Lower mounting structure of automobile fender

A technology for automobile fenders and installation structures, which is applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc. It can solve problems such as difficulty in installation, difficulty in installing fenders, difficulty in ensuring appearance quality, etc., and achieves the goal of operation and installation. Convenience, compact structure, and the effect of preventing welding penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

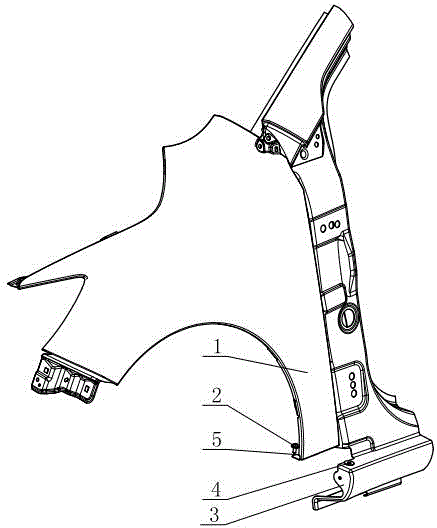

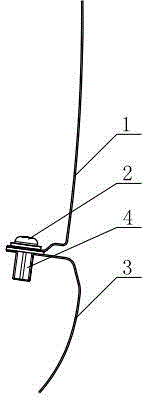

[0012] Such as figure 1 with figure 2 As shown, the installation structure of the lower part of the automobile fender of the present embodiment includes a side wall outer panel 3, and a hexagonal hole is opened on the side wall outer panel 3, and a hexagonal rivet 4 is driven into the opened hexagonal hole; it also includes The fender 1 connected with the side wall outer panel 3 has a notch 5 at the lower part of the fender 1 , and the mating surface at the notch 5 at the lower part of the fender 1 is fastened to the side wall outer panel 3 by bolts 2 .

[0013] In the actual installation process, first open a regular hexagonal hole in the lower part of the side wall outer panel 3, drive the hexagonal rivet 4 into the hole, and then install the fender 1 on the side wall outer panel 3 with the bolt 2. Installation is quick and easy.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com