A column-type heliostat installation base and installation method thereof

A technology for installing a base and an installation method, which is applied in basic structural engineering, construction, etc., can solve the problems of easy deformation of wing-shaped components, falling off of wing-shaped components, low installation efficiency, etc., and achieves low construction cost, enhanced stability, and high installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

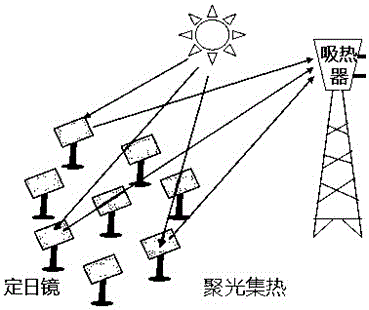

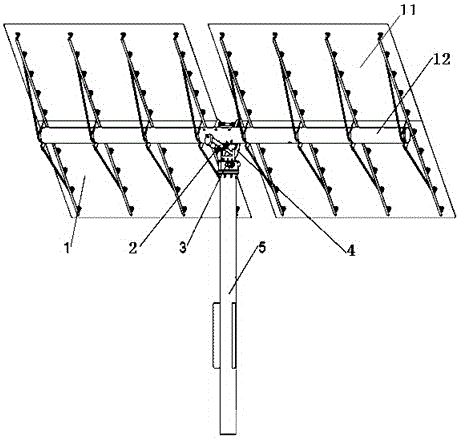

[0030] See figure 1 , tower solar thermal power generation uses a large number of directional mirrors (heliostats) to gather sunlight to a central heat exchanger (heat absorber) installed on the top of the tower, and generates electricity by heating the fluid inside to drive the turbine to rotate , where the heliostat has the function of concentrating light and heat. The overall structure of a typical heliostat see figure 2 , which mainly includes a mirror group 1, an elevation angle driving device 2, an azimuth driving device 3, a connecting seat 4, a column 5, a mirror surface 11, and a mirror group bracket 12, and the mirror group is composed of a plurality of mirror surfaces.

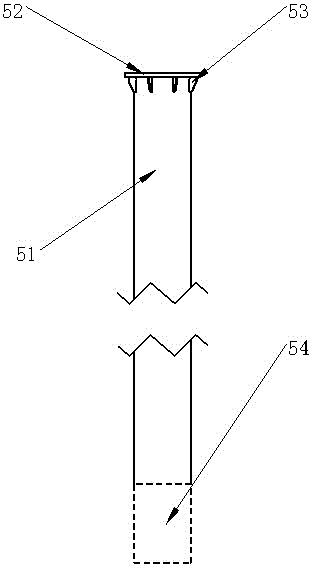

[0031] Aiming at the problems of low installation efficiency, high construction cost, and unsuitability for uneven ground due to the need for pre-embedded bases in the existing heliosta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com