Method for carrying out simulated training of non-melt argon tungsten-arc welding on liquefied natural gas (LNG) carrier for welders

A tungsten argon arc welding and LNG ship technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor welding seam tightness, wooden box ignition, poor penetration of welding joints, etc. The effect of poor welding straightness, preventing welding penetration and controlling post-weld deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

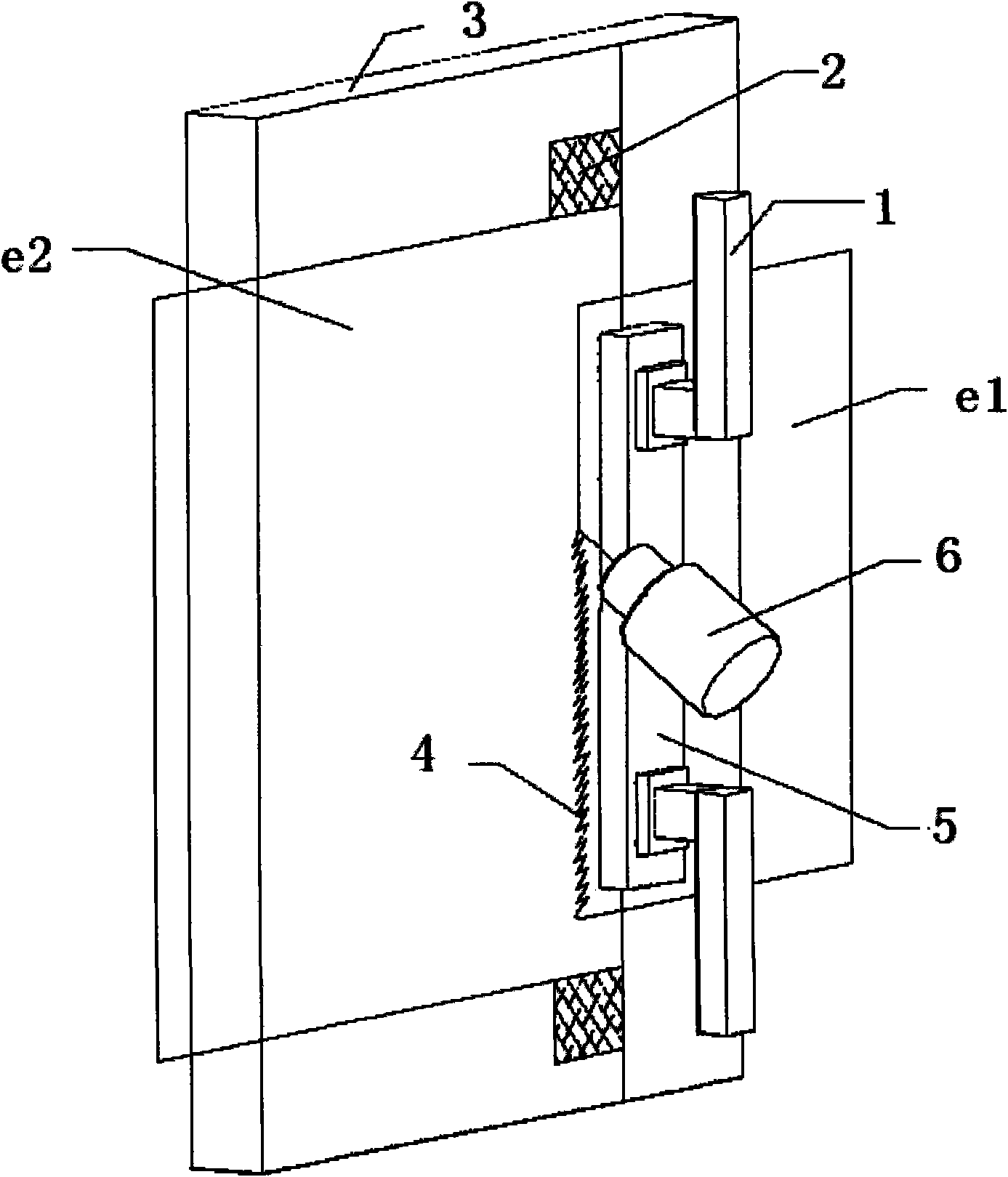

[0042] This embodiment is to carry out the welding operation of the film material on the vertical surface on the liquid cargo tank of the liquefied natural gas ship, and the purpose is to train the welding technology and process of the vertical welding between two invar film materials on the vertical surface.

[0043] like image 3 as shown, image 3It is a schematic diagram of the vertical welding of samples by the method of the present invention for the simulation training of non-melting tungsten argon arc welding of LNG ships for welders. It can be seen from the figure that during the welding operation, the second invar film material e2 as the base is placed on a piece of wood block 3, and then a piece of heat insulating material 2 is placed on the place where the weld to be welded is in contact with the wood block 3 , whose purpose is to prevent the wood block from burning due to excessive temperature. The first invar film material e1 is placed on the second invar film m...

Embodiment 2

[0048] This embodiment is to carry out the welding operation of the film material on the bottom surface of the cargo tank of the liquefied natural gas ship, and the purpose is to train the welder on the technology and process of welding between two invar film materials on the top surface of the liquid cargo tank.

[0049] like Figure 4 as shown, Figure 4 It is a schematic diagram of overhead welding of samples by the method of the present invention for the simulation training of non-melting tungsten argon arc welding for welders on LNG ships. It can be seen from the figure that this operation is to weld a piece of circular invar film material as a repair welding liner b to the invar material a on the top of the cargo tank. The weld seam here is located at the edge of the repair welding liner b, which is a circular weld seam.

[0050] After laminating the two Invar film materials, select a suitable clamping workpiece. The clamping tool here is the crocodile pliers 7. The st...

Embodiment 3

[0054] This embodiment is to carry out the welding operation of the film material on the bottom surface of the liquid cargo tank of the liquefied natural gas ship, and the purpose is to train the welder on the technology and process of welding between two Invar film materials on the bottom surface of the liquid cargo tank.

[0055] like Figure 5 as shown, Figure 5 It is a schematic diagram of using shoulder pole clamps for welding clamping in the method of the present invention for the simulation training of welders on LNG ship non-melting argon tungsten arc welding. As can be seen from the figure, the operation is to weld a circular invar film material to the invar material at the bottom of the cargo tank. The weld here is located at the edge of the two Invar materials and is a straight weld.

[0056] In this embodiment, aiming at the position and shape of the weld seam, the pole clamp 9 is selected as the clamping tool for fixing. The shoulder pole clamp 9 includes a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com