One-side welding and double-side forming method for T-shaped joint of closed supporting structure

A single-sided welding double-sided, supporting structure technology, used in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem that the quality of the back of the weld cannot be guaranteed, the amount of misalignment cannot be accurately controlled, and the assembly accuracy requirements are high. problems, to avoid root welding penetration, optimize welding process, and ensure the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

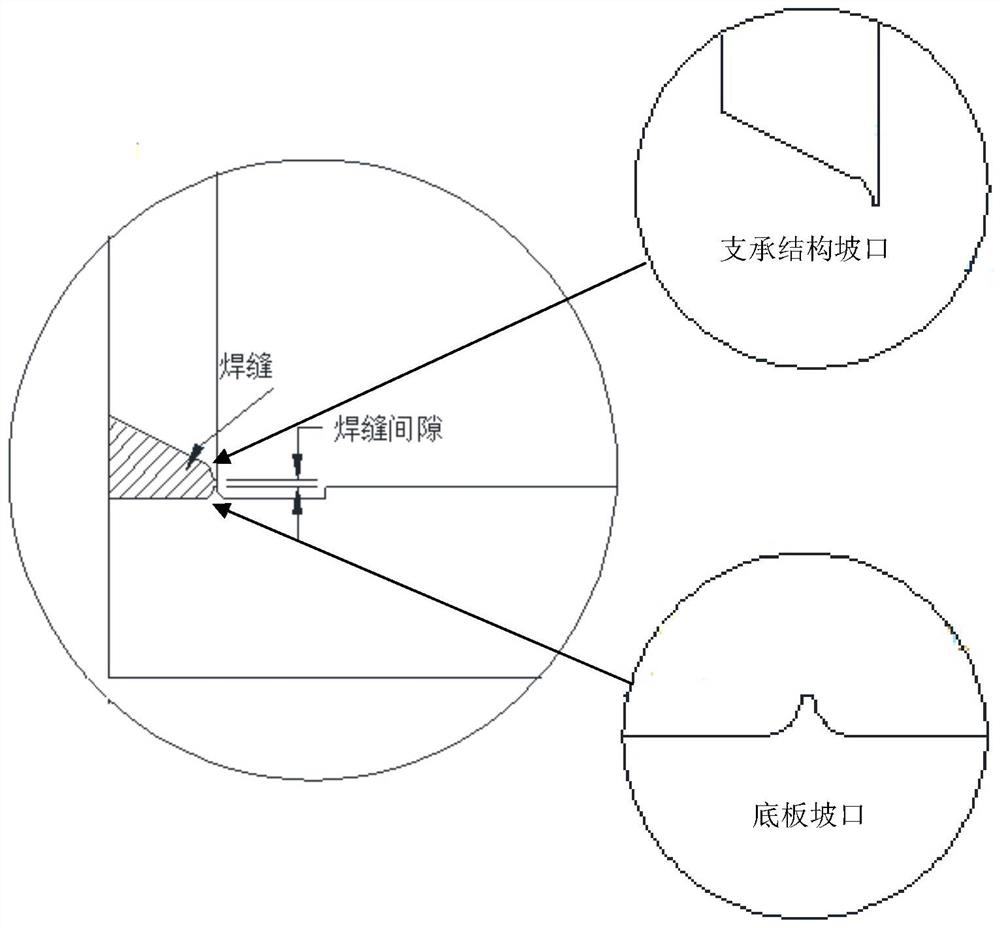

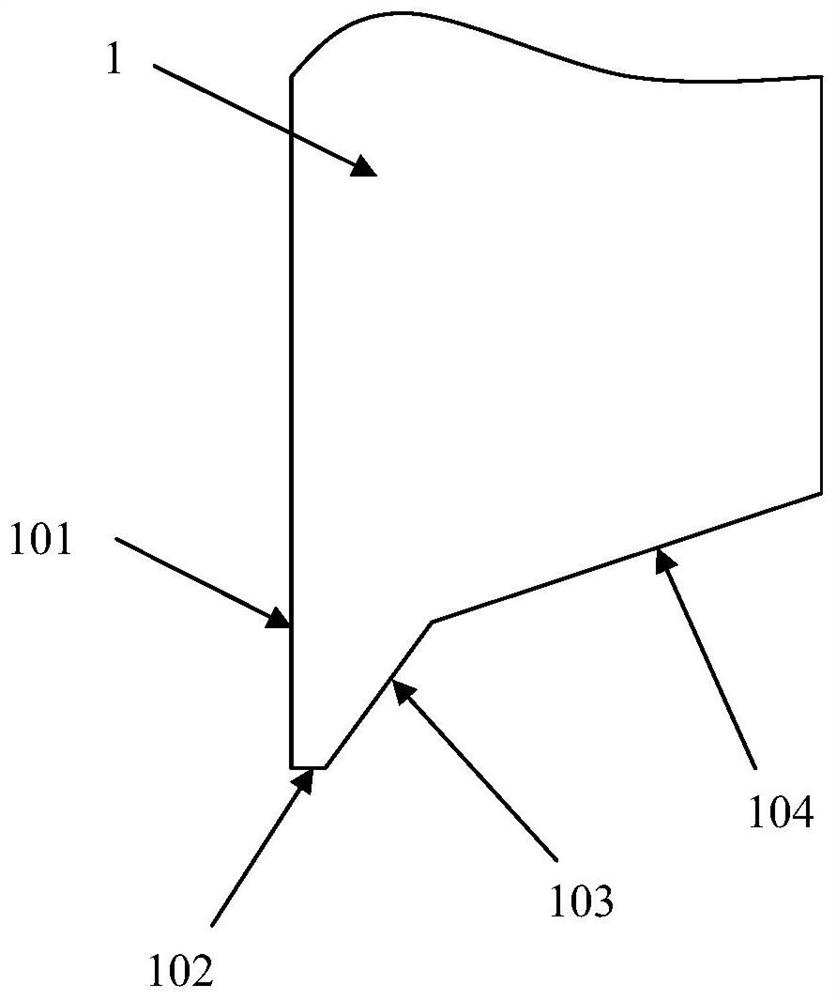

[0026] based on the following Figure 3 ~ Figure 6 , specifically describe the preferred embodiment of the present invention.

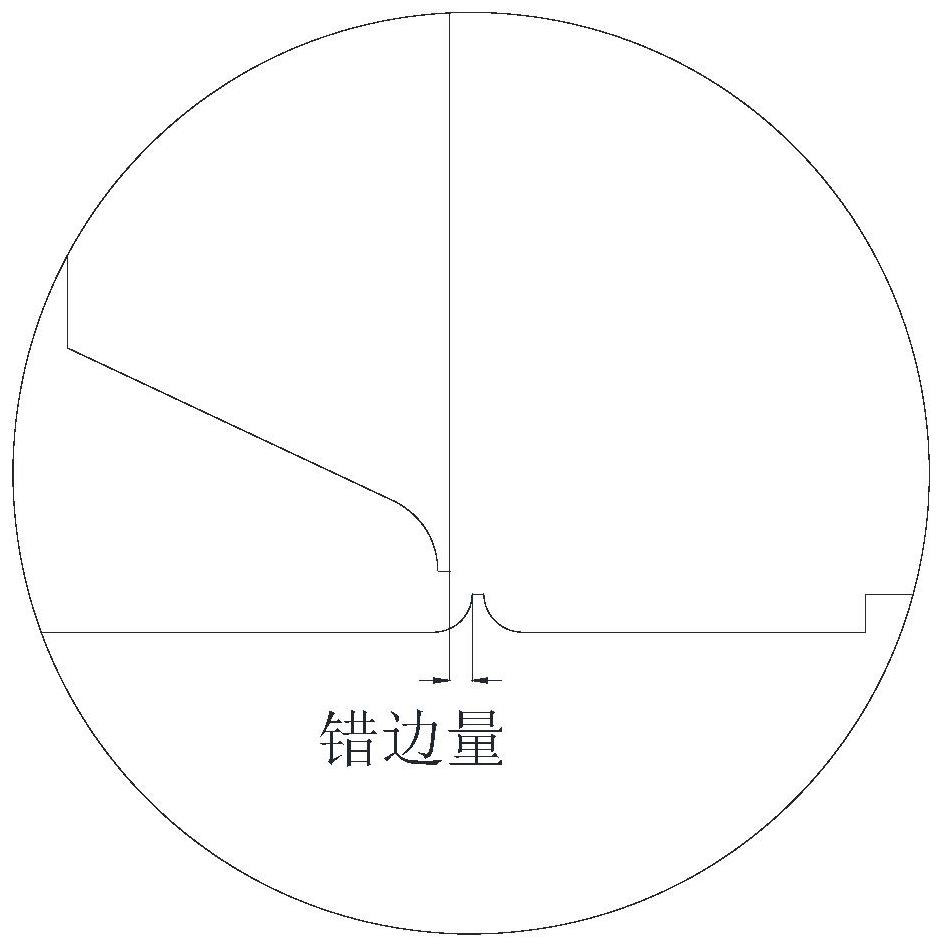

[0027] For the T-joint whose back cannot be cleaned and the amount of misalignment cannot be guaranteed to be within 2mm, the invention can reduce the assembly accuracy requirements and the sensitivity to misalignment by rationally designing the groove form and size, controlling the assembly gap, and optimizing the welding process. , Effectively realize the closed support structure T-joint single-sided welding and double-sided forming.

[0028] In one embodiment of the present invention, a closed support structure T-joint single-sided welding and double-sided forming method is provided, which specifically includes the following steps:

[0029] Step S1, processing the welding groove of the closed support structure;

[0030] In the present invention, there is no need to process grooves on the side of the bottom plate, only welding grooves are processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com