Full-automatic welding robot

A fully automatic welding and robotic technology, applied in the field of robotics, can solve problems such as difficult to ensure welding quality, difficult to weld spherical tank girth welds, and high labor intensity, so as to ensure penetration depth and forming quality, stable welding process parameters, and ensure The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

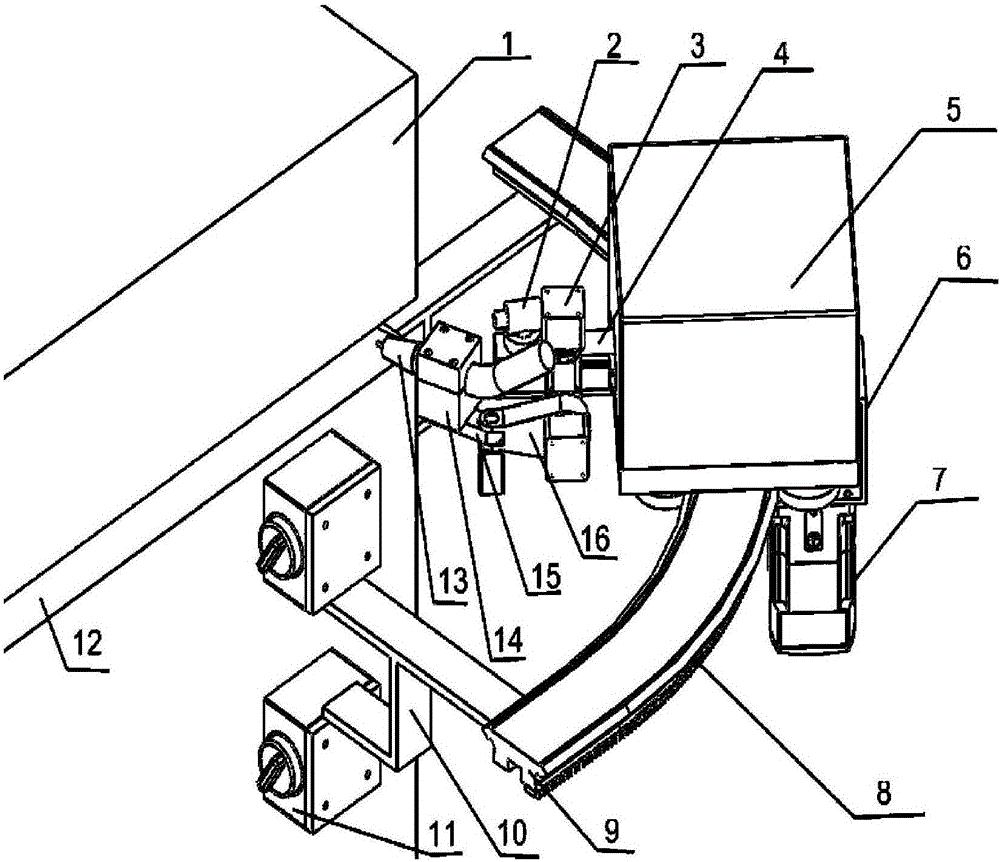

[0019] Embodiment: a fully automatic welding robot.

