provides a method for welding stainless steel optical units without cutting steel belt, and has the advantages of overcoming the defects at the butting parts, satisfying the requirements of laser welding and directly welding without cutting steel belts so as to reduce the production cost. The method comprises the following steps: shielding the border positions on two sides of two steel belts needing opposite side connection; welding the exposed opposite side connection positions through welding equipment to complete the opposite side connection of the two steel belts; placing the integrated steel belt on two steel belt placing frames; forming stainless steel pipes through a longitudinal tubing die after the two steel belt placing frames discharge the steel belts at the same time; welding the shielded border positions on the two sides of the steel belts by a laser continuous welding device in the process of forming the stainless steel pipes in the longitudinal tubing die.

Owner:FUJIKURA HENGTONG AERIAL CABLE SYST +2

A semi-automatic welding jig for thin plate welding

ActiveCN107030430BGuaranteed smooth slidingEasy to useWelding/cutting auxillary devicesAuxillary welding devicesSemi automaticEngineering

Owner:SHAANXI SCI TECH UNIV

A long-span reinforced truss floor deck for high-rise buildings and its production process

ActiveCN111794428BAvoid WeldingPrevent leakageFloorsCeramic shaping apparatusArchitectural engineeringSlurry

The invention discloses a large-span reinforced truss floor deck of a high-rise building, which comprises several bottom formworks and several steel bar trusses. The upper bearing plate, the upper bearing plate includes a buckle plate, a splicing plate and a buckle, the splicing plate and the buckle plate cooperate with the steel bar truss through the buckle, and the invention also discloses a production of a large-span steel bar truss floor deck for a high-rise building The process includes the following steps: preparing the bottom formwork; assembling the steel bar truss; assembling the steel bar truss floor deck; improving the structure of the steel bar truss floor deck on the basis of the prior art, changing the existing single-layer bottom formwork into a double-layer , to avoid grout leakage, and use the mutual fit between the buckle plate and the splicing plate, so that the upper bearing plate can be fixed with the steel truss, thus realizing the purpose of avoiding welding through the bottom formwork, further improving the risk of avoiding grout leakage, and making the steel bar Truss floor decks can be used in high-rise buildings.

Owner:南京耀丰新材料科技有限公司

Pipe gallery underground excavation primary lining plastic waterproof plate fixing device and waterproof plate laying method

PendingCN111502709AImprove construction qualityGuaranteed firmnessUnderground chambersTunnel liningArchitectural engineeringPipe

The invention discloses a pipe gallery underground excavation primary lining plastic waterproof plate fixing device and a waterproof plate laying method, and belongs to the technical field of buildingconstruction. The pipe gallery underground excavation primary lining plastic waterproof plate fixing device comprises an embedded device, a fixing base plate and a plastic waterproof plate, wherein one end of the embedded device is welded and fixed to a grating steel arch frame in an underground excavation primary lining, the other end of the embedded device is provided with the fixing base plate, and the plastic waterproof plate is pasted and fixed through the fixing base plate. The invention further provides a laying method of the pipe gallery underground excavation primary lining plastic waterproof plate, and the fixing device is adopted for laying the waterproof plate. By the adoption of the technical scheme, the phenomena that in a traditional method, the waterproof plate is missed in welding, penetrated in welding and infirm in welding in the laying process can be effectively avoided, the firmness of installation and fixation of the plastic waterproof plate is guaranteed, and the construction quality of the pipe gallery waterproof plate and the durability of a concrete structure are improved.

Owner:CHINA MCC17 GRP

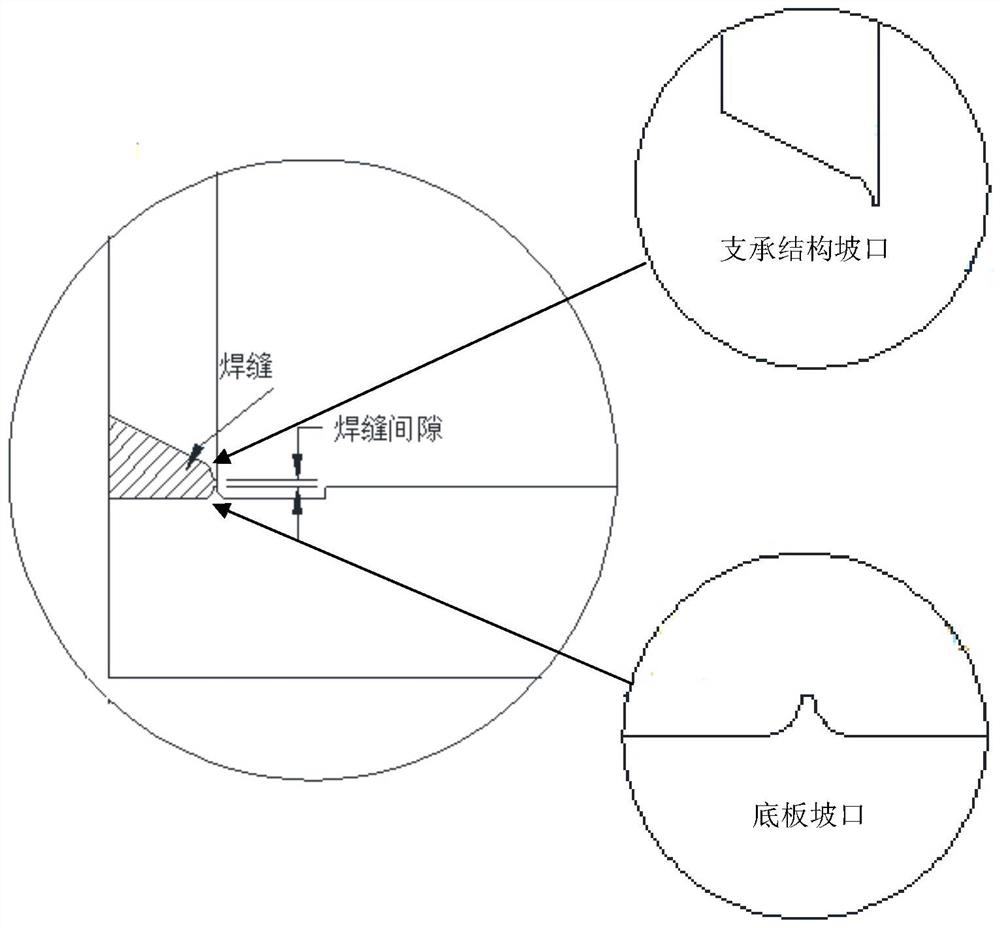

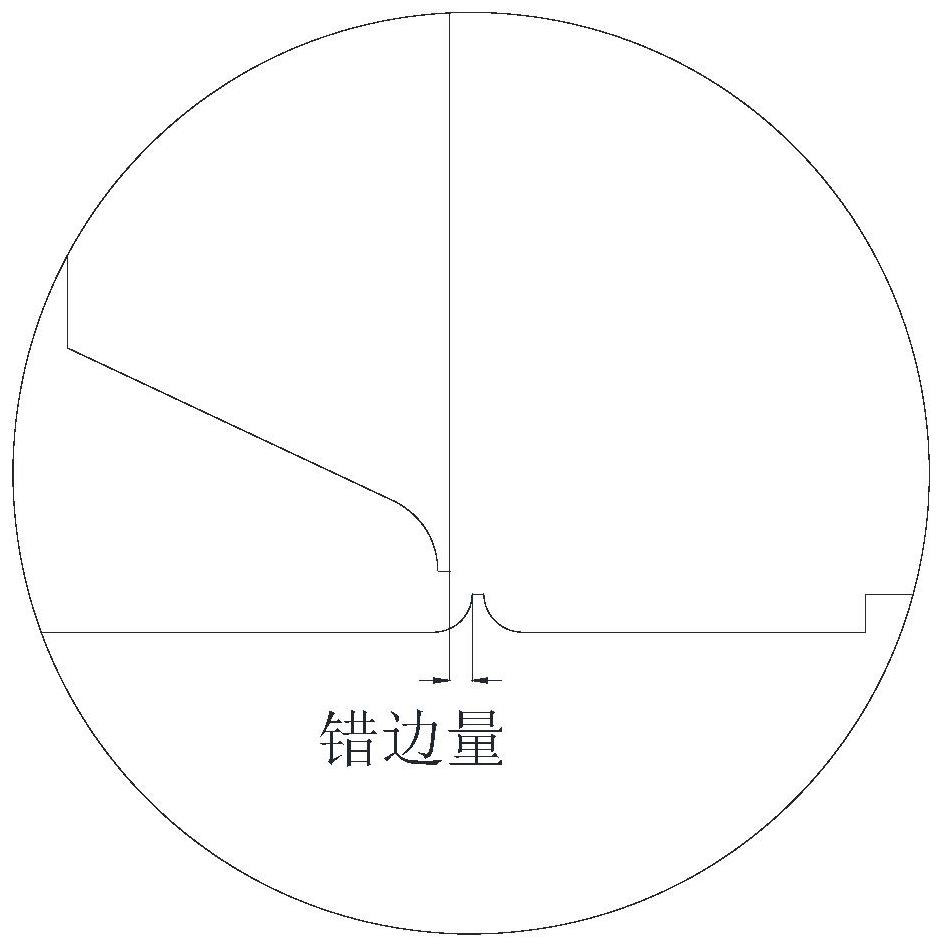

One-side welding and double-side forming method for T-shaped joint of closed supporting structure

PendingCN113977037AGuaranteed PenetrationAvoid welding throughWelding accessoriesWeld penetrationWelding process

Provided is a one-side welding and double-side forming method for a T-shaped connector of a closed supporting structure; a welding groove of the closed supporting structure is processed, the closed supporting structure and a bottom plate are assembled, and a gap is formed between the welding groove of the closed supporting structure and the bottom plate; and a closed annular welding area between the closed supporting structure and the bottom plate is welded by adopting a welding mode of combining symmetrical welding and leapfrogging welding and a welding method of manual electric arc welding. The groove form and size of the closed supporting structure are reasonably designed, the truncated edge thickness heat dissipation condition of an adopted V-shaped groove form is superior to that of a U-shaped groove, weld penetration can be effectively prevented, the assembly clearance is controlled, the welding process is optimized, the assembly precision requirement and misalignment sensitivity can be reduced, one-side welding and double-side forming of the T-shaped joint are effectively achieved, the back of a root is ensured to be fully fused, and meanwhile, the defects of root penetration or undercut and the like are avoided.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Full Penetration Welding Process of U-shaped Rib Fillet Weld in Steel Structure

ActiveCN106112224BWell formedReduce the consumption of manpower and material resourcesArc welding apparatusWelding/cutting media/materialsFillet weldEngineering

The invention discloses a full-penetration welding technology for fillet seams of a U-shaped rib plate of a steel structure. A steel top plate and the U-shaped rib plate form the steel structure with narrow space, a welding gasket is installed on an internal fillet seam inside the narrow space, an external bevel fillet seam outside the narrow space is welded, and one side welding and double side forming of the steel top