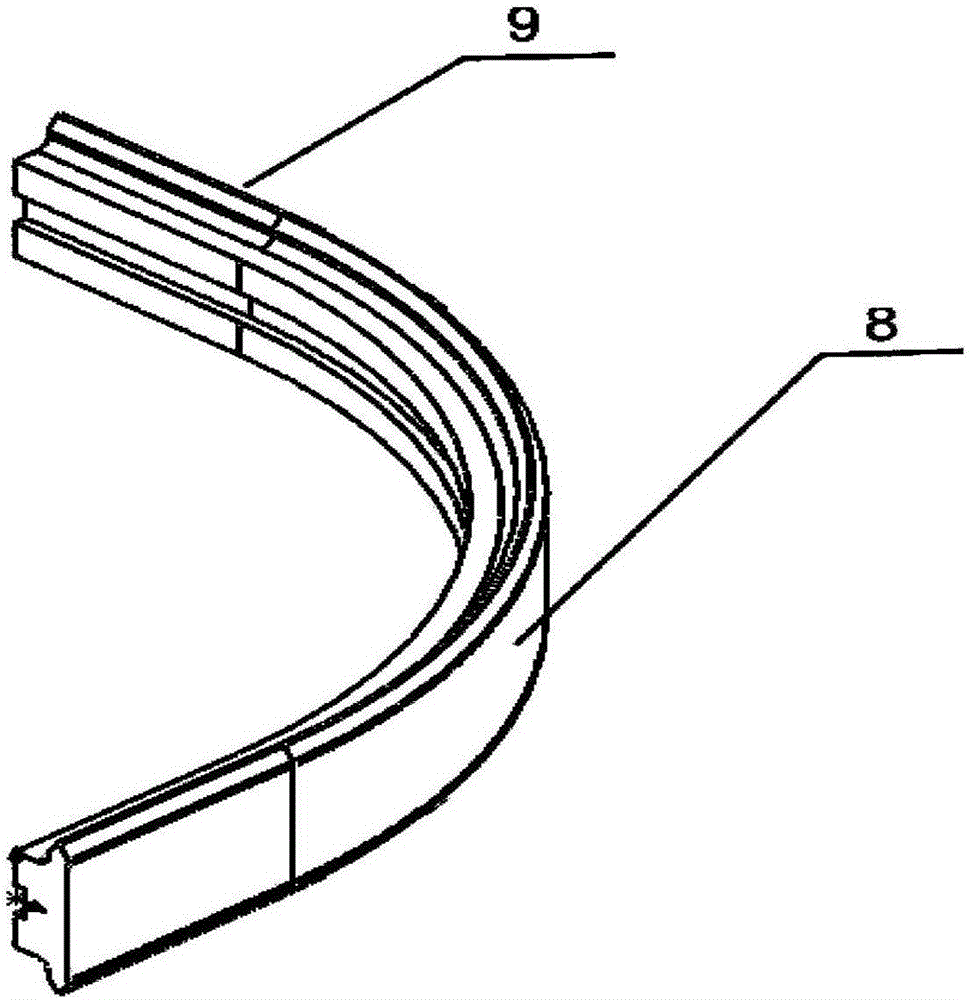

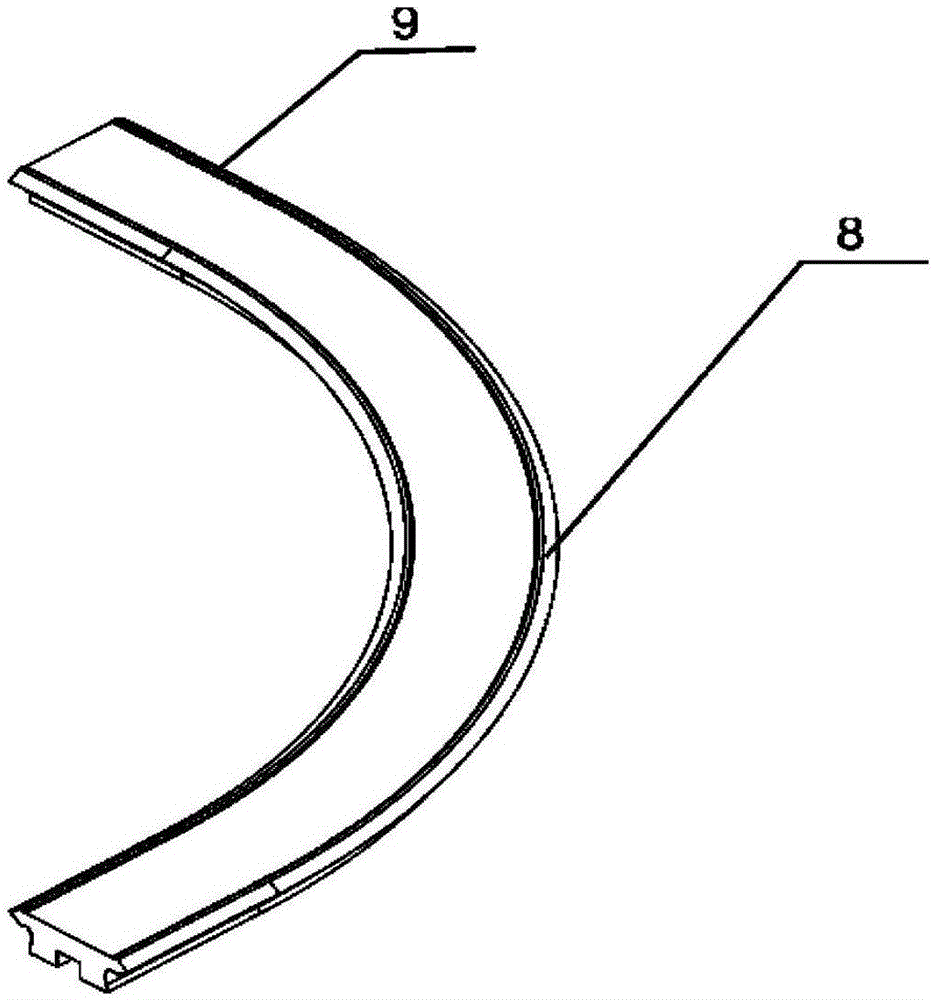

[0020] like Figure 1-6 As shown, a fully automatic welding robot described in the embodiment of the present invention includes a track, a mounting mechanism is provided on the left side of the track, a slider 6 is slidably connected to the track, and the lower part of the slider 6 is provided with Servo motor 7, a control box 5 is provided on the top of the slider 6, a digital control system is provided in the control box 5, an actuator is provided on the left side of the control box 5, and a CCD device is provided on the actuator 2. A welding torch holder 14 is provided at the left end of the actuator, and a welding torch 13 is provided on the welding torch holder 14 . The right side of the track is provided with a rack. The track is a vertical track or a horizontal track. Both the vertical track and the horizontal track include an arc track 8 with a radian of 90 degrees. The arc track 8 has two Both ends are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com