plate and the U-shaped rib plate can be realized. According to the full-penetration welding technology, the fillet seams of the U-shaped rib plate can be effectively protected against weld penetration, full penetration of the fillet seams of the U-shaped rib plate of the steel structure can be guaranteed, the front sides and the rear sides of the fillet seams can be well formed, the fatigue resistance of the fillet seams of the U-shaped rib plate of the steel structure can be improved, and the service life of the steel structure can be prolonged.

Owner:武汉天高熔接股份有限公司 +2

A pressure-resistant welding method for pressure vessel ring seam

ActiveCN110039266BAvoid scrappingAvoid deformationWelding/cutting auxillary devicesArc welding apparatusStructural engineeringWeld seam

The invention discloses a pressure-resisting welding method for a circular seam of a pressure container. The pressure-resisting welding method includes the following steps that firstly, a pressure container cylinder is assembled on a supporting rotating frame, insertion connection openings are formed in the end faces of the two sides of the pressure container cylinder in a hitting manner, and an edge milling machine is used for conducting grooving on the outer side of a sealing head of the pressure container and the outer side of the pressure container cylinder; secondly, the sealing head of the pressure container is inserted into the tail end of the pressure container cylinder, a pressure device is applied to the tail end of the sealing head of the pressure container, and positioning welding is conducted on the circular seam; thirdly, a double-wire submerged arc welding machine is arranged at the upper portion of the pressure container, a gas shield welding machine is arranged at theinner bottom of the pressure container, a rotating frame begins to rotate after preheating, and welding is conducted at the same time; fourthly, a pressure container connecting pipe and the pressure container cylinder are assembled and welded; and fifthly, stress-relief annealing is conducted, all-directional detection is conducted on the weld seam, and the interior and exterior surfaces of the pressure container are treated.

Owner:宜兴市压力容器厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com